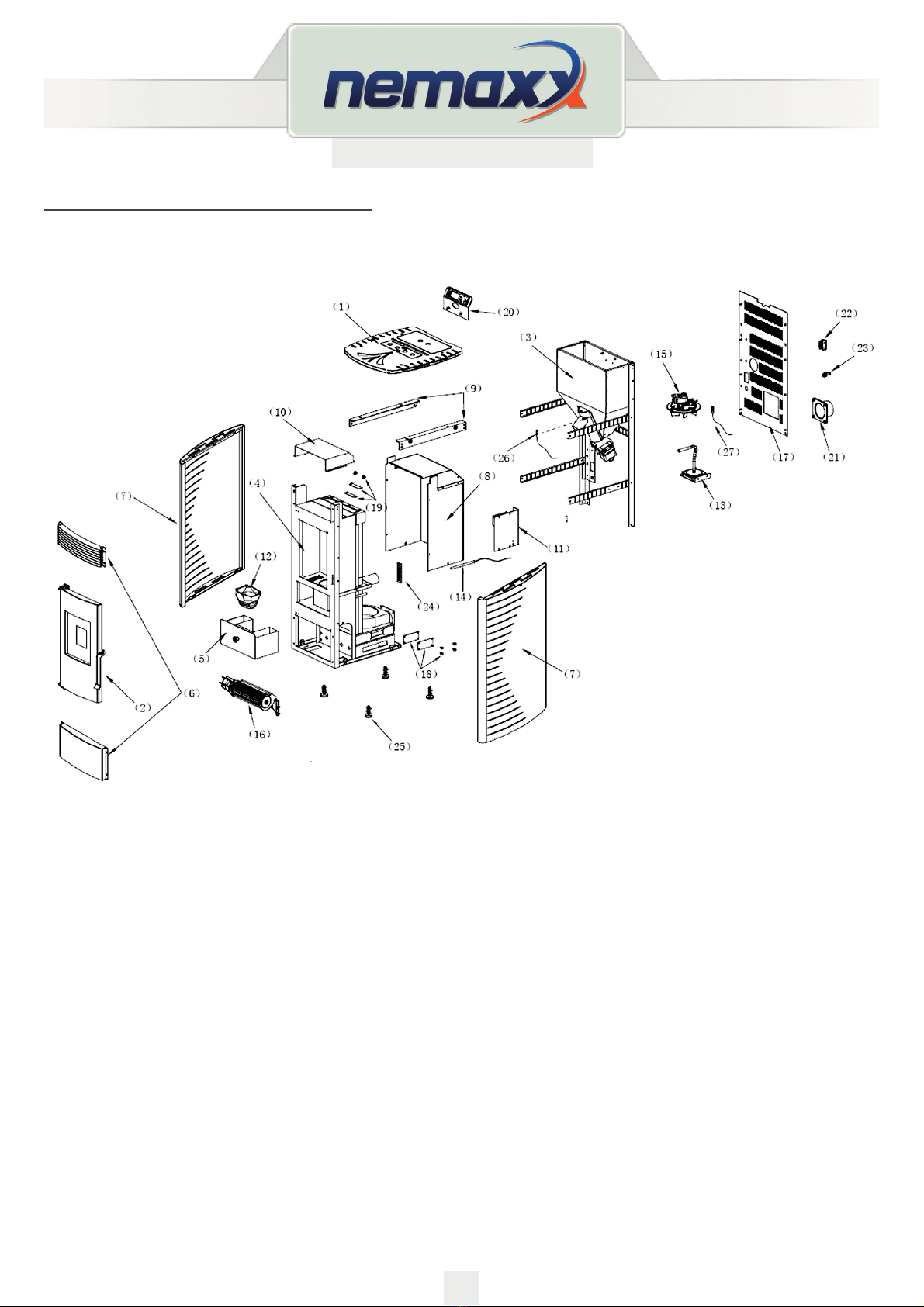

Nemaxx P6 User manual

This manual suits for next models

2

Table of contents

Other Nemaxx Stove manuals

Popular Stove manuals by other brands

Stanley

Stanley 0063AU5289 Assembly, installation and operation instructions

Charnwood

Charnwood Cove 2sr Operating & installation instructions

Duraflame

Duraflame DFS-550-20 operating instructions

Ashley

Ashley AW2020E manual

Lopi

Lopi Cypress GSR2 Deluxe owner's manual

Charnwood

Charnwood country Operating & installation instructions

Ravelli

Ravelli Sphere V Deco Use and maintenance manual

BuckMaster

BuckMaster 261 Preparations, installation, operation, maintenance, safety

Piazzetta

Piazzetta P944 installation instructions

Bosca

Bosca SOUL 700 owner's manual

Heta

Heta SCAN-LINE 40 Operating and installation instructions

Harman Home Heating

Harman Home Heating MARK III Installation and operating manual

Flavel

Flavel Rochester 5kW Installation and operating instructions

EdilKamin

EdilKamin KLIK Installation, use and maintenance

Baxi Fires Division

Baxi Fires Division 816 Installation and operating guide

Jøtul

Jøtul GF 500 DV IPI Installation and operation instructions

Premium

Premium PGS2000 PISCIS Installation and maintenance manual

Jøtul

Jøtul Allagash GF 300 DV instructions