5

Installation Guide |Thru the Wall Condensing Units NCP Series 1000/3000/4000/5000

Safety Warnings!

This appliance is not intended for use by those (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instructions concerning use of the appliance by a person

responsible for their safety. Children should be supervised to ensure

that they do not play with the appliance.

This appliance is intended to be installed up to 10,000 ft

(3,000 m) above sea level.

This appliance is only compatible with an Indoor unit that uses

R410A refrigerant.

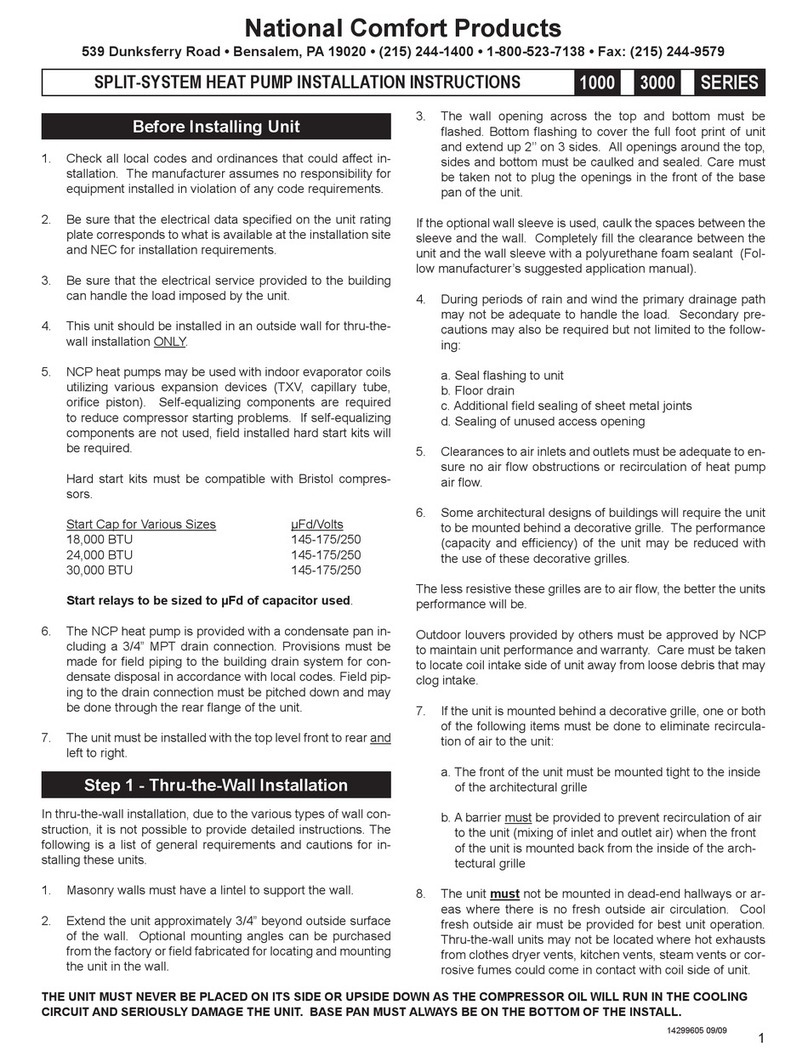

Wheninstalling thisunitwithan indoorevaporatingunit, themaximum

operating pressure is to be considered during the installation. The

maximum operating pressure of the system should not exceed the

value as indicated on the nameplate of this condensing unit.

This model series NCP4*******-** is a PARTIAL UNIT air-

conditioner, complying with PARTIAL UNIT requirements of

the International Standard of UL-60335-2-40, and must only be

connected to the other units that have been confirmed as complying

to corresponding PARTIAL UNIT requirements of the International

Standard of UL-60335-2-40.

This is a safety alert symbol. When you see this symbol on

labels or in manuals, be alert to the potential for personal injury.

Pay particular attention to words such as DANGER, WARNING or

CAUTION.

DANGER indicates an imminently hazardous situation, which will

result in serious injury or death

WARNING indicates a potentially hazardous situation, which could

potentially result in serious injury or death

CAUTION indicates a potentially hazardous situation, which may

result in minor or moderate injury. It is also used to alert against

practices that are unsafe and can result in property damage.

!WARNING

HIGH VOLTAGE! Disconnect ALL power before servicing.

Multiple power sources may be present. Failure to do so may

result in property damage, personal injury or death.

!WARNING

These instructions are intended as an aid to qualied, licensed

service personnel for proper installation, adjustment and operation of

this unit. Read these instructions thoroughly before attempting

installation or operation. Failure to follow these instructions may

result in improper installation, adjustment, service or maintenance

possibly resulting in re, electrical shock, property damage, personal

injury or death.

!WARNING

!WARNING

!WARNING

!CAUTION

!CAUTION

Installation and repair of this unit should be performed ONLY by

individuals meeting the requirements of an “entry level technician” as

specied by National Codes. Attempting to install or repair this unit

without such background may result in product damage, personal

injury or death.

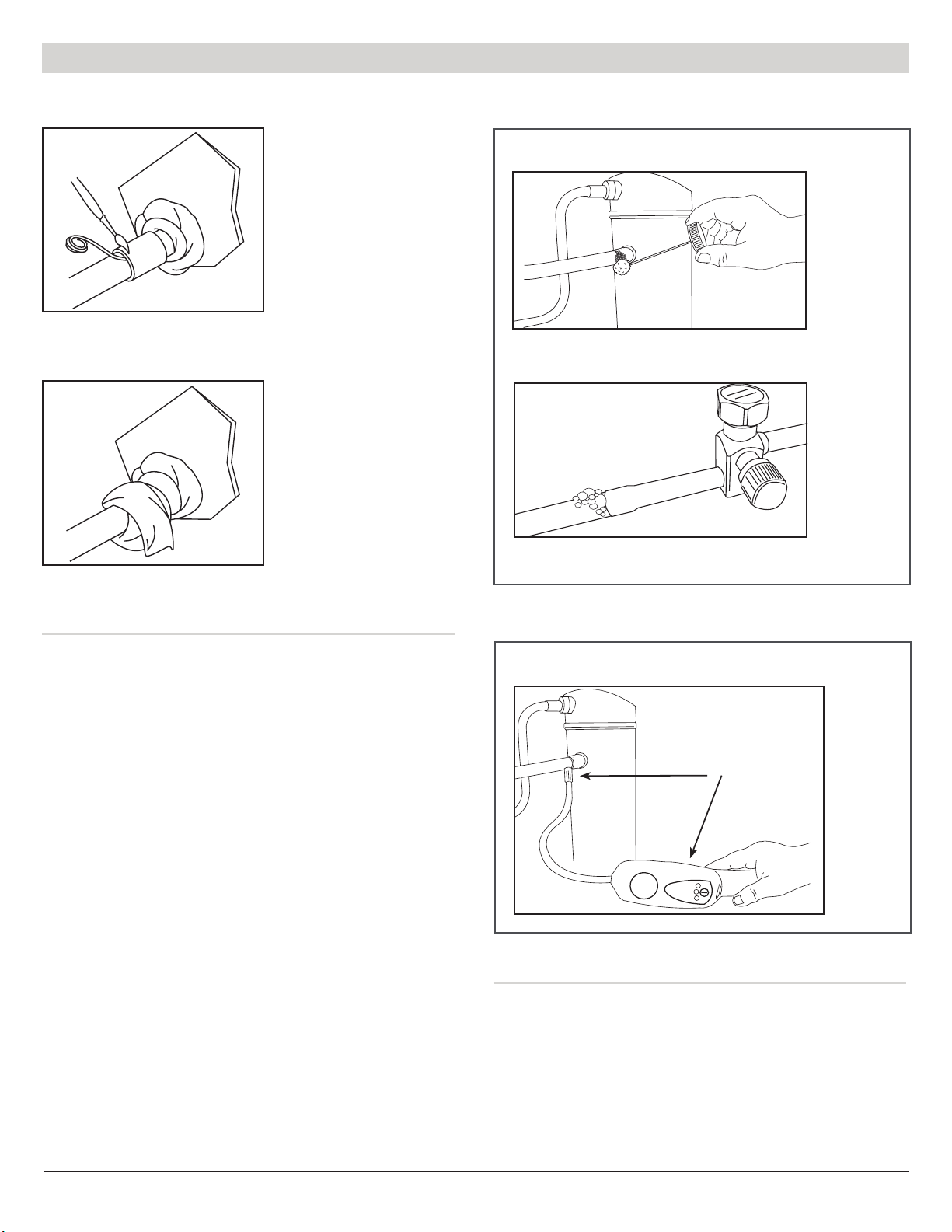

Do not use oxygen to purge lines or pressurize system for leak

test. Oxygen reacts violently with oil, which can cause an explosion

resulting in severe personal injury or death.

The unit must be permanently grounded. Failure to do so can cause

electrical shock resulting in severe personal injury or death.

Use care when handling scroll compressors. Some temperatures

could be hot!

Scroll compressors should NEVER be used to evacuate the air

conditioning system. Vacuums this low can cause internal electrical

arcing resulting in a damaged or failed compressor.

“USE COPPER SUPPLY WIRES ONLY”

!WARNING

Extreme caution should be exercised when opening the Liquid Line

Service Valve. Turn counter clockwise until the valve stem just

touches the rolled edge. No torque is required. Failure to follow this

warning will result in abrupt release of system charge and may result

in personal injury and /or property damage.