NOR INS REV 5 Nov 2017

!

Glass

If the glass is blackened by soot it can be easily cleaned using one of the many

specialist stove glass cleaning products available. Glass is not covered by the

manufacturer’s warranty.

Surface

The high temperature paint finish should require no further treatment. Any

damage or wear on small areas of the paint finish may be remedied using our

high temperature aerosol paints. Please read the instructions on the aerosol

carefully before applying.

Installation

Building Regulations Installation of your Norvik stove must comply with all local

building regulations, including those referring to national and European

standards. We advise prior to any installation a full site survey is conducted by

an installation engineer recognised within an industry standard such as NACS

or HETAS to check the suitability of your chimney and appliance. Document J

of the building regulations contains further information regarding the installation

of solid fuel appliances and can be viewed at

http://www.planningportal.gov.uk/uploads/br/BR_PDF_ADJ_2010.pdf

Ventilation

The appliance may require additional air ventilation if required. Any air inlet

grilles should be positioned so that they are not liable to blockage. An air

extraction device shall not be used in the same room as the appliance unless

adequate additional ventilation is provided. Other heating appliances requiring

air for combustion shall not be used in the same room as the appliance unless

adequate additional ventilation is provided. Stoves need a supply of air for

combustion, and to evacuate the flue gases otherwise they will not work.

Without an air supply the stove will not light and smoke is likely to pour out into

the house. The smoke will not be able to be drawn up the chimney as this

requires air movement up through the chimney which is not possible if there is

no source of air. If your stove smokes or does not burn very keenly, but this

improves when you open a window then this is a sign that you need to install

some ventilation. We recommend you discuss your ventilation requirements

with your local Norvik Stove authorised retailer/installer. Any airbricks or grilles

fitted should be positioned so that they are not liable to blockage. If other

appliances requiring ventilation operate within the vicinity of the stove there

must be adequate ventilation provided for both appliances running

simultaneously. NOTE Extractor fans when operating in the same room or

space as the stove may cause problems.

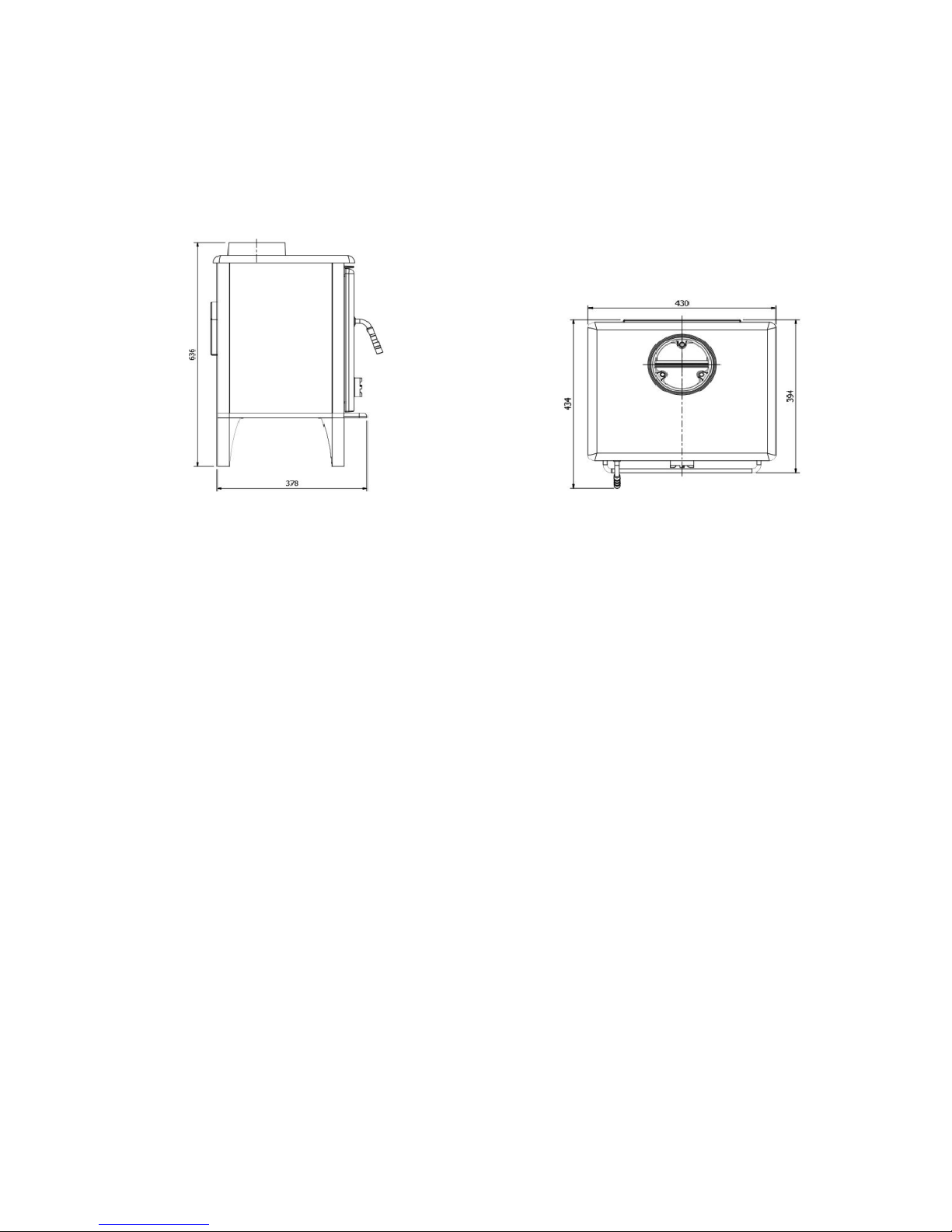

Load-bearing capacity of the floor

Before installing the stove, you must ensure that the load-bearing capacity of

the floor can withstand the weight of the stove and any flue pipes and

connections. The weight of the stove is 80Kgs.