296.GB.809.0 INHALT

- 4 -

TABLE OF CONTENTS

GB

Observe Safety Hints in the supplement!

CE sign

The CE sign, which is affixed by

the manufacturer, indicates

outwardly that this machine

conforms to the engineering

guideline regulations and the

other relevant EU guidelines.

EU Declaration of ConformityBy signing the EU

Declaration of Conformity, the manufacturer declares that

the machine being brought into service complies with all

relevant safety and health requirements.

495.151

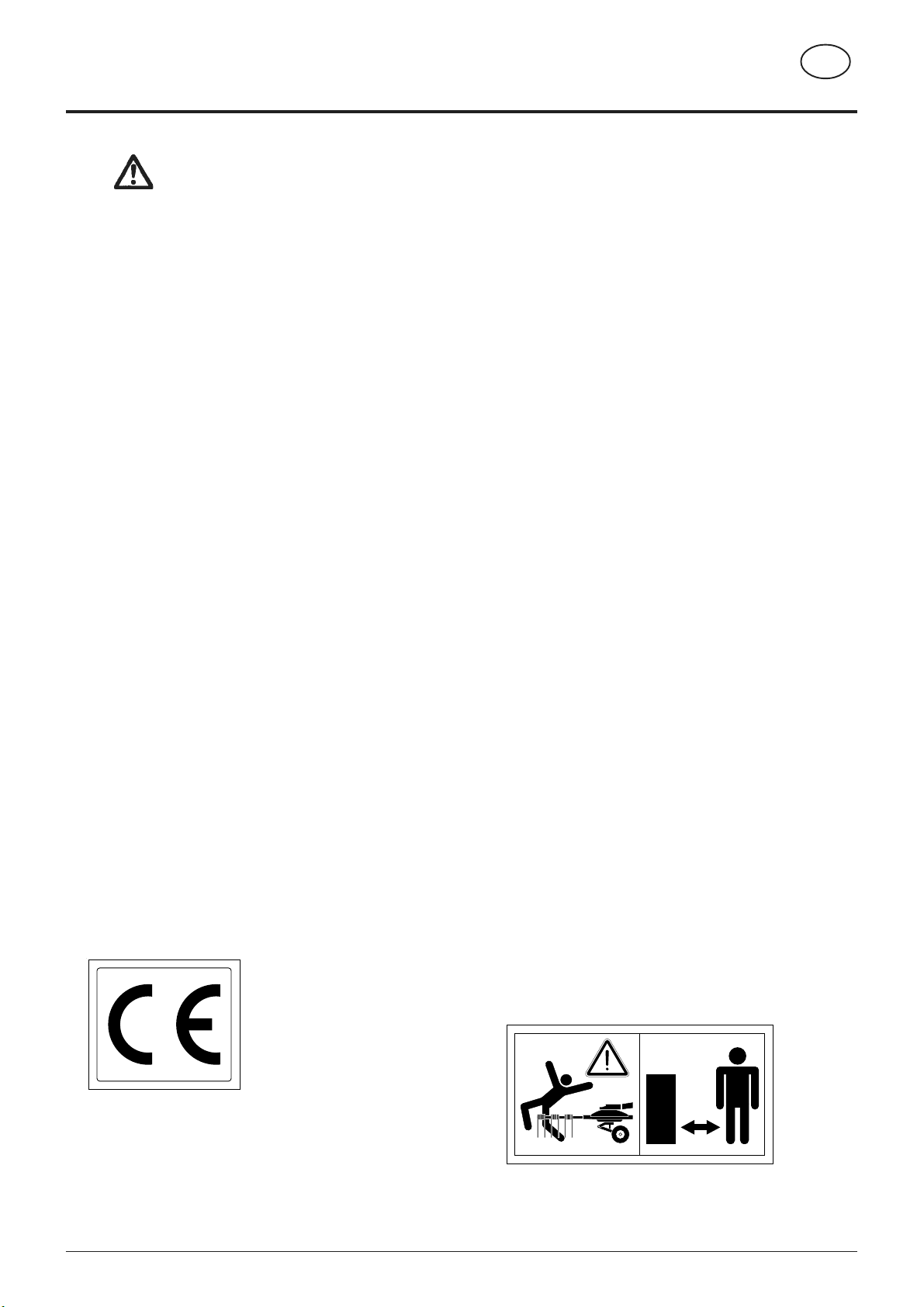

Do not enter rotor area while driving motor is

running.

Meaning of warning signs

495.173

Table of contents

HITCHING TO THE TRACTOR ================ 5

Attaching in general .............................................................. 5

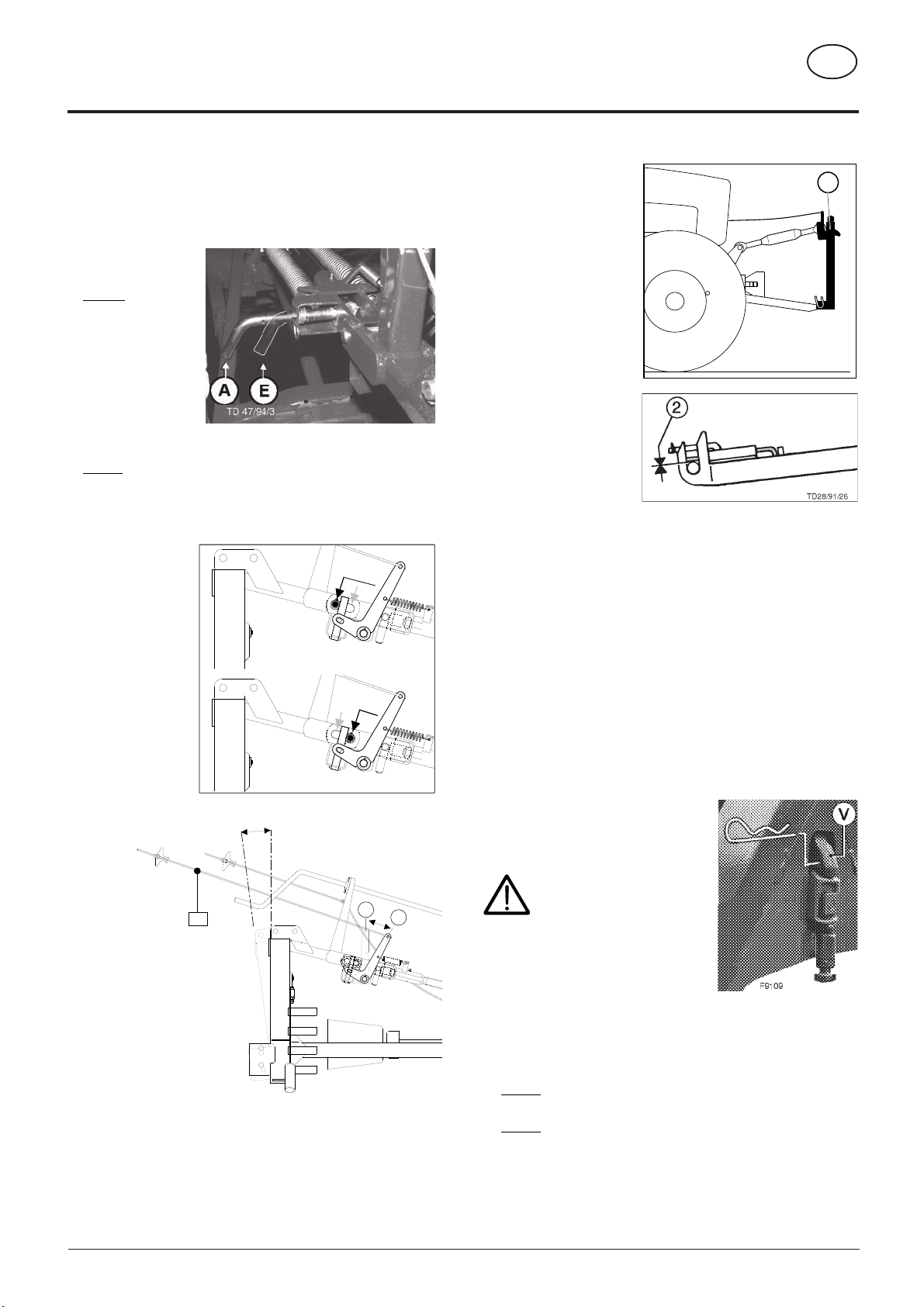

Drive shaft .............................................................................5

Road Transport...................................................................... 5

Work position ........................................................................ 5

Lowering the machine ........................................................... 5

Always park safely!................................................................5

Secure against rolling away and tipping. ............................... 5

Do not allow to rest on roller feeler - use a supporting

stanchion. ..............................................................................5

Preparing for front attachment with a Weiste triangle ........... 6

Front attachment with a Weiste triangle ................................6

Front attachment without a Weiste triangle ...........................6

TRANSPORT AND WORKING POSITION ======= 7

Conversion to transport position ...........................................7

Position of running wheels .................................................... 7

Driving on public roads..........................................................7

Conversion to working position .............................................7

OPERATION ============================= 8

General guidelines for working with the machine .................. 8

P.t.o. speed ............................................................................8

FRONT AND REAR ATTACHMENT ============ 9

Attachment and operating possibilities..................................9

Front attachment - forward travel .......................................... 9

Additional gear for front attachment ....................................10

Rear Attachment - forward travel ........................................10

Using a roller wheel with rear attachment ........................... 11

Rear attachment with a flexible upper link .......................... 11

MAINTENANCE ========================== 12

Lubrication chart ............................................................... 12

Maintenance and servicing .................................................12

Safety points .......................................................................12

Cleaning of machine parts ..................................................12

Winter storage .....................................................................12

TECHNICAL DATA ======================== 13

Defined use of the Rotary Swather .....................................13

Position of Vehicle Identification Plate ................................. 13

Special fittings: ....................................................................14

Supplement .........................................................................15

Recommendations for work safety ...................................... 16

DRIVESHAFT .....................................................................17

Important! Additional Information ........................................ 20

Combination of tractor and mounted implement ................. 20