Index

1. Revision summary ............................................................................................................................................................................... 3

2. Hazard markings and safety signs ....................................................................................................................................................... 3

3. Equipment information......................................................................................................................................................................... 4

3.1 Equipment purpose....................................................................................................................................................................... 4

3.2 Definition of UVC-disinfection ....................................................................................................................................................... 4

3.4 About the documentation .............................................................................................................................................................. 4

3.5 Declaration of conformity .............................................................................................................................................................. 5

4. Equipment overview ............................................................................................................................................................................ 6

4.1 Environment for the equipment ..................................................................................................................................................... 6

4.1.1 Surface ................................................................................................................................................................................. 6

4.1.2. Placement............................................................................................................................................................................ 6

4.1.3 Temperature and humidity .................................................................................................................................................... 6

4.1.4. Storage and environment ..................................................................................................................................................... 6

4.1.5. Requirement before use....................................................................................................................................................... 6

4.2. Mounting instructions ................................................................................................................................................................... 6

4.2.1 Connecting the device........................................................................................................................................................... 7

4.2.2 Turn of the UV device ........................................................................................................................................................... 7

5. Safety in and around UV equipment .................................................................................................................................................... 7

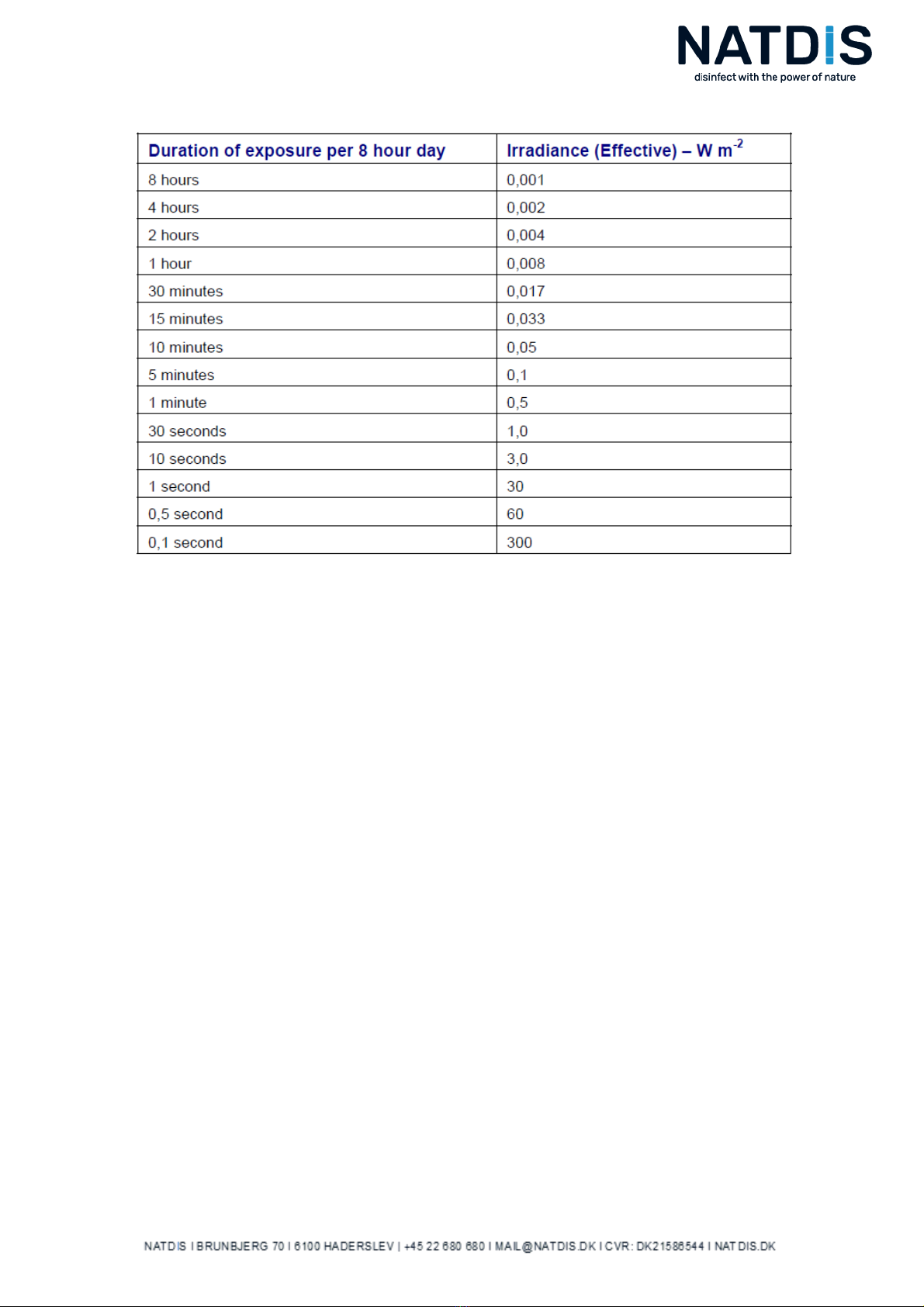

5.1 UVC physical: ............................................................................................................................................................................... 7

5.2 About the risk using UVC.............................................................................................................................................................. 8

5.3 UVC damages .............................................................................................................................................................................. 8

5.3.1 One-time injuries:.................................................................................................................................................................. 8

5.3.2 Repeated daily dose overruns:.............................................................................................................................................. 9

5.4 Environment: ................................................................................................................................................................................ 9

5.4.1 Staff: ..................................................................................................................................................................................... 9

5.4.2 Installation:............................................................................................................................................................................ 9

5.4.3. Access to area: .................................................................................................................................................................... 9

5.5 Safety: .......................................................................................................................................................................................... 9

5.5.1 Active safety: ........................................................................................................................................................................ 9

5.5.2 Passive safety:...................................................................................................................................................................... 9

5.5.3 Disposal................................................................................................................................................................................ 9

6. Service and maintenance .................................................................................................................................................................. 11

6.1 Bulb change:............................................................................................................................................................................... 11

6.2. Change of quartz glass: ............................................................................................................................................................. 11

7. Cleaning of UVC-Systems ................................................................................................................................................................. 12

7.1 Purpose ...................................................................................................................................................................................... 12

7.2. Precautions ............................................................................................................................................................................... 12

7.3. Dry cleaning............................................................................................................................................................................... 13

7.3.1 Cleaning frequency ............................................................................................................................................................. 13

7.3.2 Detergents .......................................................................................................................................................................... 13

7.4. Cleaning procedure and inspection............................................................................................................................................ 13

8. Liability and Warranty ........................................................................................................................................................................ 14