1

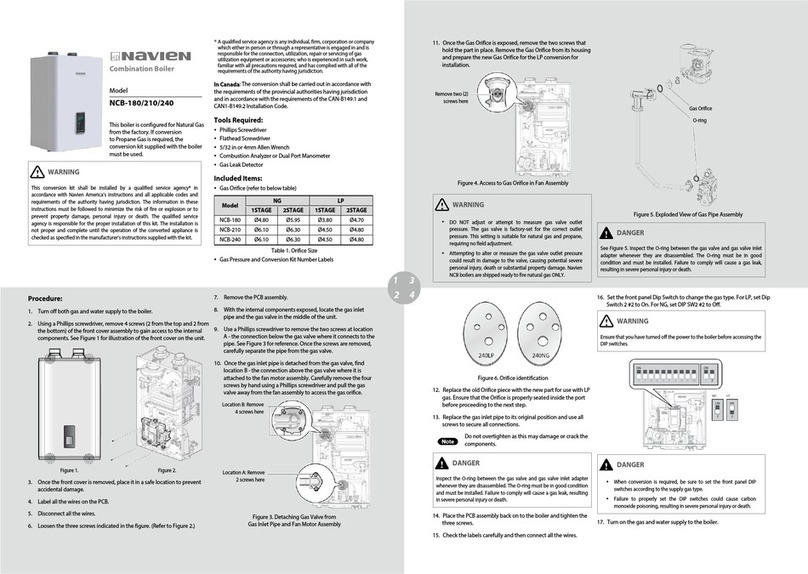

Unpacking

Navien

Condensing

Boiler

User’s

Information

Manual,

Installation

& Operation

Manual

Air Vent Condensate

Trap

Vent

Termination

Caps

Wall Flanges

Wall Mounting

Bracket (with

Anti-Vibration

Rubber Pad)

* Included in

the L box

Tapping

Screws and

Anchors

(x6)

Pressure

Relief Valve,

Heating

Conversion

Kit

Outdoor

Temperature

Sensor and

Cable

Air Vent

Bushing

(11/2

in to 3/4 in)

Universal

Temperature

Sensor

(with Clip)

PRV-Air Vent

Adapter

(with Clip)

Caps (x2)

Double

Nipple

(3/4

in to 3/4in)

Model

NFB-301C/399C

Quick Installation Guide

STEP 1 Before Installing

Read the Installation & Operation Manual before installing.

This product must be installed and serviced by a licensed plumber,

a licensed gas tter, or a professional service technician. Navien is

not liable for any damages or defects resulting from improper

installation.

WARNING

Follow all local codes and/or the most recent edition of the National Fuel Gas Code (ANSI

Z223.1/NFPA 54) in the USA, or the Natural Gas and Propane Installation Code in Canada

(CAN/CGA B149.1).

Safety

DO NOT install the boiler in areas with excessively high humidity.

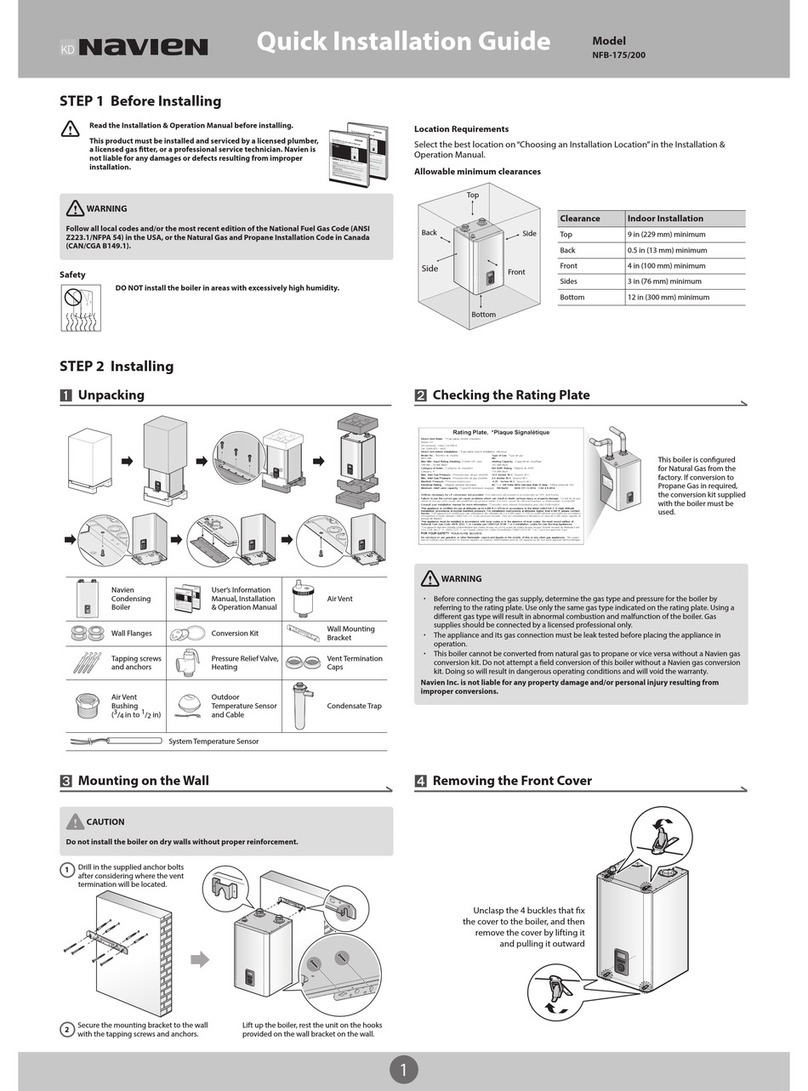

Location Requirements

Select the best location on “Choosing an Installation Location”in the Installation &

Operation Manual.

Allowable minimum clearances

Top

Back

Side

Side

Front

Bottom

Clearance from: Indoor Installation

Top 12 in (305 mm) minimum

Back 0.5 in (13 mm) minimum

Front 24 in (610 mm) minimum

Sides 6 in (152 mm) minimum

Bottom 24 in (610 mm) minimum

STEP 2 Installing

Checking the Rating Plate

>

This appliance is certied for use at altitudes up to 4,500 ft (1,370 m) In accordance to the latest CAN/CGA 2.17-High Altitude

Installation procedures at normal manifold pressure.This appliance has also been tested up to 10,100 ft(3,078 m).

For installations at altitudes up to 10,100 ft(3,078 m), follow the directions provided in the High Altitude Installations sections

of the lnstallatlon Manual. *Cet appareil est certié pour une utilisation à des altitudes de 0 à 4,500 pieds (1,370 m) conformément aux

toutes les procédures d'installation à haute altitude CAN/CGA 2.17 à une pression normale. Cet appareil a été testé jusqu'à 10,100 pieds

(3.078 m). Pour les instructions d'installation à une altitude supérieure à 10.100 pieds, suivez les instructions fournies dans la section des

installations à haute altitude du manuel d'installation.

7

2017

This boiler is congured

for Natural Gas from the

factory. If conversion to

Propane Gas in required,

the conversion kit supplied

with the boiler must be

used.

WARNING

·Before connecting the gas supply, determine the gas type and pressure for the boiler by

referring to the rating plate. Use only the same gas type indicated on the rating plate. Using a

dierent gas type will result in abnormal combustion and malfunction of the boiler. Gas

supplies should be connected by a licensed professional only.

·The appliance and its gas connection must be leak tested before placing the appliance in

operation.

·This boiler cannot be converted from natural gas to propane or vice versa without a Navien gas

conversion kit. Do not attempt a eld conversion of this boiler without a Navien gas conversion

kit. Doing so will result in dangerous operating conditions and will void the warranty.

Navien Inc. is not liable for any property damage and/or personal injury resulting from

improper conversions.

Mounting on the Wall

>

CAUTION

Do not install the boiler on drywall

without proper reinforcement.

1Remove the wall bracket from the L box.

Mount the wall bracket and the boiler following the instructions below for your installation type.

Note

The anti-vibration rubber pad must be mounted with its arrow mark ( ) facing outward.

Mounting to a wood studded wall:

Mount the wall bracket using the lag bolts provided.

Mounting to a concrete wall:

Mount the wall bracket using the anchor bolts provided. To mount the anchor bolts, drill a 3/8"

diameter hole 3-1/2" deep and insert anchor.

Mounting to a metal studded wall:

Mount the wall bracket using eld supplied toggle bolts capable of supporting 100 pounds each.

2

Removing the Front Cover

>

Unfasten the 4 latches

(2 at the top and 2 at the bottom)

to remove the front cover.