4

Install coils with the drain pan and/or casing on a flat, level

surface. Slope the coil 1/4” towards the drain. Condensate lines

must be installed in accordance with building codes. It is the

contractor’s responsibility to ensure proper condensate drainage

at the time of the installation; National Comfort Products bears

no responsibility for damages caused by improper condensate

management.

SOME COILS HAVE PRIMARY AND SECONDARY

DRAIN PORTS ON BOTH SIDES OF THE PAN TO OFFER

INSTALLATION FLEXIBILITY, SO ENSURE ALL THREADED

PLUGS ARE IN PRESENT AND TIGHTENED IN ANY

UNUSED DRAIN PORTS. THESE MAY BE HIDDEN BEHIND

THE COIL CASING ACCESS DOOR. FAILURE TO DO SO

MAY RESULT IN PROPERTY WATER DAMAGE; IT IS THE

CONTRACTOR’S RESPONSIBILITY TO ENSURE THESE

PLUGS ARE PRESENT AND TIGHT.

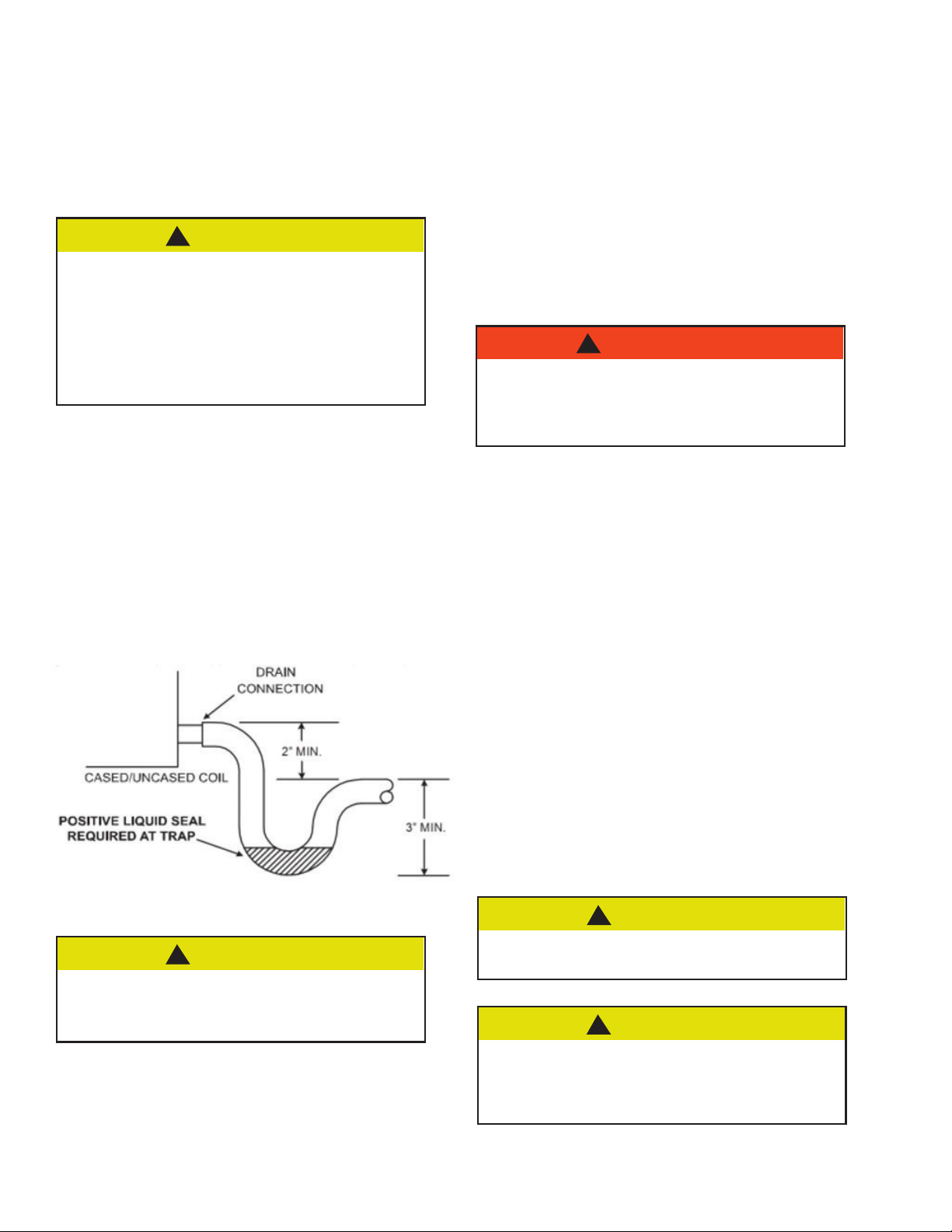

!CAUTION

The drain lines must be installed with ¼” per foot pitch to provide

free drainage. A condensate trap MUST be installed on the

primary drain line to ensure proper drainage of the condensate.

The trap must be installed in the drain line below the bottom of

the drain pan. Fig. 1 illustrates the typical drain trap installation.

Prior to installation, ensure drain pan hole is not obstructed.

Additionally, National Comfort Products recommends the drain

lines be insulated to prevent sweating and dripping.

Fig. 1

USE TEFLON TAPE TO CONNECT THE DRAIN LINES TO

THE THREADS IN THE DRAIN PAN. DO NOT USE SOLVENT

BASED PIPE DOPE. THIS WILL REDUCE THE LIFE OF THE

PAN.

!CAUTION

The drain pan has primary (white) and secondary (red) drain

connections. If a secondary drain line is required, it should be

run separately from the primary and should terminate in a highly

visible location. Condensate disposal through the secondary

drain line indicates that the primary drain line is plugged and

needs cleaning. If a secondary drain line will not be provided,

plug the secondary drain. Drain plugs are NOT to be reused

without plumbers tape or putty. Drain line connection should be

finger tightened, then turned no more than one complete turn

as needed to ensure a firm connection. DO NOT overtighten

connection or damage may occur.

Coil Installation

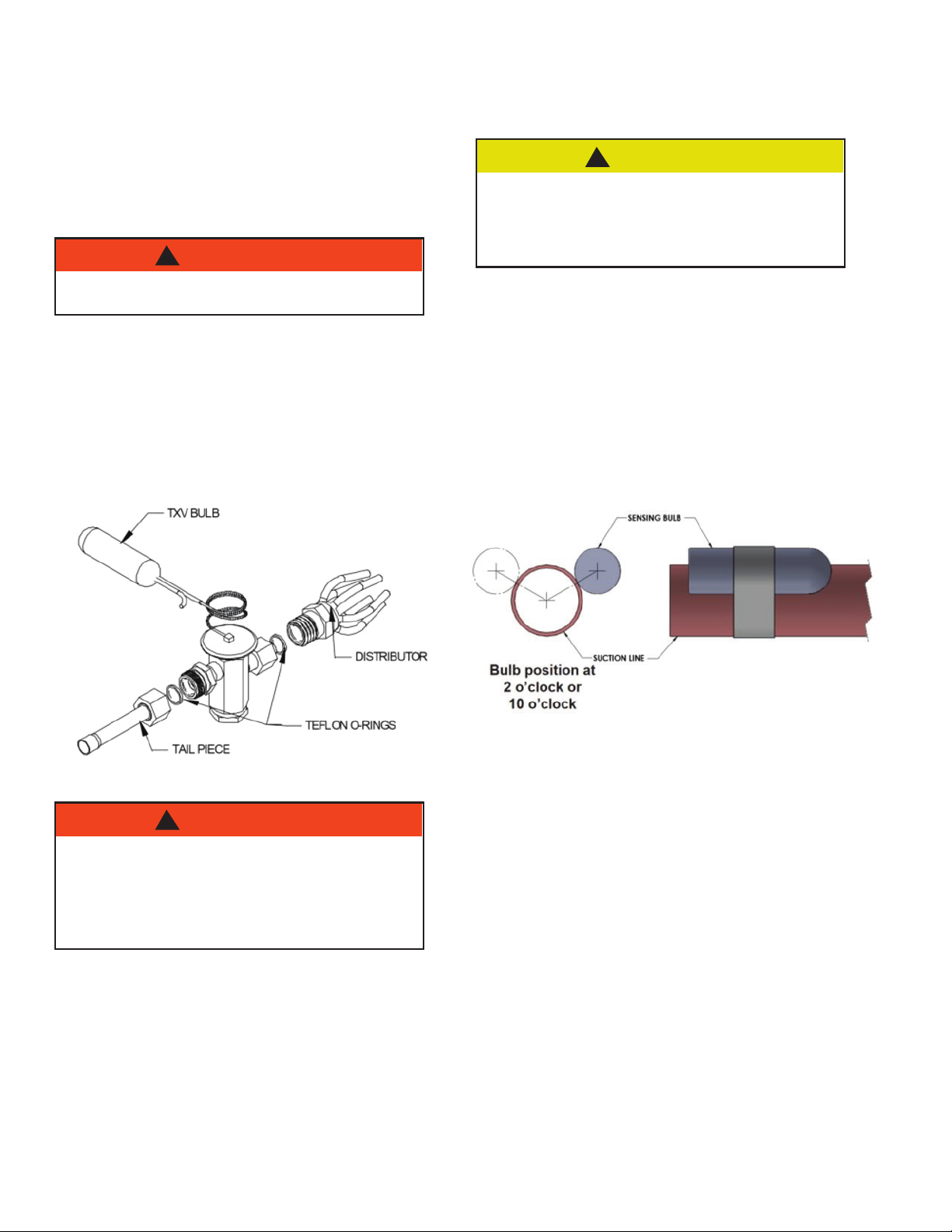

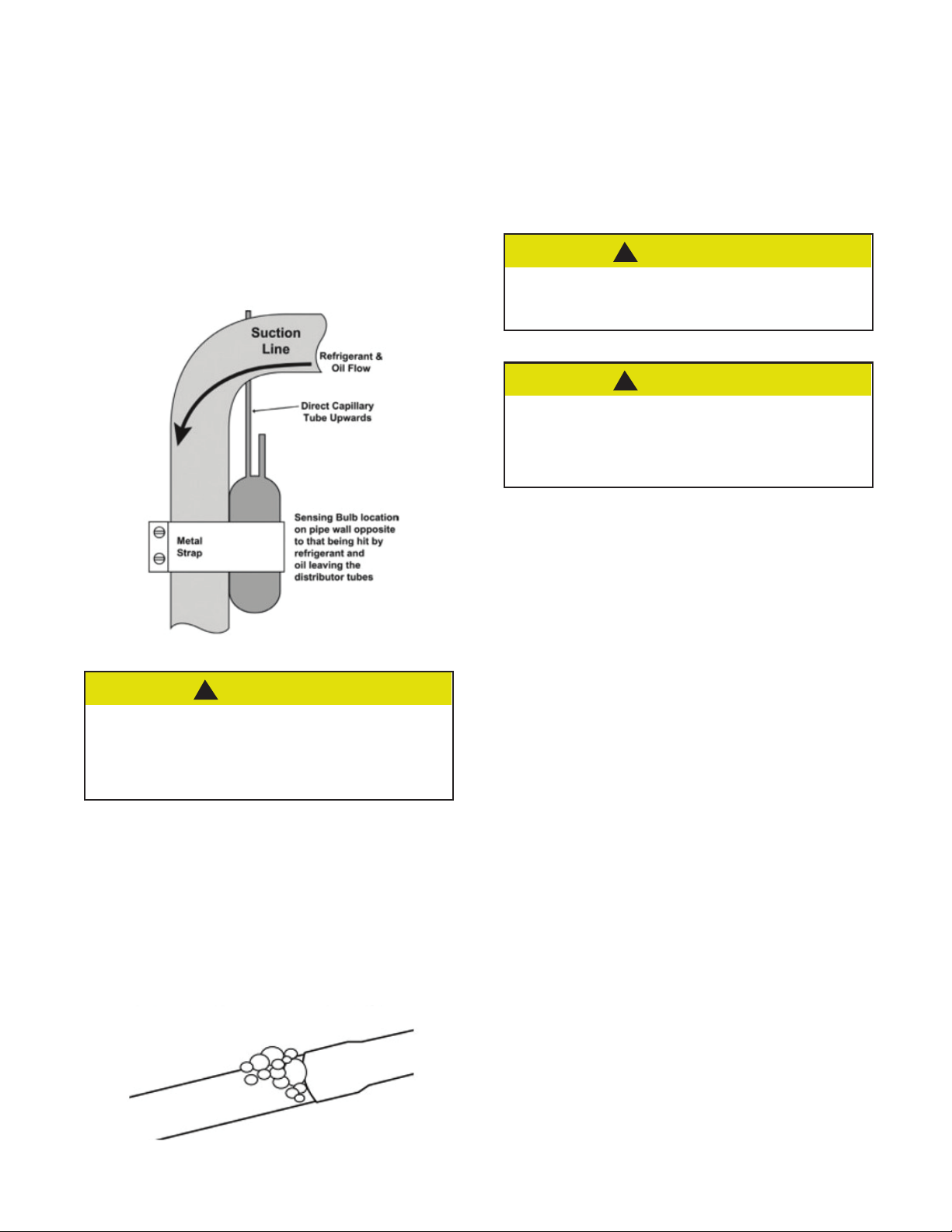

THE COIL IS MANUFACTURED WITH DRY NITROGEN

PRE-CHARGE. RELEASE THE PRESSURE THROUGH THE

SCHRADER VALVE TEST PORT PRIOR TO INSTALLATION.

IF HOLDING PRESSURE IS NOT PRESENT, RETURN COIL

TO DISTRIBUTOR FOR EXCHANGE.

!WARNING

Clean coil fins with degreasing agent or mild detergent and rinse

fins clean prior to installation. Refer to page 7 for coil cleaning/

maintenance guidance.

The refrigerant line sizes should be selected according to the

recommendations of the outdoor unit manufacturer.

Care must be taken to ensure all connection joints are burr-free

and clean. Failure to do so may increase chances of a leak. It is

recommended to use a pipe cutter to remove the spun closed

end of the suction line.

To reduce air leakage, rubber grommets may be present where

the lines pass through the coil case. To avoid damage, remove

grommets prior to brazing by sliding over the lines. Use a

quenching cloth or allow the lines to cool before reinstalling the

grommets.

Use of wet rags/quenching cloth is highly recommended to

prevent weld-related damages to the casing and Schrader valve

(if present).

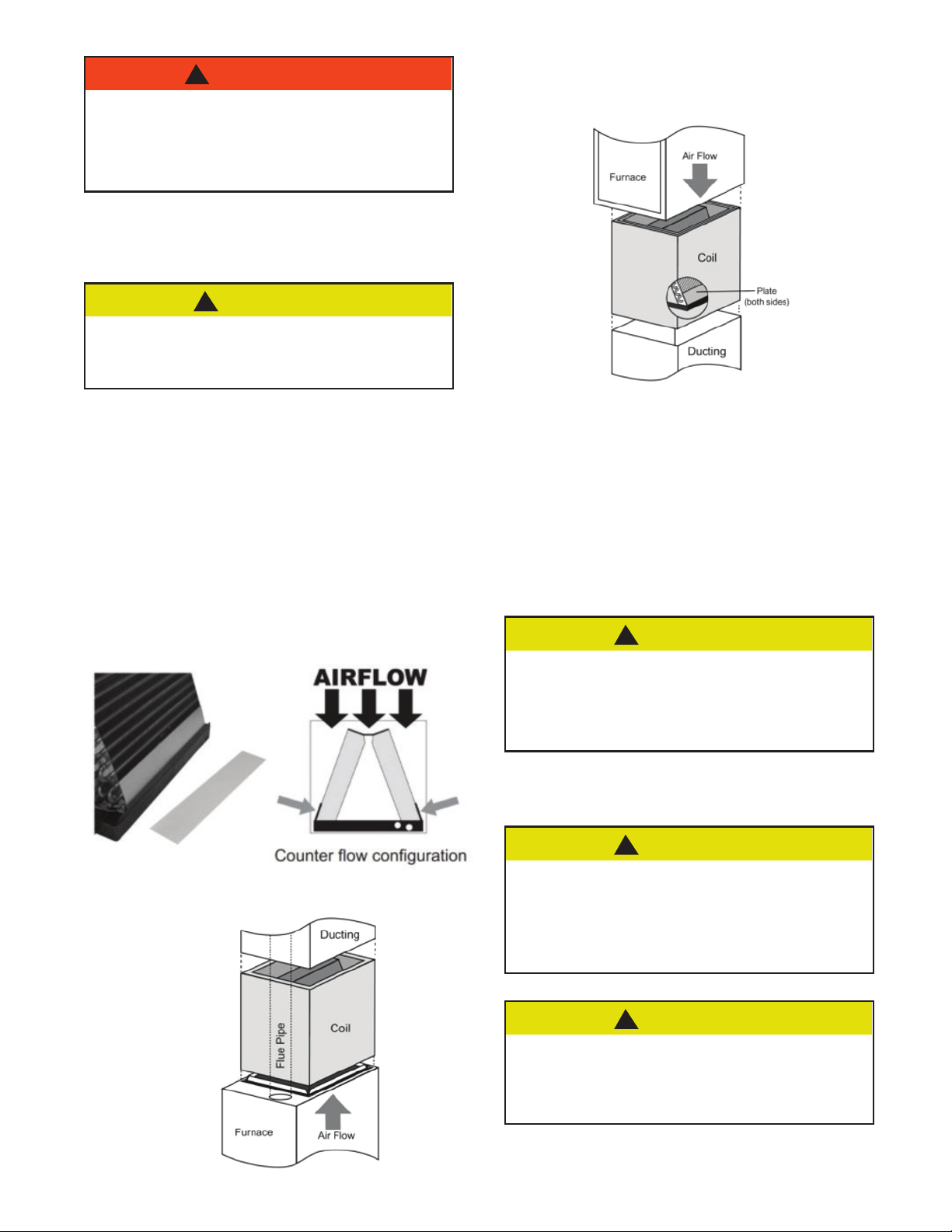

Can be installed in either an upflow or a downflow application.

COIL SHOULD BE INSTALLED ON THE DISCHARGE SIDE

OF THE FURNACE

!CAUTION

NATIONAL COMFORT PRODUCTS COILS MAY INCLUDE

A SCHRADER VALVE ON THE SUCTION MANIFOLD.

ENSURE THAT THE SCHRADER VALVE AND VALVE

CORE (WHERE PRESENT) ARE PROTECTED FROM HEAT

TO PREVENT LEAKAGE.

!CAUTION