3 1-2017

Translation

CONTENTS

1.1

Foreword ...............................................................................................................................5

1.2

EU Declaration of Conformity.............................................................................................6

1.3

Intended use of the machine ...................................................................................................7

1.4

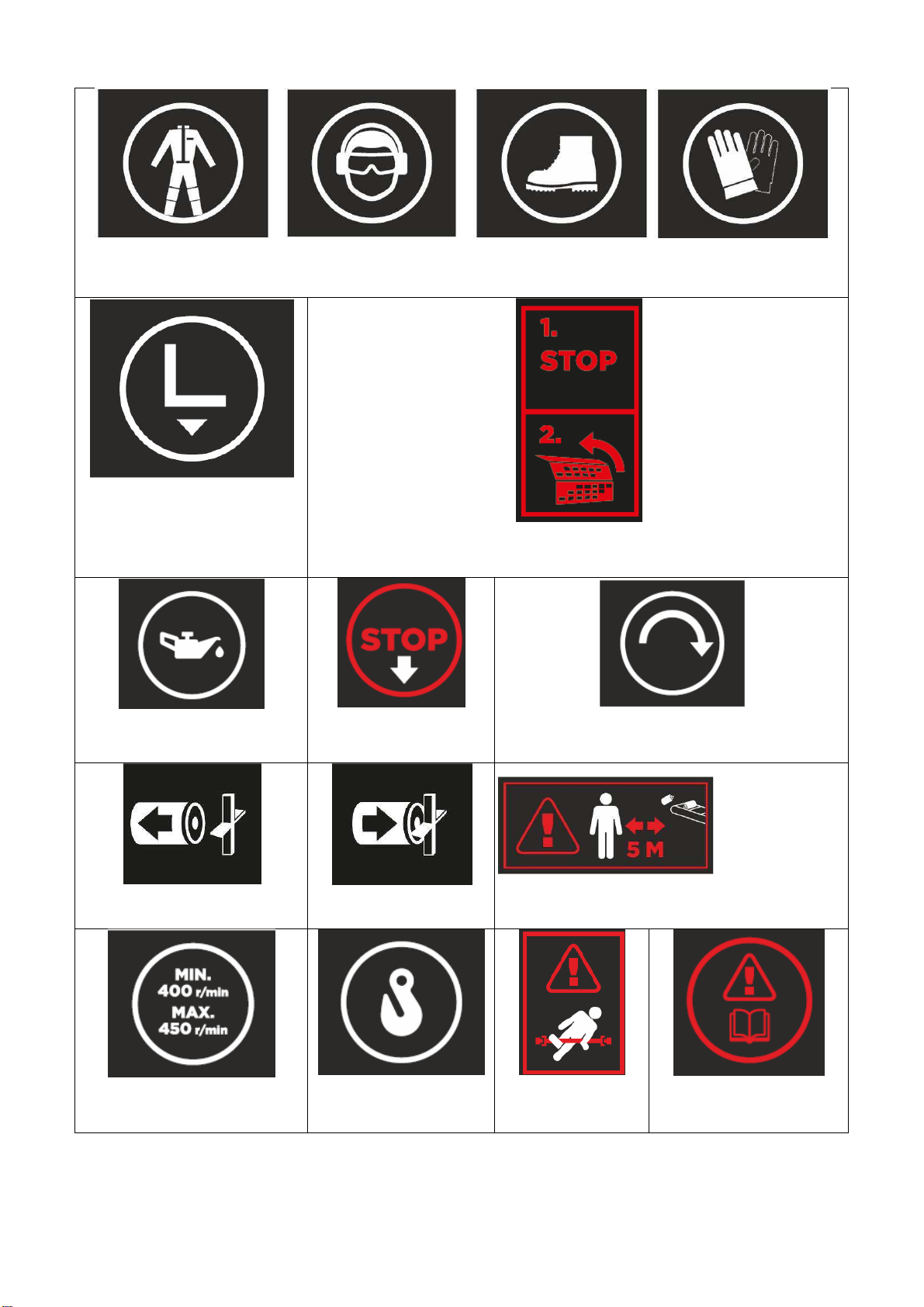

Warning signs.........................................................................................................................7

1.5

Nameplates...........................................................................................................................9

1.6

The main dimensions and models of the machine.......................................................10

1.7

Safety instructions..............................................................................................................10

1.8

Noise emission and vibration...........................................................................................11

1.9

Responsibilities of the operator .......................................................................................11

1.10

Operating conditions......................................................................................................12

1.11

Terms of warranty...........................................................................................................12

1.12

Operating instructions for the winch............................................................................12

2

Taking delivery and setting up the machine for operation..........................................13

2.1

Lifting the machine.............................................................................................................13

2.2

The transport set-up and unpacking...............................................................................13

2.3

Acceptance inspection......................................................................................................13

2.4

Main parts of the machine, Fig 1.....................................................................................13

2.5

Bringing the table extension into the work position, Fig. 2..........................................14

2.6

Bringing the conveyor into the work position, Figs. 3 and 4........................................14

2.7

Bringing the conveyor into the work position, Fig. 5.....................................................15

2.8

Adjusting the cutting length, Fig. 6..................................................................................16

3

Operation of the firewood processor powered by different power sources .............16

3.1

Testing the machine..........................................................................................................16

3.2

Powered by a tractor.........................................................................................................16

3.3

Suitable revolutions range for the PTO shaft ................................................................16

3.4

Disengagement lever for transmission, Fig. 7...............................................................17

3.5

Required measures in an emergency situation.............................................................17

3.6

Starting under cold conditions (machine powered by a tractor).................................17

3.7

Electric drive, start and emergency stop........................................................................17

3.8

Starting the electric motor using the Y/D starter, Fig. 8...............................................18

3.9

Emergency stopping of an electrically powered machine, Fig. 8.............................19

3.10

The machine is equipped with a system to prevent simultaneous operation in two

modes, Fig. 9................................................................................................................................19

3.11

Operation under cold conditions ..................................................................................19

3.12

Electric heater for oil tank..............................................................................................20

4

Full-hydraulic control.........................................................................................................20

4.1

Mastering the safety devices............................................................................................20

4.2

Joystick-valve, Fig. 10.......................................................................................................20

4.3

Other hydraulic operating controls, Fig. 11....................................................................21

5

Use of the firewood processor, crosscut operation .....................................................23

5.1

Operating the crosscut saw, before the operation........................................................23

5.2

During the operation..........................................................................................................23