Nematron iPC Series User manual

Nematron Corporation

5840 interface Drive, Suite 100

Ann Arbor, Michigan 48103-9515

USA

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014

iPC Series & nPC300

Ultra-Thin Industrial

Computers w/ i-Processors

User’s Guide

User’s Guide

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 2 of 27

Revision List

WARRANTY

Nematron warrants to Customer that the Products will be free from defects in material and

workmanship under normal use and service for a period of two years from date of invoice. Customer’s

exclusive remedy for breach of this warranty is that Nematron will either (i) repair or replace, at its option, any

Product which fails during the warranty period because of such defect (if Customer promptly reported the

failure to Nematron in writing) or, (ii) if Nematron is unable to repair or replace, Nematron will refund the

purchase price of the Product upon its return to Nematron. This warranty does not apply to any Product which

has been subjected to misuse, abnormal service or handling, or which has been altered or modified in design

or construction, or which has been serviced by anyone other than Nematron. The warranty set forth herein is

in lieu of, and exclusive of, all other warranties, express or implied.

Revision Number

Description of Change

Release Date

R1

Preliminary Release

8-2012

A

Initial Release

10-2012

B

Added ATOM N2800 and –EN Options

12-2013

C

Added ATEX Zone 2 Info

11-2014

Nematron reserves the right to make changes in specifications described herein at any time without

notice in order to improve design and reliability. Nematron does not assume any responsibility for the

use of any circuitry described; no circuit patent licenses are implied. Nematron assumes no

responsibility for damage caused by misuse or improper use of its products.

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 3 of 27

Chapter 1 - Introduction

The iPC Series products are high performance embedded ultra-thin industrial computers specifically

designed for harsh industrial environments including Class I & II, Division 2 hazardous locations. In addition

there are also ATEX Zone 2/22 certified variations.

The iPC Series offers four versions with 12.1” SVGA (800 x 600), 15” XGA (1024 x 768), 17” SXGA

(1280 x 1024), or 19” SXGA (1280 x 1024) LED backlit TFT Color LCD panels. A stand alone “node” version

without an integrated display is also available (nPC300). These high-performance embedded industrial PCs

offer processor options up to a state of the art Intel Core i7 Processor and DRAM options up to 4 GB. With a

multitude of I/O included on the standard unit many automation applications are ideally suited for use with this

series. The Ultra-Thin panel depth (2.7” to 3.42”) also makes this series ideal for space constrained

applications. With Class I and II Division 2 approvals this industrial PC makes installation in Hazardous

Locations applications simple.

Features

Processor Options up to Intel i7 options

oIntel ATOM N2800 –1.86 GHz, 1 MB Cache, 2 Cores & 4 Threads, Fanless

oIntel Celeron P4500 –1.86 GHz, 2 MB Cache, 2 Cores & 2 Threads

oIntel i5-520M –2.4 GHz, 3 MB Cache, 2 Cores and 4 Threads

oIntel i7-620M –2.66 GHz, 4 MB Cache, 2 Cores and 4 Threads

DRAM Options up to 4 GB

80 GB (minimum) easily removable SATA solid state drive

oLarger Solid State SATA drive upgrade options

o500 GB (min) SATA hybrid hard drive with Solid State Adaptive Memory Cache Option

Numerous I/O Ports

oTwo Gigabit Ethernet ports

o6 USB 2.0 ports (4 on N2800 CPU option)

o2 RS-232 serial port

o1 RS-422/485 Serial port

oAnalog VGA or HDMI port for dual screen applications

UL 508 and ANSI/ISA 12.12.01 listed for Hazardous Locations: Class I, Division 2, Groups A, B, C, D and

Class II, Division 2, Groups F and G, Class III when installed in a suitable enclosure (N/A to Enclosed

Options)

Optional ATEX Zone 2/22 configurations available (24 VDC configurations with appropriate ATEX

markings only)

NEMA 4/4X/12 & IP66 front bezel (does not include –EN or –RM options)

2-Year warranty

European CE mark compliant

Integral 100 -240 VAC power supply

Simplified installation with no studs

Ultra-Thin design –less than 3.25” behind front panel

VESA compliant –all modes up to SXGA, 75Hz (SVGA on 12” and XGA on 15” unit)

Optional 5-wire resistive touch screen

Optional NEMA 1 Enclosure

Optional 304 stainless steel front bezel

Optional iPC1900 Rack Mount front bezel (not NEMA sealed)

Optional 24 VDC input power

Windows 7 Professional 32-bit standard

oWindows XP Professional 32-bit optional

oWindows 7 Ultimate 64-bit (includes multi-language support) optional

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 4 of 27

Specifications

Front Panels

The iPC series has NEMA 4/4X/12 (IP66) sealed front panels when mounted in an appropriate NEMA

rated enclosure. The front panels and required cutouts are exactly the same as the appropriate size ePC-

Series or M-Series units for easy migration to the iPC-Series from the other units. See Chapter 2 for more

details on installation and selection of an appropriate enclosure. All four sizes have very similar front panels

with different dimensions.

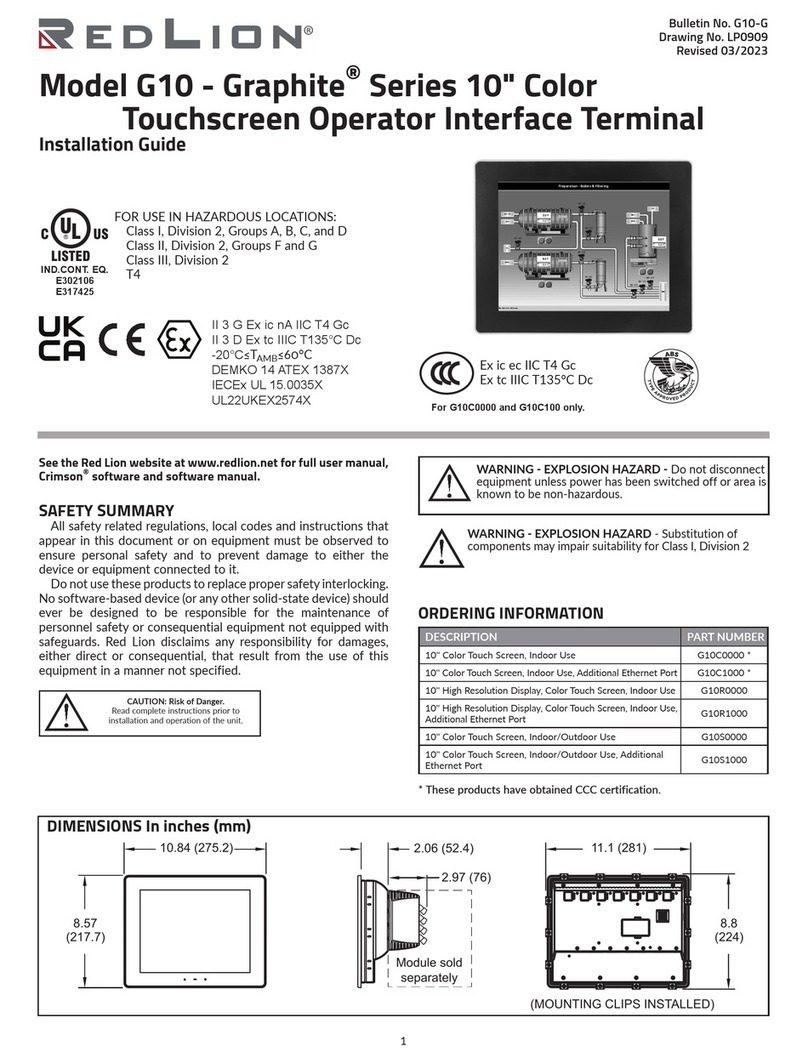

Figure 1.0: iPC Series Front Panel Comparison

The standard front panels are powder coated aluminum. The optional Stainless Steel front panel is type 304

and will not contain a logo pocket or logo on the front. The window area is clear polycarbonate when ordered

without a touchscreen (N/A on ATEX Zone 2/22 configurations). The touchscreen option is heat annealed

glass covered by a polyester overlay. The polyester overlay has better resistance to chemicals than the

polycarbonate window. Depending on the chemicals involved in your application consideration should be

given to choosing the proper window material. In addition there is a Rack Mount front panel option for the

iPC1900 (19” unit) only. This front panel is powder coated aluminum and is 9U high with four rack mount

spaced counter-bored mounting holes on each side of the panel. This panel is not NEMA sealed when

installed.

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 5 of 27

I/O Panel

All four versions of the iPC series and the nPC300 have a common Input/Output configuration. Figure 2.0

shows the base configuration of the iPC-Series (not N2800 Fanless) units.

With N2800 Fanless Option Only

Figure 2.0: iPC Series I/O configuration

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 6 of 27

Feature

Description

Analog Video

Port

A standard 15-pin analog VGA is provided. This connection allows a second screen

to be easily added to the iPC. In addition the iPC allows this second screen to be

utilized in an extended desktop configuration. See CPU manual section on

configuring the video for more details on this feature.

HDMI Port

An HDMI port is provided. This connection allows a second screen to be easily

added to the iPC. In addition the iPC allows this second screen to be utilized in an

extended desktop configuration. See CPU manual section on configuring the video

for more details on this feature.

Com 1

Com 1 is a standard 9-pin RS-232 serial port.

Com 2

Com 2 is a standard 9-pin RS-232 serial port.

Com 3

Com 3 utilizes a standard 9-pin serial port. The iPC default configuration for this port

is RS-485 or RS-422. This port automatically switches between 485 and 422

depending on the connections utilized. See CPU manual for more detailed

instructions and information on the configuration of this port.

Gigabit Ethernet

Two Ethernet ports are provided that are both capable of 10/100/1000 Base-T

communications.

USB 2.0

Six ports capable of USB 1.1 and USB 2.0 are provided.

(2 USB 2.0 and 2 USB 3.0 on ATOM N2800 unit only)

Input Power

Input power, whether AC or DC, is supplied via a Phoenix connector. See Chapter 2

on Installation for more details on how to wire this connection.

Easily Removable

SATA Drive

An easily removable high speed Serial ATA drive is provided. The captive retention

hardware, lack of cumbersome cables, and handle make changing hard drives an

easy task.

DISPLAY

ePC1200

ePC1500

ePC1700

ePC1900

Display Diagonal

12.1” (307.34mm)

15.0” (381.0mm)

17.0” (431.8mm)

19.0” (482.6mm)

Display Size

(Active Area

HxV)

9.69” x 7.26”

(246.0mm x

184.5mm)

11.97” x 8.98”

(304.0mm x

228.1mm)

13.30” x 10.64”

(337.8mm x

270.3mm)

14.82” x 11.85”

(376.4mm x

301.0mm)

Native Resolution

SVGA, 800 x 600

XGA, 1024 x 768

SXGA, 1280 x

1024

SXGA, 1280 x

1024

Displayable

Colors

16M

16M

16M

16M

Brightness,

Typical

450 Nit

400 Nit

350 Nit

300 Nit

Contrast Ratio,

Typical

600:1

600:1

1000:1

2000:1

Horizon/Vertical

View Angle,

CR>5, Typical

140/120

140/120

170/170

178/178

Backlight Life,

Typical

50,000 hrs

50,000 hrs

50,000 hrs

50,000 hrs

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 7 of 27

TOUCH SCREEN (Optional)

Touch Screen Technology

5- Wire Analog Resistive

Interface

Internally via USB

Resolution

4096 x 4096

Positional Accuracy (Maximum Error)

0.18” (0.19” ePC1900)

4.57mm (4.83mm ePC1900)

Positional Accuracy (Standard Deviation of Error)

< 0.08” (< 2.0 mm)

Expected Life

>35,000,000 Activations

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 8 of 27

PHYSICAL

iPC1200

iPC1500

iPC1700

iPC1900

Over All

Dimensions

(H x W x D)

10.475” x 12.9” x

3.42”

(266.1mm x

327.2mm x

86.75mm)

12.80” x 15.80” x

2.95”

(325.1mm x

401.3mm x

74.9mm)

14.48” x 17.14” x

3.10”

(367.8mm x

442.0mm x

78.7mm)

15.70” x 18.66” x

3.25”

(398.8mm x

474.0mm x

82.6mm)

Panel Mounting

Depth

3.165” (80.4mm)

2.70” (68.6mm)

2.90” (73.7mm)

3.00” (76.2mm)

Cutout

Dimensions

(H x W)

9.68” x 12.10”

(245.9mm x

307.3mm)

12.00” x 15.00”

(305mm x

381mm)

13.70” x 16.35”

(348mm x

415.3mm)

14.90” x 17.75”

(378.5mm x

450.9mm)

Weight

10.5 lbs (4.76kg)

15.0 lbs (6.80kg)

19.0 lbs (8.63kg)

22.5 lbs (10.22kg)

Shipping

Weight

14.0 lbs (6.35kg)

19.5 lbs (8.84kg)

23.5 lbs (10.67kg)

27.5 lbs (12.49kg)

Option Weight

(-SS)

+2.5 lbs (1.13kg)

+3.5 lbs (1.58kg)

+3.75 lbs (1.70kg)

+4.0 lbs (1.81kg)

The nPC300 is essentially the rear of the panel mount versions. It is supplied with mounting brackets so that it

can be easily attached to wall or shelf in a NEMA 1 or better enclosure. The nPC300 is not a standalone

device and must be installed in an enclosure to protect operators.

The dimensions of the nPC300 unit are as follows:

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 9 of 27

ELECTRICAL

AC Input Voltage

(N/A for ATEX Certified Units)

100 –240 VAC, 50/60 Hz

AC Input Current

(N/A for ATEX Certified Units)

1.0 A Maximum

DC Input Voltage (Optional)

18 –36 VDC

DC Input Current (Optional)

6.0 A Max

Input Power

nPC300 –60 W Typical* (40 W for N2800 Option)

iPC1200 - 70 W Typical* (50 W for N2800 Option)

iPC1700 –80 W Typical* (60 W for N2800 Option)

iPC1700 –85 W Typical* (65 W for N2800 Option)

iPC1900 –90 W Typical* (70 W for N2800 Option)

* Typical Power is measured without any additional I/O or expansion options. Any additional I/O installed

during application can increase this value.

ENVIROMENTAL

Operating Temperature

0C to 55C

(0C to 50C for Enclosed Options

Non-Operating Temperature

-20C to 60C

Operating & Non-Operating Humidity

20% to 80% RH, non-condensing

Operating Shock*

15g peak acceleration, 11msec

Non-Operating Shock

30g peak acceleration 11msec

Operating Vibration (5-2000 Hz) 1

0.006” peak to peak displacement,

1g maximum acceleration

Non-Operating Vibration (5-2000 Hz) 1

0.015” peak to peak displacement,

2.5g maximum acceleration

Operating Altitude 2

Sea level –10,000 feet

Non-Operating Altitude 2

Sea level –40,000 feet

1 Shock and Vibration specifications are established using Solid State drives and non-rotating media.

2 Altitude Specification is established by using all internal component specifications.

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 10 of 27

AGENCY CERTIFICATIONS AND APPROVALS

Front Panel NEMA Rating

NEMA 4/4X/12, IP66

FCC

47 CFR, Part 15, Class A

European Union CE Marking Compliance

CE, EN 55022: CISPR 11, Group 1, Class A,

EN 61326-1, EN 60950-1

North American Safety Agency Approvals (panel mount

and nPC300 versions only)

UL 508 Listed, cUL Listed CSA C22.2, #142,

ANSI/ISA 12.12.01 UL Listed* & CSA C22.2,

#213* cUL Listed*

European Union ATEX Zone 2/22 Approvals (optional

configurations)*

Certificate Number: DEMKO 14 ATEX 1374X

Note: Not all variations of the iPC-Series and nPC300 are

ATEX zone 2/22 certified, only those with the appropriate

ATEX markings on the label are certified for use in ATEX

hazardous locations.

All ATEX Certified iPC-Series & nPC300

Models:

EN 60079-0:2012+A11:2013

EN 60079-15:2010

ATEX Certified iPC-Series Models Only:

EN 60079-11:2012

EN 60079-31:2009

iPC-Series:

II 3G Ex ic nA IIC T4 Gc IP66

II 3D Ex tc IIIC T67°C Dc IP66

0°C ≤ TAMB ≤ 55°C

nPC300: II 3G Ex nA IIC T4 Gc

0°C ≤ TAMB ≤ 55°C

North American Safety Agency Approvals (enclosed

versions only)*

UL 508 Listed, cUL Listed CSA C22.2 #142

* See appropriate note below for the applicable unit or option being utilized.

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 11 of 27

NOTES FOR CLASS I DIVISION 2 INSTALLATIONS:

WARNING –EXPLOSION HAZARD –DO NOT DISCONNECT EQUIPMENT

WHILE THE CIRCUIT IS LIVE OR UNLESS THE AREA IS KNOW TO BE FREE

OF IGNITABLE CONCENTRATIONS.

NOTE FOR CLASS I DIVISION 2 INSTALLATIONS (RACK MOUNT VERSIONS):

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C AND D

HAZARDOUS LOCATIONS, OR NONHAZARDOUS LOCATIONS ONLY

FOR RACK MOUNT INSTALLATION ON A TYPE 1 ENCLOSURE WITH

PROVISIONS FOR CLASS I DIVISION 2 WIRING METHODS

TEMPERATURE CODE: T6 (T4A FOR N2800 OPTION)

NOTE FOR CLASS I DIVISION 2 INSTALLATIONS (NP300 UNITS):

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C AND D

HAZARDOUS LOCATIONS, OR NONHAZARDOUS LOCATIONS ONLY

FOR USE ON A FLAT SURFACE OF A TYPE 1 ENCLOSURE WITH

PROVISIONS FOR CLASS I DIVISION 2 WIRING METHODS

TEMPERATURE CODE: T6 (T4A FOR N2800 OPTION)

WARNING –EXPLOSION HAZARD –SUBSTITUTION OF ANY COMPONENTS

MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2

NOTE FOR CLASS I DIVISION 2 INSTALLATIONS (PANEL MOUNT VERSIONS):

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C AND D, CLASS II

DIVISION 2, GROUPS F AND G, CLASS III HAZARDOUS LOCATIONS, OR

NONHAZARDOUS LOCATIONS ONLY

FOR USE ON A FLAT SURFACE OF A TYPE 1, 4, 4X, OR 12 ENCLOSURE WITH

PROVISIONS FOR CLASS I DIVISION 2 WIRING METHODS

TEMPERATURE CODE: T6 (T4A FOR N2800 OPTION)

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 12 of 27

NOTES FOR ATEX ZONE 2/22 INSTALLATIONS (ATEX MARKED UNITS

ONLY):

NOTE –NOT ALL VARIATIONS OF THE IPC-SERIES AND NPC300 ARE ATEX

ZONE 2/22 CERTIFIED, ONLY THOSE WITH THE APPROPRATE ATEX

MARKINGS ON THE LABEL ARE CERTIFIED FOR USE IN ATEX HAZARDOUS

LOCATIONS.

CONDITIONS FOR SAFE USE IN ATEX GROUP IIIC (ZONE 22)

INSTALLATIONS ONLY -

FOR THE PURPOSE OF ESD PROTECTION –

IPC-SERIES MODELS WITH TOUCHSCREEN OPTION INSTALLED -

THE TOUCHSCREEN MUST BE WIPED WITH A DAMP CLOTH PRIOR

TO USE.

CONDITIONS FOR SAFE USE IN ATEX ZONE 2/22 INSTALLATIONS -

IPC-SERIES MODELS - EQUIPMENT IS NOT INTENDED TO BE USED IN

AREAS THAT CAN RESULT IN SEVERE IMPACT TO THE WINDOW.

WARNING –EXPLOSION HAZARD –DO NOT DISCONNECT THE USB PORTS

UNLESS THE POWER HAS BEEN SWITCHED OFF AND THE AREA IS KNOWN

TO BE NON-HAZARDOUS

ATTENTION: RISQUE D'EXPLOSION - NE PAS BRANCHER OU DÉBRANCHER

LE PORTS USB À MOINS QUE L'ALIMENTATION À ÉTÉ COUPÉE OU SI LA

ZONE N'EST PAS HAZARDEUSE.

ADVERTENCIA: PELIGRO DE EXPLOSIÓN - NO CONECTE O DESCONECTE

LOS PUERTOS USB A MENOS QUE LA COMPUTADORA SE ENCUENTRE

APAGADA O EL ÁREA SE CONSIDERE NO PELIGROSA.

WARNUNG: EXPLOSIONSGEFAHR - USB PORTS NUR ANSCHLIEßEN ODER

TRENNEN, WENN KEINE SPANNUNG ANLIEGT ODER DER BEREICH NICHT

EXPLOSIONGEGEFÄHRDET IST.

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 13 of 27

CONDITIONS FOR SAFE USE IN ATEX GROUP IIC (ZONE 2)

INSTALLATIONS ONLY -

UNITS NEED TO BE INSTALLED IN AN APPROVED ATEX RATED

ENCLOSURE ACCORDING TO THE FOLLOWING CRITERIA:

INSTALLATION WITHIN END-EQUIPMENT THAT PROVIDES AN INTERNAL

“MICRO-ENVIRONMENT” *OF POLLUTION DEGREE 2 OR BETTER:

FOR THIS INSTALLATION OPTION, THE OPEN-TYPE IPC-SERIES AND NPC300

INDUSTRIAL COMPUTERS SHALL BE INSTALLED WITHIN END-EQUIPMENT

THAT COMPLIES WITH ALL OF THE FOLLOWING CONDITIONS:

1. THE ENCLOSURE OF THE END-EQUIPMENT SHALL PROVIDE A DEGREE

OF PROTECTION NOT LESS THAN IP 64 IN ACCORDANCE WITH IEC/EN

60079-15; AND

2. THE END-EQUIPMENT SHALL PROVIDE AN INTERNAL ENVIRONMENT OF

POLLUTION DEGREE 2 OR BETTER, AS DEFINED IN IEC/EN 60664-1; AND

3. TRANSIENT PROTECTION SHALL BE PROVIDED THAT IS SET AT A LEVEL

NOT EXCEEDING 140 % OF THE PEAK RATED VOLTAGE VALUE AT THE

SUPPLY TERMINALS TO THE END-EQUIPMENT; AND

4. ENCLOSURE MUST UTILIZE A TOOL REMOVABLE COVER, DOOR, OR

PANEL.

INSTALLATION WITHIN AREAS THAT PROVIDE AN EXTERNAL “MACRO-

ENVIRONMENT” ** OF POLLUTION DEGREE 2 OR BETTER:

FOR THIS INSTALLATION OPTION, THE OPEN-TYPE IPC-SERIES AND NPC300

INDUSTRIAL COMPUTERS SHALL BE INSTALLED WITHIN END-EQUIPMENT

THAT COMPLIES WITH ALL OF THE FOLLOWING CONDITIONS:

1. THE END-EQUIPMENT SHALL BE USED IN A POLLUTION DEGREE 2 OR

BETTER AREA, AS DEFINED IN IEC/EN 60664-1; AND

2. THE ENCLOSURE OF THE END-EQUIPMENT SHALL PROVIDE A DEGREE

OF PROTECTION NOT LESS THAN IP 54 IN ACCORDANCE WITH IEC/EN

60079-15; AND

3. TRANSIENT PROTECTION SHALL BE PROVIDED THAT IS SET AT A LEVEL

NOT EXCEEDING 140 % OF THE PEAK RATED VOLTAGE VALUE AT THE

SUPPLY TERMINALS TO THE END-EQUIPMENT; AND

4. ENCLOSURE MUST UTILIZE A TOOL REMOVABLE COVER, DOOR, OR

PANEL.

*THE TERM “MICRO-ENVIRONMENT”, PER IEC 60664-1, IS DEFINED AS THE

“IMMEDIATE ENVIRONMENT OF THE INSULATION WHICH PARTICULARLY

INFLUENCES THE DIMENSIONING OF THE CREEPAGE DISTANCES” (INSIDE

ENCLOSURE).

**THE TERM “MACRO-ENVIRONMENT”, PER IEC 60664-1, IS DEFINED AS AN

“ENVIRONMENT OF THE ROOM OR OTHER LOCATION IN WHICH THE

EQUIPMENT IS INSTALLED OR USED” (OUTSIDE ENCLOSURE).

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 14 of 27

NOTE FOR ENCLOSED UNIT INSTALLATIONS:

CONDITIONS FOR SAFE USE IN ATEX (ZONE 22) INSTALLATIONS ONLY-

FOR GROUP IIIC ENVIRONMENTS - THE ENCLOSURE OF THE END-

EQUIPMENT SHALL PROVIDE A DEGREE OF PROTECTION NOT LESS

THAN IP 64 IN ACCORDANCE WITH IEC/EN 60079-31.

FOR GROUP IIIA AND IIIB ENVIRONMENTS - THE ENCLOSURE OF THE

END-EQUIPMENT SHALL PROVIDE A DEGREE OF PROTECTION NOT

LESS THAN IP 54 IN ACCORDANCE WITH IEC/EN 60079-31.

NOTE: (ENCLOSED IPC VERSIONS):

A LISTED VESA STYLE MOUNT SUITABLE WITH A MINIMUM LOAD RATING

OF 40 POUNDS SHALL BE USED IN THE END INSTALLATION

FOR USE IN NON-HAZARDOUS (ORDINARY) LOCATIONS ONLY

TYPE 1 ENCLOSURE

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 15 of 27

Chapter 2 - Installation of Computer

Panel Mount iPC-Series Unit installation

The panel mount versions of the iPC-Series are intended to be mounted in and used where NEMA 1,

NEMA 4/4x and NEMA 12 type enclosures are employed. Enclosures made of heavier gauge metal work

better because they won’t deform or bend as easily when the monitor’s sealing gasket is compressed. The

monitor meets NEMA 4/12 sealing specifications when properly installed in an approved NEMA enclosure

constructed from 14-gauge or heavier steel. The computer uses “U”-shaped clips and a special gasket to

achieve the proper seal.

When selecting an enclosure remember to allow adequate space around the rear of the computer for

good air flow. Do not block air flow from below or above the monitor. If possible mount the computer in a

vertical orientation. The unit is designed to work in environments up to 50 degrees Centigrade ambient

temperature inside the enclosure. Remember to account for heat dissipated from other equipment that may be

installed inside the same enclosure.

To install the computer, make a cutout according to the diagrams below in one of the walls of your

NEMA enclosure. Next hold the unit in place while you install the mounting clips. Tighten the clips to the

point were the back of the unit’s front bezel just begins to contact the front of the NEMA enclosure. The use of

an adjustable torque driver is recommended. The screws should be tightened to 8 inch-pounds. Tighten the

clips in a cross pattern. This will help to develop an even pressure on the sealing gasket. DO NOT OVER

TIGHTEN AS DAMAGE CAN RESULT IN THE COMPUTER CAUSING LOSS OF SEALING INTEGRITY.

iPC1200

iPC1500

iPC1700

iPC1900

Cutout

Dimensions

(H x W)

9.68” x 12.10”

(245.9mm x

307.3mm)

12.00” x 15.00”

(305mm x

381mm)

13.70” x 16.35”

(348mm x

415.3mm)

14.90” x 17.75”

(378.5mm x

450.9mm)

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 16 of 27

UPMENU DOWNSELECT POWER

FRONT PANEL

OF NEMA

ENCLOSURE

TIGHTEN TO 8

INCH-POUNDS

COMPRESSABLE NEMA

SEALING GASKET

.25" THICK MONITOR

FRONT BEZEL

MAXIMUN ALLOWABLE

PANEL THICKNESS

CUT AWAY

.325"

FRONT PANEL OF

NEMA ENCLOSURE

MOUNTING CLIP

WITH 10x32 SCREW

Mounting Clip Installation

NOTE: WHEN INSTALLING THE MOUNTING CLIPS TIGHTEN THE SCREWS

TO 8-10 INCH-POUNDS MAXIMUM. OVERTIGHTENING THE SCREWS WILL

RESULT IN A COMPRIMISED NEMA SEAL AND MAY CAUSE TOUCH SCREEN

BREAKAGE.

REAR VIEW OF PANEL

MOUNTED ePC

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 17 of 27

nPC300 Unit Installation

The nPC300 is intended to be mounted on the flat surface on the inside of a NEMA Type 1, 4/4x or

NEMA 12 enclosure. See the specifications section for the dimensions and mounting dimensions required for

mounting this unit.

When selecting an enclosure remember to allow adequate space around the computer for good air

flow. Do not block air flow around the unit except for the mounting surface. The computer can be mounted on

a horizontally or vertically to a wall or shelf within the enclosure. The unit is designed to work in environments

up to 50 degrees Centigrade ambient temperature inside the enclosure. Remember to account for heat

dissipated from other equipment that may be installed inside the same enclosure.

Rack Mount Unit Installation

The iPC1900 with a rack mount front panel is intended to be mounted to a 19.0” wide rack in a NEMA

Type 1 or better enclosure. The unit can be mounted using standard rack mount hardware (not supplied) via

the eight (4 each side) counter-bored holes in the front of the panel. The front panel is intended to be mounted

in a vertical height of 9 U (16.0”) on the rack. This unit is not NEMA sealed when mounted like the panel

mount versions.

When selecting an enclosure remember to allow adequate space around the rear side of the computer

for good air flow. The unit is designed to work in environments up to 50 degrees Centigrade ambient

temperature inside the enclosure. Remember to account for heat dissipated from other equipment that may be

installed inside the same enclosure.

Enclosed Unit Installation

The enclosed iPC-Series products are intended to be stand-alone NEMA Type 1 units. These are

required to be mounted to a VESA style mount with a minimum load rating of 40 pounds. A desktop stand,

wall mount, or articulating arms are examples of VESA style mounts that can be utilized. These units are

vented for air flow and are not dust or water proof. Care should be taken to not utilize these units in areas

where high concentration of particulate matter or moisture are present. If these conditions do exist then the

use of the panel mount versions in an appropriate NEMA 4, 4x, or 12 enclosure should be considered. The

warranty may be voided if high levels of moisture or particulate matter are determined to be the cause of a

failure. The ePC-Series –EN units (except fanless version) have a filter over the CPU fansink to filter incoming

air. This filter should be carefully removed and cleaned periodically depending on service conditions. In some

applications this may need to be checked and cleaned often.

These units are designed to work in environments up to 50 degrees Centigrade ambient temperature

around the enclosure. Impeding the airflow around this unit or clogged filters will severely affect the reliability of

the unit by raising the internal temperature. Assure that there is adequate airflow around the unit.

NEMA Type 1 is not sealed against water and/or dust; it is simply provides protection from operators

shocking themselves. It also offers a certain amount of fire containment it the event of a catastrophic failure

inside the unit. As stated previously NEMA 1 is not waterproof or dust proof and is not intended to be utilized

in environments exhibiting high levels of these conditions.

Example of an Enclosed Unit Mounted

To an Articulating Arm

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 18 of 27

321

31 2

TOP VIEW

FRONT VIEW

PHOENIX CONTACT P.N. 1777992

Connecting Power to the iPC-Series

Connecting power to the Panel Mount, Rack Mount, and nPC300 units:

The iPC-Series and nPC300 units are powered from 100-240 VAC, 50/60 Hz or optionally from 24

VDC. Damage will occur if 100-240 VAC power is connected to an iPC-Series unit equipped with the 24

VDC input power option. iPC-Series equipped units with the 24 VDC option will have a “-DC” suffix in their

model number (such as iPC1500T-i5-4GB-80SS-W7-DC)

Because the iPC-Series (not –EN option) is UL 1604 listed for Hazardous Location use, (Class I

Division2, Groups A, B, C, D; Class II Division 2 Groups F and G: Temperature Code T6 or T4A), the units do

not have a power switch for switching off supplied power. Consideration should be give to the installation of an

appropriately rated external power switch if the application requires powering off the iPC-Series unit.

Power is connected to the units through a removable Phoenix Contact plug (Phoenix Contact P.N.

1777992) that allows for screw termination of field wiring. This plug is included with each unit and is keyed to

prevent installation in a unit with the wrong input voltage rating. When Field Wiring to these terminals the

use of 18 AWG or greater (12 AWG maximum) copper wire with 60ºC or 60/75ºC wire insulation and the

terminal tightening torque of 7.0 lb/in. (0.79 Nm) is required. The terminal screws are shown in “Top View”

below. Connect the field wiring according to the appropriate voltage in the table below. Strip the wire insulation

back on each conductor 6.5 mm (0.26 in) and assure that the remaining wire is twisted together, not frayed,

and clean. If an outer jacket over each conductor is utilized then strip the outer jacket back an additional 19.0

mm (0.75 in) as shown in figure below. When installing the conductors take care that there are not any stray

strands of wire that can contact an adjoining connection. Tinning of each lead can be utilized to prevent frays if

desired. Optionally the included protective cover can be utilized to prevent electrical shocks when handling the

power connector and provide strain relief for each conductor connection (see the following section for

installation instructions). After the connections are made, make sure the plug retention screws (the two screws

shown in the “Front View” below) are securely tightened. This will prevent the plug from pulling out. The use of

these screws is mandatory when the unit is utilized in applications requiring hazardous locations approvals.

FRONT VIEW

PIN NUMBER

100 VAC –240 VAC INPUT

18 VDC –36 VDC INPUT

1

AC Line Input

+ DC Input

2

AC Neutral Return

-DC Return

3

Protective Earth Ground

Protective Earth Ground

31 2

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 19 of 27

WARNING –EXPLOSION HAZARD –DO NOT DISCONNECT THE USB PORTS

UNLESS THE POWER HAS BEEN SWITCHED OFF AND THE AREA IS KNOWN

TO BE NON-HAZARDOUS

ATTENTION: RISQUE D'EXPLOSION - NE PAS BRANCHER OU DÉBRANCHER

LE PORTS USB À MOINS QUE L'ALIMENTATION À ÉTÉ COUPÉE OU SI LA

ZONE N'EST PAS HAZARDEUSE.

ADVERTENCIA: PELIGRO DE EXPLOSIÓN - NO CONECTE O DESCONECTE

LOS PUERTOS USB A MENOS QUE LA COMPUTADORA SE ENCUENTRE

APAGADA O EL ÁREA SE CONSIDERE NO PELIGROSA.

WARNUNG: EXPLOSIONSGEFAHR - USB PORTS NUR ANSCHLIEßEN ODER

TRENNEN, WENN KEINE SPANNUNG ANLIEGT ODER DER BEREICH NICHT

EXPLOSIONGEGEFÄHRDET IST.

WARNING –EXPLOSION HAZARD –DO NOT DISCONNECT EQUIPMENT

WHILE THE CIRCUIT IS LIVE OR UNLESS THE AREA IS KNOW TO BE FREE

OF IGNITABLE CONCENTRATIONS.

NOTE: TO PREVENT INADVERTENT DISCONNECTION OF VIDEO AND/OR

SERIAL TOUCHSCREEN CABLES ASSURE THAT THE THUBSCREWS ARE

SUFFICIENTLY TIGHTENED.

NOTE: WHEN USING USB CONNECTIONS THE USE OF THE USB RETENTION

BRACKET IS REQUIRED FOR HAZARDOUS LOCATIONS AND HIGHLY

RECOMMENDED FOR NONHARDAOUS LOCATIONS.

________________________________________________________________________________________

Document No. DOC-IPC-003,

User Manual iPC-Series & nPC300, Rev C Rel. 11-2014 Page 20 of 27

Protective Cover Installation

(Optional if desired)

Step 1: Gather the parts of the protective cover; top shell,

bottom shell, label insert, and wire tie. The picture

shows wire tie (top), label insert (right), bottom

shell (left), and top shell (lower right).

Step 2: Insert your pre-wired connector (with the screws facing

up) into the bottom shell. (See manual for cable

wiring instructions).

Step 3: Insert the wire tie from the bottom shell, loop around the

cable and come back out of the opposite hole in the

bottom shell.

Step 4: Tighten the wire tie around the cable and the bottom

shell.

Step 5: Seat the top shell onto the bottom as shown. Insert label

strip (if desired) in slot on top shell and bottom shell.

Step 6: Snap the top and bottom shells together.

This manual suits for next models

1

Table of contents