INDEX

Specifications... .,....5

Lifting and Cleanlines. . . .. . .. . .6

Foundation ....'..7

Levellingand EletricalConnections.... .........8

DimensionsandPrincipal Assemblies... .......9

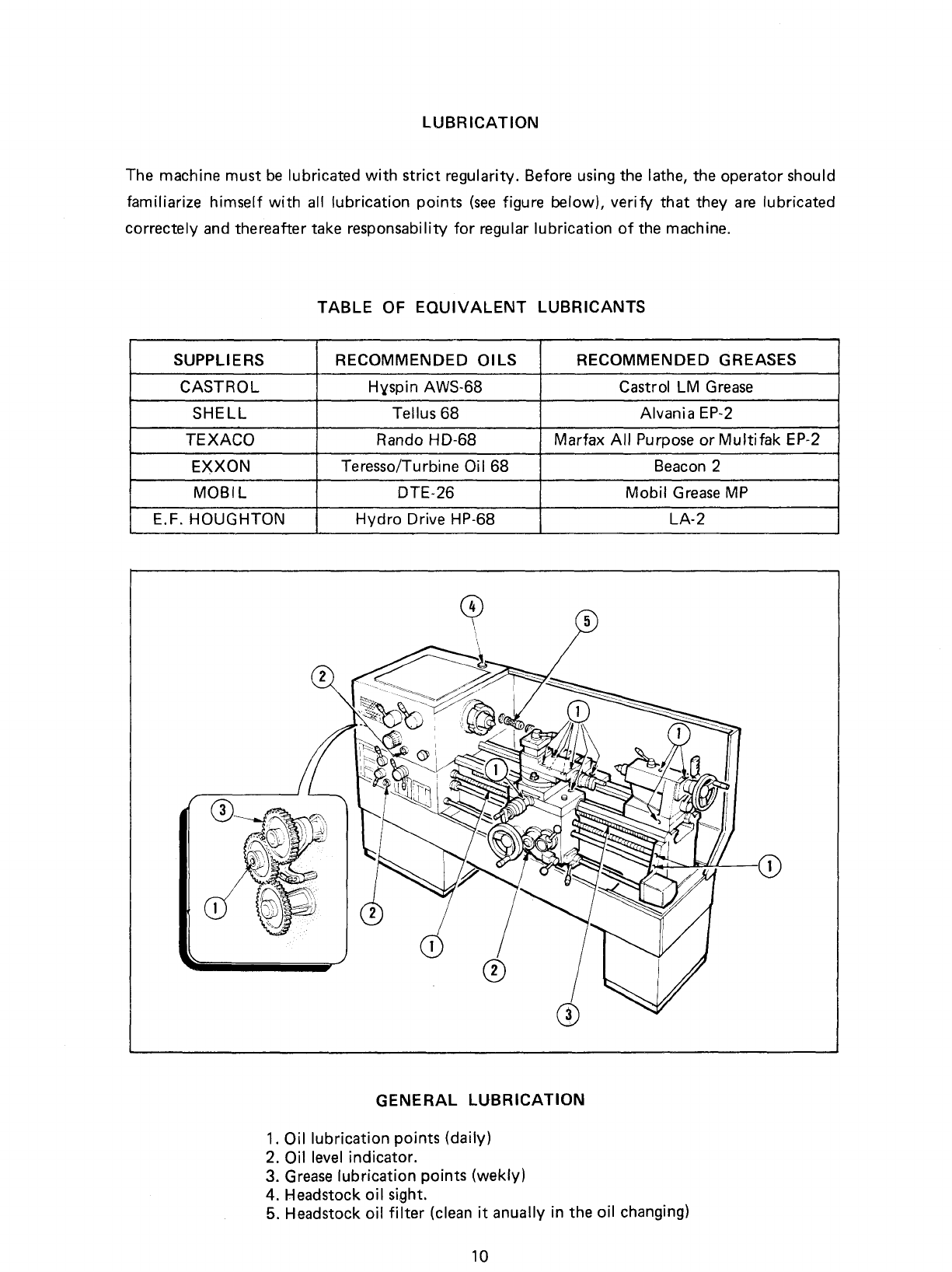

Lubrication ......10

Oil change ........11

LatheControls ....12

LatheOperations. ......13

Headstock lnstructions ........14

Threads and Feeds Gear Box lnstructions .. .. , .. .15

Threads and Feeds Gear Box Data Plate .. . . . .16

Saddle lnstructions ......18

Apron (left - hand) lnstructions . . .19

Apron (right-hand) Instructions .......20

Tailstock lnstructions ....21

MotorDriveSystem lnstructions... .... '22

Change Gears and Safety Coupling lnstructions . . . . . .23

Threads Cutting lndicator lnstructions (Leadscrew 4 TPI) . , . .24

Threads Cutting lndicator lnstructions (Leadscrew 6mm). . . . . .25

Spindle and Leadscrew Axle Adjustment lnstructions . . . .. .. .26

BrakeSystem ........27

Electrical Diagram ......28

Part Listlntroduction.... .,.....31

Headstock (MS-M|-401C) . .. . .32

Headstock(Ms-Ml-402C) ... ......34

Headstock (MS-M1"403C) ...,...36

GearBox (MS-M|-404C) .......38

GearBox (MS-M|-405C) ... ,....40

Gear Box (MS-M|-406C) . ... ... .42

Saddle (MS-M|-407C) ........44

Apron(left-hand) (MS-M|-408C). ....,46

Apron(left-hand) (MS-M|-409C). ..... '48

Tailstock (MS-M|-410C) ...50

Bed(MS-Ml-411C) ...52

Change Gears (ledascrew4TPl)(MS-MI-412C1 ........54

Change Gears (leadscrew 6mm) (MS-MI-413C) . . .56

Motor Drive System (MS-M l-4143lr . . . .58

SteadyRest(MS-Ml-415C) ....59

Follow Rest (MS-M|-416C) . .. . . 60

Tool Post (MS-M|-417C\ . .. . . .. .61

Drive Plate, Universal Chuck Flange, Back Plate (MS-M|-418C) .......62

TaperAttachment (MS-M|-419C) .....64

CoolantPump (MS-Ml-42rc\ ....,66

Threads Cutting lndicator (leadscrew 4 TPI) (MS-M|-421C], . . . . 67

MicrometerStop (MS-M|-422C]r ........68

ChipGuard (MS-M|-423C\ .....70

Chuck Guard (MS-M|-424C\ .........71

Threads Cutting lndicator (leadscrew 6mm) (MS-M|-425C\ . . . . .72

Apron (right-hand) (MS-M|-426C). . . .74

Apron (right-hand (MS-M|-427C\ .....76