Bondascope 350 Operator's Manual

1 INTRODUCTION ..................................................................................................................................... 1

1.1 IMPORTANT: ................................................................................................................................... 1

1.2 General Features: ............................................................................................................................... 1

2 AREAS OF APPLICATION ..................................................................................................................... 2

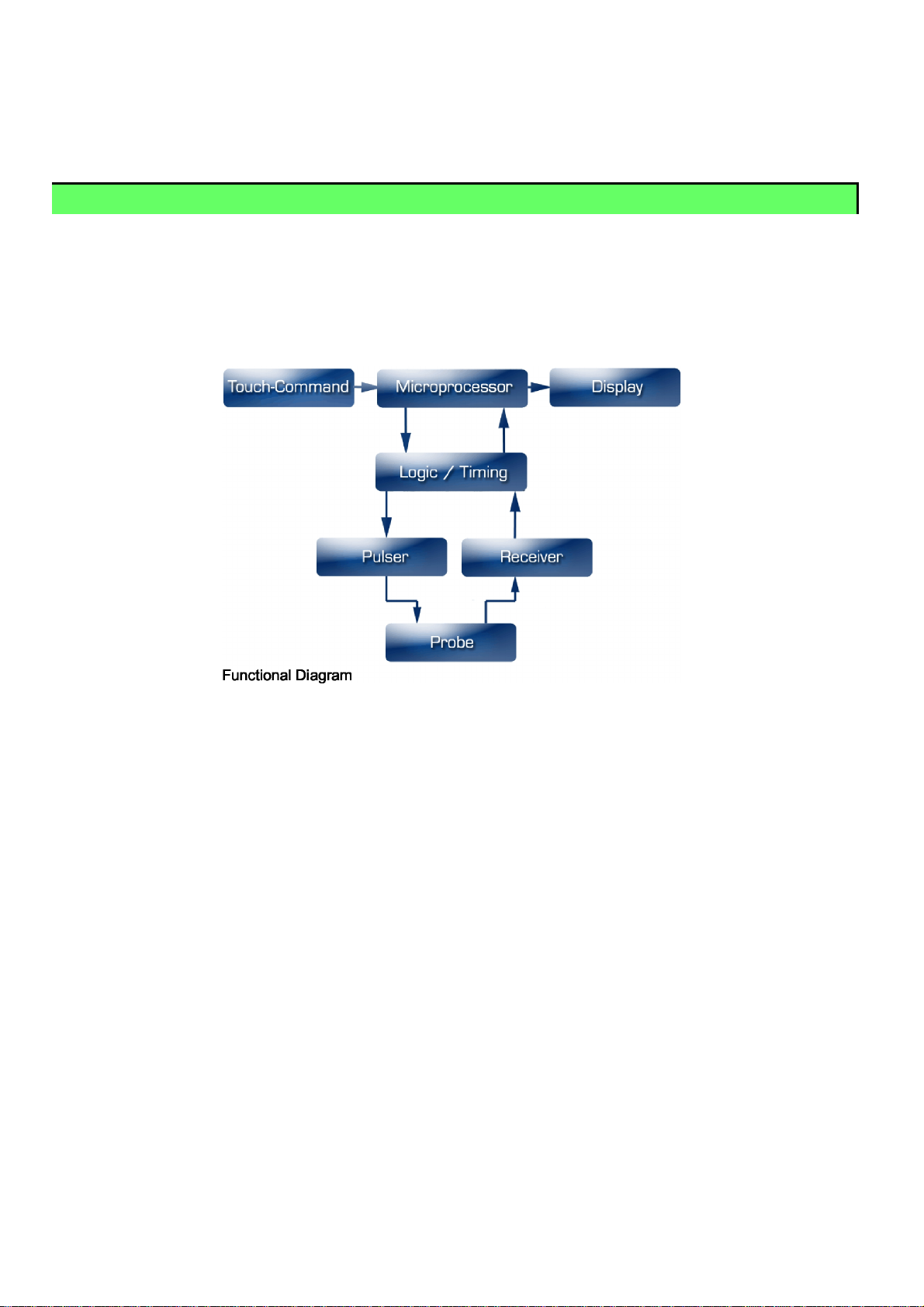

3 PRINCIPLE OF OPERATION.................................................................................................................. 3

3.1 Resonance: ......................................................................................................................................... 3

3.2 Pitch-Catch:........................................................................................................................................ 3

4 4.0 BASIC DESIGN .................................................................................................................................. 4

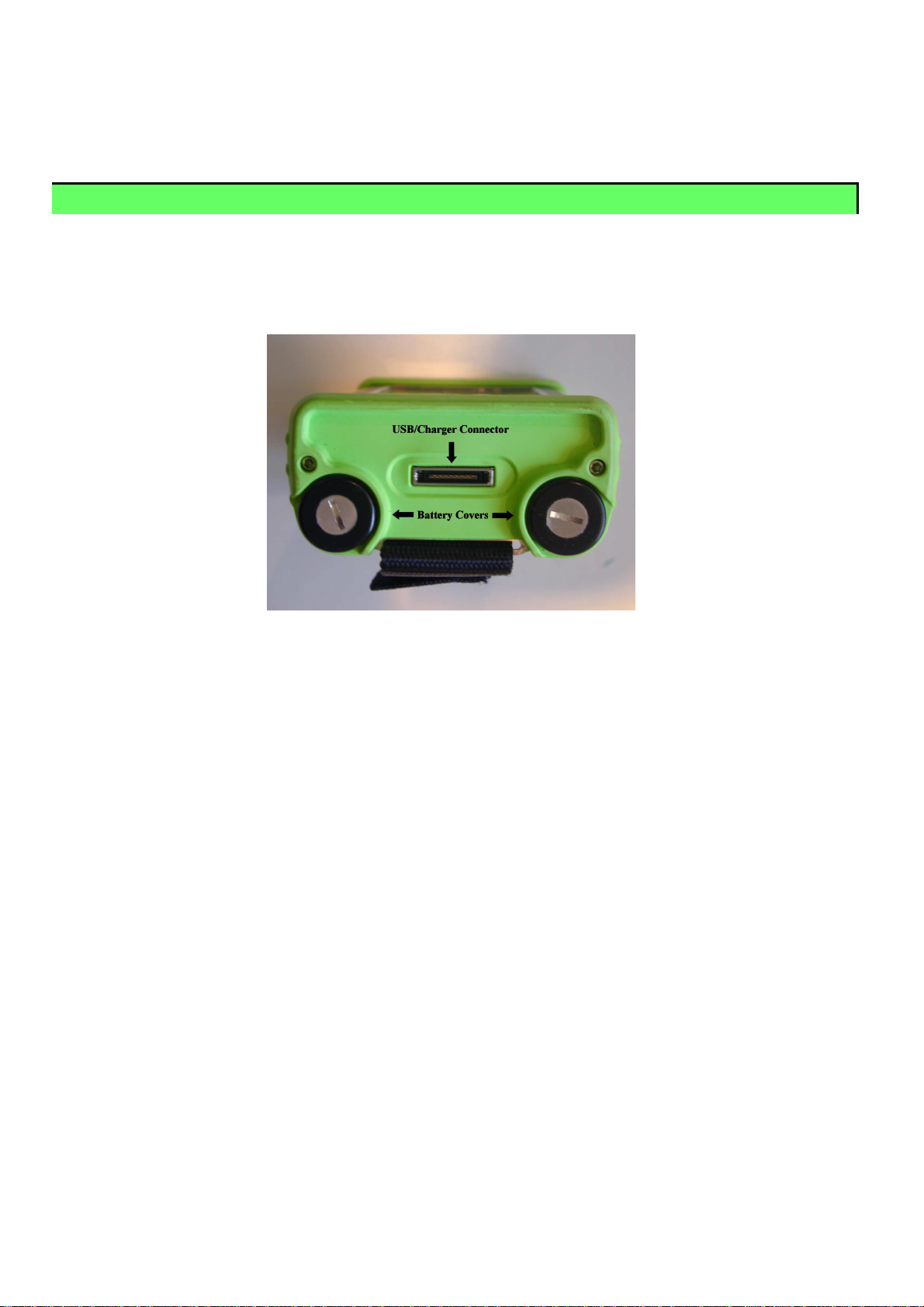

5 Description of Connections........................................................................................................................ 5

6 PREPARATION FOR USE....................................................................................................................... 6

6.1 Batteries: ............................................................................................................................................ 6

6.2 Probe Selection : ................................................................................................................................ 7

6.3 Reference Samples - IMPORTANT!!................................................................................................ 7

7 KEYPAD AND OPERATION.................................................................................................................. 8

7.1 ON/OFF COMMAND....................................................................................................................... 8

7.2 SETUP ............................................................................................................................................... 8

7.3 GAIN.................................................................................................................................................. 8

7.4 MENU/ESC BUTTON ...................................................................................................................... 8

7.5 LEFT, RIGHT, UP, DOWN ARROW and ENTER Keys................................................................. 8

7.6 NULL – Also acts as a BALANCING function where required ....................................................... 8

7.7 PROFILE ........................................................................................................................................... 9

7.8 Alarm Key.......................................................................................................................................... 9

7.9 MODE Keys (RF/DOTS, SWEEP & GATES) ................................................................................. 9

7.9.1 RF / DOTS Key.............................................................................................................................. 9

7.9.2 SWEEP Key................................................................................................................................... 9

7.9.3 GATES Key................................................................................................................................... 9

8 MAIN SCREEN & MENU Items............................................................................................................ 11

8.1 Main Menu Screen........................................................................................................................... 11

8.2 MAIN MENU ITEM DESCRIPTION ............................................................................................ 12

8.2.1 Gain.............................................................................................................................................. 12

8.2.2 RNG – RANGE ........................................................................................................................... 12

8.2.3 DLY – DELAY............................................................................................................................ 12

8.2.4 VLTS - VOLTS ........................................................................................................................... 12

8.2.5 GATE........................................................................................................................................... 12

8.2.6 FREQ – FREQUENCY ............................................................................................................... 12

8.2.7 PRB – PROBE ............................................................................................................................. 12

8.2.8 CYCLES ...................................................................................................................................... 12

8.2.9 DISP............................................................................................................................................. 13

8.2.10 ALRM – ALARM........................................................................................................................ 13

8.2.11 SET - SETUP............................................................................................................................... 14

8.2.12 SCRN - SCREEN SAVE............................................................................................................. 14

8.3 MAIN MENU ITEM OPERATION................................................................................................ 15

8.3.1 DOTS ........................................................................................................................................... 15

8.3.2 FREQ - FREQUENCY................................................................................................................ 15

8.3.3 ROT – ROTATE.......................................................................................................................... 15

8.3.4 POS - Position.............................................................................................................................. 16

8.3.5 Xscl – X Scale Factor................................................................................................................... 16

8.3.6 Yscl – Y Scale Factor................................................................................................................... 16