3

Venting

>

Electrical Connections/High Altitude DIP Switch Settings

>

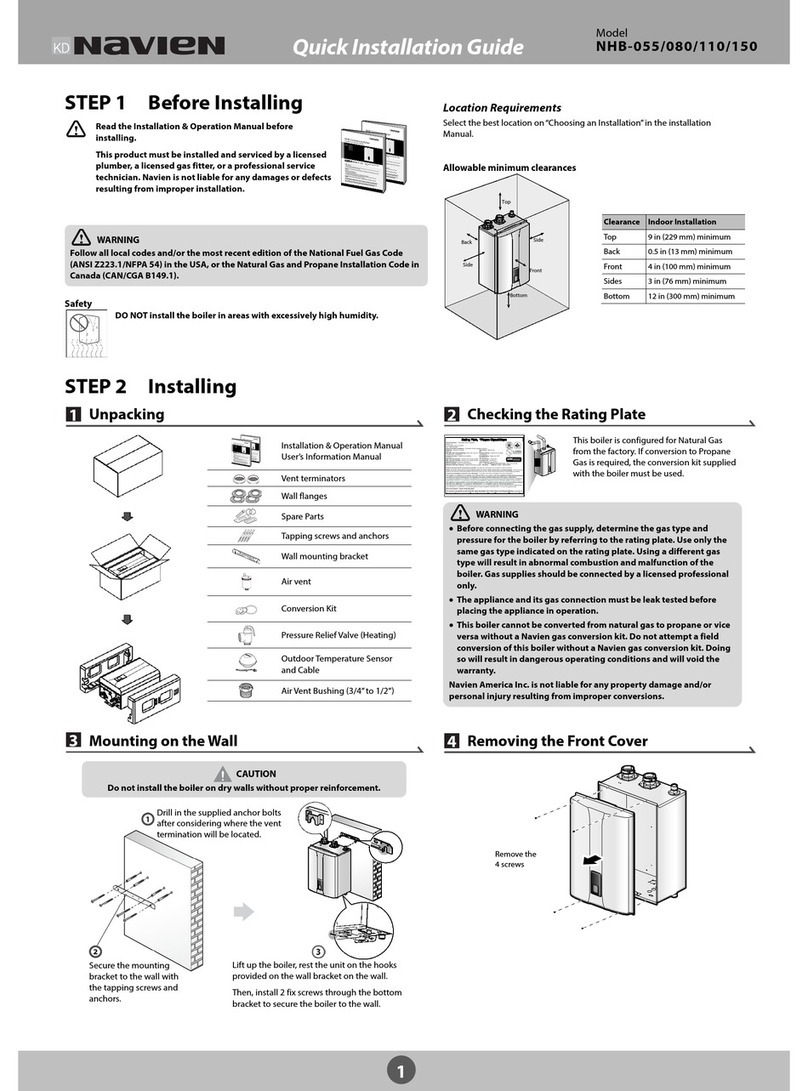

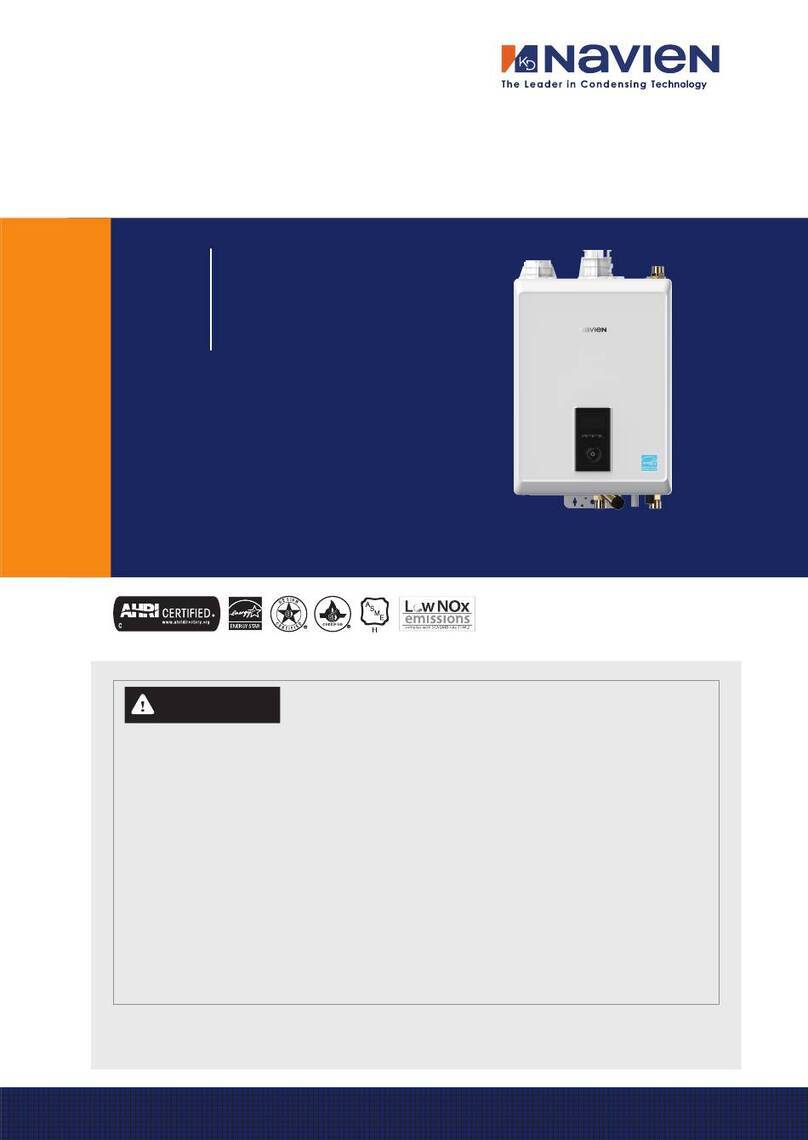

Vent Termination Options

Horizontal vent termination

12" (300 mm) min.

12" (300 mm) min.

Interior view

Intake Air

Exhaust Gas

12" (300 mm) min.

Exterior view

Vertical vent termination Sidewall vent termination

Maintain 12”(300mm)

from any obstruction

above, below, left, or right

12" (300 mm) min.

12" (300 mm) min.

Concentric Vent Termination

Sidewall installation

Combustion Air

Combustion Air

1" (25mm) min.

Maintain 12" (300

mm) min. clearance

above highest

anticipated snow

level or grade,

whichever is greater

Vent

Roof installation

Vent

Vent

Combustion Air

Maintain 12” (300mm) min.

clearance above highest

anticipated snow level or

grade, whichever is greater

(maximum of 24” above roof)

Combustion

Air

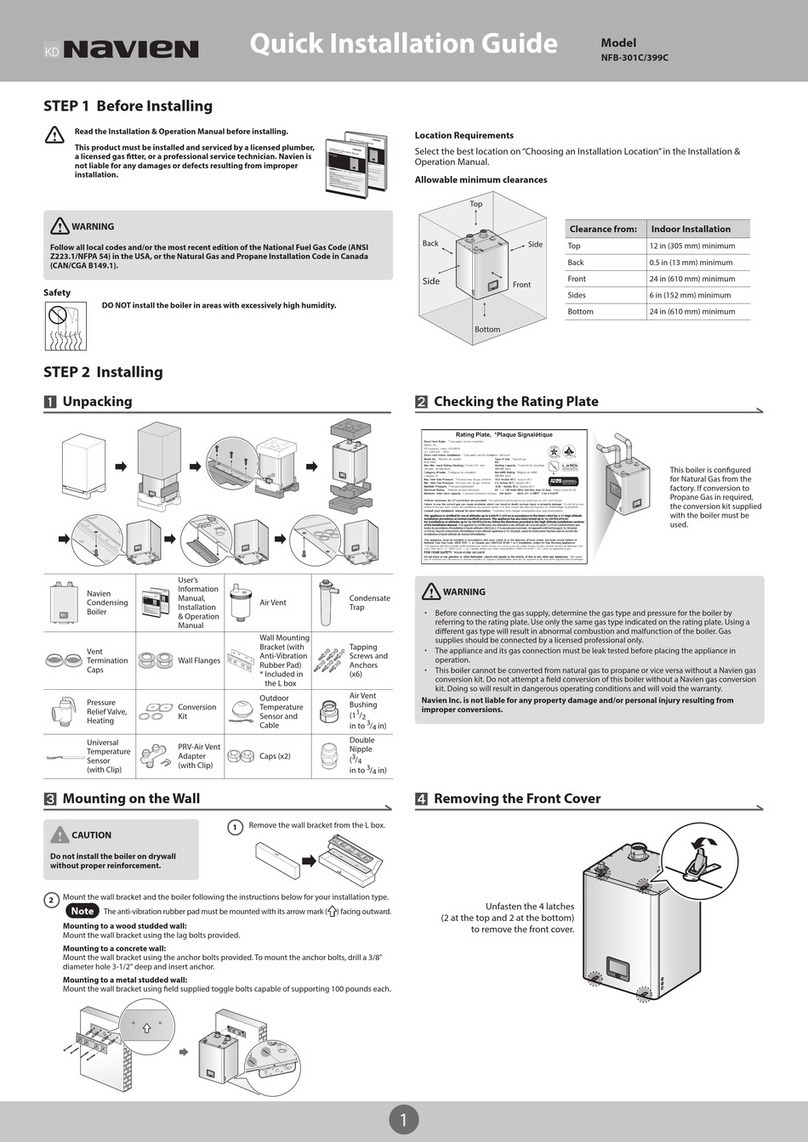

Venting Length

3” pipe venting 2” pipe venting

8

1

3

7

2

Maximum Length 150'

Maximum number

of elbows: 8

2-to-3-inch

6

1

3

4

5

2

Maximum number

of elbows: 6

Maximum Length 60'

·90˚ elbow = 5 linear feet of venting

·45˚ elbow= 3 linear feet of venting

·90˚ elbow = 8 linear feet of venting

·45˚ elbow= 4 linear feet of venting

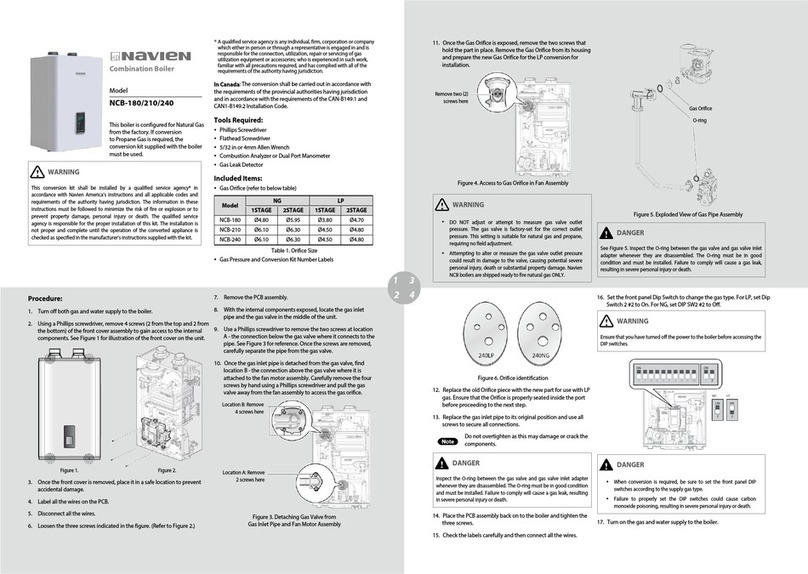

Exhaust Vent Piping Materials

·All Navien boilers are Category IV appliances.

·The venting system should be approved for use with Category IV appliances (typically Type BH

Special Gas Vent approved by UL 1738-S636).

·Venting requirements in the USA and Canada are dierent (see below).

Navien recommended venting materials

Locale Recommended Vent Materials

USA

·PVC/CPVC Schedule 40 or 80 (Solid Core)

·Approved Polypropylene (PP)

·Approved Stainless Steel (SS)

Canada*

·Type BH Special Gas Vent Class IIA (PVC)

·Type BH Special Gas Vent Class IIB (CPVC)

·Type BH Special Gas Vent Class IIC (Polypropylene/Stainless Steel)

* For installation in Canada, eld-supplied plastic vent piping must comply with CAN/CGA B149.1 (latest

edition) and be certied to the Standard For Type BH Gas Venting Systems, ULC-S636. Components of this

listed system must not be interchanged with other vent systems or unlisted pipes or ttings. All plastic

components and specied primers and glues of the certied vent system must be from a single system

manufacturer and must not be intermixed with another system manufacturer’s parts.

The supplied vent connector and vent termination are certied as part of the boiler.

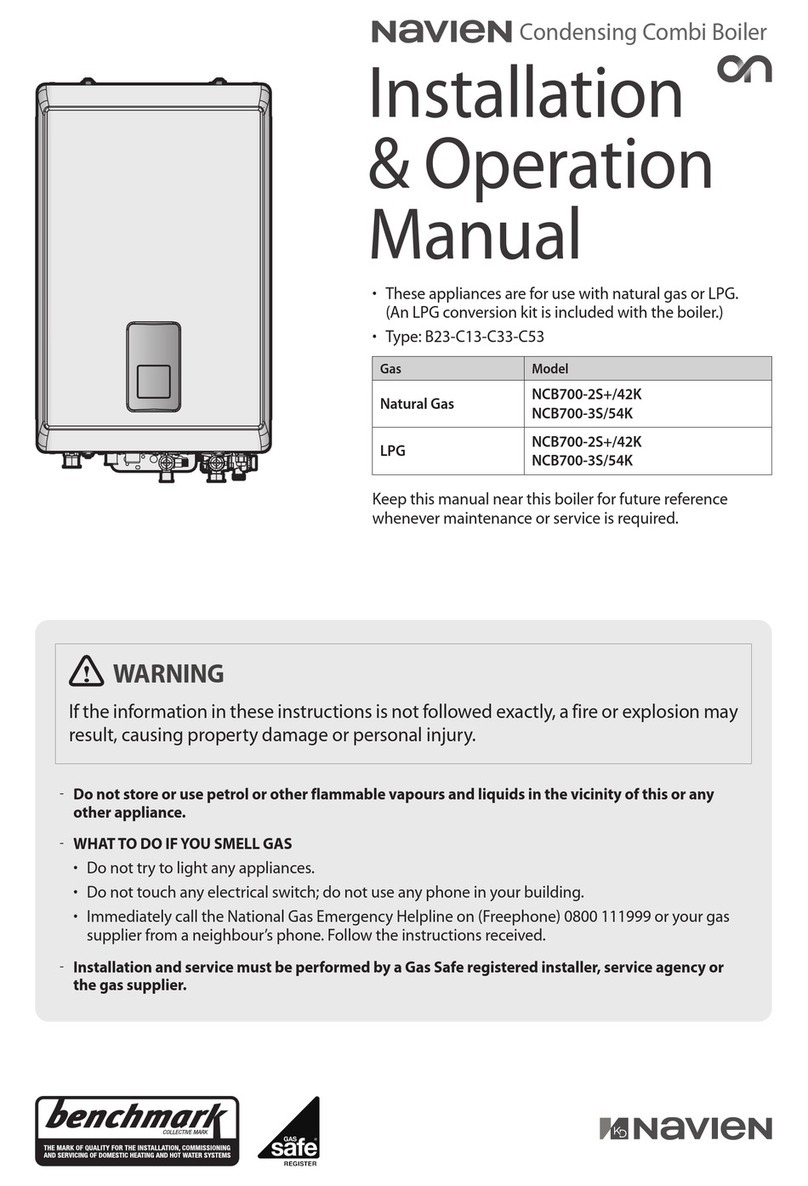

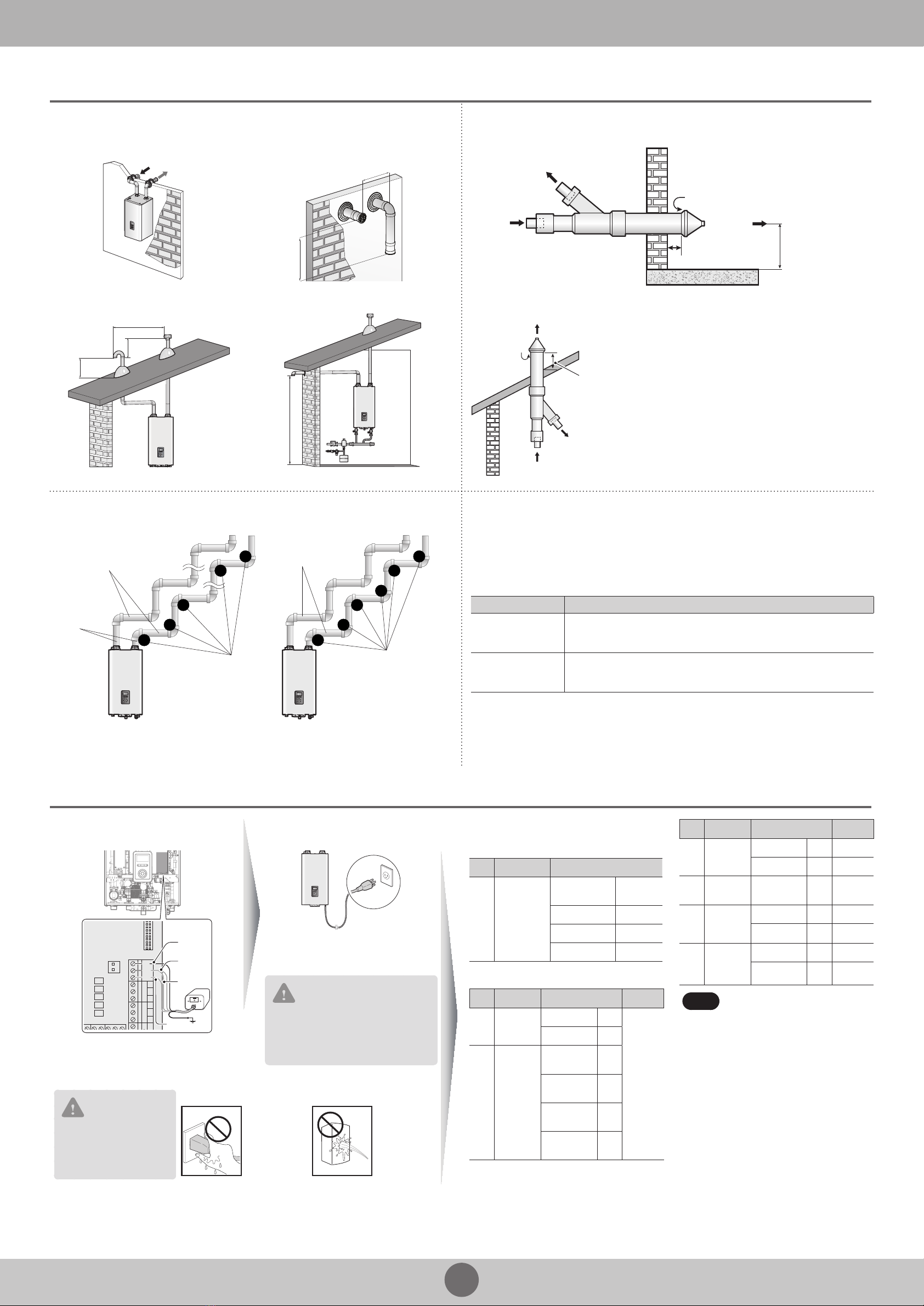

External LWCO Connection

(if required by local codes)

Power Connection

AC24VN

AC24VL

lLWCO

RWC

T/S_Recir.

RWC

C

T/S_CH_ZONE1

Neutral

Live

Live

LWCO

Refer to your local codes to determine if an

LWCO device is required for your system and

ensure that the built-in device meets the

requirements.

120 V AC 60 Hz

Min. 2 Amp current with proper

grounding

CAUTION

Using abnormally high or low AC

voltage may cause abnormal operation,

thereby causing re which reduces the

life expectancy of this product.

CAUTION

Disconnect the power to

the boiler before installing

any wire connections on

the main PCB.

Safety

DO NOT touch

the power

cord with wet

hands.

DO NOT allow

the boiler to be

exposed to

excessive

amounts of

water.

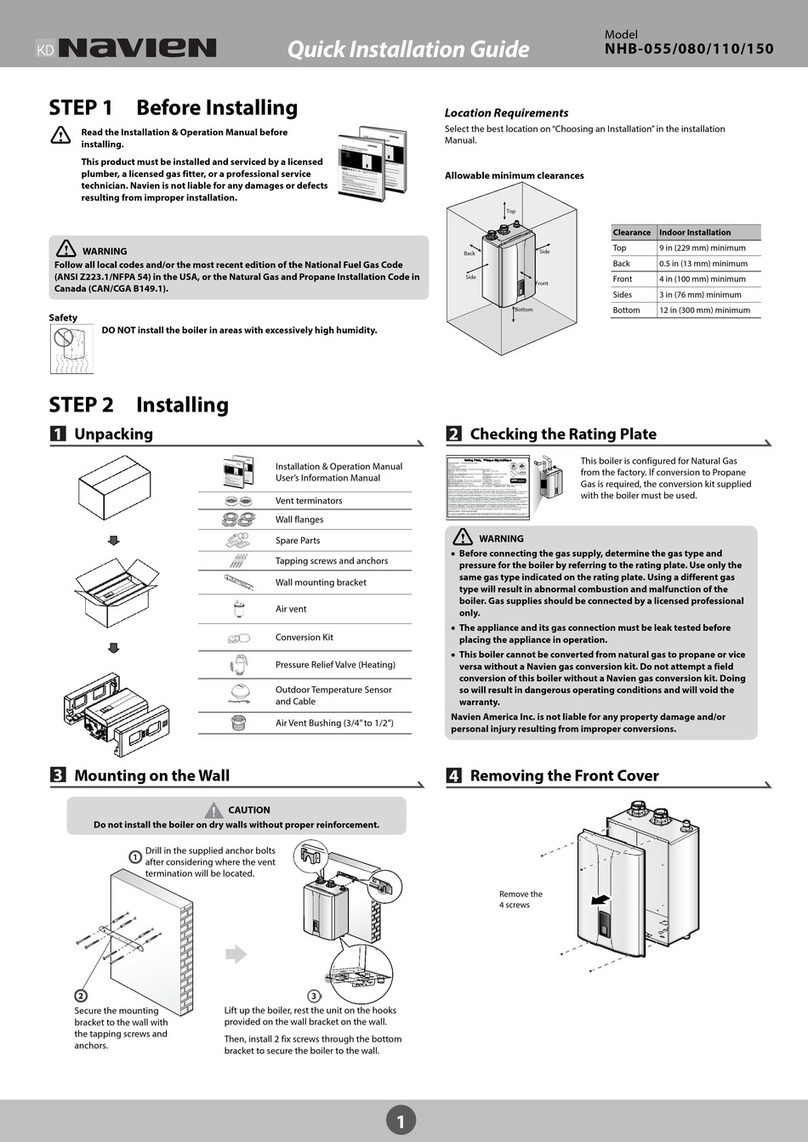

Conrmation of DIP Switch Settings

DIP Switch 1 (6 switch unit)

SW Function Setting

1 & 2 Operation

Status

Normal

Operation 1-OFF, 2-OFF

2-stage MAX 1-ON, 2-OFF

1-stage MIN 1-OFF, 2-ON

1-stage MAX 1-ON, 2-ON

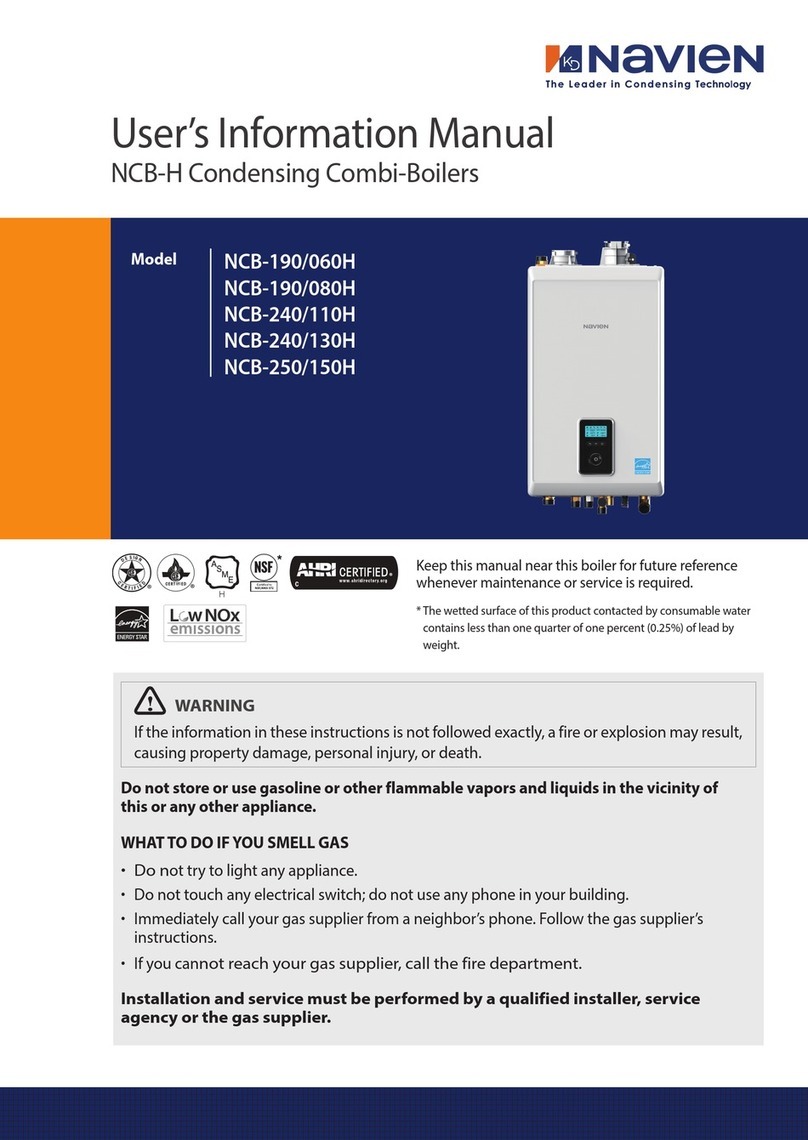

DIP Switch 2 (8 switch unit)

SW Function Setting

Comment

1Gas Type

Natural Gas

1-OFF

Refer to

Table 1

on page

103 in the

Installation

&

Operation

Manual.

Propane Gas

1-ON

2 & 3 High

Altitude

0-1,999 ft

(0-609 m)

2-OFF,

3-OFF

2,000-5,399 ft

(610-1,645 m)

2-ON,

3-OFF

5,400-7,699 ft

(1,646-2,346 m)

2-OFF,

3-ON

7,700-10,100 ft

(2,347-3,078 m)

2-ON,

3-ON

SW Function Setting

Comment

4Well Pump

Used

4-ON

-

Unused

4-OFF

-

5 & 6 Country

US/Canada

5-OFF,

6-OFF

-

7

Space

Heating

Thermostat

Used

7-OFF

-

Unused

7-ON

-

8

Exhaust

Temperature

Control

Used

8-OFF

-

Unused

8-ON

-

Note

·When PCB DIP switch 2 #8 is set to

On, ensure that CPVC,

polypropylene, or stainless steel is

used for exhaust venting.

·This unit may be installed at

elevations up to 10,100 ft (3,078 m)

for use with natural gas and

propane. To use the unit at a specic

altitude, the DIP switches should be

set as described above.

·High Altitude: Above 2,000 ft (610 m),

the unit will de-rate by 3% for each

1,000 ft (305 m) of altitude gain.

·For NG, if you install the unit at

above 5,400 ft (1,646 m), it is

required to change the Gas Orice

for high altitude. Be careful not to

confuse it with the LP Gas Orice.

For detail, refer to page 103 in the

Installation & Operation Manual.