5

4. ASSEMBLY

Carefully remove everything from the packaging and compare it against the contents

list. If anything appears to be missing please contact the place of purchase.

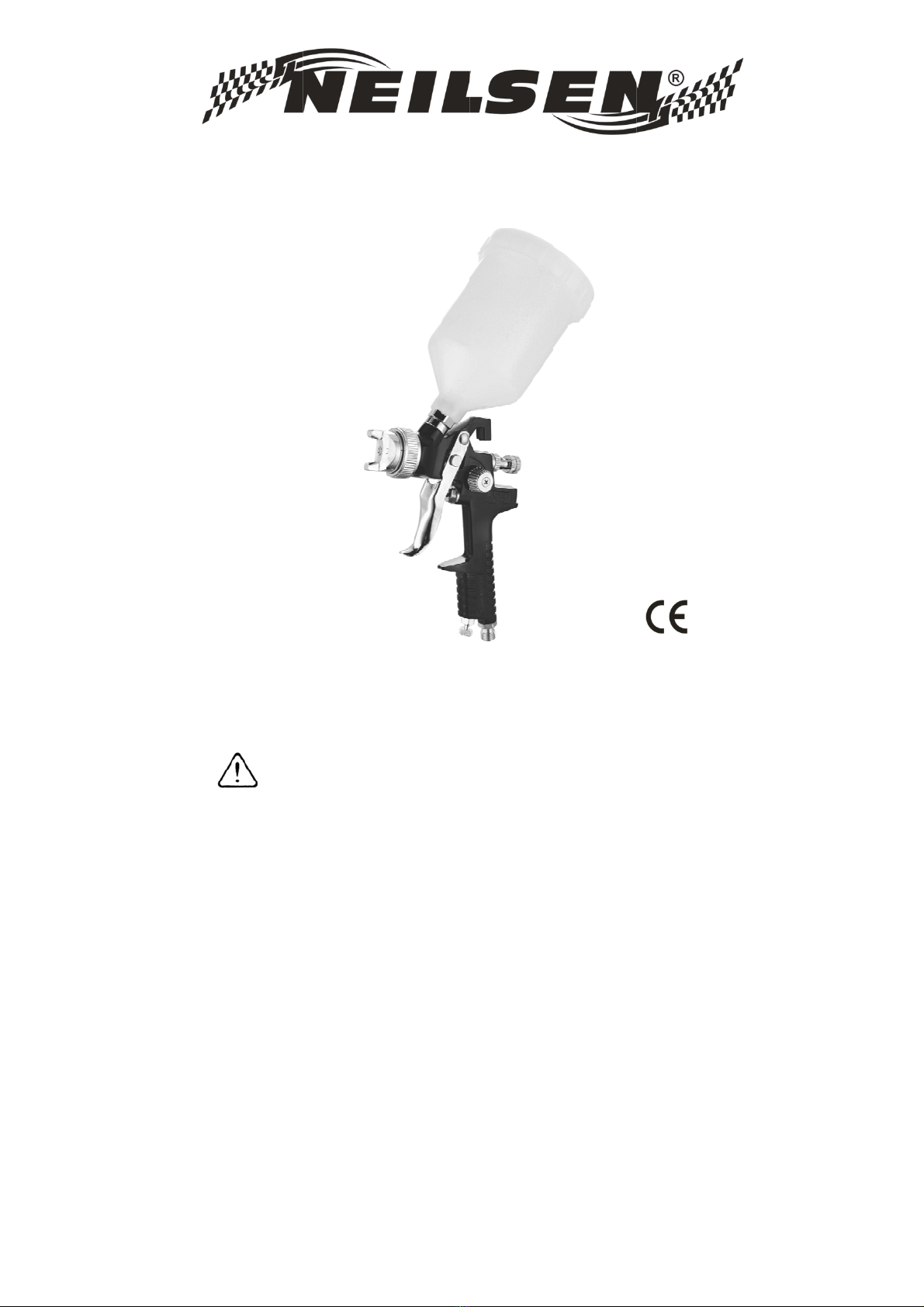

ATTACHING AN AIR LINE COUPLING (Fig.1):

After purchasing the spray gun and before initial use an

air line coupling must be fitted that is compatible with

your compressor's trailing hose.

1. Select a suitable 1/4” female thread air line coupling.

2. Wind a length of PTFE tape around the thread.

3. Screw the coupling on to the spray gun.

4. The connection must be firm for an airtight union.

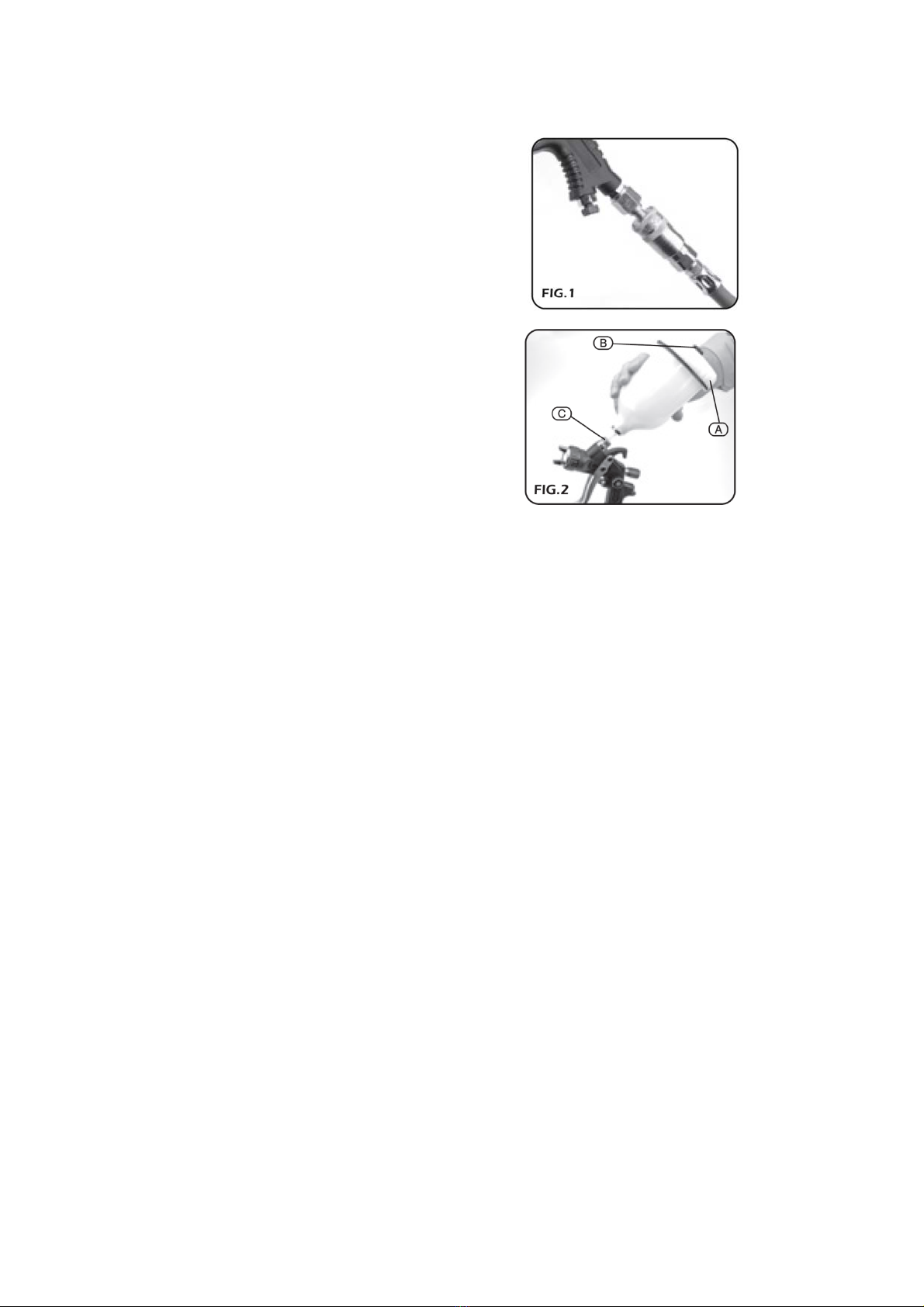

CONNECTING THE PAINT POT (Fig.2):

After purchasing the spray gun and before initial use,

wash the spray gun through to clear the air and paint

channels of any debris or dust.

1. Turn the paint pot lid (A) anticlockwise to remove it.

2. Fill the paint pot with material.

3. Carefully refit the pot lid (A). Turn the lid

anticlockwise a little to seat it correctly on the

thread, before turning it clockwise to tighten.

4. Make sure the bleed screw (B) is screwed in to

prevent paint loss.

5. Screw the paint pot assembly into the top of the

spray gun connector (C). Turn the pot clockwise

until tight.

5. OPERATION

5.1 Putting into operation

Before putting into operation,and especially after any repair work. check to see that all nuts and

bolts are tight. Always disconnect the unit from the air supply before carrying out any repair

work.

a) Mount the nozzle set tightly Align the air nozzle so that the number stamped into it can be

read from the front the right way round.

b) Blow out the air hose before attaching it to the air connection (1/4").(Air hose

pressure-resistant up to min.10 bar and) solvent-resistant. Total electric resistance: less than

100 million Ohm;)

c) The paint spray gun has been treated with an anticorrosive agent before leaving the factory

and must therefore get flushed out thoroughly with thinner before use.

5.2 Adjusting the volume of air using the compressed-air micrometer.

The air supply can be regulated extremely fine to suit all potential conditions. Micrometer in