SC-32

CNC LATHE

OPERATING MANUAL

NCT Ipari Elektronikai Kft. 2 / 29 Dátum: 2013.09.27.

1148 Budapest, Fogarasi út 7.

Tel.: 06-1-467-6300

www.nct.hu

CONTENTS

1. ACCURACY RECORD .................................................................................................... 2

2. SAFETY PRECAUTIONS ................................................................................................ 2

2.1. Safety Rules................................................................................................................. 2

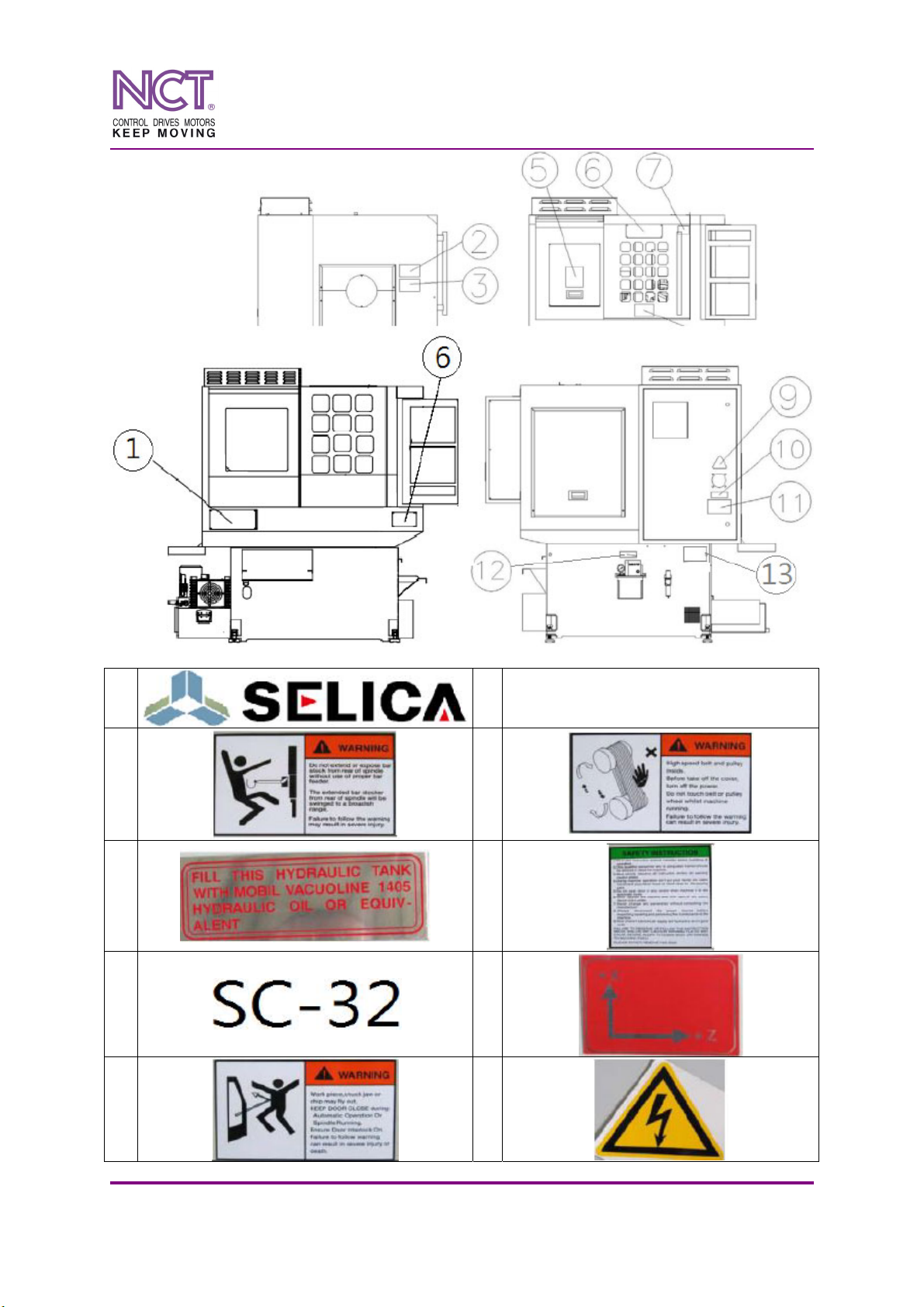

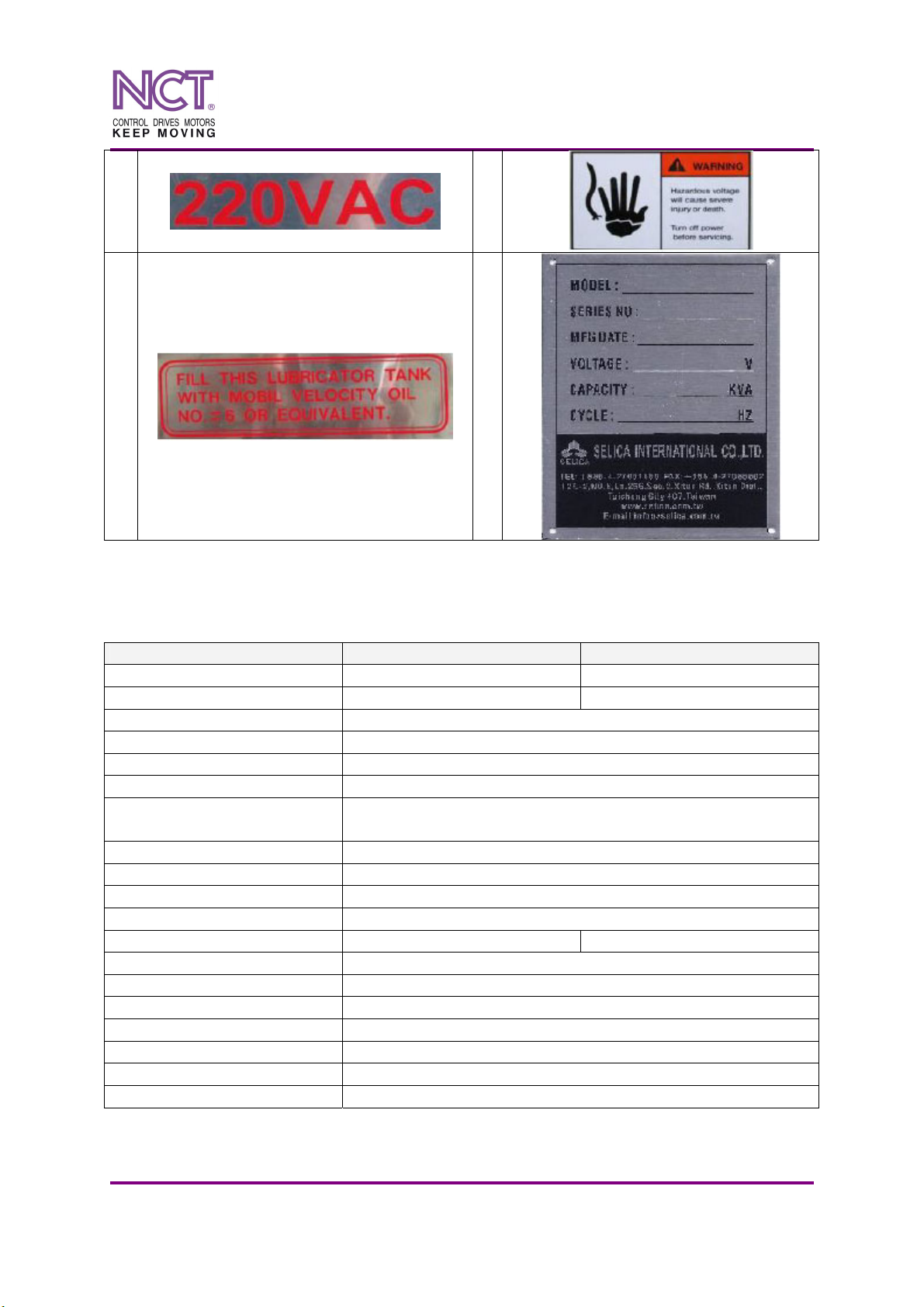

2.2. Warning label attaching positions ............................................................................... 2

3. DESCRIPTION OF THE MACHINE ............................................................................... 2

3.1. Specifications .............................................................................................................. 2

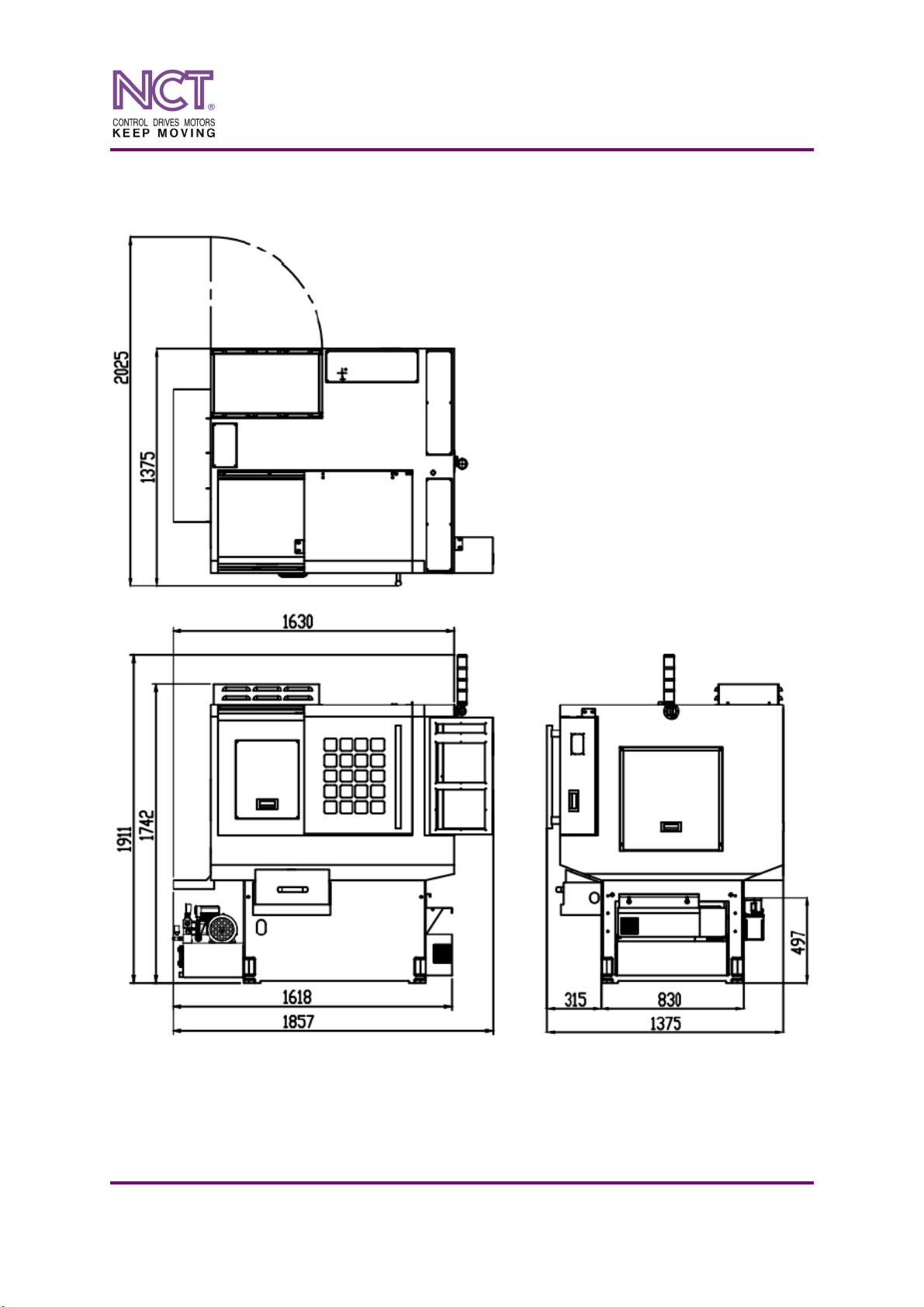

3.2. Machine overall dimensions........................................................................................ 2

3.3. Main components of the machine ............................................................................... 2

3.3.1. Spindle belt......................................................................................................... 2

3.3.2. Spindle collet...................................................................................................... 2

3.4. Recommended Spare Parts.......................................................................................... 2

3.5. Machinable materials .................................................................................................. 2

3.6. Machining capacity ..................................................................................................... 2

3.7. Movement.................................................................................................................... 2

3.8. Block position ............................................................................................................. 2

3.9. Installation................................................................................................................... 2

3.9.1. Power supply and environmental demand ......................................................... 2

3.9.2. Oil requirement .................................................................................................. 2

3.9.3. Maintenance ....................................................................................................... 2

3.10. Machine installation .................................................................................................... 2

3.10.1. Installation place ................................................................................................ 2

3.10.2. Machine cleaning ............................................................................................... 2

3.10.3. Installation steps................................................................................................. 2

3.10.4. Spindle speed setting.......................................................................................... 2

3.10.5. Precaution for program executing ...................................................................... 2

4. SUB-SYSTEMS.................................................................................................................2

4.1. Hydraulic system......................................................................................................... 2

4.2. Air pressure system ..................................................................................................... 2

4.3. Trouble shooting ......................................................................................................... 2

4.4. Three-jaw hydraulic chuck installation procedure ...................................................... 2

5. PART LIST ........................................................................................................................ 2

5.1. Base unit...................................................................................................................... 2

5.2. X-axis slide unit .......................................................................................................... 2

5.3. Z-axis slide unit........................................................................................................... 2

5.4. Spindle unit ................................................................................................................. 2

5.5. Tool unit ...................................................................................................................... 2

5.6. Coolant unit ................................................................................................................. 2

5.7. Side live tool................................................................................................................ 2

5.8. Front side live tool....................................................................................................... 2

5.9. Coolant tank unit .........................................................................................................2

5.10. Hydraulic unit.............................................................................................................. 2