2

Index

1. MIDA Introduction ............................................................................................................................................................ 3

2. Safety Instructions............................................................................................................................................................. 3

3. Technical Characteristics ................................................................................................................................................... 4

3.1 Performance ............................................................................................................................................................................ 4

3.1 Weight and dimensions .......................................................................................................................................................... 4

3.2 Cable entries ............................................................................................................................................................................ 4

4. MIDA installation .............................................................................................................................................................. 5

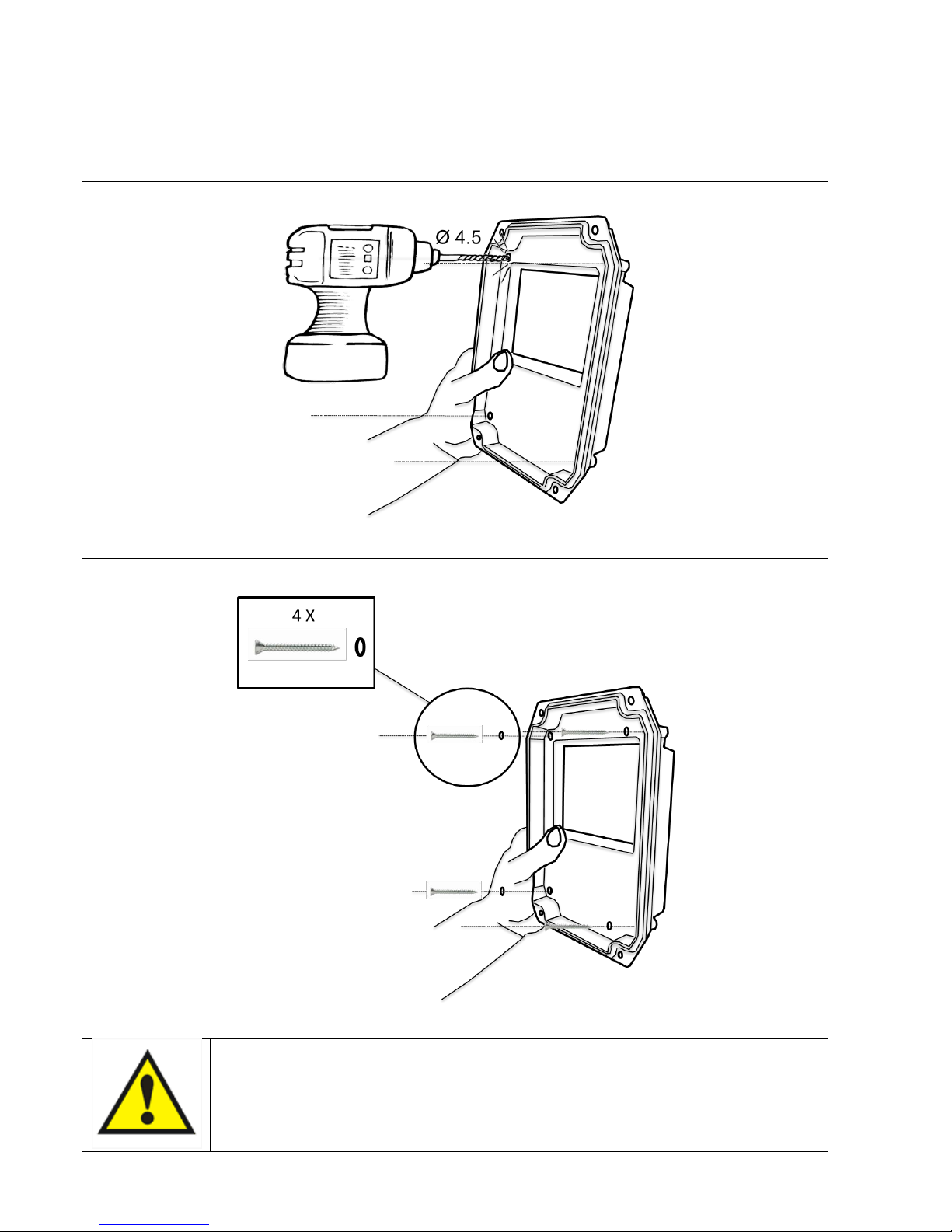

4.1 Mechanical installation ............................................................................................................................................................ 5

4.2 MIDA Installation for constant pressure control ..................................................................................................................... 7

4.2.1 Pressure tank ................................................................................................................................................................ 7

4.2.2 Pressure sensor............................................................................................................................................................. 7

4.3 MIDA installation for differential constant pressure applications ........................................................................................... 8

4.3.1 Sensors wiring ............................................................................................................................................................... 8

4.3.2 Programming................................................................................................................................................................. 8

5. Electric wiring.................................................................................................................................................................... 9

5.1 Protections............................................................................................................................................................................. 13

5.2 Electromagnetic compliance.................................................................................................................................................. 13

5.3 Installation with long motor cables ....................................................................................................................................... 13

6. MIDA use and programming.............................................................................................................................................14

6.1 Monitoring and programming............................................................................................................................................... 15

6.1.1 Monitoring ................................................................................................................................................................. 15

6.1.2 Programming.............................................................................................................................................................. 16

6.2 COMBO operation.................................................................................................................................................................. 23

7. Protections and alarms.....................................................................................................................................................25