CONTACT US TODAY AT

E. SALES@NAVCO.US W. NAVCO.US

P. 832.467.3636 F. 832.467.3800

A. 11929 Brittmoore Park Dr.

Houston, TX 77041

Vibration Technology for Processing Bulk Materials

NATIONAL AIR VIBRATOR CO.

®

Page 5

Work Safety

The symbol to the left signies safety

instructions which deal with danger to

the health and life of a person. These

instructions must be strictly observed.

The guidelines within this document

must be understood prior to operation of

the equipment. General local safety and

accident prevention regulations must be

observed in addition to the work safety

instructions in this operating manual.

Attention

The symbol above signies notes, regulations and guidelines

which deal with damage to or destruction of the equipment as a

result of improper operation.

ATTENTION

Symbols to Know

General Work Safety and Attention Instructions

It must be ensured that every person charged with the installation, operation and maintenance of the equipment has read and

understood this operating manual prior to commencing work.

If equipment is improperly operated by untrained persons, it may cause grave injury and damage.

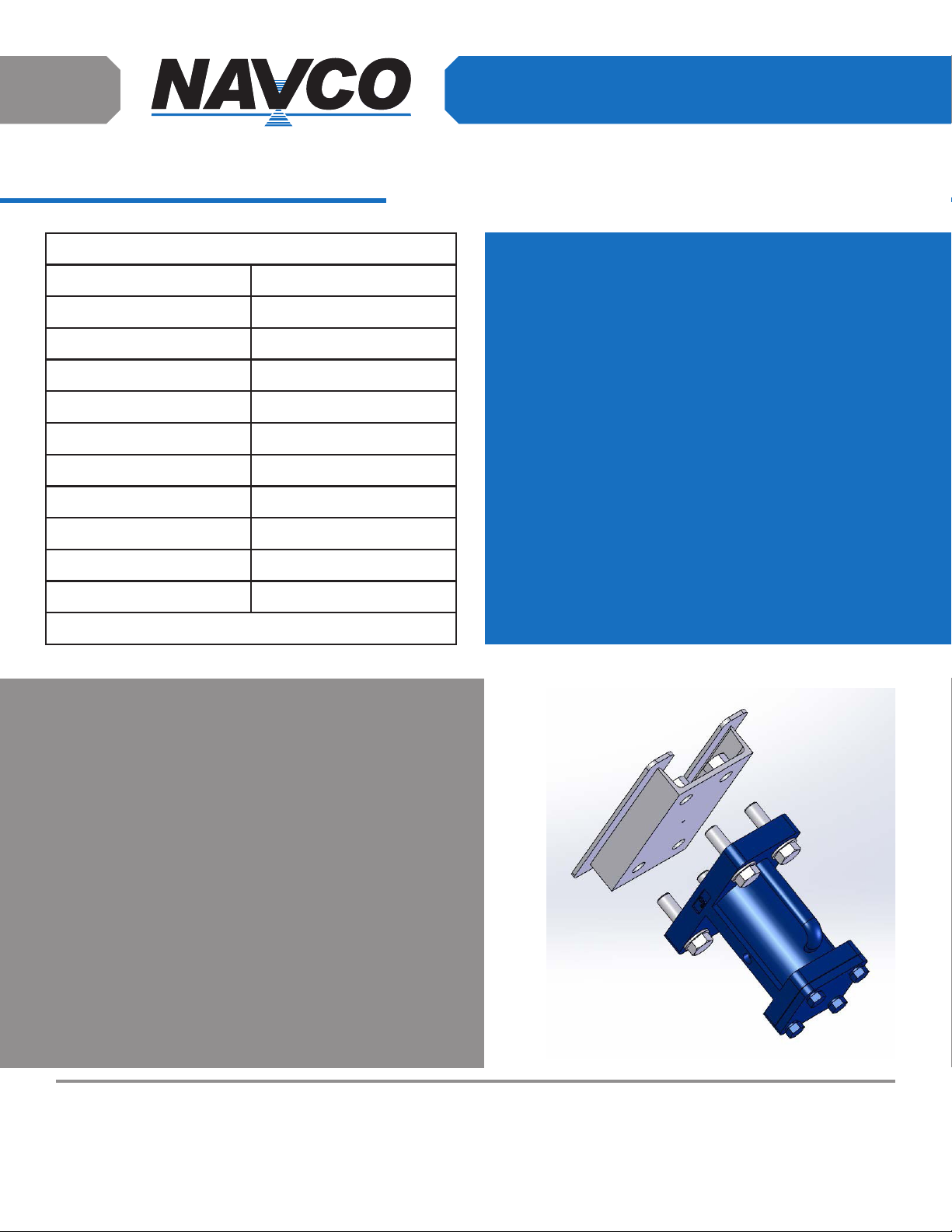

1. The BH vibrator is intended exclusively for the application

agreed with the manufacturer.

2. The BH vibrator must only be operated in its original condition.

3. All maintenance work on the BH vibrator must only be carried

out while the equipment is off. Before starting work, ensure

that the equipment cannot be switched on accidentally or by

unauthorized persons.

4. A safety cable or chain must always secure the vibrator to

a supporting structure to prevent injury in case of mounting

failure.

ATTENTION

ATTENTION