Metallkraft SBM 140-12 E User manual

SBM 140-12 E

Instruction Manual

SBM 140-12 E

SBM 140-12 E

Bead bending machine

2 SBM-Series | Version 2.04

Imprint

Product identification

Type of machine I em number

SBM 140-12 E 3814003

Manufacturer

S ürmer Maschinen GmbH

Dr.-Rober -Pfleger-S r. 26

D-96103 Halls ad

Fax: 0049(0)951 96555-55

E-Mail: info@me allkraf .de

In erne : www.me allkraf .de

Indications regarding the operating instructions

Original ins ruc ions

Edi ion: 24.09.2020

Version: 2.04

Language: English

Au hor: RL

Indications regarding the copyright

Copyrigh © 2019 S ürmer Maschinen GmbH, Halls ad ,

Germany.

The con en s of hese opera ing ins ruc ions are he sole

proper y of he company S ürmer.

Passing on as well as copying of his documen , he use

and dis ribu ion of i s con en are prohibi ed if no explic-

i ly permi ed. Con raven ions are liable o compensa-

ion.

Subjec o echnical modifica ions and error.

Contents

1 Introduction................................................. 3

1.1 Coyprigh ..................................................................3

1.2 Cus omer service...................................................... 3

1.3 Limi a ion of liabili y .................................................. 3

2 Safety........................................................... 3

2.1 Symbol explana ion .................................................. 3

2.2 Requiremen s o s aff ...............................................4

2.3 Personal pro ec ive equipmen ................................. 4

2.4 S andards and guidelines......................................... 5

2.5 General safe y regula ions........................................ 5

2.6 Safe y measures when dealing wi h elec rici y.........6

2.7 Safe y ins ruc ions for he use of ools...................... 6

2.8 Safe y ins ruc ions for working on he machine .....6

2.9 Safe y measures during main enance and servicing .7

2.10 Safe y markings on he bead bending machine .....7

3 Intended use ............................................... 7

3.1 Residual riks............................................................. 7

3.2 Technical condi ion...................................................8

4 TechnicalData ............................................. 8

4.1 Table.........................................................................8

4.2 Type pla e.................................................................8

4.3 Scopa of delivery......................................................8

4.4 Accessories .............................................................. 9

Transport, packaging, storage .................. 9

5.1 Delivery and Transpor .............................................9

5.2 Packaging............................................................... 10

5.3 S orage...................................................................10

5.4 Se up .....................................................................10

5.5 Elec rical connec ion............................................... 10

6 Description of the device......................... 11

7 Description of the standard roles ........... 11

7.1 Applica ion examples and roles.............................. 11

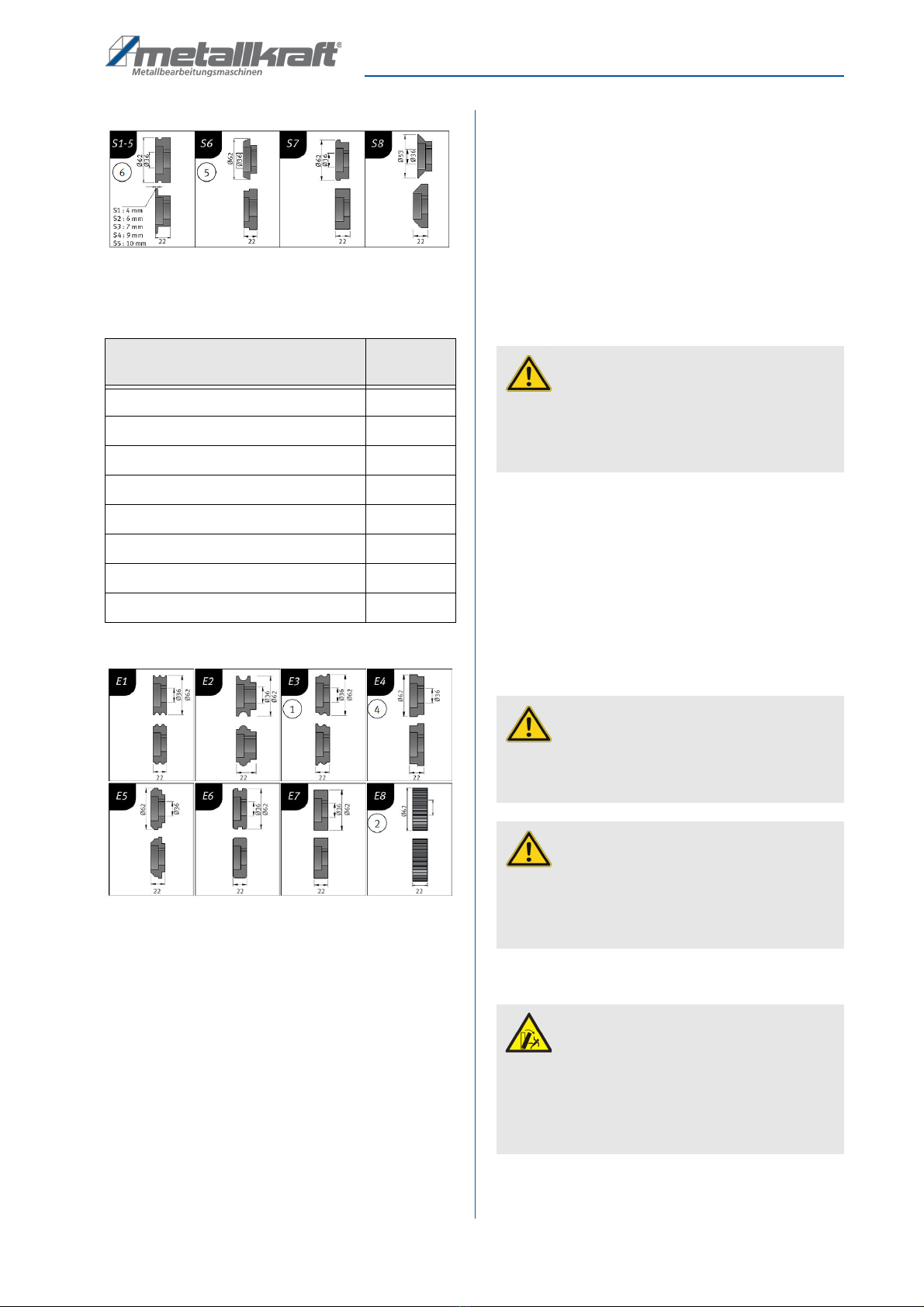

7.2 Roller se S1 o S5.................................................. 11

7.3 Roller se S6........................................................... 12

7.4 Roller se S7........................................................... 12

7.5 Roller se S8........................................................... 12

8 Replacing the rollers (Fig.12) .................. 12

9

Working with the bead bending machine

. 13

10 Care, maintenance and repair ............... 14

10.1 Care by cleaning................................................... 14

10.2 Lubrica ion char (Fig. 14)..................................... 14

11 Troubleshooting .................................... 14

12 Disposal, recycling of used devices..... 1

12.1 Decommissioning .................................................15

12.2 Disposal of new equipmen packaging................. 15

12.3 Disposal of he old device..................................... 15

12.4 Disposal of elec rical and elec ronic componen s. 15

12.5 Disposal of lubrican s ........................................... 16

12.6 Disposal via municipal collec ion poin s ............... 16

13 Spare parts.............................................. 16

13.1 Ordering spare par s............................................. 16

13.2 Spare par s drawing ............................................. 17

13.3 Spare par s lis ...................................................... 18

14 Electrical schematics ............................. 19

Introduction

SBM-Series | Version 2.04 3

1 Introduction

You have made a good choice by purchasing he ME-

TALLKRAFT Bead bending machine.

Read the operating manual thoroughly before com-

missioning the machine.

I gives you informa ion abou he proper commissioning,

in ended use and safe and efficien opera ion and main-

enance of your Bead bending machine.

The opera ing manual is par of he Bead bending ma-

chine package. Always keep his opera ing manual in he

loca ion where your Bead bending machine is being ope-

ra ed. All local acciden preven ion regula ions and gene-

ral safe y ins ruc ions for he opera ing range of your

Bead bending machine mus also be complied wi h.

1.1 Coypright

The con en s of hese ins ruc ions are copyrigh . They

may be used in conjunc ion wi h he opera ion of he de-

vice. Any applica ion beyond hose described is no per-

mi ed wi hou he wri en approval of S ürmer GmbH.

For he pro ec ion of our produc s, we shall regis er ra-

demark, pa en and design righ s, as his is possible in

individual cases. We s rongly oppose any infringemen

of our in ellec ual proper y

1.2 Customer service

Please con ac your dealer if you have ques ions con-

cerning your Bead bending machine or if you need ech-

nical advice. They will help you wi h specialis informa-

ion and exper advice.

Germany:

S ürmer Maschinen GmbH

Dr.-Rober -Pfleger-S r. 26

D-96103 Halls ad

Repair service:

Fax: 0049 (0) 951 96555-111

E-Mail: service@s uermer-maschinen.de

Spare part orders:

Fax: 0049 (0) 951 96555-119

E-Mail: ersa z eile@s uermer-maschinen.de

We are always in eres ed in valuable experience and

knowledge gained from using he applica ion-which hen

could be shared and be valuable o develop our produc s

even fur her.

1.3 Limitation of liability

All informa ion and no es in hese opera ing ins ruc ions

were summarised while aking applicable s andards and

rules, he s a e-of- he-ar echnology and our long- erm

knowledge and experiences in o considera ion.

In he following cases he manufac urer is no liable for

damages:

- Non-observance of he opera ing ins ruc ions,

- Inappropria e use

- Use of un rained s aff,

- Unau horised modifica ions

- Technical changes,

- Use of no allowed spare par s.

The ac ual scope of delivery may devia e from he expla-

na ions and presen a ions described here in case of spe-

cial models, when using addi ional ordering op ions or

due o la es echnical modifica ions.

The obliga ions agreed in he delivery con rac , he gen-

eral erms and condi ions as well as he delivery condi- i-

ons of he manufac urer and he legal regula ions a he

ime of he conclusion of he con rac are applicable.

2 Safety

This sec ion provides an overview of all major safe y pac-

kages for personal pro ec ion and safe and rouble-free

opera ion. Fur her ask-rela ed safe y ins ruc ions are con-

ained in he individual chap ers.The erm "machine" below

replaces he usual rade name of he objec o which hese

opera ing ins ruc ions refer (see cover shee ).

2.1 Symbol explanation

Safety instructions

The safe y no es in hese opera ing ins ruc ions are high-

ligh ed by symbols. The safe y no es are in roduced by

signal words which express he concern of he risk.

DANGER!

This combina ion of symbol and signal words indi-

ca es an imminen ly dangerous si ua ion which may

lead o dea h or severe injury if no avoided.

WARNING!

This combina ion of symbol and signal words indi-

ca es a po en ially dangerous si ua ion which may

lead o dea h or severe injury if no avoided.

4 SBM-Series | Version 2.04

Safety

Tips and recommendations

I is necessary o observe he safe y no es wri en in

hese opera ing ins ruc ions in order o reduce he risk of

personal injuries and damages o proper y.

2.2 Re uirements to staff

Qualifications

The differen asks described in his manual represen

differen requiremen s o he qualifica ion of he persons

en rus ed wi h hese asks.

Only persons reliable working procedures can be ex-

pec ed from, are allowed o perform all works. Persons

he responsiveness of which is affec ed by e. g. drugs,

alcohol or medica ion, are no allowed o work wi h he

machine.

The qualifica ions of he personnel for he differen asks

are men ioned below:

Operator

The opera or is ins ruc ed by he opera ing company

abou he assigned asks and possible risks in case of

improper behaviour. Any asks which need o be per-for-

med beyond he opera ion in he s andard mode mus

only be performed by he opera or if i is indica ed in

hese ins ruc ions and if he opera ing company expres-

sively commissioned he opera or.

Electrically qualified person

Elec rically qualified person is due o heir professional

raining, knowledge and experience as well as knowl-

edge of he relevan s andards and regula ions, in a posi-

ion o carry ou work on he elec rical sys ems and o in-

dependen ly recognize and avoid possible dangers.

Qualified personnel

Due o heir professional raining, knowledge and experi-

ence as well as heir knowledge of relevan regula ions

he specialis s aff is able o perform he assigned asks

and o recognise and avoid any possible dangers hem-

selves.

Manufacturer

Cer ain works may only be performed by specialis per-

sonnel of he manufac urer. O her personnel is no au-

horized o perform hese works. Please con ac our cus-

omer service for he execu ion of all arising work..

2.3 Personal protective e uipment

The personal pro ec ive equipmen serves o pro ec per-

sons agains impairmen s of safe y and heal h while wor-

king. The s aff member has o wear personal pro ec- ive

equipmen while performing differen asks on and wi h

he machine which are indica ed in he individual para-

graphs of hese ins ruc ions.

The personal pro ec ive equipmen is explained in he

following paragraph:

CAUTION!

This combina ion of symbol and signal words indi-

ca es a po en ially dangerous si ua ion which may

lead o sligh or minor injury if no avoided.

ATTENTION!

This combina ion of symbol and signal words indi-

ca es a possibly dangerous si ua ion which may lead

o proper y and environmen al damages if hey are

no avoided.

NOTE!

This combina ion of symbol and signal words indi-

ca es a po en ially dangerous si ua ion which may

lead o ma erial or environmen al damage if no avoi-

ded.

Tips and recommendations

This symbol highligh s useful ips and recommenda-

ions as well as informa ion for an efficien and rou-

ble-free opera ion.

WARNING!

Danger in case of insufficient quali-

fication of the staff!

Insufficien ly qualified persons canno es ima e he

risks while using he vacuum cleaner and expose

hemselves and o hers o he danger of severe or le -

hal injuries.

- Have all works only performed by qualified persons.

- Keep insufficien ly qualified persons ou of he work-

ing area.

Protective gloves

The pro ec ive gloves serve o pro ec he hands

agains sharp componen s as well as agains fric-

ion, abrasions or deep injuries.

Safety

SBM-Series | Version 2.04 5

2.4 Standards and guidelines

The design adhered o he essen ial heal h and safe y

requiremen s of applicable laws, s andards and guideli-

nes. The safe y of he machine is documen ed by he CE

marking and by he declara ion of conformi y.

All safe y informa ion refers o he curren ly valid regula i-

ons of he European Communi y. In o her coun ries, he

applicable laws and regula ions mus be complied wi h.

In addi ion o he safe y ins ruc ions in his opera ing ma-

nual, he generally valid regula ions for acciden preven-

ion and environmen al pro ec ion mus be observed and

adhered o.

2.5 General safety regulations

Please note the following:

1. Despi e he observance of all working ins ruc ions,

safe y and acciden preven ion regula ions, here re-

mains a residual risk when handling he machine. Th-

rough concen ra ed and forward-looking work and ac-

ion, you can reduce he residual risk.

2. The machine may only be opera ed and main ained by

persons who have read and unders ood his opera ing

manual. The opera or mus be adequa ely rained in ap-

plica ion, adjus men and opera ion.

3. If you pass on his machine, you mus hand over all

he ools and documen s supplied wi h he machine.

4. Swi ch on he machine immedia ely before s ar ing he

bending work. Swi ch off he machine during breaks and

when he machine is no in use. Never leave he ma-

chine on s andby una ended.

5. Never open he pro ec ive covers by hand while he

machine is running.

6. Keep he workplace and he floor in he vicini y of he

machine free of any objec s which jeopardize your s abi-

li y or pose a risk of ripping. Keep order in he work-

place. Clu er can resul in acciden s.

7. Before and during work, check he danger zone so

ha here are no unau horized persons in i . Do no allow

he machine o be ouched by o her people, especially

children.

8. Use he machine only in dry rooms or in a dry environ-

men and ensure a sufficien ly li work area.

9. Pro ec your work from rain, mois ure and mois ure so

ha he machine does no pose an elec rical hazard.

10. Main ain he machine wi h care. Keep he bending

machine in working order and clean in order o be able o

work well and safely in he long erm. Observe he no es

on main enance and service.

11. A he end of heir service life, he machine and all re-

placed wear and spare par s, as well as all auxiliary ma-

erials, such as lubrican s, mus be disposed of in accor-

dance wi h environmen al and

regula ions.Sicherhei shinweise zum Personenschu z

Safety boots

Safe y boo s pro ec he fee from being crushed, fall-

ing par s and slipping over on slippery ground.

Protective clothes

Pro ec ive clo hes are made of a igh ly fi ed fabric

wi hou he pro ruding par s of low ear s reng h.

WARNING!

Danger in case of misuse!

The bead bending machine may only be opera ed in

a echnically perfec condi ion. Any faul s mus be eli-

mina ed immedia ely. Unau horized changes o he

bead bending machine or improper use of he bead

bending machine as well as he disregard of he

safe y ins ruc ions or he opera ing ins ruc ions

exclude a liabili y of he manufac urer for resul ing

damage o persons or objec s and cause he war-

ran y o expire!

DANGER!

Before s ar ing, using, servicing or o herwise in erve-

ning on he machine, read he ins ruc ions for use

and main enance carefully. Dealing wi h and working

wi h he machine is only allowed for people who are

familiar wi h he handling and opera ion of he machi-

neare exac ly familiar.

WARNING!

Repairs, main enance and upgrades may only be

carried ou by qualified personnel a shu down and

secured machine (pull power plug!)!

6 SBM-Series | Version 2.04

Safety

Please note the following:

1. Do no use he machine if you are unfocused.

2. Opera ion or main enance of he machine is prohibi ed

for persons under he age of 16 or under he influence

of alcohol, drugs or medica ion.

3. Before s ar ing he processing, find ou abou he ype

of ma erial o be processed. Take appropria e precau-

ions, if necessary.

4. Always wear pro ec ive goggles when working wi h he

machine. The wearing of loose clo hing ( ies, scarves,

open jacke s and igh -fi ing garmen s) is prohibi ed.

There is a risk of injury from being caugh or pulled

in o moving machine par s. For long hair, a hairne

should be worn.

5. Pro ec yourself from noise by wearing sui able and

approved hearing pro ec ion.

6. Profiles can be sharp-edged. Wear pro ec ive gloves if

necessary. Pay a en ion o your pos ure and keep

your balance a all imes. Wear work shoes o in-

crease heir s abili y. Wear appropria e work clo hes

2.6 Safety measures when dealing with electri-

city

Please note the following:

1. The condi ions for elec rical equipmen apply o he

machine. These mus be checked for elec rical safe y

a regular, recurring in ervals by a recognized elec ri-

cian. The es cycles depend on he applicable regula-

ions.

2. To pro ec yourself agains elec ric shock, have he

machine clamped by a qualified elec rician only o a

sui able, secure power ou le .

3. Do no use he machine if i can no be properly swi -

ched on or off wi h he swi ch and he con rol compo-

nen s will no reach heir proper opera ing condi ion.

4. Pro ec he power cord from hea , oil and sharp edges.

2.7 Safety instructions for the use of tools

Please note the following:

1. Use only bending rollers ha are no deformed or da-

maged.

2. Use only original bending rollers.

3. Immedia ely replace deformed and damaged bender

rollers. Un il he bending rolls are replaced, he use of

he machine is prohibi ed.

4. Always use bending rolls adap ed o he workpiece.

5. Only use bending rolls wi h sui able dimensions.

6. Check he drive componen s of he bending rollers for

con amina ion. Clean he clamping area of he ben-

ding rollers before moun ing.

2.8 Safety instructions for working on the

machine

Please note the following:

1. Use he machine only for performing normal work.

2. Do no use he machine for purposes i is no in ended

o, for example for bending bri le ma erials.

3. Observe he maximum dimensions of he workpieces

specified in he echnical da a (see chap er "Technical

da a").

4. Do no overload he machine. She works be er and

safer in he specified performance range. Do no use

he machine for heavy work requiring a more powerful

machine.

5. Check he s abili y of he machine and he secure

screw connec ion wi h he founda ion.

6. No e ha using ools o her han hose recommended

by he manufac urer may resul in injury o you and

o her accessories.

7. Do no leave any ools s uck. Before swi ching on,

check ha all repair and adjus men ools have been

removed.

8. Do no leave he machine una ended in he machi-

ning process and keep a sufficien safe y dis ance o

he moving machine par s.

9. Only s ar he machine when he bending rollers are

free o run.

10.Block he bending rollers during machining by clam-

ping he workpiece, s op he mo or ro a ion by pres-

sing he emergency s op bu on.

11.The clamping or removal of workpieces may only be

carried ou wi h fully s anding bending rollers.

Intended use

SBM-Series | Version 2.04 7

2.9 Safety measures during maintenance and

servicing

Please note the following:

1. When carrying ou main enance and repair work al-

ways swi ch off he machine a he main swi ch and

secure i by aking appropria e measures o preven i

being res ar ed by a hird par y.

2. Af er main enance, repair and cleaning work, check

ha all coverings and pro ec ive devices are correc ly

moun ed on he machine again and ha no ools are

lef inside or in he processing area of he machine.

3. Damaged pro ec ive devices, machine par s and swi -

ches mus be replaced or repaired as in ended by a

recognized specialis workshop.

4. Make sure ha repairs o elec rical machines may only

be carried ou by a qualified elec rician. Only original

spare par s may be used. O herwise, he opera or is a

risk of acciden s.

5. Avoid acciden ally s ar ing he machine and make

sure ha he main swi ch is swi ched off when connec-

ing he machine o he mains.

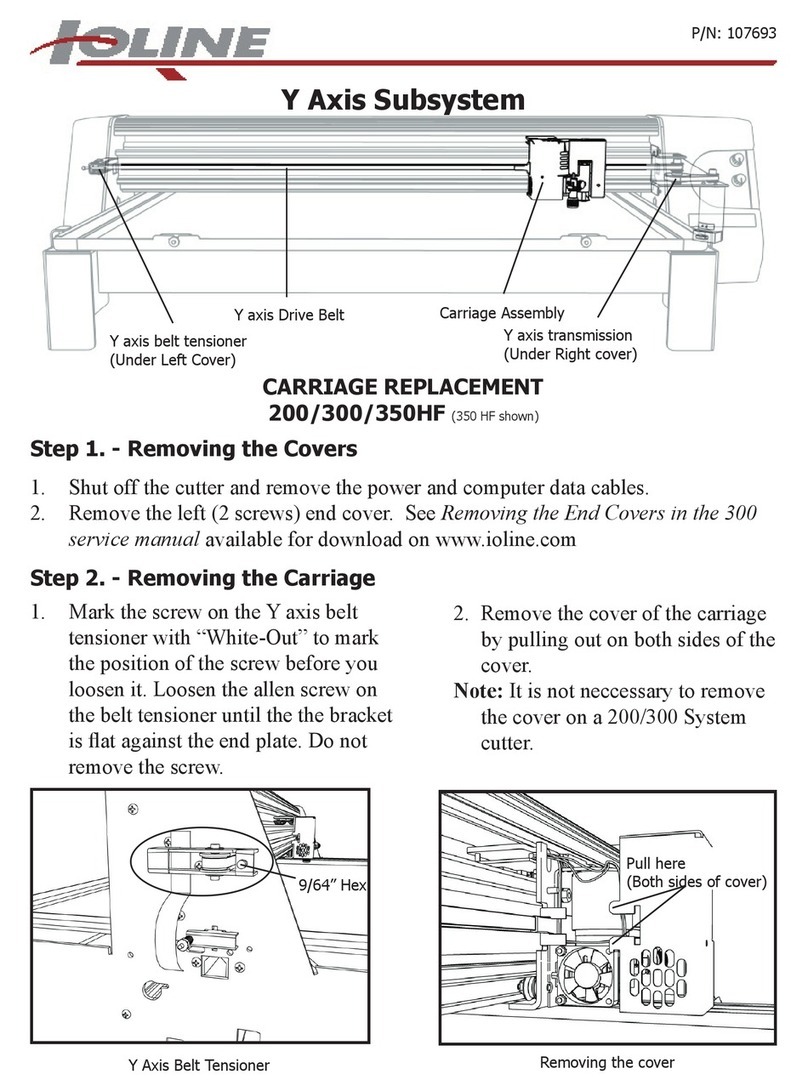

2.10 Safety markings on the bead bending machine

There are various warning labels and safe y labels a a-

ched o he bead bending machine, which mus be ob-

served and followed. The safe y markings a ached o

he bead bending machine mus no be removed. Dama-

ged or missing safe y markings can lead o malfunc ions,

personal injury and proper y damage. They are o be re-

placed immedia ely. If he safe y markings are no imme-

dia ely recognizable and comprehensible, he bead ben-

ding machine should be aken ou of opera ion un il new

safe y markings have been made.

Fig. 1: Safe y labls

3 Intended use

The bead bending machine SBM 140-12 E is an elec ri-

cally opera ed bending machine. The machine may only

be used as described in his manual. The bead bending

machine is designed for beading and beading up o a

maximum shee hickness of 1.2 mm. I may only be ope-

ra ed by persons rained and rained in he use and

main enance of Bead Bending Machines.

Proper use also includes compliance wi h all informa ion

in his manual. Any use beyond he in ended use or

o herwise is considered misuse. Use of he bead ben-

ding machine in o her areas and for o her purposes is

considered improper use. For s ruc ural and echnical

changes o he bead bending machine, he company

S ürmer Maschinen GmbH assumes no liabili y. Claims

of any kind due o damage due o improper use are ex-

cluded.

3.1 Residual riks

Even if all safe y regula ions are observed and he ma-

chine is used correc ly, here are s ill residual risks lis ed

below:

- There is a risk of injury o he upper limbs (e.g., hands,

fingers).

- Danger from falling workpieces.

WARNING!

Dangers in case of unintended use!

Misuse of he machine can lead o dange-rous si ua-

ions.

- Only opera e he bead bending machine in he ca-

paci y range specified in he echnical da a.

- Never bypass or override he safe y devices.

- Only opera e he bead bending machine in a echni-

cally perfec condi ion.

8 SBM-Series | Version 2.04

TechnicalData

3.2 Technical condition

The machine corresponds in design and execu ion he

curren s a e of he ar and is buil according o he recog-

nized safe y rules. The CE conformi y explici ly refers

only o he machine as delivered.

Note the following:

1. The func ionali y of pro ec ive covers and guards mus

be guaran eed.

2. Any manipula ion of pro ec ive covers and o her safe y

devices is prohibi ed.

3. Before each res ar he machine should be checked

for ex ernally visible damage.

4. Af er each res ar , he opera ing behavior is observed.

5. In he even of safe y-relevan devia ions from he deli-

very condi ion, he machine mus be inspec ed by an

au horized specialis and, if necessary, repaired.

6. From he poin in ime when he machine is no longer

in he normal opera ing condi ion, he profile bending

machine mus be aken ou of service un il repaired.

4 TechnicalData

4.1 Table

* Performance da a based on ma erial wi h ensile s reng h 400N / mm²

4.2 Type plate

Fig. 2: Type pla e SBM 140-12 E

4.3 Scopa of delivery

DANGER

Unau horized modifica ions or changes, in par icular

hose ha affec he securi y of he

Opera or are basically prohibi ed.

Technical changes, conversions and ex ensions

made by he user a he

Machine, he CE conformi y of he machine may

become invalid

leave and are he responsibili y of he opera or.

DANGER!

In he in eres of fur her echnical developmen or

changing regula ions, he ma nufac urer reserves he

righ o make changes o he charac eris ics of he

produc a any ime wi hou prior no ice.

Type SBM 140-12 E

Roller leng h 140 mm

Max. shee hickness* 1,2 mm

Roller Ø 62 mm

Collar wid h 100 mm

Roller speed 32 rpm

Mo or ou pu 0,75 kW

Elec rical connec ion 400 V / 50 Hz

Weigh 110 kg

Dimensions

Leng h 900 mm

Wid h 450 mm

Heigh 1.350 mm

Description Amou

nt

Bead bending machine SBM 140-12 E 1

S andard rollers S1-S8 8

Foo pedal 1

Special wrench for disassembly and as-

sembly of he rollers

1

Transport, packaging, storage

SBM-Series | Version 2.04 9

Fig. 3: S andard rollers Type S

4.4 Accessories

Fig. 4: Bending rollers ype E

5 Transport, packaging, storage

5.1 Delivery and Transport

5.1.1

Delivery

Check he Machine on delivery for any visi-ble ranspor-

a ion damage. If you no ice any damage o he device

please repor his immedia ely o he carrier or dealer.

All packaging mus be removed; he corresponding in-

s ruc ion of his ins alla ion manual mus be read. Pos-

sible ranspor damages are o be pho ographically do-

cumen ed immedia ely for he purpose of insurance

benefi s.

To avoid acciden s, he necessary precau ions mus be

aken when unloading and ranspor ing he machine. Re-

fer o he chap er on safe handling of his machine.

5.1.2 Transport

Improper ranspor of individual devices, unsecured de-

vices s acked on op of each o her or nex o each o her

in packed or already unpacked condi ion is acciden -

prone and can cause damage or malfunc ions for which

we do no gran any liabili y or guaran ee.

Transpor he scope of delivery secured agains shif ing

or il ing wi h a sufficien ly dimensioned indus rial ruck o

he ins alla ion si e.

General risks during internal transport

Description Item num-

ber

Bending rollers ype E1 3880131

Bending rollers ype E2 3880132

Bending rollers ype E3 3880133

Bending rollers ype E4 3880134

Bending rollers ype E5 3880135

Bending rollers ype E6 3880136

Bending rollers ype E7 3880137

Bending rollers ype E8 3880138

CAUTION!

Injuries caused by par s falling over or off a forklif ,

palle ruck or ranspor vehicle.

Only use means of ranspor ha can carry he o al

weigh and are sui able for i .

DANGER!

When ranspor ing and lif ing he bead bending

machine, observe ha he ranspor and lif ing equip-

men can ake he load.

WARNING!

Danger to life!

If he weigh of he machine and he permissible lif-

ing capaci y of he lif ing gear are no observed

during ranspor or lif ing, he machine may ip over

or fall.

CAUTION: DANGER OF TIPPING!

The device may be lif ed unsecured by a maximum

of 2cm.

Employees mus be ou side he danger zone, he

reach of loads. Warn employees and, if necessary,

advise employees of he hazard.

10 SBM-Series | Version 2.04

Transport, packaging, storage

Devices may only be ranspor ed by au horized and qua-

lified persons. Ac responsibly during ranspor and al-

ways consider he consequences. Refrain from daring

and risky ac ions.

Gradien s and descen s (e.g. driveways, ramps and he

like) are par icularly dangerous. If such passages are

unavoidable, special cau ion is required.

Before s ar ing he ranspor check he ranspor rou e for

possible danger poin s, unevenness and dis urbances

as well as for sufficien s reng h and load capaci y.

Danger poin s, unevenness and dis urbance poin s mus

be inspec ed before ranspor . The removal of danger

spo s, dis urbances and unevenness a he ime of rans-

por by o her employees leads o considerable dangers.

Careful planning of in ernal ranspor is herefore essen-

ial.

5.2 Packaging

All used packaging ma erials and packaging aids are re-

cyclable and should be aken o a ma erials recycling de-

po o be disposed of.

The delivery packaging is made of cardboard, so please

dispose carefully by having i chopped up and given o

he recycling collec ion

The film is made of polye hylene (PE) and he cushioned

par s of polys yrene (PS). Deliver hese subs ances o a

collec ion poin for recyclable ma erials or o he was e

disposal company which looks af er your region.

5.3 Storage

The bead bending machine mus be horoughly cleaned

before s oring in a dry, clean and fros -free environmen .

5.4 Set up

To achieve good func ionali y and long life of he pla e

rolling machine, he si e should mee he following cri e-

ria:

- The subs ra e mus be level, firm and vibra ion-

free.

- For a safe foo ing, he machine should be firmly an-

chored in he ground, wi h he lower working shaf

aligned wi h he spiri level. Only use quali y soil

anchors ha have sufficien sizing.

- There mus be sufficien space for he opera ing

personnel, for ma erial ranspor as well as for ad-

jus men and main enance work.

5.5 Electrical connection

The connec ion diagrams are loca ed under he chap er

"Circui diagrams". Connec ion only af er reading he in-

s ruc ions and comple e unders anding of he ske ches.

In case of ambigui y, con ac he manufac urer or he de-

aler immedia ely.

The elec rical connec ion may only be made by qualified

personnel. When swi ching on he mo or for he firs ime,

pay a en ion o he correc direc ion of ro a ion.

Wear safety gloves!

Wear safety shoes!

ATTENTION!

Danger of Crushing!

The Machine can il when se ing up and cause

injury.

DANGER!

Damage caused by incorrec connec ions is no

covered by he warran y, and

Me allkraf disclaims any responsibili y for conse-

quen ial damages resul ing herefrom.

Always disconnec he mains connec ion before

connec ing or disconnec ing.

Description of the device

SBM-Series | Version 2.04 11

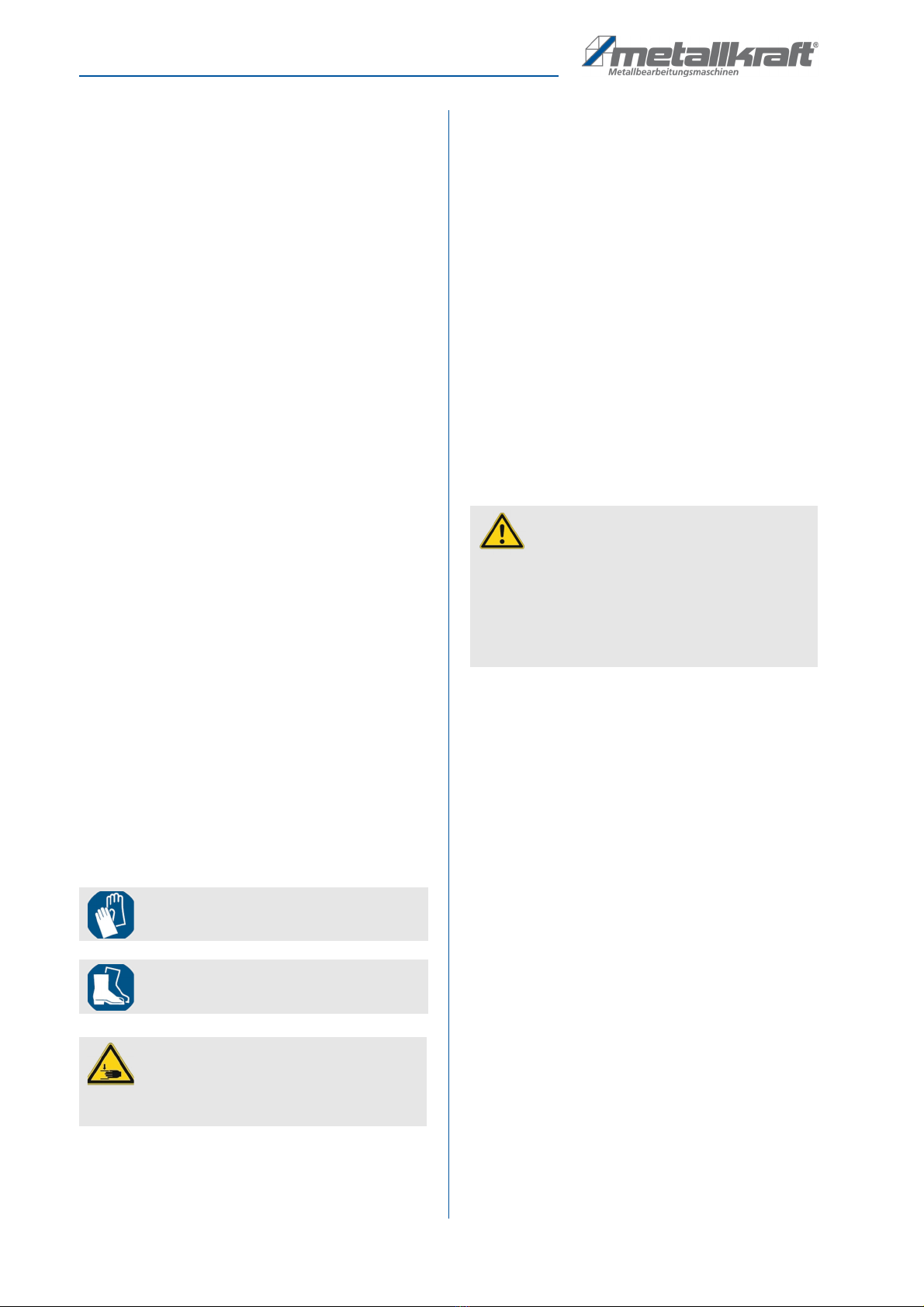

6 Description of the device

Illustrations in this operating manual serve the gene-

ral understanding and may deviate from the actual

design.

Fig. 5: Descrip ion of he device

1. Bending rolls

2. S op pla e

3. Gearbox pro ec ion cover

4. Gear

5. Elec ric mo or

6. Shee me al subs ruc ure

7. Con rol cabine

8. EMERGENCY STOP swi ch

9. Foo pedal

7 Description of the standard roles

7.1 Application examples and roles

Fig. 6: Applica ion examples wi h he S-rolls

Fig. 7: Applica ion examples wi h he E-rollers

7.2 Roller set S1 to S5

Fig. 8: Dimensions of he roller se S1-S5

The dimensions of he s andard bending roll se s are li-

s ed in he able. Here is S1 for roller se 1, S2 for roller

se 2, e c.

1

2

7

6

43

8

9

Description S1 S2 S3 S4 S

A mm 3 3,5 4 4 4

B mm 6,4 8,4 9,4 11,4 12,4

C mm 12,6 10,1 8,6 6,6 5,6

D mm 4 6 7 9 10

E mm 18 16 15 13 12

3x6 Keyway

3x6 Keyway

A B C

Ø 62

Ø 43

Ø 26

Ø 36

Ø 53

Ø 26

Ø 36

Ø 62

12 10

DE

12 10

12 SBM-Series | Version 2.04

Replacing the rollers (Fig.12)

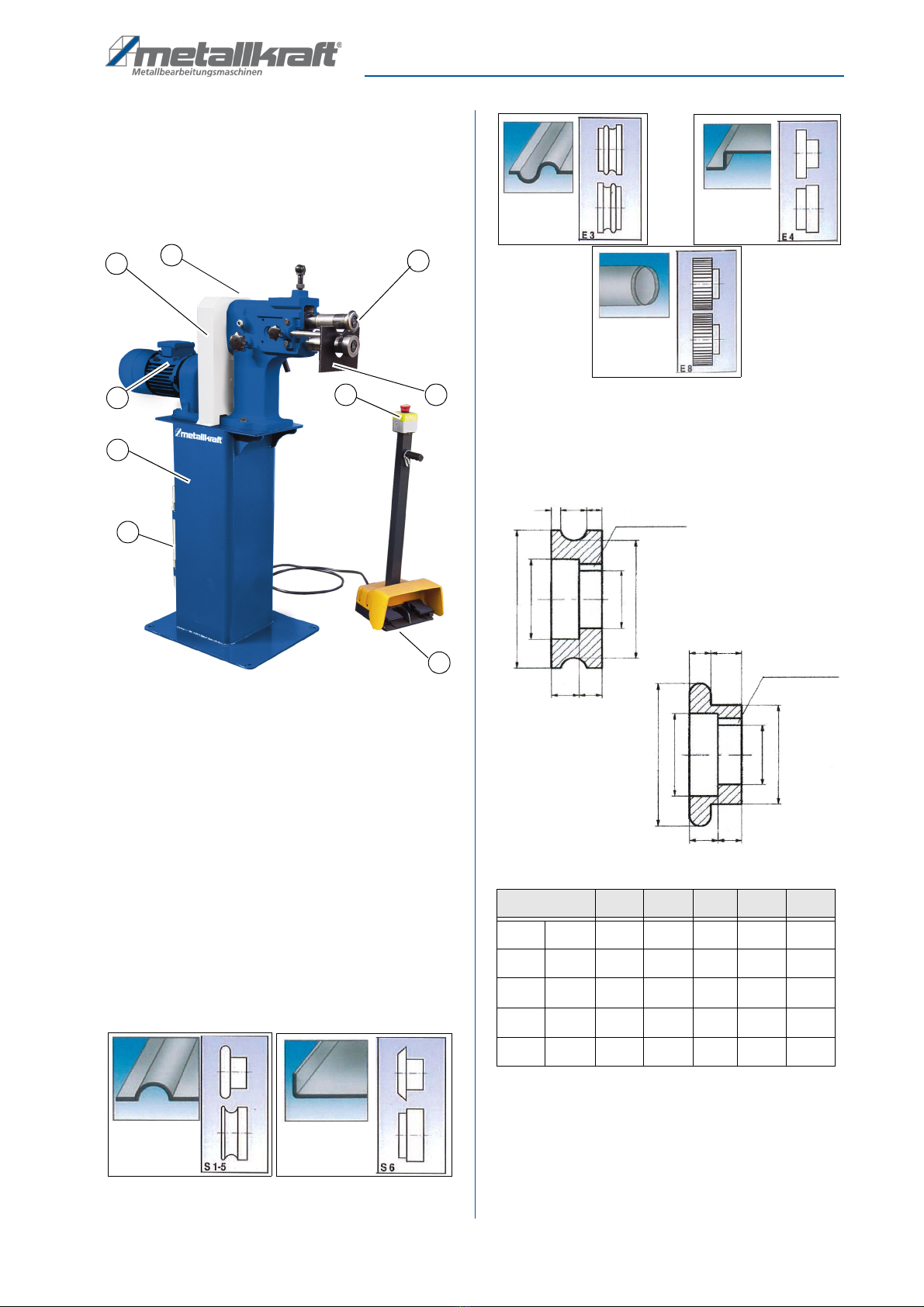

7.3 Roller set S6

Fig. 9: Dimensions of he roller se S6

7.4 Roller set S7

Fig. 10: Dimensions of he roller se S7

7.5 Roller set S8

Fig. 11: Dimensions of he roller se S8

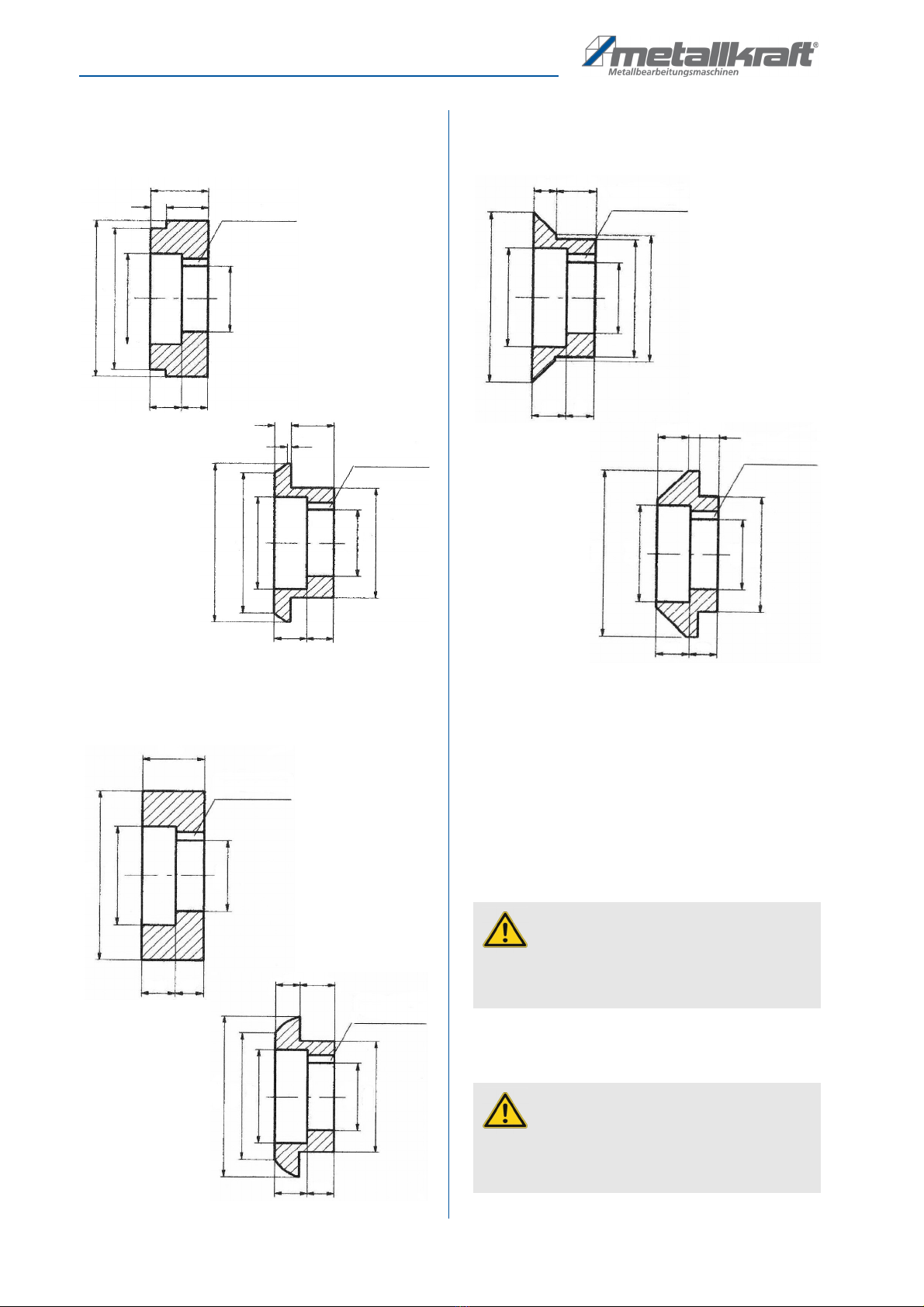

8 Replacing the rollers (Fig.12)

S ep 1: Using he humbscrew, move he upper drive

shaf upwards so ha he rollers are free and can

be pulled off.

S ep 2: Open he wo fas ening nu s from he bending

rollers. Use he supplied special key for his pur-

pose.

S ep 3: Now remove he wo cas ors and assemble he

ones you wan .

3x6 Keyway

3x6 Keyway

22

616

Ø 26

Ø 26

Ø 43

10

12

Ø 62

Ø 55

Ø 38

6 16

1,5

12 10

Ø 62

Ø 58

Ø 38

3x6 Keyway

3x6 Keyway

22

Ø 62

Ø 36

Ø 26

12 10 913

12 10

Ø 36

Ø 49

Ø 62

Ø 43

Ø 26

DANGER!

The hread on he upper roller is a righ -hand hread

and he hread on he lower roller is a lef -hand

hread.

DANGER!

In order o preven in erchanging he upper and lower

rollers, he shaf diame ers

differen ly.

3x6 Keyway

3x6 Keyway

814

Ø 43

Ø 38

Ø 62

Ø 48

Ø 43

Ø 38

Ø 62

Ø 26

Ø 26

12 10

8410

12 10

Working with the bead bending machine SBM 140-12 E

SBM-Series | Version 2.04 13

S ep 4: Tigh en he wo nu s af er moun ing he bending

rollers.

S ep 5: Then pull he rollers o cen er. To do his, open

he adjus ing screw of he longi udinal adjus -

men and adjus he rollers o he middle, hrough

he lever loca ed on he opposi e side.

Fig. 12: Replacing he rollers

9 Working with the bead bending ma-

chine SBM 140-12 E

S ep 1: As a firs s ep you have o assemble he righ

rolls for your upcoming work (see chap er "Re-

placing he rolls").

S ep 2: Now adjus he s op pla e by loosening he wo

locking screws on he lef and righ and manually

moving he s op pla e o he desired dimension.

Then fix he s op pla e again wi h he wo locking

screws.

S ep 3: Se he max. Delivery by he upper shaf wi h he

help of he humb screw o he desired level and

urn he nu all he way down.

S ep 4: For he bends in he shee , e.g. S iffening ribs,

use he heigh adjus men knob o move he up-

per shaf up un il he ma erial fi s be ween he

bending rollers. Slide he ma erial o he s op

pla e. Now urn he upper shaf down o he s op

screw (se in s ep 3).

S ep 5: Now move he foo swi ch o drive he shaf s / rol-

lers in he desired direc ion and reshape he

shee me al.

If it is not possible to deliver the complete delivery in one

go due to the high material thickness, this is also possible

in several sub-steps. Repeat steps 3 to until the desired

infeed depth / forming is achieved.

Before the actual bending process, press the foot switches

to test the running direction of the rollers.

Fig. 13: Working wi h he SBM 140-12 E

Locking screw of the

longitudinal adjustment

Locking screw of

the stop plate

Right thread

Left thread

Height adjustment /

of the upper roll

Stop plate

Lever for longitudinal adjustment

the lower drive shaft

Wrench to change the roles

14 SBM-Series | Version 2.04

Care, maintenance and repair

10 Care, maintenance and repair

Af er main enance, repair and cleaning, check ha all

panels and guards are correc ly ins alled on he bead

bending machine and ha here is no ool lef inside or

inside he bead bending machine.

10.1 Care by cleaning

Regularly clean he bead bending machine wi h a sof ,

damp clo h.

10.2 Lubrication chart (Fig. 14)

All moving par s and guides should be oiled weekly wi h

SAE 30 oil.

The gear wheels are o be lubrica ed mon hly wi h he

commercial grease.

Should he service life of he machine be more han 8

hours per day, i mus be lubrica ed more frequen ly.

To lubrica e he gear wheels, you mus firs unscrew he

4 screws and remove he gear cover

Fig. 14: Lubrica ion char

11 Troubleshooting

Tips and recommendations

To ensure ha he bending machine is always in

good opera ing condi ion, regular care and main-

enance work mus be carried ou .

NOTE!

Before servicing and main aining he bead bending

machine, he main enance ins ruc ions mus be read

carefully. The handling of he bead bending machine

is only permi ed o persons who are familiar wi h he

bead bending machine.

DANGER!

Danger due to insufficient qualifica-

tion of persons!

Insufficien ly qualified persons can no assess he

risks involved in main enance work on he machine

and expose hemselves and o hers o he risk of

serious injury.

-All main enance work should only be carried ou by

qualified persons.

NOTE!

The bead bending machine mus be greased a regu-

lar in ervals o ensure efficien opera ion and long life

of he machine.

DANGER!

The bending rolls of he bead bending machine mus

never be lubrica ed or oiled, as o herwise he ma e-

rial could slip hrough and no be ben . Always keep

he bending rollers free of oil and grease. Also make

sure ha he ma erial o be ben is free of oil, grease

and dir .

When no using he machine for a long ime, ligh ly

oil he bending rollers. This oil layer should be remo-

ved before res ar ing.

DANGER!

If one of he following errors occurs, s op working wi h

he machine immedia ely. I could lead o serious inju-

ries. All repairs or replacemen work may only be car-

ried ou by qualified and rained specialis personnel.

Fault Possible cause Remedy

The Ma-

chine does

no work.

1. The mecha-

nics are bro-

ken.

1.Check he me-

chanics.

2.

Con ac he dealer.

The Ma-

chine does

no bend he

ma erial cor-

rec ly.

1.The ma erial

hickness

could be

wrong.

2

.The wrong ma-

erial has been

inser ed.

1.max. No e pla e

hickness.

2.Inser only he

correc ma e-

rial

Öl SAE 30 Grease

Disposal, recycling of used devices

SBM-Series | Version 2.04 15

12 Disposal, recycling of used devices

Please ake care in your own in eres and in he in eres

of he environmen ha all componen par s of he ma-

chine are only disposed of in he in ended and permi ed

way.

12.1 Decommissioning

Disused equipmen mus be aken ou of service immedi-

a ely in order o avoid la er misuse and endangering he

environmen or people.

- Unplug he power plug.

- Cu he connec ion cable.

- Remove all environmen ally hazardous fluids from

he Al device.

- If available, remove ba eries and rechargeable

ba eries.

- If necessary, disman le he machine in o manage-

able and usable assemblies and componen s.

- Guide he machine componen s and opera ing ma-

erials o he appropria e disposal rou es.

12.2 Disposal of new e uipment packaging

All packaging ma erials and packaging aids used in he

machine are recyclable and mus always be recycled.

The packaging wood can be sen for disposal or recy-

cling.

Packaging componen s made of cardboard can be crus-

hed for was e paper collec ion.

The films are made of polye hylene (PE) or uphols ery

par s made of polys yrene (PS). These subs ances can

be reused af er reprocessing if hey are forwarded o a

recycling cen er or o he disposal company responsible

for hem.

Only pass on he packaging ma erial sor ed, so ha i

can be direc ly recycled.

12.3 Disposal of the old device

Elec rical equipmen con ains a varie y of recyclable ma-

erials and environmen ally harmful componen s.

These componen s mus be separa ed and properly dis-

posed of. If in doub , con ac municipal was e manage-

men .

If necessary, he help of a specialized was e manage-

men company can be used for he rea men .

12.4 Disposal of electrical and electronic com-

ponents

Please ensure proper disposal of he elec rical compo-

nen s in accordance wi h he legal requiremen s.

The device con ains elec rical and elec ronic compo-

nen s and mus no be disposed of as household was e.

According o European Direc ive 2002/96 / EC on was e

elec rical and elec ronic equipmen and i s ransposi ion

in o na ional law, used elec ric ools and elec rical machi-

nes mus be collec ed separa ely and recycled in an env-

ironmen ally sound manner.

As a machine opera or, you should ob ain informa ion

abou he au horized collec ion or disposal sys em ha is

valid for you.

Please ensure ha he ba eries and / or rechargeable

ba eries are properly disposed of in accordance wi h le-

gal regula ions. Please hrow only discharged ba eries

in o he collec ion boxes a re ailers or municipal was e

disposal companies.

The Ma-

chine does

no bend he

ma erials as

indica ed in

he ca alog.

1.The ma erial

hickness could

be wrong.

2.The mecha-

nics are faul y.

1.

Check he ma e-

rial o be ben .

2.Con ac he de-

aler.

Fault Possible cause Remedy

16 SBM-Series | Version 2.04

Spare parts

12.5 Disposal of lubricants

The disposal ins ruc ions for he lubrican s used are pro-

vided by he lubrican manufac urer. If necessary, ask for

he produc specific da a shee s.

12.6 Disposal via municipal collection points

Disposal of used elec rical and elec ronic equipmen

(Applicable in he coun ries of he European Union and

o her European coun ries wi h a separa e collec ion sy-

s em for hese appliances).

The symbol on he produc or i s packaging

indica es ha his produc should no be

rea ed as normal household was e, bu

mus be re urned o a collec ion poin for he

recycling of elec rical and elec ronic equip-

men . By helping o properly dispose of his

produc , you are pro ec ing he environmen and he

heal h of o hers. Environmen and heal h are endange-

red by improper disposal. Ma erial recycling helps o re-

duce he consump ion of raw ma erials. For more infor-

ma ion abou recycling his produc , con ac your local

communi y, municipal was e managemen , or he shop

where you purchased he produc .

13 Spare parts

13.1 Ordering spare parts

The spare par s may be purchased wi h he au horised

dealer or direc ly wi h he manufac urer. Please find he

corresponding con ac da a in Chap er 1.2 Cus omer

service.

Indica e he following basic informa ion for reques s or

orders of spare par s:

- Type of device

- I em No.

- Posi ion No.

- Year of cons ruc ion:

- Quan i y

- Required mode of dispa ch (mail, freigh , sea, air,

express)

- Address of dispa ch

Spare par orders which do no include he above indica-

ions may no be aken in o considera ion. If he indica- i-

ons regarding he mode of dispa ch are missing, he pro-

duc is dispa ched a he discre ion of he supplier.

You will find informa ion regarding he device ype, i em

No. and year of manufac ure on he ype pla e fixed o

he Machine.

Example

The lower shaf for he Bead bending machine SBM 140-

12 E mus be ordered. The lower shaf has he number 5

in he spare par s drawing 1.

By ordering spare par s, send a copy of he spare par s

drawing (1) wi h he marked par (lower shaf ) and mar-

ked posi on number (5) o he dealer or spare par s de-

par men and provide he following informa ion:

Type of device:

Bead bending machine

SBM 140-12 E

- I em number:

3814003

- Drawing number:

1

- Posi ion number:

Item number of your machine:

SBM 140-12 E 3814003

DANGER!

Please pay a en ion o an environmen ally friendly

disposal of he used coolan s and lubrican s.

Observe he disposal ins ruc ions of your municipal

disposal companies.

INFORMATION!

Spen coolan emulsions and oils should no be

mixed wi h each o her as only non-mixed was e oils

can be used wi hou pre rea men .

DANGER!

Danger of injury by the use of

wrong spare parts!

Dangers may resul for he user and damages as well

as malfunc ions may be caused by using wrong or

damaged spare par s.

- Only use original spare par s of he manufac urer or

spare par s admi ed by he manufac urer.

- Always con ac he manufac urer in case of uncer-

ain ies.

NOTE!

The manufac urer's warran y will become null and

void if non-permissible spare par s are used

Spare parts

SBM-Series | Version 2.04 17

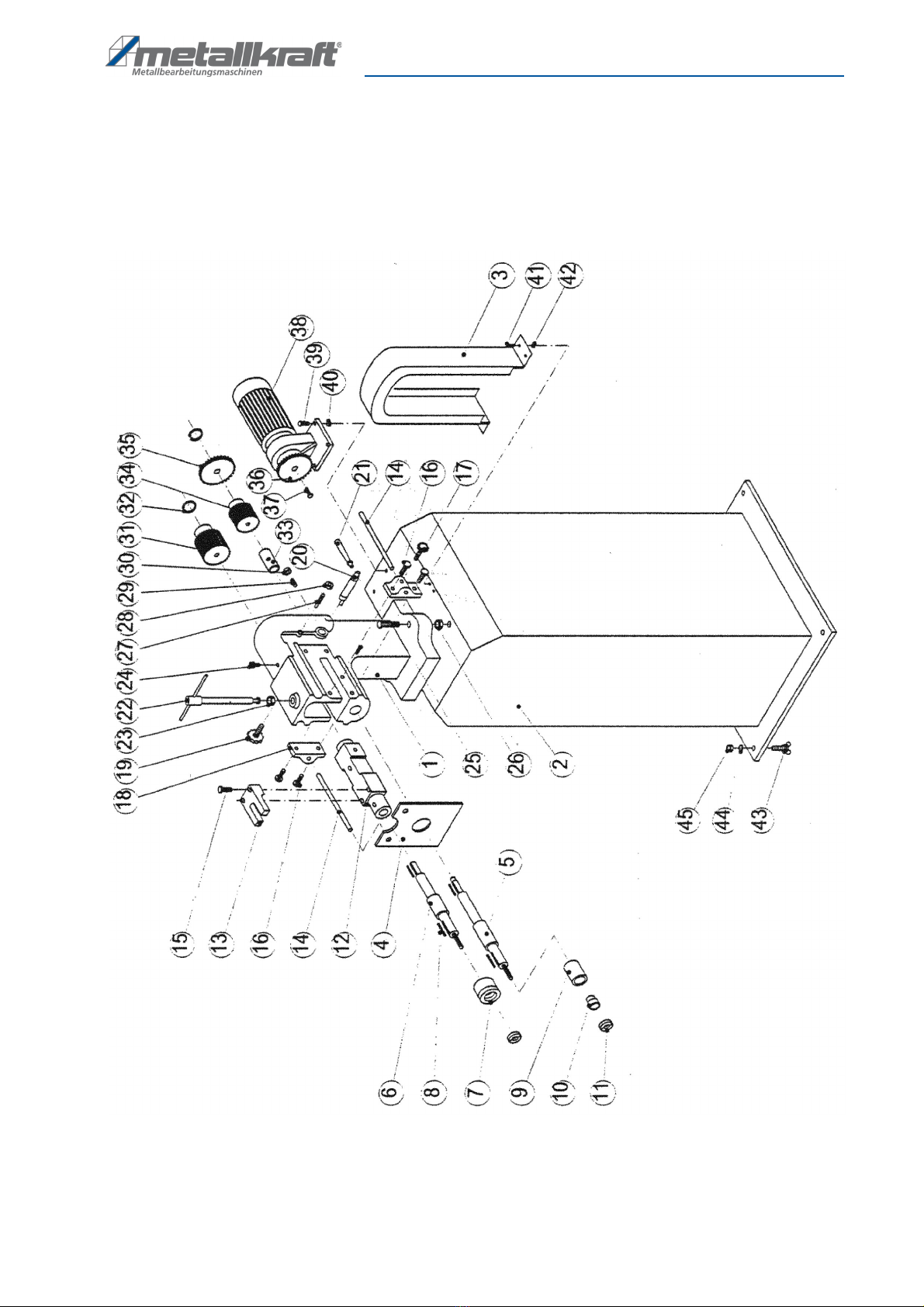

13.2 Spare parts drawing

In case of service, he following drawing shall help o iden ify he necessary spare par s. If necessary, send a copy of he

par s drawing wi h he marked componen s o your au horised dealer.

Fig. 15: Spare par s drawing

18 SBM-Series | Version 2.04

Spare parts

13.3 Spare parts list

Pos. Description

1 Machine housing

2 Undercarriage

3 gear cover

4 s op pla e

5 Lower shaf

6 Upper shaf

7 In ermedia e sleeve above

8 Adjus ing spring

9 In ermedia e sleeve below

10 Ring

11 Fixing nu

12 Shaf guide upper shaf

13 Guidance of he heigh adjus men

14 Guide rod for s op pla e

15 Screw

16 Screw

17 Clamping screw guide rod

18 Guide housing

19 Locking screw leng hwise adjus men

20 Eccen ric shaf longi udinal adjus men

21 Lever for eccen ric shaf

22 Screw for heigh adjus men

23 Nu

24 Oiler

25 Screw

26 Nu

27 Connec ing bol s

28 Nu

29 Bol

30 Nu

31 Drive gear upper shaf

32 Circlip

33 Spacer sleeve

34 Drive gear lower shaf

35 In ermedia e gear above

36 In ermedia e gear below

37 Screw

38 Engine

39 Screw

40 Shaf

41 Screw

42 Nu

43 Machine base

44 Washer

45 Nu

46 Foo pedal

(without picture.)

Pos. Description

Electrical schematics

SBM-Series | Version 2.04 19

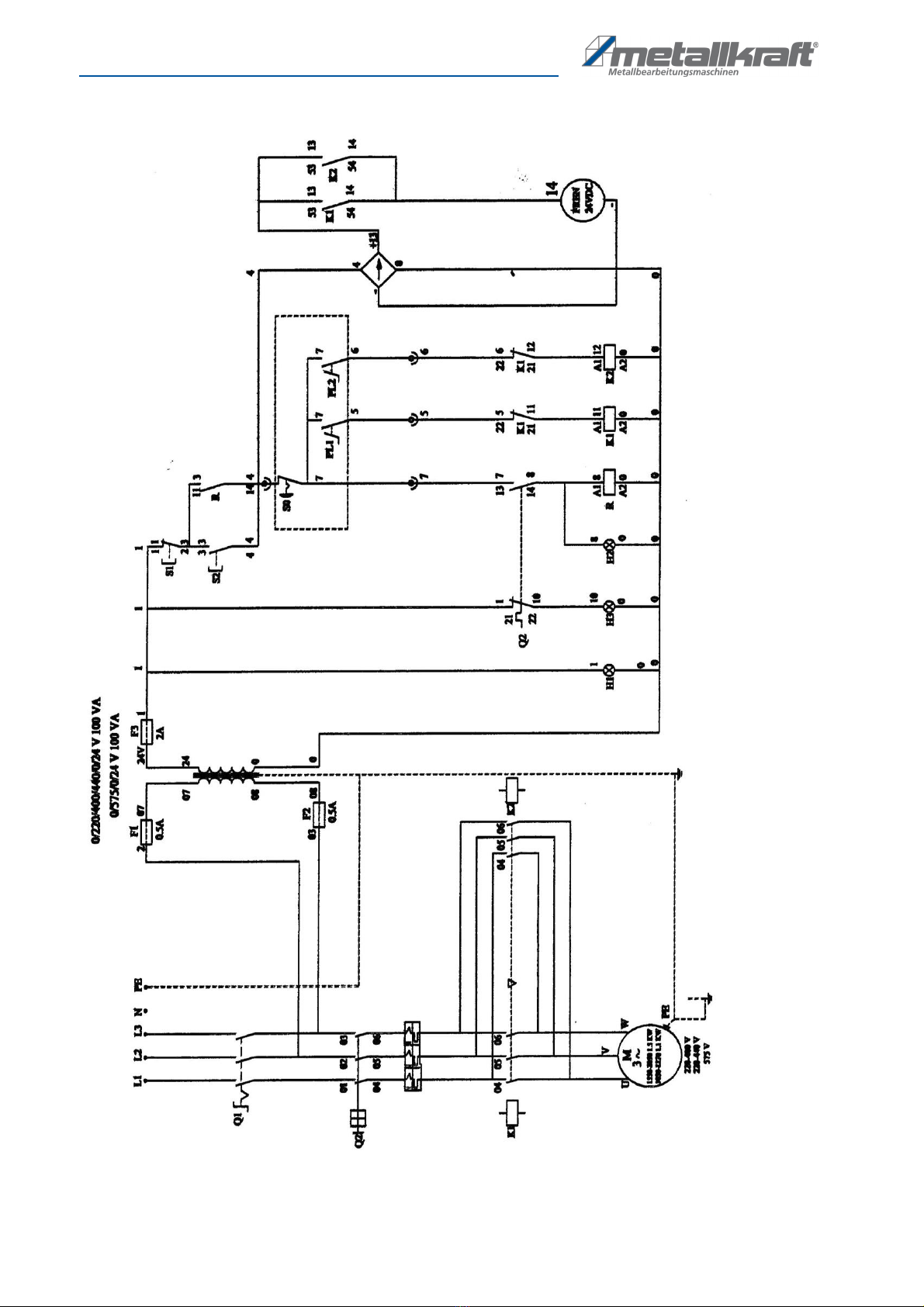

14 Electrical schematics

Fig. 16: Elec rical schema ics 1

20 SBM-Series | Version 2.04

Electrical schematics

Fig. 17: Elec rical schema ics 2

This manual suits for next models

1

Table of contents

Other Metallkraft Cutter manuals

Popular Cutter manuals by other brands

Powermate

Powermate 024-0089 instruction manual

Chicago Pneumatic

Chicago Pneumatic CP861 instruction manual

KONWA

KONWA KW-123 instruction manual

Textron

Textron Greenlee Gator ES20L Operation manual

Cembre

Cembre B-TC650NA Operation and maintenance manual

Vitrex

Vitrex TORQUE-MASTER POWER Owner's safety and operating manual

Bosch

Bosch GUS 10 Original instructions

Battipav

Battipav Queen 180 operating instructions

Ozito

Ozito MCS-5000 instruction manual

Roto Zip Tool

Roto Zip Tool RZ1 Operating/safety instructions

Land Pride

Land Pride RCP2560 Series Operator's manual

Titan Implement

Titan Implement Flex-Wing 1912 Operation and parts manual