INDEX

1. MACHINE DETAILS ........................................................................................................... 3

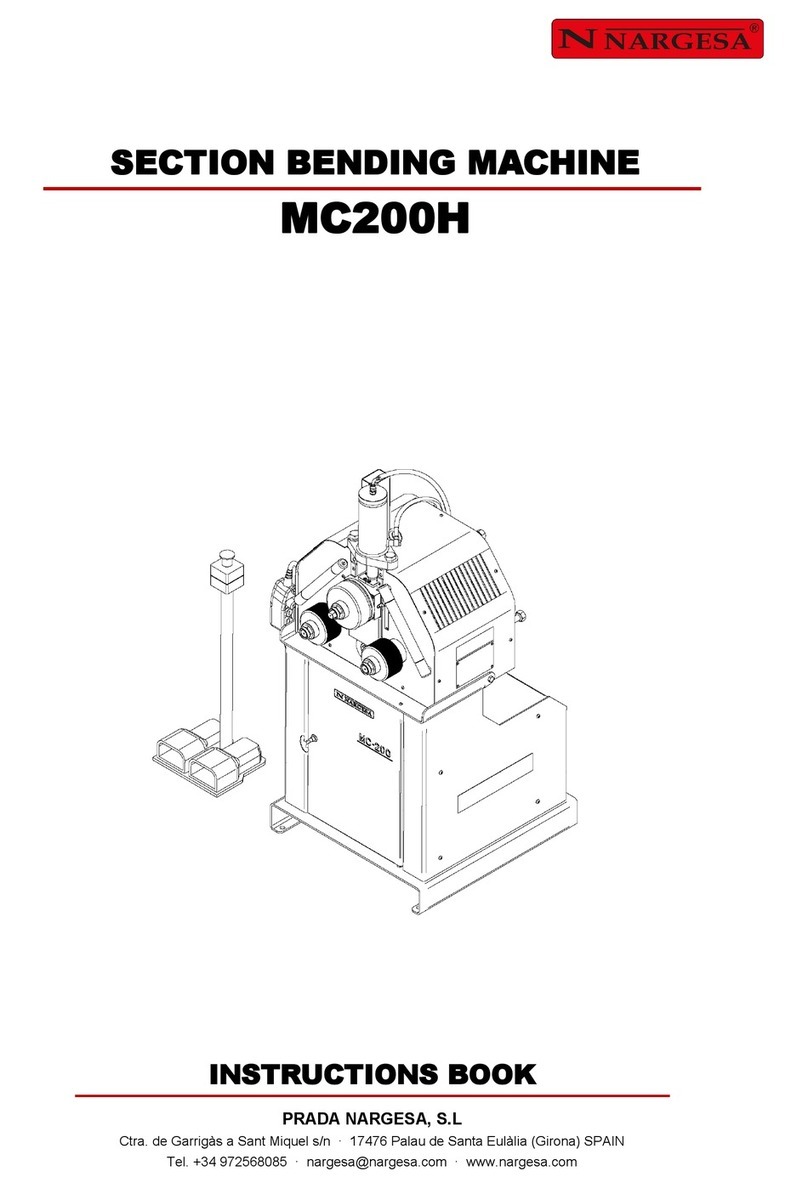

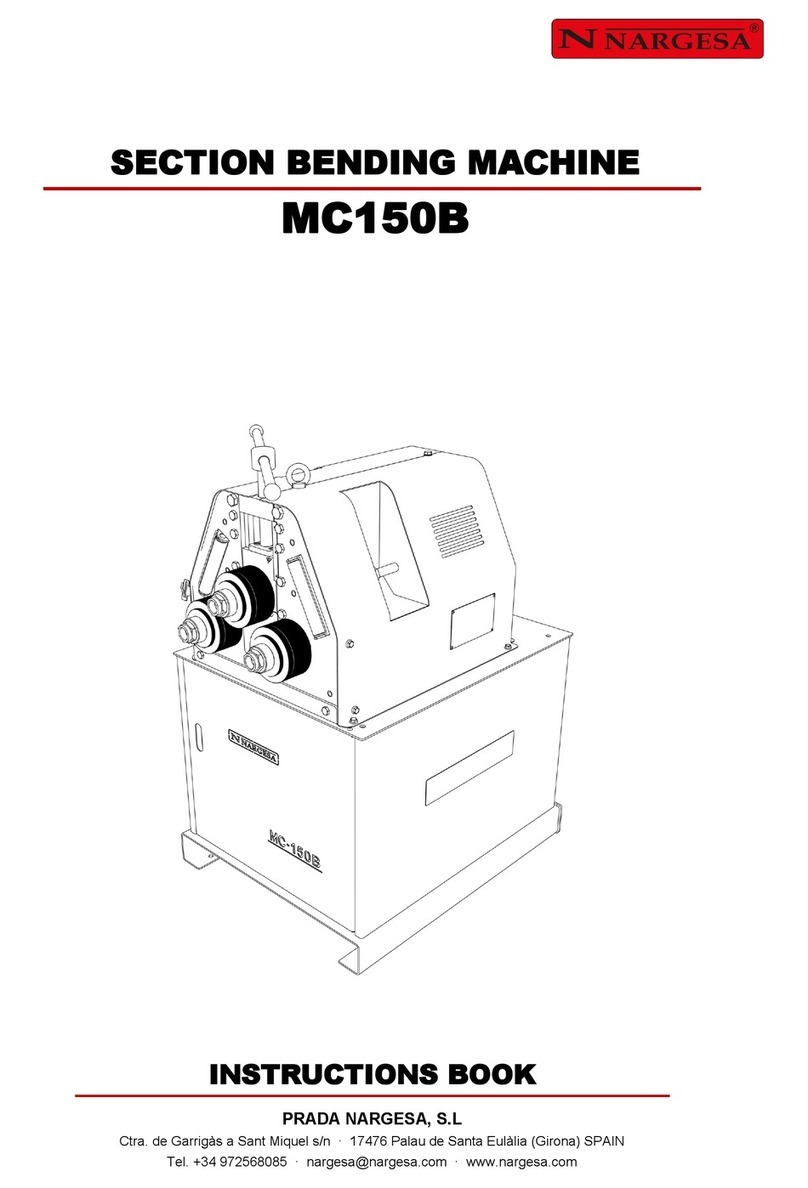

1.1. Machine identification details ................................................................................... 3

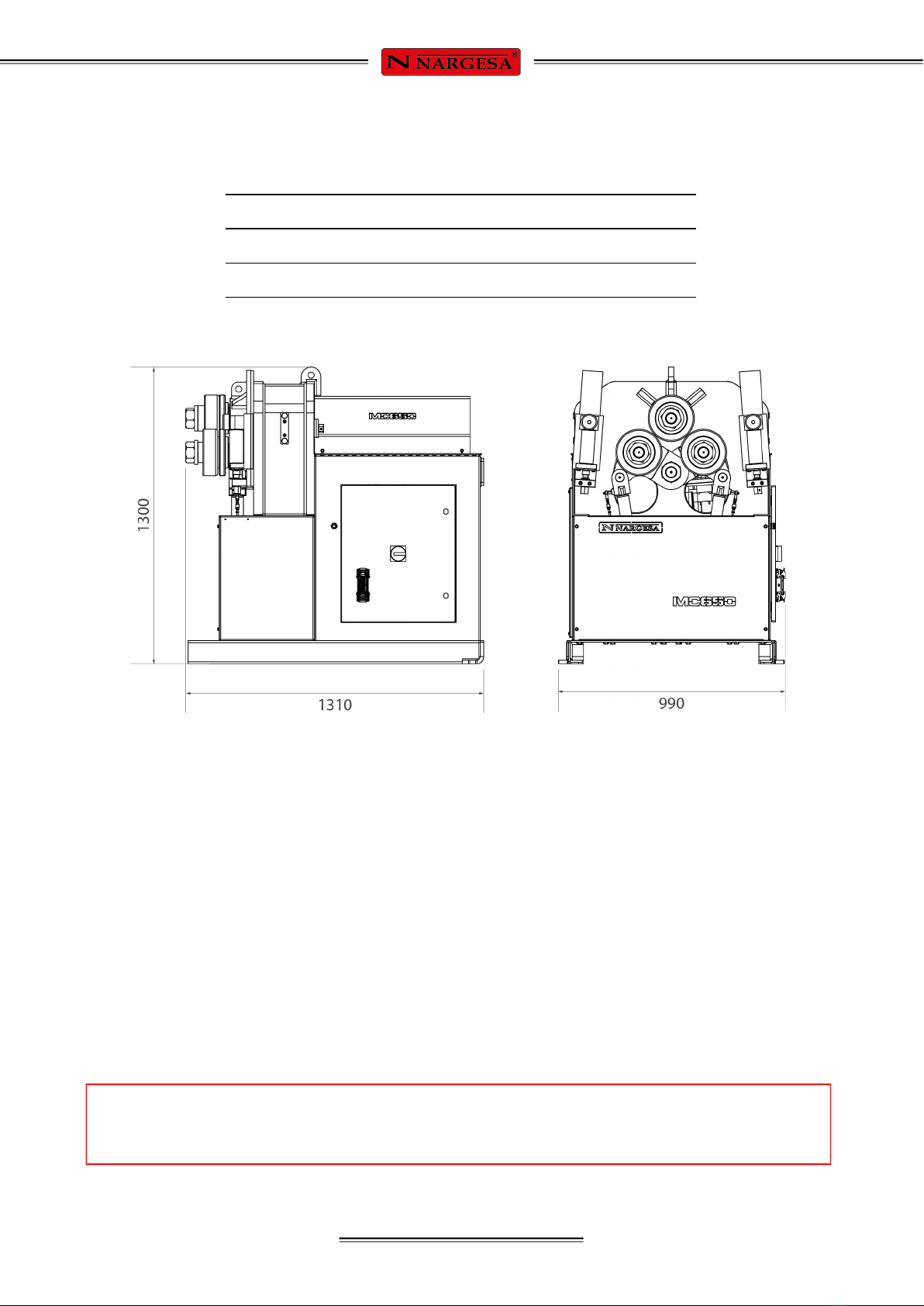

1.2. Dimensions .............................................................................................................. 3

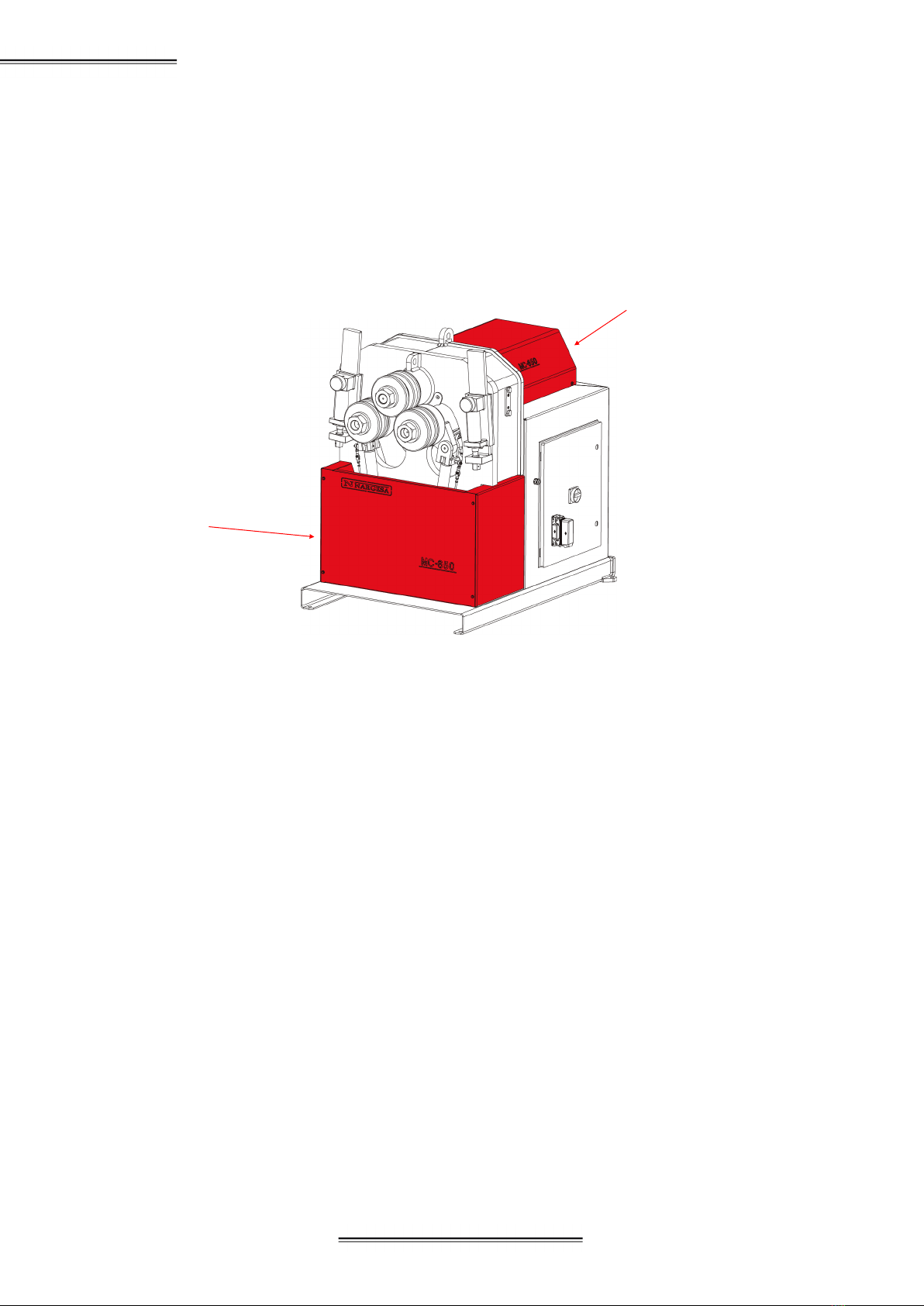

1.3. Description of the machine ...................................................................................... 3

1.4. Machine part identification ....................................................................................... 4

1.5. General characteristics ............................................................................................ 5

1.6. Description of the guards ......................................................................................... 6

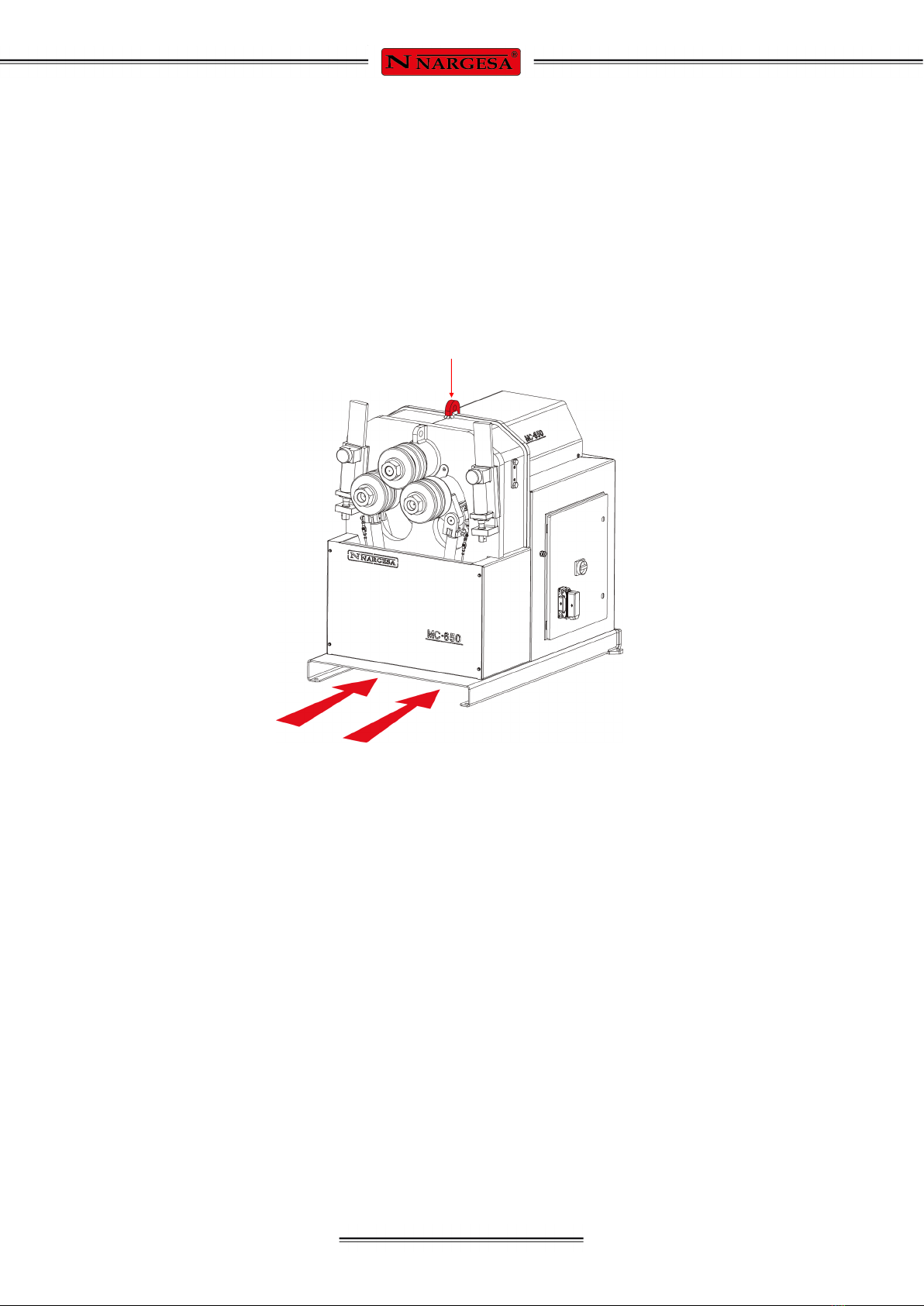

2. TRANSPTRANSPORT AND STORAGE ........................................................................... 7

2.1. Transport .................................................................................................................. 7

2.2. Storage conditions ................................................................................................... 7

3. MAINTENANCE ................................................................................................................. 8

3.1. Lubrication of moving parts ...................................................................................... 8

3.2. Lubrication of straigthener arms …………………………………………………….…. 8

3.3. Hydraulic oil change ………………..……………...……………………………………. 9

3.4. Ckeckup of hydraulic instalation …………………..………………………………… 10

4. INSTALLATION AND START UP .................................................................................... 11

4.1. Positioning the machine ......................................................................................... 11

4.2. Dimensions and work area .................................................................................. 11

4.3. External permisible conditions ............................................................................... 11

4.4. Instructions for connecting to the power supply ..................................................... 12

5. INSTRUCTIONS FOR USE ......................................................................................... 16

5.1. Bending principles ….............................................................................................. 16

5.2. Assembly of the rollers ........................................................................................... 16

5.3. Instruction manual .................................................................................................. 17

5.3.1. Manual operating mode…………………………………………………….. 17

5.3.2. Automatic operating mode ………………………………………………… 19

5.3.2.1. General Data …………………...………………………………… 20

5.3.3. Using the Programs ……………………………………………………… 23

5.3.4. Creating a New Program ………………………………………………….. 25

5.3.5. Production Mode ………………………………………………………… 28

5.3.6. Using Materials and Tools …………………………………………….….….. 31

5.3.7. Importing and Exporting Data ………….………………………………….. 34

5.3.8. Using the Alarms ………….………………………….…………………….. 35

5.4. Working position ……………...………………………………….…………………… 37

6. WARNINGS ...................................................................................................................... 39

6.1. Residual hazards ................................................................................................... 39

6.2. Counter-productive methods .................................................................................. 39

6.3. Other recommendations ........................................................................................ 39

7. ASSEMBLY OF THE ROLLERS ...................................................................................... 40

7.1. Bending capacity .................................................................................................... 41

8. OPTIONAL ACCESSORIES ............................................................................................ 42

TECHNICAL ANNEX