Nemaxx PW18 User manual

KEN002PW18

PELLET STOVE ●PELLETOFEN

POÊLE À GRANULÉS ●STUFA A PELLET

ESTUFA DE PELLETS

Nemaxx PW18

EN INSTRUCTION MANUAL page 2 - 41

DE GEBRAUCHSANLEITUNG Seite 42 - 81

FR MANUEL D'UTILISATION page 82 - 121

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 2]

TABLE OF CONTENTS

Introduction.......................................................................................................................................................... 3

1. WARNINGS. .......................................................................................................................................................... 4

1.1. Safety instructions ................................................................................................................................................. 4

1.2. Operating instructions ........................................................................................................................................... 5

1.3. Important information for correct disposal of the product with EC Directive 2002/96/EC ..................................... 5

2. Theoretical notions for installation ................................................................................................................... 6

2.1 Pellets ................................................................................................................................................................... 6

2.2 Precautions for installation..................................................................................................................................... 7

2.3. Operating environment ......................................................................................................................................... 7

2.4. Connection to the external air intake .................................................................................................................... 8

2.5. Connection of smoke discharge pipe .................................................................................................................... 9

2.6. Connection to the chimney ................................................................................................................................. 10

2.7. Connectiontoanexternaluewithinsulatedordouble-wallpipe ...................................................................... 10

2.8. Connectiontotheuepipe .................................................................................................................................. 11

2.9. Operatingproblemscausedbydraughtdefectsintheue.................................................................................. 11

2.10. Hydraulic connection ........................................................................................................................................... 12

3. Installation and assembly ................................................................................................................................ 13

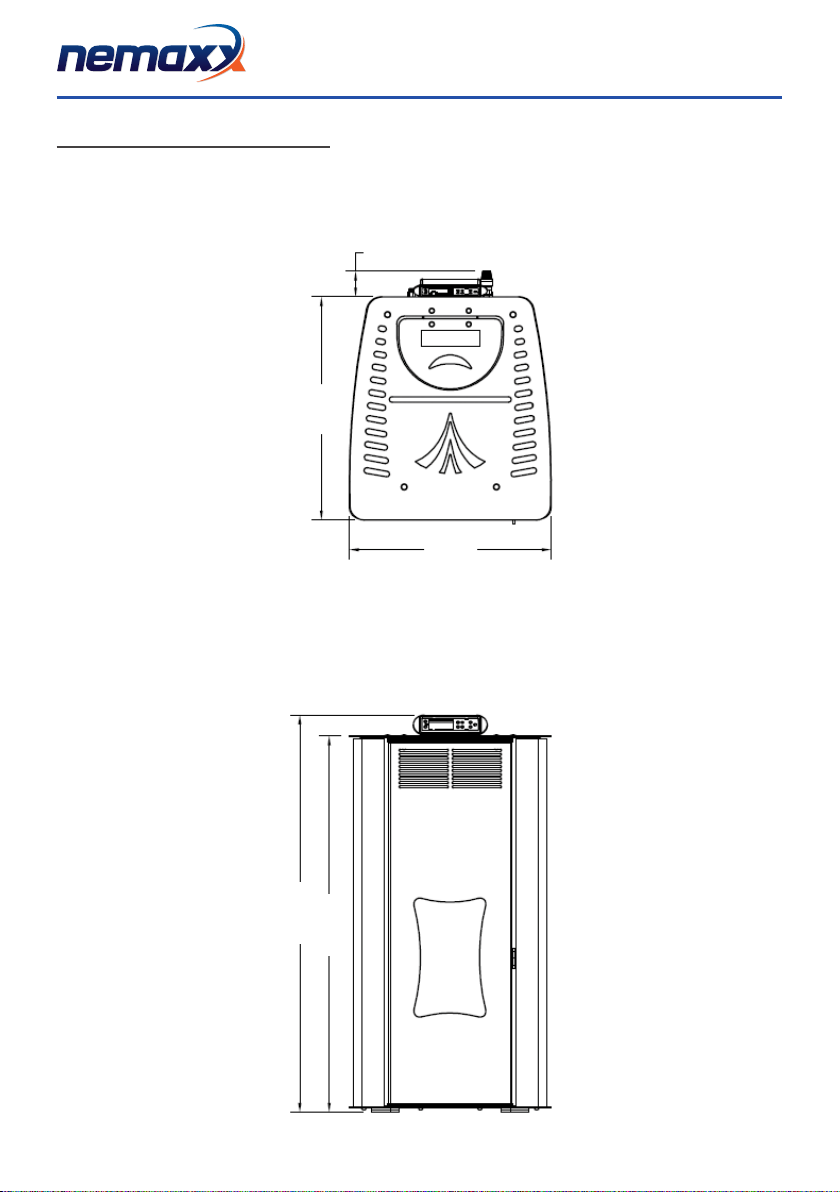

3.1. Drawingsandspecications ............................................................................................................................... 13

3.1.1. Dymensions of hydro stove ................................................................................................................................. 13

3.1.2. Technical data sheet ........................................................................................................................................... 14

3.2. Preparation and unpacking ................................................................................................................................. 15

3.3. Hydro connection diagramm ............................................................................................................................... 15

3.3.1. Connections to the system .................................................................................................................................. 16

3.3.2. Filling the water network ..................................................................................................................................... 16

3.3.3. Water characteristics ........................................................................................................................................... 17

3.4. Kit water production ............................................................................................................................................ 17

3.5. Example installation diagrams ............................................................................................................................ 17

3.5.1. Installation diagram for heating system with domestic hot water kit (SUITE/CLUB/MUSA) ................................ 17

3.5.2. Heatinginstallationincombinationwithastoragetank ...................................................................................... 18

3.5.3. Heatinginstallationincombinationwithaboiler .................................................................................................. 19

4. Operation Instructions - Quick reference quide - Safety................................................................................ 20

5. Maintenance and cleaning ............................................................................................................................... 31

5.1. Dailyorweeklycleaningperformedbytheuser ................................................................................................. 31

5.1.1. Before each ignition ............................................................................................................................................ 31

5.1.2. Check every 2/3 days ......................................................................................................................................... 32

5.1.3. Cleaning the glass .............................................................................................................................................. 32

5.1.4. Cleaningthestainlesssteelandsatin-nishsurfaces ......................................................................................... 32

5.1.5. Cleaning of painted parts .................................................................................................................................... 32

5.2. Cleaningtobeperformedbyspecializedtechnician........................................................................................... 32

5.2.1. Cleaning the heat exchanger and the pipe unit ................................................................................................... 32

5.2.2. Shutting the stove dovn (end of season) ............................................................................................................ 33

5.3. Check of internal components ............................................................................................................................ 34

6. Problems / Causes / Solutions ........................................................................................................................ 35

7. Electrical diagrams ........................................................................................................................................... 37

Declaration of performance and test report ................................................................................................... 39

The full text of the Declaration of Conformity can be found here: https://efulllment-online.com/downloads/

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 3]

IMPORTANT:

●Please read this entire manual before installation and use of this pellet fuel burning room heater.

●Failure to follow these instructions could result in property damage, bodily injury, or even death.

●Save these instructions!

INSTALLER: THIS MANUAL MUST STAY WITH APPLIANCE!

INTRODUCTION

Dear Customer,

Inordertoobtaintheoptimumperformanceofthestoveandtoenjoythewarmthandsenseofwellnessbeing

thatthewarmthoftheamecanspreadinyourhome,werecommendthatyoureadthismanualcarefully

beforemakingtherststart-upofthestove.

Congratulationsagain,foryourchoice,pleasenotethatthepelletstoveMUSTNOTbeusedbychildren,which

shouldalwaysbekeptatasafedistance!

Revisionstothepublication

Inordertoimprovetheproduct,toupdatethispublicationthemanufacturerreservestherighttomakechanges

without notice.

Consultation

●Take care of this manual and keep it in a place of easy and quick access

● Ifthismanualshouldbelostordestroyed,orifstillinpoorcondition,askforacopyfromyourdealer

● Akeytopicorthatrequiresspecialattentionishighlightenedina"boldtext".

Symbols on this manual

WARNING

Thiswarningsymbolindicatesthatyoureadandunderstandthemessagethatisreportedasthe

non-observanceofwhatiswritten,couldcauseseriousdamagetothestoveandputatriskthesafetyof

the user.

INFORMATION

Thissymbolisintendedtoemphasizetheimportantinformationfortheproperfunctioningofthestove.A

failure to comply with the requirements affect the use and operation of the stove will prove unsatisfying.

SEQUENCE OF OPERATIONS

Indicatesasequenceofbuttonstopresstoaccessthemenuormakeadjustments.

INSTRUCTION MANUAL

Indicates you should read this manual or instructions.

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 4]

1. WARNINGS

1.1 SAFETY INSTRUCTIONS

● Installation,electricalconnection,checkthattheinstallationandmaintenanceareperformedonlybyquali-

edandauthorizedpersonal.

●Install the heater according to the regulations of the place, region or state.

● Thisapplianceisnotintendedtobeusedbypeople(includingchildren)withreducedphysical,sensory,

mental, or with limited experience and knowledge, unless they are trained to use the device or supervised

bythepersonwhoisfullyresponsibleforhissecurity.

●For the correct use of the stove and electronic equipment connected to it and to prevent accidents it is

importanttofollowandobserveallindicationsandinformationandinstructionsreportedinthismanual.

● Theuse,regulationandsettingsmustbecarriedoutbyanadult.Errorsorbadsettingscancausehazar-

dous conditions and / or erratic operation.

● Beforestartinganyoperation,theuseroranyonewhoisabouttooperateonthestovemusthavereadand

correctlyandcompletelyunderstoodtheentirecontentsofthisinstructionbooklet.

● Thestovemustbeintendedsolelyforthepurposeforwhichitisintended.Anyotheruseisconsideredim-

properandthereforedangerousunderthefullresponsibilityofthosewhomakeimproperuse,andtherefore

void with immediate effect a guarantee thereof.

●Do not use the stove as a ladder or support structure.

●Do not put towels on the stove to dry.

● Anyclothesorsimilarmustbekeptataspecicdistancefromtheheater,duetopossiblerehazard.

● AnyliabilityformisuseoftheproductissolelyresponsibleanddesignraisesGracefromallcivilandcrimi-

nalresponsibility;

● Anytypeofunauthorizedtamperingorsubstitutionofnon-originalpartsofthestovecanbedangerousto

the operator safety and lifts manufacturer from all civil and criminal.

● Mostofthesurfacesareveryhot(door,doorhandle,frontdoorglass,uepipes,etc..).Itistherefore

necessary to avoid contact with these parts without adequate protective clothing or special thermal protec-

tion, such as gloves and thermal protection systems devices such as "cold hands", not supplied with this

ovenandcompleteresponsibilityanddiscretionoftheenduser.

● Explaincarefullythedangertotheelderly,disabledandparticularlychildren,keepingthemawayfromthe

stove during operation.

● Itis'forbidden'tooperatethestovewiththedooropenorwithbrokenglass.

● Donottouchthestovewithwethands,beinganelectricalappliance.Alwaysremovethepowercordbefore

opening.

●Before performing any cleaning or maintenance work make sure, in advance, to disconnect the heater from

themainsbyunpluggingthepowercable.

● Incaseofreinthechimney,turnoffthestove,pleasedisconnectfromthenetworkandneveropenthe

door. Then call the appropriate authorities.

● Thestovemustbeelectricallyconnectedtoanetworkwithgroundeddischargefacility.

● Thestovemustbeconnectedtoanelectricalnetworkappropriatelysizedtotheelectricpowerofthestove.

● Incorrectinstallationorpoormaintenance(non-conformingtotheinformationinthisbooklet)cancause

damagetopersons,animalsorthings.Inthiscasemanufacturerisrelievedofanycivilorcriminalliability.

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 5]

1.2 OPERATING INSTRUCTIONS

●Turn off the heater in case of failure or malfunction.

● NEVERmanuallyloadthepelletintotheburner.

● Theaccumulationofunburnedpelletsintheburnerafterrepeated"misre"mustberemovedbefore

proceeding with a new ignition.

●Do not wash the inside of the stove with water.

●Do not wash the stove with water. Water may enter the unit and damage the electrical insulation, causing

electric shock.

● Donotexposeyourbodytohotairforalongtime.Donotoverheattheroomwhereyouarestayingand

wherethestoveisinstalled.Thiscandamagethephysicalconditionandcausehealthproblems.

● Donotexposetodirecttheowofhotairplantsoranimals.Itcouldhaveharmfuleffectsonplantsor

animals.

● DonotuseotherfuelotherthanDINPLUSCertied-ÖNORMwoodpellets.

● Installthestoveinasuitablelocationwhichhasavailableallnecessaryfacilitiesrequiredsuchasrepre-

ventionfacilitiesandallnecessaryutilitiesareavailablesuchas-butnotlimited-powersupplies(airand

electric) and exhaust fume, in conformity with the provisions in force.

● Thestorageofthestoveandtheceramiccoatingmustbestoredinadryandhumidityfreepremises.

● Itisrecommendedtoplacethestovedirectlyontheoor,andwhereasthisoorismadeofammable

materials, in this case it is required to isolate properly.

● Neverturnonanyheaterwithammablematerialsintheeventoffailureoftheignitionsystem.

INFORMATION

● Incaseofanyproblems,getintouchwithyourdealer,oraqualiedauthorisedengineer,andifarepairis

necessary, insist on the use of original spare parts.

● Useonlythefuelrecommendedbymanufacturer(forItalypelletswithadiameterof6mmandforother

European countries with a diameter of 6-8 mm) and provided only with an automatic supply system.

● Periodicallycheckandcleanthesmokeoutletducts(connectiontotheuepipe).

● Accumulatedunburntpelletsintheburnerafterrepeatedfailedignitionsmustberemovedbefore

1.3 IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE PRODUCT IN ACCORDANCE WITH

EC DIRECTIVE 2002/96/EC

Attheendofitsworkinglife,theproductmustnotbedisposedofasurbanwaste.

Itmustbetakentoaspeciallocalauthoritydifferentiatedwastecollectioncenterortoadealerprovidingthis

service.

Disposingofaapplianceseparatelyavoidspossiblenegativeconsequencesfortheenvironmentandhealth

derivingfrominappropriatedisposalandenablestheconstituentmaterialstoberecoveredtoobtainsignicant

savings in energy and resources.

As a reminder of the need to dispose of appliances separately, the product is marked with a crossed-out

wheeleddustbin.

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 6]

2. THEORETICAL NOTIONS FOR THE INSTALLATION

2.1 PELLETS

Thepelletisobtainedbyprocessingthesawdustproduced

duringworkingwoodandtimber(driedwoodandpaintfree).The

compactnessofthematerialisguaranteedbytheligninwhichis

contained in the wood itself and allows the production of pellets

withouttheuseofgluesorbinders.

The market offers different types of pellets with characteristics

thatvarybasedonmixturesofwoodused.Thediametervaries

between6and8mm,withastandardlengthbetween5and30

mm. The pellets of good quality has a density ranging from 600

to more than 750 kg/m3with a water content that is maintained

between5%and8%ofitsweight.

Inadditiontobeinganenvironmentallyfriendlyfuel,asyoupush

thelimitsofwoodresiduesresultinginacleaner-burningthan

that produced with fossil fuels, the pellets also have technical

advantages.Whileagoodwoodhasacaloricvalueof4.4kW/kg

(15%RH,after18monthsofseasoning),thepelletis4.9kW/kg.

Toensuregoodcombustion,andnopowerproblems,itisimpera-

tive that the pellets are stored in a dry place, protected from dirt,

and the thermo stove is placed in a place where the conditions

arethesame,nottogeneratethesametypeofproblemsonthe

power pellets in the tank. The pellet is usually supplied in 15 kg

bags,sostorageisveryhandy.

Agoodqualitypelletensuresgoodcombustionloweringharmful

emissions into the atmosphere.

If the fuel is poor, the more often cleaning inside the grate and the combustion cham-

ber will be required.

ThemaincerticationsofqualityforpelletsintheEuropeanmarketareDINplusandÖNormM7135;these

ensure respect of:

● Caloricpower:4.9kW/kg

● Watercontent:max10%ofweight

● Percentageofashes:max0,5%ofweight

●Diameter: 5 - 6 mm

●Length: max 30 mm

● Contents:100%untreatedwood,withnoaddedbondingsubstances(barkpercentage5%max)

● Packaging:insacksmadefromecologicallycompatibleorbiologicallydecomposingmaterial

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 7]

Nemaxxstronglyrecommendsusingcertiedfuelinitsstoves(DINpluseÖNormM7135).

Theuseoffuelofinferiorqualityornotconformingtothespecicationgivenabovecompro-

mises the running of your stove and can therefore lead to the termination of the guarantee

andofthemanufacturer'sresponsibilityfortheproduct.

Nemaxx pellet stoves run exclusively on pellets with a diameter of 6 mm (only for Italy) and 6-8 mm

(European countries) with lengths that go from 5 mm to 30 mm.

2.2 PRECAUTIONS FOR INSTALLATION

IMPORTANT!

Installationandassemblyofthestovemustbecarriedoutbyqualiedpersonnel.

Thestovemustbeinstalledinasuitablepositiontoallowthenormaloperationsofopeningandordinary

maintenance.

Thesitemustbe:

● capableofprovidingtheenvironmentalconditionsforoperation

● equippedwithpowersupply230V50Hz

● capableoftakinganadequatesystemforsmokedischarge

●provided with external ventilation

●provided with an earth connection complying with IEC standards

Thestovemustbeconnectedtoauepipeoraninternalorexternalverticalductconformingtocurrentstan-

dardsUNI7129-71319615.Thestovemustbepositionedinsuchawaythattheelectricalplugisaccessible.

The stove must be connected to a ue pipe or a vertical duct which can discharge the fumes at the hig-

hest point of the building. The fumes are however derived from the combustion of wood products and

if they come into contact with or close to walls, they can make dirty marks. Also take care because the

fumes are very hot but almost invisible, and can cause burns on contact. The holes for the passage of

the smoke pipe and for the intake of air from outside should be made before positioning the stove unit.

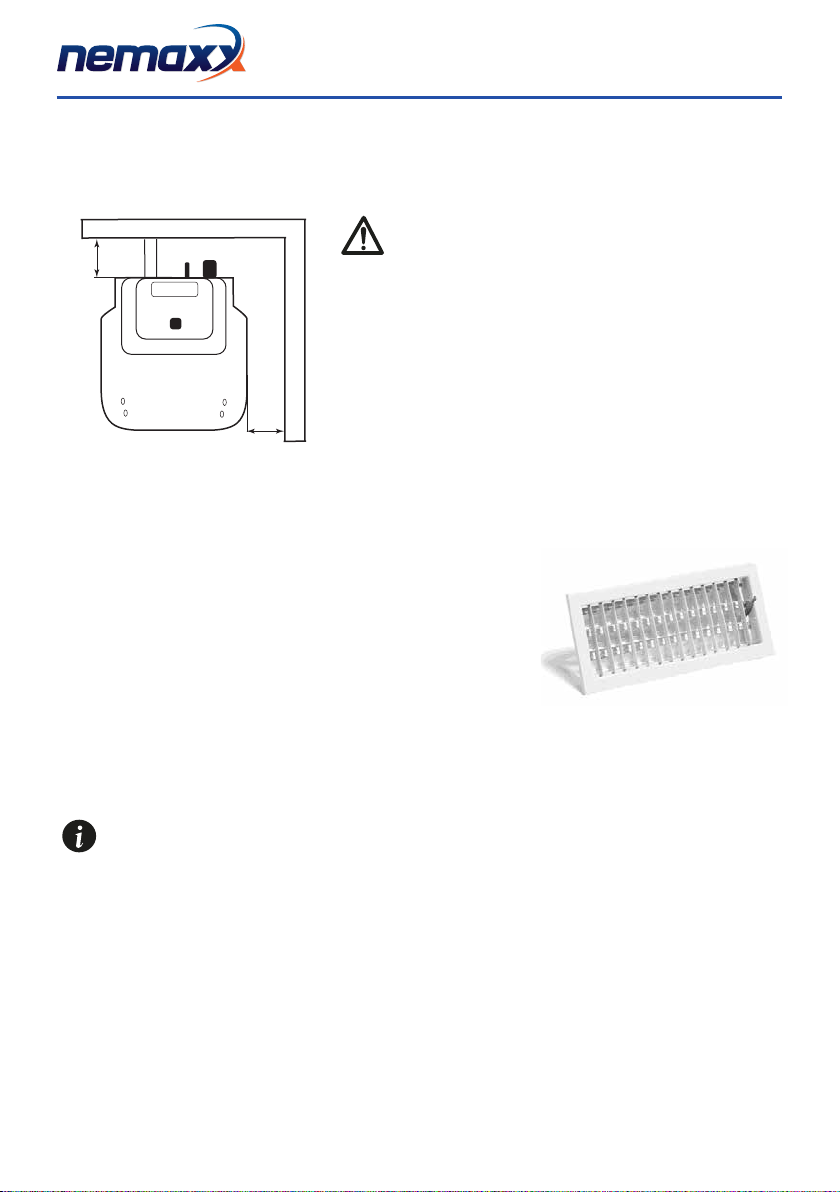

2.3 OPERATING ENVIRONMENT

IMPORTANT!

Forproperoperation,andauniformdistributionoftemperature,

thestoveshouldbeplacedinalocationwithanairowthat

guaranteestheairneededforcombustionofthepellets(should

beavailableapproximately40m3/h) according to the installation

and the second regulations in the country.

Thevolumeoftheenvironmentmustnotbelessthan30m3.

The air must enter through permanent openings on the walls

(near the stove) with a minimum of 100 square centimeters.

Theseopeningsmustbemadesothattheycannotbeobstructed

inanyway,andallowproperairow.Aircanalsobetakento

ventilateroomsadjacentprovidedtheyareequippedwithairhose

andarenotusedasabedroomandbathroom,orwherethereis

100 cm2

20 cm

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 8]

norehazardsuchas:garages,sheds,storageofcombustiblematerials,etc.,strictlycomplyingwiththe

requirementsundercurrentrules.Itisabsolutelyprohibitedtoinstallationthestoveinbedrooms,bathrooms,

andwhereitisalreadyinstalledanotherdheatingdevicewithoutadequateairow(replace,stove,etc.).

Itisexpresslyprohibitedtheplacementofthestovein

environmentswithexplosiveatmospheres.Theoorof

theroomwherethestovewillbeinstalledmustbesized

appropriately to support the weight of the stove itself (which

shouldbeconsideredinadditiontotheweightofthemachine

saidthesameloadmustbeaddedamaximumof60kgforthe

pellets, and 80 kg for water). When installing, keep a minimum

distancefromobstaclesandnotammable(B)of20cmtherear

to, lateral (LR) of 20 cm and anterior (C) of 80 cm. In the presence

ofobjectsbelievedtobeparticularlysensitivesuchasfurniture,

curtains, sofas, carpets, etc., greatly increase the distance of the

stovefromthem.Inthepresenceofwoodenooroor-prepare

the plan and in accordance with rules in force in the country, on

reprevention.

A

B

2.4 CONNECTION TO THE EXTERNAL AIR INTAKE

It is essential that the room where the stove is installed, the stove can

availofanairowinsufcientquantityasitisrequiredbytheregular

combustionequipmentandventilation.Thiscanbedonebymeansof

permanentopeningsonthewallsthatgivetheroomtobeventilatedto

the outside, ventilation ducts or through individual or collective. Within

this scope, the outer wall near the stove must have an opening minimum

100 cm2,protectedbyagridinsideandoutside.

The air intake must also:

●becommunicatingdirectlywiththeinstallationenvironment

●beprotectedbyagrate,wiremeshorothersuitableprotection,provideditdoesnotreducetheminimumsection.

●positioninasuitablemannerastopreventitfrombeingobstructedinanyway

It is prohibited to connect the air directly to the stove (communicating directly from the out-

side), to avoid compromising thermodynamic performance, however it is required that the

conditions still guarantee about 50 m3/h of air replacement, as provided in the current UNI

10683.

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 9]

2.5 CONNECTION OF SMOKE DISCHARGE PIPE

Whenmakingtheholefortheuepipeitmustbetaken

intoaccountthepossiblepresenceofinammable

materials. If the hole has to go through a wood wall or

otherthermolabilematerial,theinstallerMUSTusethe

Industrial insulated pipe (with min thermal conductivity

of 0.07 W/m°K). The same applies if the stove pipe

mustgoverticalorhorizontalsectionsremainnear

(min.20cm)toaheat-labilewall.

Thecombustionchamberworksindepression,sothe

exhaustductfortheexhaustfumeswillbelinkedto

depressionwheneffectivechimneyasprescribed.

It should always use pipes and ttings with

appropriate seals to ensure airtightness in

order to avoid possible harmful CO fumes

into the environment.

All sections of the exhaust duct must be

inspectable and removable to allow for

periodic cleaning of the interior, which is necessary

for the proper functioning of the system (T-piece

with inspection). Position the stove strict accordan-

ce with all regulatory requirements and attention to

highlighted date

All changes direction 90 degrees of the ue gas channel must be prepared if possible, with the appro-

priate ttings to "T" with inspection. It is absolutely forbidden to use a net at the end of the hose as it

can cause serious problems for the proper and safe operation of the stove.

In connection do not use the chimney sections of pipe horizontally, but always the same place at an

angle of 5° minimum to rise, possibly avoiding the use of a 90-degree (you can use up to 3) and use

preferably 45° curves. It is recommended to not use a total length of the pipe diameter 80 mm, greater

than 6 m in total.

IMPORTANT!

2 - 3 m max

3-5%

H > 4 m

H > 1,5 m

example of pellet stove installation

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 10 ]

2.6 CONNECTION TO THE CHIMNEY

The chimney must have inside dimensions of no more

than cm. 20X20 or 20 cm diameter. In the case of

larger or poor condition of the chimney (ie: cracks, poor

insulation, etc.) it is recommended to insert stainless

steeltubeinthechimneyofaofsuitablediameterfor

its entire length, to the very top. Check with suitable

instruments that there is a minimum draft. Gua-

ranteed 15 Pa. Atthebottomofachimneyinspection

forperiodicinspectionandcleaning,whichmustbe

done annually. You must ensure that a chimney top is

installed according to regulations for wind force.

This type of connection must guarantee of 15

Pa, allows the correct discharge of smoke with

a natural draft even if there is no electricity.

1. Windproof cowl

2. Flue pipe

3. Inspection

The external pipe must have minimum internal

dimensions of cm. 10X10 or 10 cm diameter. cm,

and maximum. 20X20 or 20 cm diameter. Check with

appropriate tools that there is a draw of 10 Pa. It must

useonly,andonlypipesinsulated(doublewall)within

thesmoothstainlesssteel(stainlesssteelexibletubes

arenotallowed)xedtothewall,toprevent,and/or

minimizecondensationproblems.Atthebottomof

the outer vertical duct an inspection tap for periodic

inspectionsandcleaningtobedoneannually.Youmust

ensure that the chimney is installed according to wind

force.

This type of connection, even in case of mo-

mentary power failure, ensuring the evacuation

of the fumes.

1. Windproof cowl

2. Flue pipe

3. Inspection

2.7 CONNECTION TO AN EXTERNAL FLUE PIPE WITH ISOLATED OR DOUBLE WALL

1

2

3

0,5 m

1

2

3

0,5 m

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 11 ]

Theconnectionbetweenstoveandchimneyoruefor

theproperoperationmustnotbelessthan5%slope

inthehorizontalsectionswhosetotallengthshould

notexceed1.5meters.andtheverticalbya"T"to

another(changingdirection)mustnotbelessthan1.5

meters.Checkwithsuitableinstrumentsthatthereisa

minimumdraft.of10Pa.Atthebottomofthechimney

inspected for periodic inspections and cleaning, which

mustbeconducted annually.

You must ensure that a chimney is installed according

to wind force.

This type of connection, even in case of mo-

mentary power failure, ensuring the evacuation

of the fumes.

1. Windproof cowl

2. Flue pipe

3. Inspection

2.8 CONNECTION TO THE FLUE PIPE

3

2

1

0,5 m

3 - 5 %

2 - 3 m max

H > 1,5 m

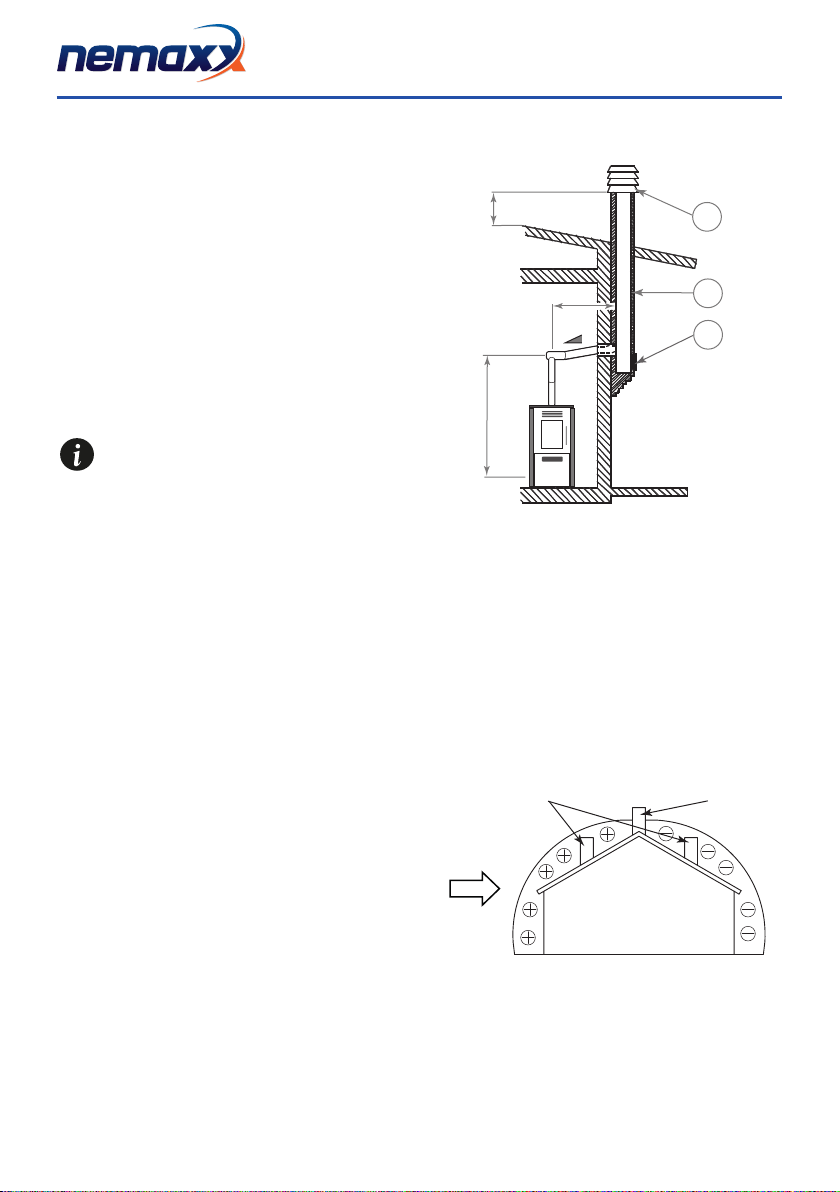

2.9 OPERATING PROBLEMS CAUSED BY DRAUGHT DEFECTS IN THE FLUE

Of all the meteorological and geographical factors that

affecttheoperationofaue(rain,fog,snow,altitude

abovesealevel,periodofinsulation,exposuretothe

cardinal points, etc.) the wind is certainly the most de-

cisive.Infact,besidesthethermaldepressioncaused

bythedifferenceintemperaturebetweentheinside

and the outside the chimney, there is another type of

depression (or overpressure): the dynamic pressure

inducedbythewind.Anascendingwindalwayshas

the effect of increasing depression and then the draft.

Ahorizontalwindincreasesdepressionforproperins-

tallation of the chimney. A descending wind always has

the effect of relieving depression, sometimes inverting

it. In addition to the direction and force of the wind, the

positionoftheueandthechimneyfromtheroofofthe

house and the surrounding landscape is important.

+= HIGH PRESSURE ZONE

-= LOW PRESSURE ZONE

A= LESS FAVOURABLE POSITION

B= MOST FAVOURABLE POSITION

AB

WIND

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 12 ]

Thewindaffectstheoperationofthereplacealsoindi-

rectlybycreatingzonesoverpressureanddepression

aswellastheoutsidebutinsidethehome.Inareas

directly exposed to the wind (2) can create an internal

overpressure which can promote the draft of stoves and

replaces,butmaybecounteredbyexternaloverpres-

sure if the chimney is placed on the side exposed to the

wind (1). In contrast, in areas opposite to the direction

of the wind (3) can create a dynamic depression that

comes into competition with the natural thermal depres-

siondevelopedbythereplace,butcanbecompensa-

ted(sometimes)byplacingtheexhaustductfromthe

side opposite to the direction of the wind (4)

1

23

4

1-2 = ZONE IN OVER PRESSURE

3-4 = ZONE IN DEPRESSION

WIND

The operation of the pellet stove is noticeably sensitive to the conformation and position of the ue

which is adopted. Hazardous conditions can only be overcome by suitable setting-up of the stove

carried out by qualied personnel.

IMPORTANT!

The connection of the stove to the hydraulic system must be made ONLY by qualied personnel and

can perform the installation in "ART" and in compliance with all statutory and regulatory provisions

in force and not in the country of installation. If the installation of the stove requires interaction with

another existing facility complete with another heater (gas boiler, gas boiler, oil boiler, etc...), is recom-

mended for more qualied personnel who can then be challenged to answer the Full compliance of the

system, per the applicable law, and issuing the certicate. Nemaxx disclaims any liability for damage

to persons or property or in the event of failure or improper operation, if not complied with the above

warnings, and issued the necessary certicates of compliance enforcement work in an appropriate

manner. It is absolutely necessary that the network is designed properly sized to dispose of all the heat

ux produced by the stove to avoid raising the temperature inside the boiler.

IMPORTANT!

2.10 HYDRAULIC CONNECTION

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 13 ]

3. INSTALLATION AND ASSEMBLY

3.1 DRAWINGS AND SPECIFICATIONS

3.1.1 Dimensions of hydro stove

69 mm

546,0 mm

603,0 mm

1074,0 mm

1017,5 mm

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 14 ]

3.1.2 Technical data sheet

Model Nemaxx PW18

Ratingvoltageandfrequenzy V/HZ 230V/50Hz

Maximum water pressure Bar 1.5

Electronic consumption MAX W / H 380

COemissionat13%oxygen(mg/m3) Max mg / m3185

COemission3%oxygen(mg/m3) Min mg / m3250.1

EfciencyMax % 93.9

EfciencyMin % 92.4

Heat area m3280

Rating power Max / Min kW 18 / 10

Rating power (water) Max / Min kW 12.5 / 6.1

Thermal power to the environment Max / Min kW 4 / 3.9

Ø pellet mm 6

Length of pellet mm 30

Hopper capacity kg 40

AutomaticburningtimeMax/Min H 18 / 11

Weight kg 150

Size(WxHxD) mm 545x1017x682

Ø Air outlet pipe mm 80

Temperature of the smoke output Max / Min °C 89.5 - 80

Flue draught pressure Pa 0.1 - 15

Product data sheet in accordance to regulation EU 2015/1186 Annex IV ProduktdatenblattgemäßVerordnungEU2015/1186AnhangIV

Name or trademark supplier Nemaxx

Model Nemaxx PW18

Energyefciencyclass A+

Direct heat output in kW 5.4

Indirect heat output in kW 16

EEIEnergyEfciencyIndex 123

Usefulenergyefciencyatnominalheatoutputin% 90,8

Usefulenergyefciencyatminimumheadoutputin% 93,3

Specialprecautionsforassembly,installationor

maintenance of the room heater

●Before commissioning, please read and strictly follow the operating instructions

● Thereprotectionandsafetydistancestocombustiblebuildingmaterialsmust

becomplied!

● Thecombustionchambermustalwaysbeabletosupplysufcientcombustion

air.Airsuckingsystemscaninterferewiththecombustionairsupply!

● Heaterswithwatertechnology/boilerstovesmayonlybeputintooperationif

allsafetyequipmentisreadyforoperationandfunctional!

●Use only permited fuels

● Theproductmaynotbechanged

● Theproductmustbecleanedregulary

● Allinstructionsandrulesinthemanualinstructionsmustbeobserved.

AllthedatashavebeenmeasuredusingapprovedpelletsincompliancewithENISO17225-2.

Comply with the warnings and instructions concerning installation and routine maintenance provides in this manual

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 15 ]

3.2 PREPARATION AND UNPACKING

Openthebox,unloadthestovefromtheplatformwithextremecaution,andplacethedesiredlocation,making

sure that it complies with the requirements.

Thebody,orblockshouldalwaysbehandledexclusivelybytruckinanuprightposition.Youshouldpay

particularattentiontothedooranditsglasstobeshieldedfromshocksthatmightcompromisetheirintegrity.

However,thehandlingoftheproductsmustbedonewithextremecaution.Unpackthestovenearthearea

whereitwillbeinstalled.

The materials that make up the package are neither toxic nor harmful, thus do not require special disposal pro-

cesses. So, the storage, disposal or recycling is eventually complete recovery from the end user in accordance

withapplicablelaws.

Donotstorethereplaceandcoveringswithouttheirpackaging.

Positionthestove,inthecorrectpositionthatrespectsfaithfullyaspreviouslydescribedabove,andproceed

with the connection to the chimney.

Ifyouconnectyourstovetoadischargepipethatrunsthroughthebackwall(totakeinthechimney)pay

extreme caution not to force the entrance in any way.

Iftheueofthestoveisforcedorimproperlyusedtoliftorplacedintoposition,itwillcompromisebeyond

repair,theoperation,andmanufacturerisnotconsideredinanywayresponsibleforsuchamaladroitand/or

neglect in the work, so in these conditions any Recovery operations are excluded from warranty.

3.3. HYDRAULIC CONNECTION DIAGRAM

A1 = Heating water delivery 3/4" M

A2 = Heating water return 3/4" M

C=Safevalve3bar-1/2"F

Ø 50 Ø 80

102

191

89 546 262 197 175

430

331 331

A

B

C

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 16 ]

3.3.1 CONNECT TO THE SYSTEM

Carry out the connections to the connections illustrated in the diagram corresponding to the previous page

takingcaretoavoidtensioninthepipeandundersizingofthepipes.

IT IS NECESSARY TO PROVIDE THE PROPER CLEANING THE WHOLE SYSTEM BEFORE YOU

CONNECT THE STOVE TO ELIMINATE WASTE AND DEPOSITS

IMPORTANT!

C

D

A

B

A = TAP

B = DOMESTIC SYSTEM

C = PRESSURE DISCHARGE

D = FLEXIBLE PIPES

Always install the heater upstream of the valve gate valve to isolate the same water system or move it move

it if necessary, to perform routine maintenance and / or extraordinary. Connect the heater hoses for not using

theover-constrainthestovetoallowtheplantandthelightshifts.Thepressurereliefvalve(C)mustalwaysbe

connectedtoadrainhose.Thepipemustbesuitabletowithstandthehightemperatureandpressure.

3.3.2 FILLING THE WATER NETWORK

Toloadoftheheater,theheatermustbeequippedwithatap(optional)withanon-returnvalve(D)inorderto

manuallyllthenetwork,youcanusetheloadtapalreadyontheboileronthestove.

Duringthatoperation,theoutletofanyairinthesystemisguaranteedbythepresentautomaticventunderthe

top. To guarantee that the valve discharges air, it is recommended to loosen the grey tap and leave the red tap

locked(refertog.).

Grey plug loosened

- 1 turn

Redplugblocked

Vent valve under the top

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 17 ]

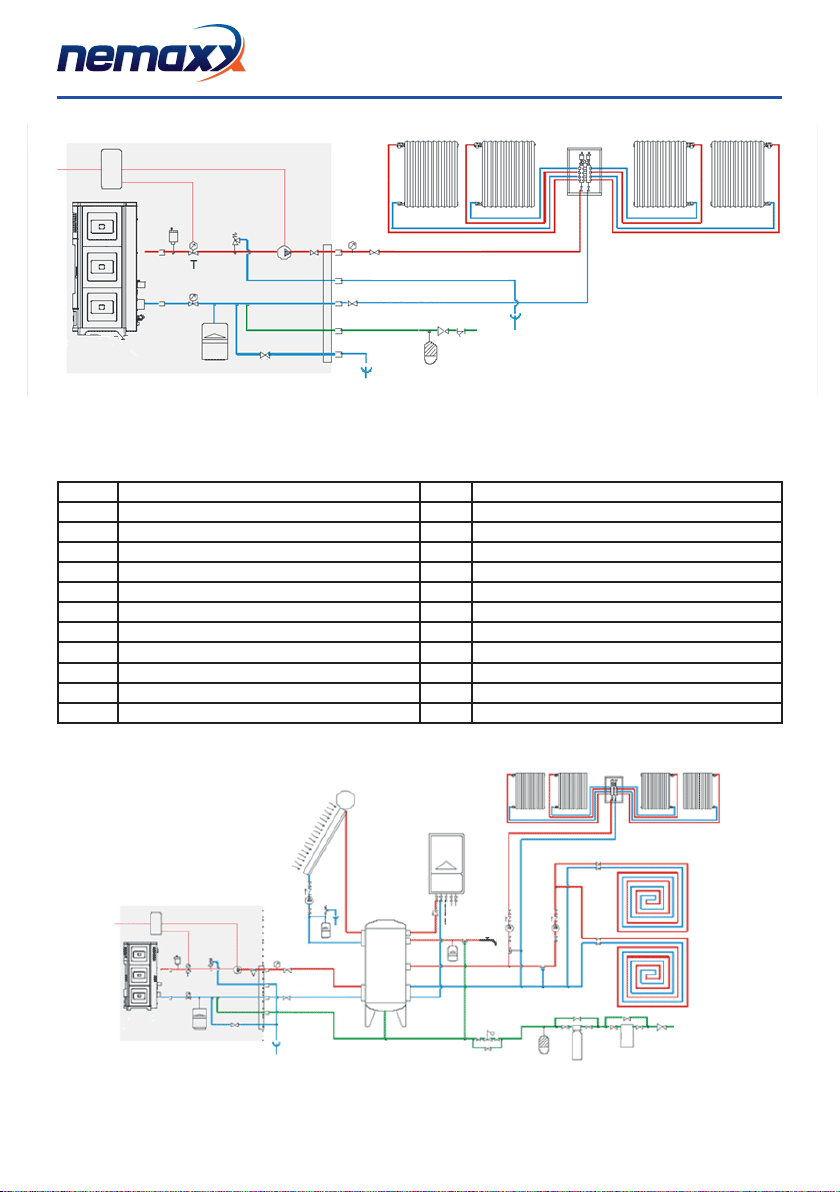

3.5. EXAMPLE OF INSTALLATION DIAGRAMS

Thediagramsbelowaremerelyindicative.Foraproperconnection,alwaysfollowthenotesoftheplumbingandheatinginstallerwith

proven experience. The hydraulic system must meet the mandatory regulations of the place, region or state. The installation, testing and

certicationofoperationmustbeperformedonlybyauthorizedpersonnel,withtheissueofcerticationthattheworkhasbeencompleted

in a "state of art" performance, attesting the conformity of the work in compliance with laws and regulations. The manufacturer disclaims

anyresponsibilityincaseofnon-compliancetotheabove,especiallyintheabsenceofproofofcerticationworkina"STATEOFART"

execution.

3.5.1 INSTALLATION DIAGRAM FOR HEATING SYSTEM WITH DOMESTIC HOT WATER KIT (SUITE/CLUB/MUSA)

SE Electronic card VD One-way valve

SAutomativ vent TMeasurement of boiler temperature

M Pressure gauge VE Expansion tank 1.5 bar of 6 l.

VS Vent valve 3 bar W3-way motorized valve

VValve SC Plate heat exchanger

P Pump F Flow switch

C Mezhane gas boiler A Pounding absorber

B Boiler RP Pressure reduction valve

BA Storage boiler VSC Boiler / system discharge valve

RA Radiators FIT System lter

PR Radiant panels ADD Softener

PS Solar panels

The lling pressure during cold status should be 1 bar.

If during operation the system pressure drops (due to evaporation of the gas dissolved in water) to values less than the

minimumindicatedabove,theUsershall,actingonthevalvefromtheloadbacktotheinitialvalue.

Foroptimaloperationofthestoveinoperation(hot),theboilerpressuremustbe1.5bar.Donotexceed2bar.Attheendof

theoperationalwaysclosethellingtap.

3.3.3 WATER CHARACTERISTICS

Thecharacteristicsofthewaterforllingtheplant,areveryimportanttoavoidthedepositionofmineralsandthecreationof

depositsalongthepipingwithintheboilerandheatexchangers.Therefore,itisadvisedtocheckwithyourplumber/tterthe

following characteristics:

● Hardnessofwatercirculatinginthesystemtoremedyanyproblemsandlimestonedepositsespeciallyinthehotwater

heat exchanger. (> 25° French)

●Installing a water softener (if the water hardness is > 25° French)

● Fillthesystemwithtreatedwater(demineralized)

●Any set of a circuit condensation.

● Installationofhydraulicshockabsorberstoavoidthephenomenonof"waterhammer"alongthettingsandpipes.

For those with very large systems (with large water content) or who require frequent replenishment of the plants in

the plant to install water softeners, especially because the scale signicantly reduce the thermal conductivity!

3.3.4 KIT WATER PRODUCTION

AllthermostovesareequippedwithHANKSkitfortheproductionofhotwatercharacterizedby:

●Plate heat exchanger

●3-way diverter valve, electric motor-driven

●Electrical Flow meter

● Stainlesssteelnnedpipesandttingsforconnecting

●Pressure valve

Thekithasthetaskofheatinghotwaterfromthewaterlineofthehouse.Atatimewhenthereishotwaterdemandbyopeningatap,

theinternalow-metercommandsthedivertervalvetoconveythehotwatercontainedinsidetheboiler,totheplateheatexchanger.

Thehotwatertemperaturewilldependentonthewatertemperatureinsidetheheater,withapproximation,iscalculatedbyremoving

10°-15°Ctothevaluereadonthecontrolpaneloftheheater(boilerwatertemperature).Forproperlifetimeoperationoftheheat

exchangerplates,itisnecessarytoknowthehardnessofyourwatertopreventfouling,andtoblocktheexchange.

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 18 ]

Conguration: stare/ego/suite/club/musa/ with domestic hot water kit system of system with closed tank only

for heating by means of radiators

SYSTEM DELIVERY

PRESSURE SAFETY DISCHARGE

SE

SYSTEM RETURN

SYSTEM REFILL

SVS P

V

MV

V

T

VE Vsc

RP

RA RA

RARA

AFlt

3.5.2 HEATING INSTALLATION IN COMBINATION WITH A STORAGE TANK

SE Electronic card VD One-way valve

SAutomativ vent T Measurement of boiler temperature

M Pressure gauge VE Expansion tank 1.5 bar of 6 l.

VS Vent valve 3 bar W3-way motorized valve

VValve SC Plate heat exchanger

P Pump F Flow switch

C Mezhane gas boiler A Pounding absorber

B Boiler RP Pressure reduction valve

BA Storage boiler VSC Boiler / system discharge valve

RA Radiators FIT System lter

PR Radiant panels ADD Softener

PS Solar panels

Conguration: stare/ego/suite/club/musa/ without domestic hot water kit combined with storage system of system with boiler

and solar panels. System diagram with closed tank for heating with radiators or radiant panels and for the production of

domestic hot water.

PERFORMANCE: HEATING WITH STORAGE SYSTEM PRODUCTION OF DOMESTIC HOT WATER WITH STORAGE SYSTEM

230V 50Hz

230V 50Hz

RA RA

RARA

SYSTEM DELIVERY

PRESSURE SAFETY

DISCHARGE

SYSTEM RETURN

SYSTEM

REFILL

SE

SVS P

T

M

V

VE

Vsc

PS

BA

C

A Add Flt

RP

PR

PR

HOT DOMESTIC

WATER OUTLET

COLD DOMESTIC

WATER INLET

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 19 ]

3.5.2 HEATING INSTALLATION DIAGRAM IN COMBINATION WITH A BOILER

SE Electronic card VD One-way valve

SAutomativ vent T Measurement of boiler temperature

M Pressure gauge VE Expansion tank 1.5 bar of 6 l.

VS Vent valve 3 bar W3-way motorized valve

VValve SC Plate heat exchanger

P Pump F Flow switch

C Mezhane gas boiler A Pounding absorber

B Boiler RP Pressure reduction valve

BA Storage boiler VSC Boiler / system discharge valve

RA Radiators FIT System lter

PR Radiant panels ADD Softener

PS Solar panels

PERFORMANCE: HEATING WITH STOVE. PRODUCTION OF DOMESTIC HOT WATER WITH BOILER.

Conguration: stare/ego/suite/club/musa/ without domestic hot water kit combined with boiler. Heating with strage production

of domestic hot water with storage system.

COLD DOMESTIC

WATER INLET

HOT DOMESTIC

WATER OUTLET

SYSTEM DELIVERY

SYSTEM RETURN

SYSTEM REFILL

PRESSURE SAFETY DISCHARGE

Version: 2.0

KEN002PW18 25.11.2019

[ EN ● 20 ]

4. OPERATIONS INSTRUCTIONS - QUICK REFERENCE GUIDE

Start / Stop

Auto / Manual

Power Level

Thermostat Temperature

Start

Stop Automatic

Schedule

Power

Level

Skip the process

to stablition

Thermostat

Temperature

Check

Temperature

Press

Start/Stop

Display turns on so you

can change settings with

other buttons

Display turns off after 10

seconds of inactivity

Press &

hold 3

seconds

Start Up Process

commences

Press &

hold 3

seconds

Shutdown Process

commences

Press &

hold 3

seconds

Increase or

decrease the

set point

Press Pellet

Feed Rate

to cycle

through P1,

P2, P3 or P4

Press to

toggle

between

Auto and

Manual

Press to show

current room

temperature

(R)

Press to show

current

Exhaust

temperature

(S)

Press to show

current

Protectiontem-

perature

(P)

Table of contents

Languages:

Other Nemaxx Stove manuals