Neslab Steelhead 1 Manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the Thermo / Neslab Steelhead 3 CHX at our website: Click HERE

Instruction and Operation Manual

Thermo Manual P/N U00206

Rev. 06/11/04

STEELHEAD 1 CE97

30°C to 130°C

Stainless Steel

Heat Exchanger

w/ M DIC MM RS-485 (CHX)

Serial Communication

Model 620099991707

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

STEELHEAD HEAT EXCHANGER

PREFACE

Compliance ........................................................................................................ 2

Nameplate Data ................................................................................................. 2

Unpacking ........................................................................................................... 2

After-sale Support ............................................................................................... 2

SECTION I SAFETY

Warnings ............................................................................................................. 3

Material Safety Data Sheets ............................................................................... 3

SECTION II GENERAL INFORMATION

Description..........................................................................................................

Specifications .....................................................................................................

SECTION III INSTALLATION

Site ...................................................................................................................... 5

Electrical Requirements ..................................................................................... 5

Safety Control Requirements ............................................................................. 5

Plumbing Requirements .................................................................................... 6

Facility Water Requirements .............................................................................. 6

Fluids .................................................................................................................. 6

Front Panel Gauges ........................................................................................... 7

Front Panel Controls ........................................................................................... 7

Low Profile Membrane Key Functions ................................................................ 9

LED Indicators .................................................................................................... 10

Controller Loops ................................................................................................. 12

Error Messages .................................................................................................. 15

MODICOMM RS- 85 (CHX) ................................................................................ 16

Serial Communication Specifications ................................................................ 16

SECTION IV OPERATION

Pre Start Up & Filling Requirements .................................................................. 18

Start Up & Shut Down ......................................................................................... 19

Changing a Value ............................................................................................... 20

Remote Operation .............................................................................................. 20

Temperature Control .......................................................................................... 21

Flow Control ........................................................................................................ 21

Flow Monitors ...................................................................................................... 21

Low Level Monitors ............................................................................................. 21

Resistivity and Temperature Sensor .................................................................. 21

SECTION V PREVENTATIVE MAINTENANCE

Service Contracts ................................................................................................ 22

General Guidelines ............................................................................................ 22

Daily Preventative Maintenance .......................................................................... 2

Fluid Inspection/Draining ................................................................................... 25

Fluid pH ............................................................................................................... 25

Stainless Steel Particulate Filter ........................................................................ 26

Barnstead DI Filter .............................................................................................. 26

Culligan DI Filter ................................................................................................. 27

Pump Motor Ball Bearing Lubrication ................................................................ 27

Reservoir Cleaning ............................................................................................. 27

SECTION VI TROUBLESHOOTING

Facililitization Problem Troubleshooting ............................................................ 28

Error Message Troubleshooting ........................................................................ 30

SECTION VII DIAGRAMS

Flow Diagram ..................................................................................................... 33

Fork Lift Channel Dimensions ........................................................................... 3

Wiring Diagram ................................................................................................... 35

APPENDIX A

Remote Electronic Interface ............................................................................... A-1

APPENDIX B

Quick Start Up Procedures ................................................................................. B-1

APPENDIX C

Using the AMAT Heat Exchanger Configuration Touch Screen ......................... C-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 2 -

Preface

Com liance

This product has been tested and found to be in compliance with the require-

ments defined in the EMC standards defined by 89/33 /EEC as well as Low

Voltage Directive (LVD) 73/23/EEC and the Machinery Directive 93/44/EEC .

The testing has demonstrated compliance with the following directives:

LVD, 73/23/EEC Complies with UL 3101-1:93 and IEC 1010-1

EMC, 89/33 /EEC EN 55011, Class A Verification

IEC 1000-4-2:1995 Electro-Static Discharge

IEC 1000-4-3:1994 Radiated Elecromagnetic Field

IEC 1000-4-4:1995 Conducted Electrical Fast Transient/Burst

93/44/EEC Machinery Directive

For any additional information refer to the Letter of Compliance that shipped

with the unit (Declaration of Conformity).

Name late Data

MODEL: STEELHEAD 1 PHASE: 3/PE 4WIRE

FREQUENCY: 50/60 HERTZ

FULL LOAD AMPS: 23/25

HEATER: 6KW 208VOLTS PUMP: 3.0 HP

LARGEST LOAD HEATER 16.7 AMPS

INTERRUPT CAPACITY: 10KA PER EN60898

10KAIC W/MAX 120 AMP FUSE PER UL1077

MASS: 385LBS 174KG

ELECTRICAL DIAGRAM: 6.3259

Un acking

Retain all cartons and packing material until the unit is operated and found to

be in good condition. If the unit shows external or internal damage contact the

transportation company and file a damage claim. Under ICC regulations, this is

your responsibility.

After-sale Su ort

Thermo Electron Corporation is committed to customer service both during and

after the sale. If you have questions concerning the operation of your unit,

contact our Sales Department. Before calling, please refer to the serial number

label on the rear of the unit to obtain the following information (see Section II,

Description for serial number label location):

- unit BOM number__________________________________

- unit serial number _________________________________

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 3 -

Section I Safety

Warnings

Make sure you read and understand all instructions and safety precautions

listed in this manual before installing or operating your unit. If you have any

questions concerning the operation of your unit or the information in this

manual, please contact our Sales Department (see After-sale Support).

Performance of installation, operation, or maintenance procedures

other than those described in this manual may result in a hazardous

situation and may void the manufacturer's warranty.

Transport the unit with care. Sudden jolts or drops can cause damage.

Do not attempt to move the unit without proper lifting or moving e uip-

ment serious injury can occur.

Do not lift unit by the filter.

Observe all warning labels.

Never remove warning labels.

Never operate damaged or leaking e uipment.

Never operate the unit without fluid in the reservoir.

Always lock the main circuit breaker in the OFF position, turn off the

unit and disconnect the power supply from the power source before

performing any service or maintenance, or before moving the unit.

Never operate e uipment with damaged power cords.

Refer service and repairs to a ualified technician.

Some circuits in the enclosure will remain energized even with the line

cord disconnected. Control voltages will be present. If repairs are

authorized inside the enclosure, the main power and 15-pin plug must

be removed from the unit.

In addition to the safety warnings listed above, warnings are posted

throughout the manual. Read and follow these important instructions. Failure

to observe these instructions can result in permanent damage to the unit,

significant property damage, or personal injury or death.

Material Safety

Data Sheets

Ethylene Glycol Union Carbide Chemicals and Plastics Company Inc.

Industrial Chemicals Division

39 Old Rid ebury Road

Danbury, CT 06819-000

307-744-3487

Teflon® Paste Hercules Chemical Company

Passaic, NJ 07055-7398

1-800-221-9330

De-Ox Anti-Oxident Ilsco

4730 Madison Road

Cincinnati, OH 45227

513-871-4000

If you have Internet access, you can access numerous MSDS forms via the EPA

Chemical Substances Database.

Cornell Univ. has ~325,000 on line searchable MSDS at

http://www.pdc.cornell.edu/issearch/msdssrch.htm

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 4 -

S ecifications

Temperature Range

Reservoir Volume

Unit Dimensions

(Outer Envelope)

(H x W x D)

Frame Dimensions

(H x W X D)

Cooling Capacity1

Heating Capacity2

Flow 3

Pressure

5 Gallons

19 Liters

8KW @ 5.0 GPM Facility Water Flow Rate

KW @ 208V

8.0 Gallons/Minute

30.3 Liters/Minute

30 to 0 PSI - 130 PSI Max

1. 22°C facility water with 2 - 8 GPM process water flow rate. 8°C or greater difference

between process water and facility water.

2. 39 watts per s uare inch.

3. 15 meters from unit through 3/8 inch ID hose. Flow split e ually between flow channels.

30°C to 130°C

Section II General Information

Descri tion

The heat exchanger system consists of a thermal fluid recirculating system

which provides a constant fluid flow. A second loop consists of a facilities

water loop which recirculates through a plate heat exchanger for fluid cooling.

A kilowatt heater is located in the fluid recirculating system.

The recirculating fluid loop has a deionizing package with a replaceable

cartridge and a 20 micron particulate filter with a replaceable filter element. A

small plate heat exchanger is used to cool the fluid entering the deionizing

cartridge.

Throughout the manual, you will be asked to consult the units serial number label for

specific information. The label is located on the right of the control box.

32 x 203/8 x 313/8 Inches

812.8 x 517.5 x 79 .9 Millimeters

28½ x 20 x 25 Inches

723.9x 508.0 x 35.0 Millimeters

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 5 -

Section III Installation

Site

Locate the unit in a laboratory or clean industrial environment where ambient

temperatures are inside the range of +10°C to +40°C (+50°F to +104°F).

Never place the unit in a location where excessive heat, moisture, or

corrosive materials are present.

Excessively dusty areas should be avoided and a periodic cleaning schedule

should be instituted.

Install the Steelhead unit on a level surface. The unit is equipped with locking

casters on the front left and right rear of the unit to prevent movement. The

unit is also equipped with adjustable leveling feet.

To prevent damage, raise the leveling feet to the full up position when

not in use. Secure the leveling feet by securing the jam nut on the

leveling foot shaft to the case bottom.

The unit is designed to stand alone or can also be stacked with another

Steelhead unit, or a standard AMAT 0 or 1 heat exchanger. See the Fork Lift

Channel Dimension Diagram in Section VII.

Electrical

Requirements

The unit construction provides protection against the risk of electrical

shock by grounding appropriate metal parts. It is the user's responsibil-

ity to assure that a proper ground connection is provided to the unit.

Rated Voltage: 200 to 208VAC, 50/ 0Hz, 3Ø

Rated Circuit: 30Amps

Make sure the voltage of the power source meets the specified voltage, ±10%.

Safety Control

Requirements

EMERGENCY OFF guarded mushroom push-button with pull reset is pro-

vided to turn off the unit in case of an emergency. An EMERGENCY OFF

connector is provided on the top left portion of the rear of the unit to include

the system into the emergency off circuit. An isolated set of normally closed

contacts is provided for the EMERGENCY OFF safety circuit. Contact rating

is 0AMP make and 10AMP break at 24VAC.

The EMERGENCY OFF safety connector receptacle port is part number AMP

20 0 1-1. The mating plug part number is AMP 20 0 0-1 which uses sock-

ets part number AMP 101-1.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- -

Plumbing

Requirements

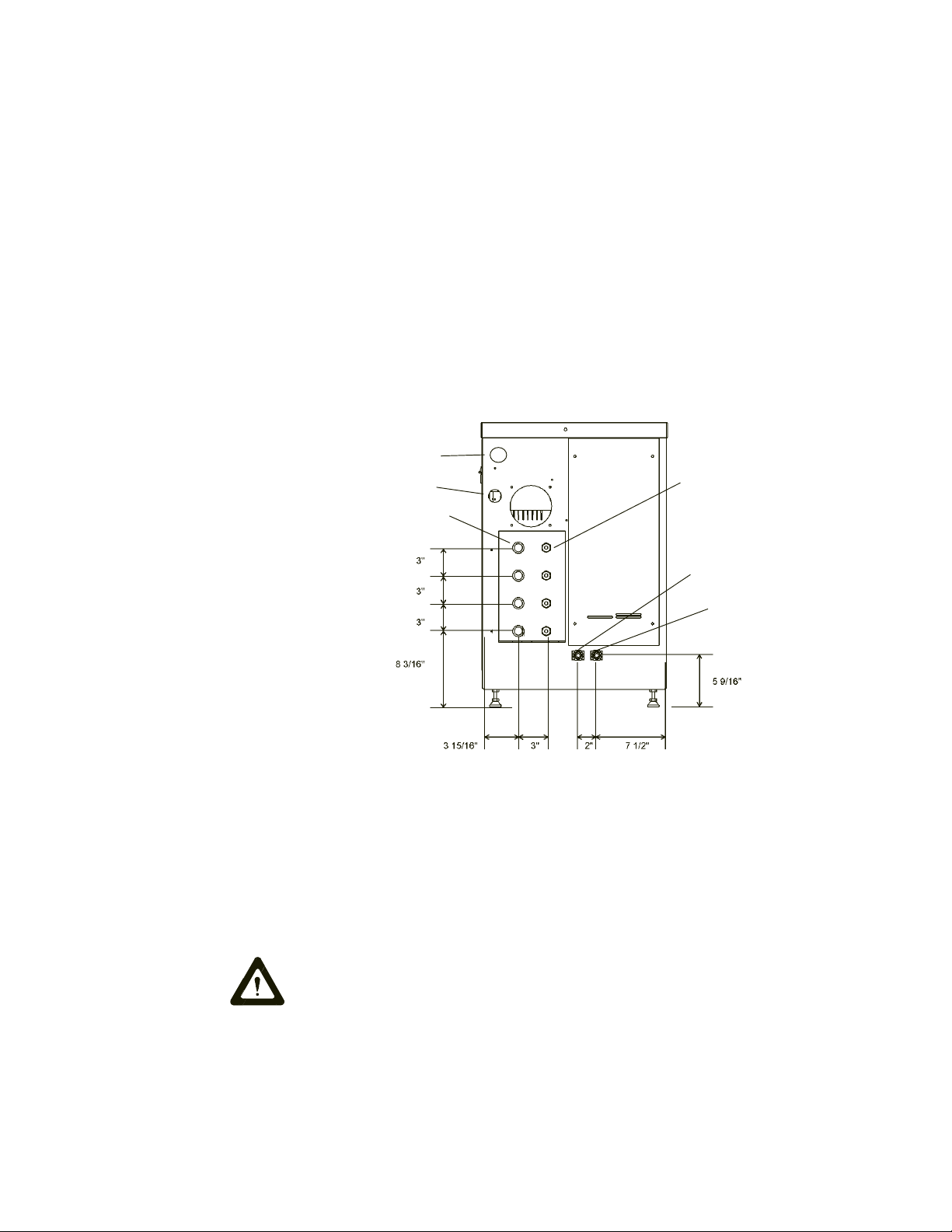

The plumbing connections are located on the bottom rear of the unit and are

labelled THERMAL FLUID CHAMBER #1, #2, #3, #4. The four THERMAL

FLUID SUPPLY (to the tool) connections have ½" quick disconnect nipples.

The four THERMAL FLUID RETURN (from the tool) connections have ½"

quick disconnect couplers.

Keep the distance between the heat exchanger system and your application

as short as possible, and use the largest diameter tubing practical. Tubing

should be straight and without bends. If diameter reductions are needed make

them at the inlet and outlet of your application, not at the heat exchanger

system.

Facility Water Requirements

Facility water inlet and outlet connections are located at the bottom-center-

rear of the unit and are labelled FACILITY WATER. The facility water connec-

tions are 3/8" (Parker push-loc male hose nipples).

Fluids

Never use flammable or corrosive fluids with this unit. Do not use

automobile anti-freeze. Commercial anti-freeze contains silicates that

can damage the pump seals and cause leaks. Use of automobile anti-

freeze will void the manufacturers warranty.

The unit is designed to use a 100% electronic grade ethylene glycol as

the thermal fluid. Change the fluid as required, see Section V.

Facility Water Inlet

Thermal Fluid Return

(from the tool)

Power Inlet

EMO Connector J3

Facility Water Outlet

Thermal Fluid Supply

(to the tool)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 7 -

Front Panel

Gauges

1. Pump Pressure. Reads the pressure at the outlet of the unit.

2. Filter Pressure Gauge. The filter cartridge should be cleaned/replaced

when the gauge reads 1Bar (15psi) more than the pump pressure gauge.

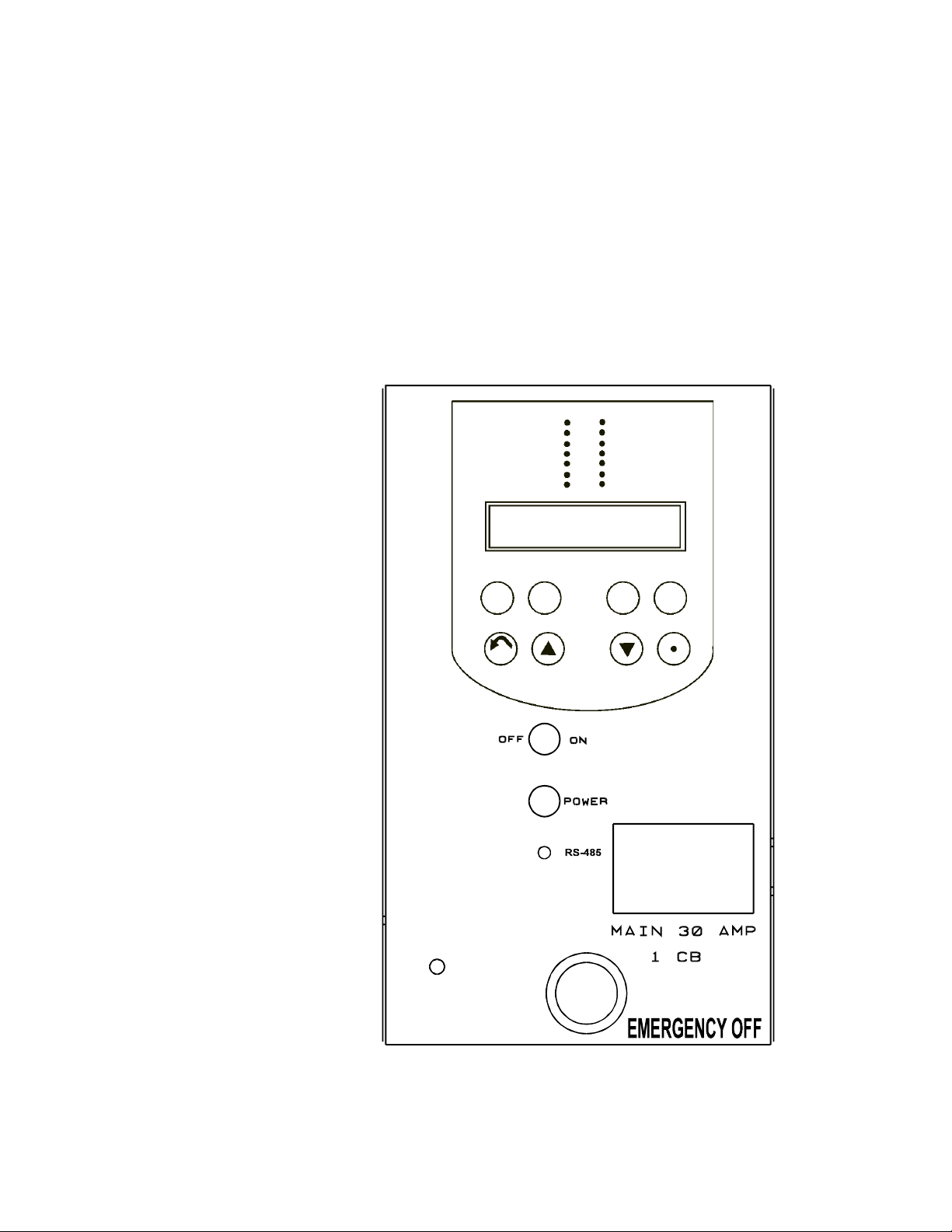

Front Panel

Controls

Main Disconnect Circuit Breaker

30 Amp, 3 Pole 10 KAIC used to locally disconnect main power at the unit.

HEAT ENABLE

COOL

PUMP

LOCAL

REMOTE

FLUID LEAK

LEVEL FAULT

EXT SENSOR

LOW FLOW

ADD FLUID

FILTER

BREAKERS

HIGH TEMP

HEAT

ON/OFF LOC/REM INT/EXT RESET

NEXT YES NO ENTER

RS485

HIGH TEMP

RESET

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 8 -

Pad Lock - Lockout

When the unit is not in use or is being serviced, the Pad Lock - Lockout

should be used. The lockout requires a padlock with a ¬ diameter shackle.

POWER - Amber

The POWER light indicates that the main disconnect circuit breaker is on,

power is available, and the control and secondary circuit breakers (in the

electrical enclosure) are on.

RS485

The RS485 light indicates that the serial communication mode (MODICOMM/

RS485) is active. The light flashes each time a query is received.

ON/OFF

Turning the ON/OFF rotary switch to the ON position enables the unit. The

controller illuminates and runs a diagnostic test, and then the unit enters the

standby mode.

Turning the ON/OFF rotary switch to the OFF position disables the unit.

NOTE: The machine circuit is interlocked to the electrical enclosure so the

removal of the panel will turn off the unit and the controller.

HEATER HIGH TEMPERATURE MANUAL RESET

The HEATER HIGH TEMPERATURE MANUAL RESET button allows the

heater high temperature switch to be reset once the temperature is below the

Heater High Temperature setting.

Resetting the button will automatically start the unit if the unit is in the

ON mode.

J1

DB-15 Female Connector. J1 connects to the standard AMAT 5000 Heat

Exchanger Interface. See Appendix A for connector and pinout information.

Supplying the wrong voltage to any of the remote interface pins can

seriously damage the controller. Verify that the cable is plugged into the

correct port on the AMAT tool before beginning remote operation.

J2

DB-9 Female Connector. J2 connects to an approved AMAT temperature

probe for external temperature control, display and temperature feedback

signal.

J4 & J5

DB-9 Female Connectors. Configured for RS485 and MODICOMM Serial

Communication Protocol.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 9 -

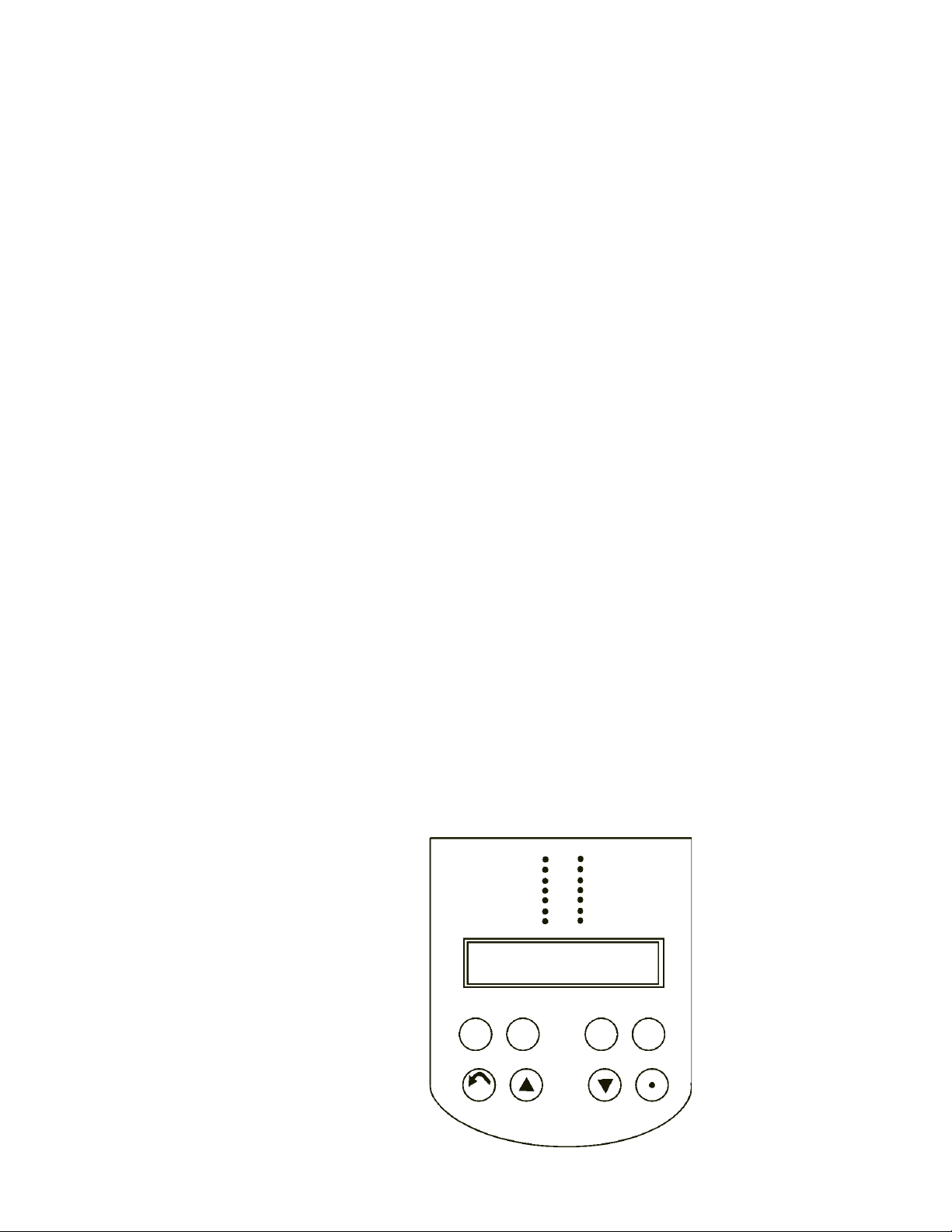

Low Profile Membrane

Key Functions

ON/OFF

The ON/OFF key toggles the controller from on to off and vice versa. The

controller will not switch to the ON mode unless proper conditions exist inside

the unit. See Error Messages in this section.

LOC/REM RS485

The LOC/REM RS485 key toggles the unit from local to remote to RS485

operation. The RS485 mode is serial communication.

INT/EXT

The INT/EXT key switches between the internal and external RTD probe.

Display #1 will alternate from INT T XXC to EXT T XXC. The control of the

fluid temp will switch from internal RTD probe to the external RTD probe. If

there is no external probe the controller will continue to display and to control

from the internal RTD probe.

RESET

The RESET key will attempt to clear the Add Fluid or Change Filter condition

status.

NEXT

The NEXT key is used to sequence through the controller displays.

YES

The YES key is used to increment values displayed on the controller.

NO

The NO key is used to decrement values displayed on the controller.

ENTER

The ENTER key is used to accept values displayed on the controller.

HEAT ENABLE

COOL

PUMP

LOCAL

REMOTE

FLUID LEAK

LEVEL FAULT

EXT SENSOR

LOW FLOW

ADD FLUID

FILTER

BREAKERS

HIGH TEMP

HEAT

ON/OFF LOC/REM INT/EXT RESET

NEXT YES NO ENTER

RS485

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 10 -

LED Indicators

EXT SENSOR - Amber

When this is lit the controller is using the external RTD probe to control the

fluid temperature and Display #1 EXTT XXXC is shown. When it is not lit the

controller is using the internal RTD probe.

LOW FLOW - Amber

This LED is lit whenever any flow drops below the flow setpoint. Also, when-

ever a low flow condition exists a signal is sent to the tool through P1. The

low flow condition status and LOW FLOW LED is turned off automatically

when the low flow condition returns to above the setpoint, or when the flow is

disabled in the setup mode.

ADD FLUID - Amber

This LED is lit and an add fluid signal is sent to the tool whenever there is

approximately 3¾ gallons left in the tank. The ADD FLUID LED goes out and

the signal to the tool is automatically removed when the add fluid condition is

corrected.

NOTE: When the ADD FLUID LED is on and the digital signal to the tool goes

high (open circuit), fill the unit using the procedures and cautions mentioned

in this manual or equipment damage or safety shut down of the heat ex-

changer could occur.

FILTER - Amber

This LED is lit when the particulate fluid filter has been in service for six

months. This signals the operator to change the filter. The LED goes out and

the filter timer is reset when the RESET key is depressed. NOTE: The RESET

key will not reset the filter timer unless the FILTER LED is lit.

BREAKERS - Amber

This LED is lit whenever the pump circuit breaker or the heater circuit breaker

is tripped. An ERROR message PUMP TRIP or HEAT TRIP will also flash on

the display. The BEAKERS LED will go out and the error message will stop

flashing whenever the error condition is corrected.

A heat breaker trip condition will light the BREAKERS LED and flash the

HEAT TRIP warning message. A heat breaker condition will clear itself

automatically when the condition is corrected.

A pump breaker trip condition will light the BREAKER LED, flash the

PUMP TRIP warning message and turn off the HEAT ENABLE LED. The

BREAKER LED will go out, the PUMP TRIP warning message will stop and

the HEAT ENABLE LED will turn on when the pump breaker trip

condition is corrected.

HIGH TEMP - Amber

This LED is lit whenever a high temperature condition exists. When this

condition is detected the controller turns off the unit and illuminates the HIGH

TEMP LED. When the high temperature condition is corrected press the

heater high temperature reset switch to automatically restart the unit.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 11 -

HEAT - Amber

This LED is on steady when the controller is supplying 100% heat. The HEAT

LED is off when the controller is not supplying any heat. The HEAT LED

flashes when the controller is controlling the temperature inside the heat PID

proportional band.

HEAT ENABLE - Green

This LED is lit whenever the controller is on and conditions are proper for

allowing heat to be supplied to the fluid.

The following conditions are needed for the HEAT ENABLE LED to light.

1. ON/OFF mode must be ON

2. There is no high temperature condition

3. Pump signal on

COOL - Green

This LED is on steady when the controller is supplying 100% cooling to the

fluid. The LED is off when the controller is not supplying any cooling to the

fluid. The LED flashes when the controller is controlling temperature by

cooling inside the cool PID proportional band.

PUMP - Green

This LED indicates the status of the pump control logic.

In the REMOTE mode, the LED is lit whenever the pump on signal from the

tool is on and the controller ON/OFF status is ON. 24VDC must be supplied

to pin 10 of P1.

In either the LOCAL or REMOTE mode, pressing the control ON button will

turn on either the LOCAL or REMOTE LED (whichever has been previously

selected). Pressing the controller ON button again will turn both the LOCAL

and REMOTE LED off.

NOTE: The machine circuit is interlocked to the electrical enclosure so the

removal of the panel will turn off the unit and the controller.

LOCAL - Green

This LED is lit whenever the controller is in the local mode and is off when the

controller is in the remote mode, as selected by the LOC/REM key (ON mode

only).

REMOTE - Green

This LED is lit whenever the controller is in the remote mode and is off when

the controller is in the local mode, as selected by the LOC/REM key (ON

mode only).

FLUID LEAK - Amber

This LED is lit whenever a leak is detected by the controller.

LEVEL FAULT - Amber

This LED is lit when the controller detects two gallons remaining in the tank.

When a low level condition is detected the controller disables the heater and

turns off the HEAT ENABLE LED. Once the condition is corrected it must be

cleared with the RESET key before the heater will be enabled.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 12 -

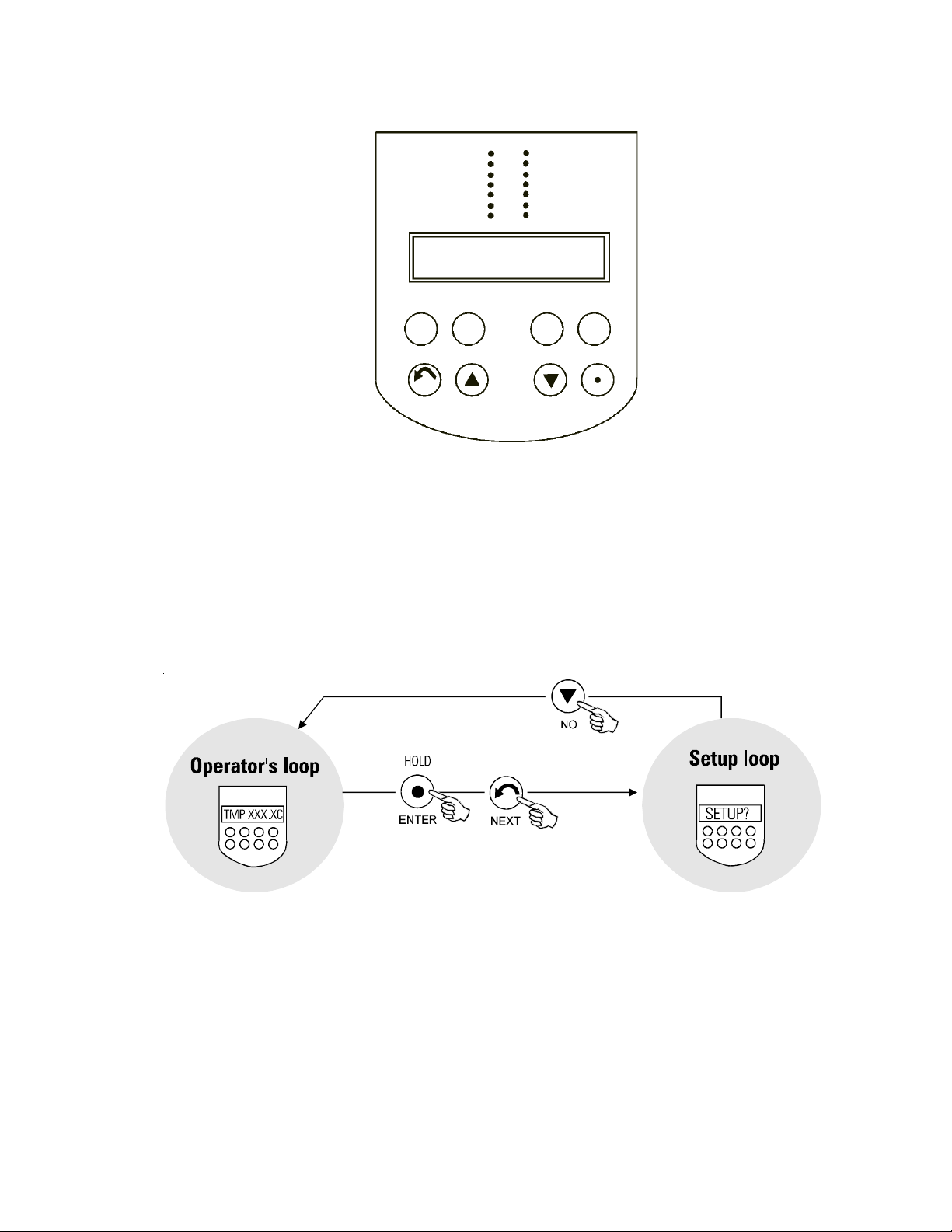

Controller Loo s

Two controller loops allow the operator to display and/or alter different

parameters of the controller. The loops can be accessed from the tempera-

ture display by pressing and holding the key combinations shown on Figure 1

below.

When the controller is first powered up it goes through a short self test and

then enters the Operator's Loop, displaying the reservoir fluid temperature.

HEAT ENABLE

COOL

PUMP

LOCAL

REMOTE

FLUID LEAK

LEVEL FAULT

EXT SENSOR

LOW FLOW

ADD FLUID

FILTER

BREAKERS

HIGH TEMP

HEAT

ON/OFF LOC/REM INT/EXT RESET

NEXT YES NO ENTER

RS485

Figure 1 Changing Loops

See page 14. See page 15.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 13 -

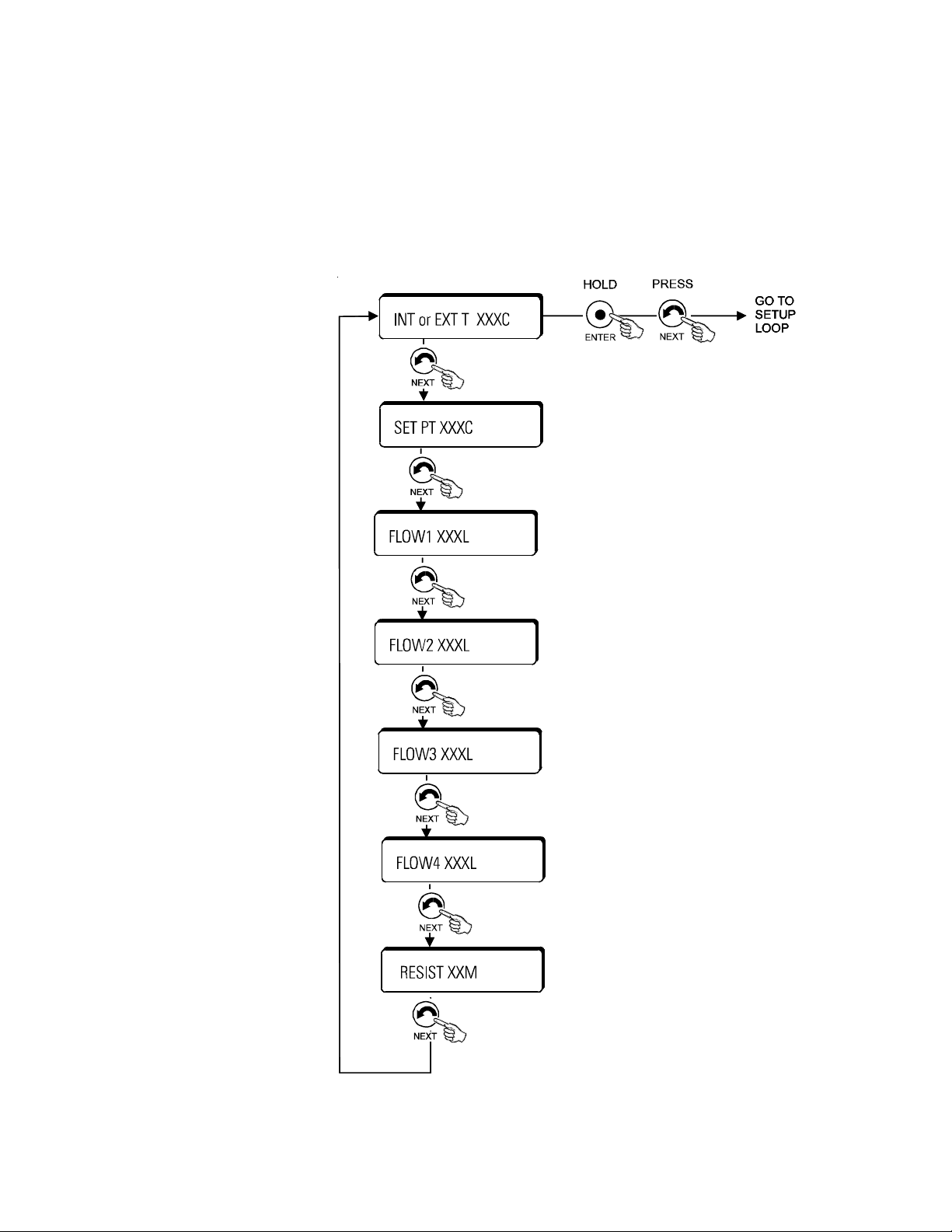

Operators Loop

When the controller is first powered it goes through a short self test and then

enters the Operator's Loop, displaying the reservoir temperature as measured

by either the internal or external RTD probe.

By pressing the NEXT key the controller will step through the menu shown

below.

YES key increments setpoint. NO key decrements

setpoint. See Changing a Value on page 20.

The display will flash while the setpoint is being

changed. The new value is not used by the

controller until the ENTER key is depressed.

Displays the flow rate of the individual circulation

loops in liters/minute. If the flow alarm is set to

zero (see Setup Loop) FLOW OFF will be

displayed instead.

Figure 2 Operator's Loop

This displays the resistivity of the bath fluid in

megohm-cm. Tenths will be display up to 9.9 meg.

10 - 20 meg will not display tenths. Resistivity is

maintained at or above the setpoint.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 14 -

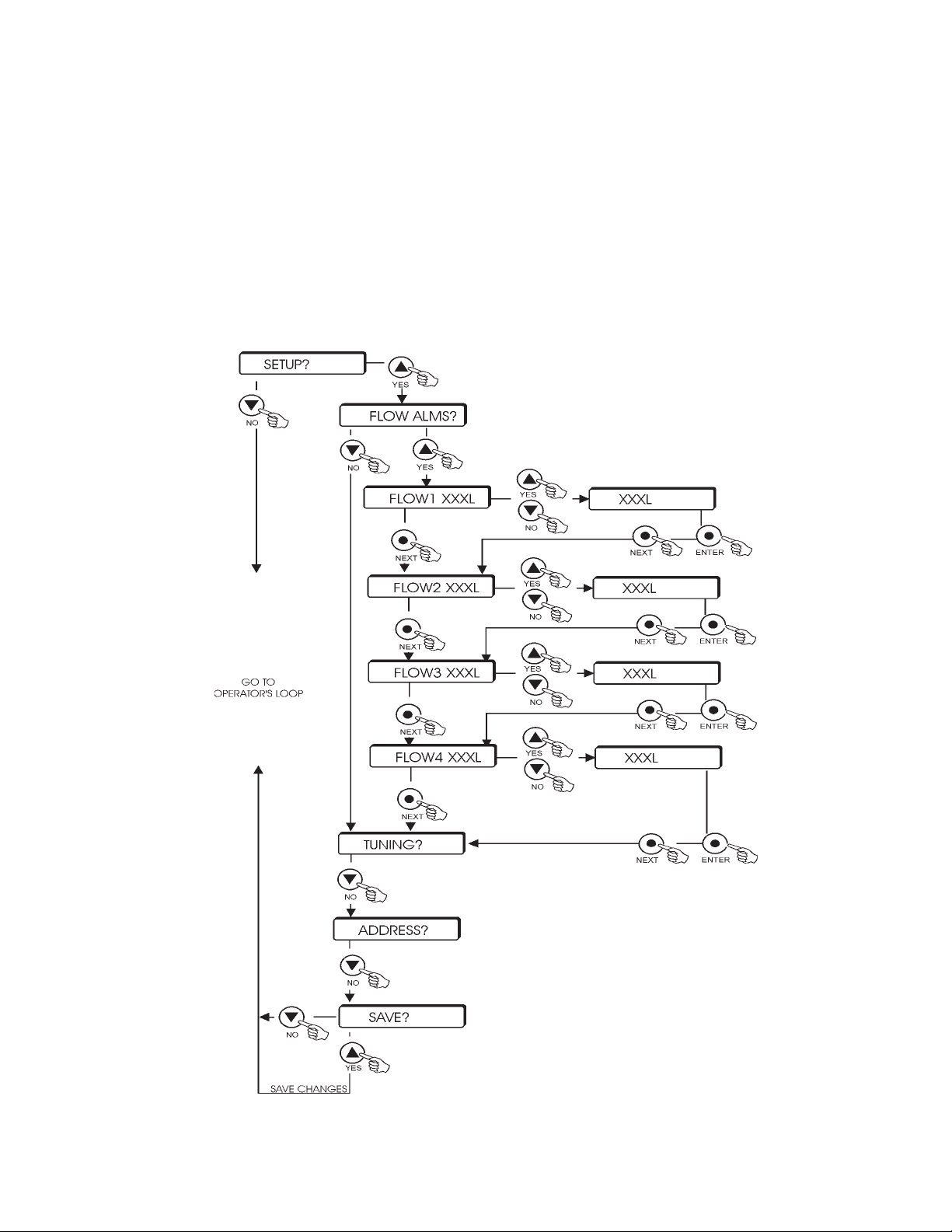

Figure 3 Setup Loop

Setup Loop

The Setup Loop allows the operator to change the flowrate setpoints. To enter this loop you

must be in the Operator's Loop and displaying the temperature. Depress and hold the

ENTER key while pressing the NEXT key. Follow the menu shown in Figure 3.

Each of the four flows can be set independently. The controller compares this value to the

actual flow of the circulation loop. If the actual flow drops below the alarm value, the

controller signals a low flow condition. If the alarm is set to zero, the flow checking for the

circulation loop will be disabled and the operators loop display will display FLOW X OFF.

Adjust values with the UP and DOWN arrows. See Changing a Value on page 20. Press

ENTER then NEXT for the controller to accept each new entry.

Only ualified technicians should change the

TUNING and ADDRESS values. Should you

inadvertently find yourself in either area of the

loop, press the NEXT key until the SAVE?

prompt is displayed. Press NO to abort all

changes. NOTE: This procedure will also restore

the flow alarms to their previous values.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 15 -

ERROR Messages

Error messages are displayed whenever certain conditions are detected.

When this occurs the error message will be displayed by alternating the error

message and the normal display. The keys and menus will perform normally.

All error messages, except for OVER TEMP, disappear when the error

condition is corrected. Corrective action for all error messages is listed in the

Maintenance Section of this manual.

PHASE ERR

This message is displayed whenever the controller senses a phase error or

missing phase coming into the unit. This condition will not allow the controller

to switch to ON.

24V OFF (Remote Mode Only)

This message is displayed whenever the controller looses the 24 volt input

signal from the tool. This signal loss turns off the unit and will not allow the

controller to switch to ON.

PUMP TRIP

This message is displayed whenever the controller senses the pump circuit

breaker has tripped.

PUMP OVRLD

This message is displayed whenever the controller senses a pump motor

overload condition.

HEAT TRIP

This message is displayed whenever the controller senses the heater circuit

breaker has tripped.

PUMP CNTL

This message is displayed whenever the controller senses a pump controller

error condition. This condition causes the heater to be disabled and turns off

the PUMP LED.

HEAT CNTL

This message is displayed whenever the controller senses a heat control

error condition. This condition disables the heater.

RTD FAIL

This message is displayed whenever the internal temperature probe has

failed, i.e. shorted or opened, and the probe is controlling (displaying) tem-

perature at the time of failure. This condition stops heating and cooling but the

pump continues to operate. This condition automatically resets.

OVER TEMP

This message is displayed whenever the controlling temperature, i.e. INT T or

EXT T, goes beyond 140°C. This condition will turn off the heat exchanger.

The unit will be in the standby mode and will not restart until power is cycled

to the controller.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 1 -

MODICOMM RS485 (CHX)

Interface

Author: Applied Materials.

Title: Heat Exchanger Serial Communication.

ID #: 0250-359 5.

Date: 2/28/97.

Revision: A.

Serial Communication

When the controller is in the ON mode, depressing the RS485 local/remote

pushbutton releases control of temperature setpoint to the MODICOMM

(CHX) interface. The interface can also be used to turn the unit on and off.

Outputs are provided for fluid level, fluid flow, resistivity and fluid temperature.

There are also digital outputs for fault summary and warning summary.

Serial Communication

S ecification

Connection Point

The RS-485 connector is a nine pin, metal shell D-connector with female

pins, mounted on the back of the unit with 4-40 threaded jack sockets. J4 and

J5 are connected in parallel to accommodate daisy chain: connections.

RS-485 connector pinout information

Pin 5 Ground

Pin 9 T+

Pin 1 T-

Configuration

Number of heat exchangers per heat exchanger controller 1

Base address (in 4X memory) for the input segment 0

Input segment size 9

Base address (in 4X memory) for the output segment 9

Output segment size

Optional Digital Input Points

Digital Input Point 1 Fluid level fault (1=fault, 0=OK)

Digital Input Point 2 Fluid flow fault (1=fault, 0=OK)

Digital Input Point 3 not used

Digital Input Point 4 not used

Digital Input Point 5 Fuse fault (1=fault, 0=OK)

Digital Input Point -32 reserved

Optional Analog Input Points

Analog Input Point 1 Fluid resistivity, engineering units are MOhm-cm

Analog Input Point 2 Fluid flow rate, engineering units are gpm

Analog Input Point 3-5 reserved

Number of Configurable Digital Input Points. 0

Number of Configurable Analog Input Points. 0

Number of Configurable Digital Output Points. 0

Number of Configurable Analog Output Points. 0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 17 -

Analog range values

These are scaling ranges only. The heat exchanger does not need to meet this range for operation.

Number Name eu_lo eu_hi

REQUIRED INPUT 1 Actual temperature - 0° C 1 0° C

OPTIONAL INPUT 1 Fluid resistivity 0 MW-cm 20 MW-cm

OPTIONAL INPUT 2 Fluid flow rate 0 GPM 10 GPM

REQUIRED OUTPUT Temperature set point - 0° C 1 0° C

Configurable Names NOT APPLICABLE

Configurable Terminology NOT APPLICABLE

Configurable Engineering Units NOT APPLICABLE

Heat Exchanger Controllers 4X memory map

4X Adrs. Description

100 Required Digital Inputs 1..2 (2 used; 14 not used)

101 Required Analog Input 1 (Actual temperature)

102 Optional Digital Inputs 1,2,5 (3 used; 2 not used; 11 reserved)

103 Optional Digital Inputs (1 reserved)

104 Optional Analog Input 1 ( Fluid resistivity)

105 Optional Analog Input 2 (Fluid flow rate)

10 ...108 Optional Analog Inputs (3 reserved)

109 Required Digital Output 1 (1 used; 15 not used)

10A Required Analog Output 1 (Temperature set point)

10B Optional Digital Outputs (1 reserved)

10C...10E Optional Analog Outputs (3 reserved)

Fault Summary (Digital Input Point 1 is the logical OR of these conditions): Fault condition shuts unit down.

Pump circuit breaker open fault

Pump overload fault

Pump TRIAC fault

Fluid major leak fault

Power phase error fault

Fluid low level fault

Fluid high temperature fault

Warning Summary (Digital Input Point 2 is the logical OR of these conditions)

Heater circuit breaker open warning

Heater TRIAC warning

Internal RTD warning

Fluid low flow warning

Reference

Applied Materials Serial Communication Specification No. 0250-359 5, 4/28/97 Rev. A.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 18 -

Section IV Operation

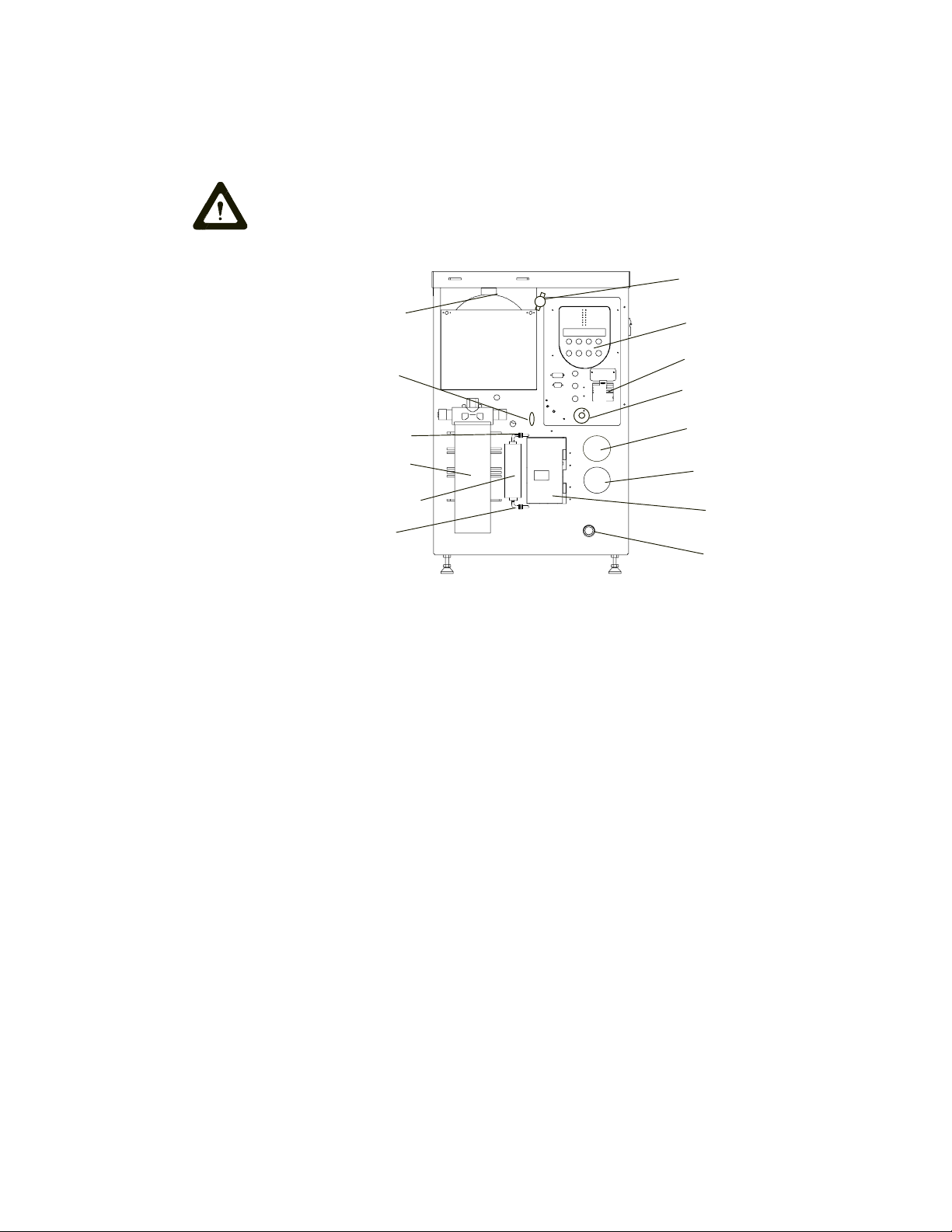

Pre Start U & Filling

Requirements

Whenever removing the fill cap or refilling the unit release any built up

pressure in the reservoir by opening the manual air bleed valve. When

refilling the heat exchanger should be running or the chamber uick

disconnects detached from the unit so fluid will not run back from the

lines or application to the reservoir and create an over-spill condition.

Ensure that the deionizer (DI) cartridge is installed and that the DI flow control

valve is in the OPEN position. NOTE: Use the flow meter, located on the rear of

the unit, to regulate flow control to meet your DI requirements.

Turn the main breaker on and the amber POWER LED will light. Turn the ON/

OFF rotary switch to ON.

Remove the 1¼" filler cap from the top of the reservoir. Using a funnel, carefully

fill the reservoir with recirculating fluid. If the units are stacked, the lower unit

will need a funnel with an extended flexible neck (due to the proximity of the

filter on the upper unit).

NOTE: Immediately stop filling when the ADD FLUID LED extinguishes.

Replace the filler cap on the reservoir. Also, close the manual bleed valve

located to the right of the tank fill fitting.

Depress the RESET button to remove the level fault and extinguish the LEVEL

FAULT LED.

The amount of recirculating fluid needed depends on the total requirements of

your system. Also, if substantial lengths of recirculating lines are used, add

enough fluid to compensate for their volume. The maximum reservoir volume is

5 gallons (19 liters).

NOTE: When refilling, the heat exchanger should be running or the chamber

quick disconnects detached from the unit so fluid will not run back from the

lines or tool to the reservoir to create an over-spill condition.

Control and Display

Filter

Tank Filler Cap

Air Bleed Valve

DI Cartridge

DI Flow Control Valve

Compression Fitting

Compression Fitting

Main Breaker with Lockout

EMERGENCY OFF

Filter Pressure Gauge

Recirculating Supply

Pressure Gauge

Flow Control

Access Door

Drip Pan Drain

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

1

Table of contents

Other Neslab Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Siemens

Siemens 3VA9113-0RL21 operating instructions

Envirotainer

Envirotainer RKN e1 Operation manual

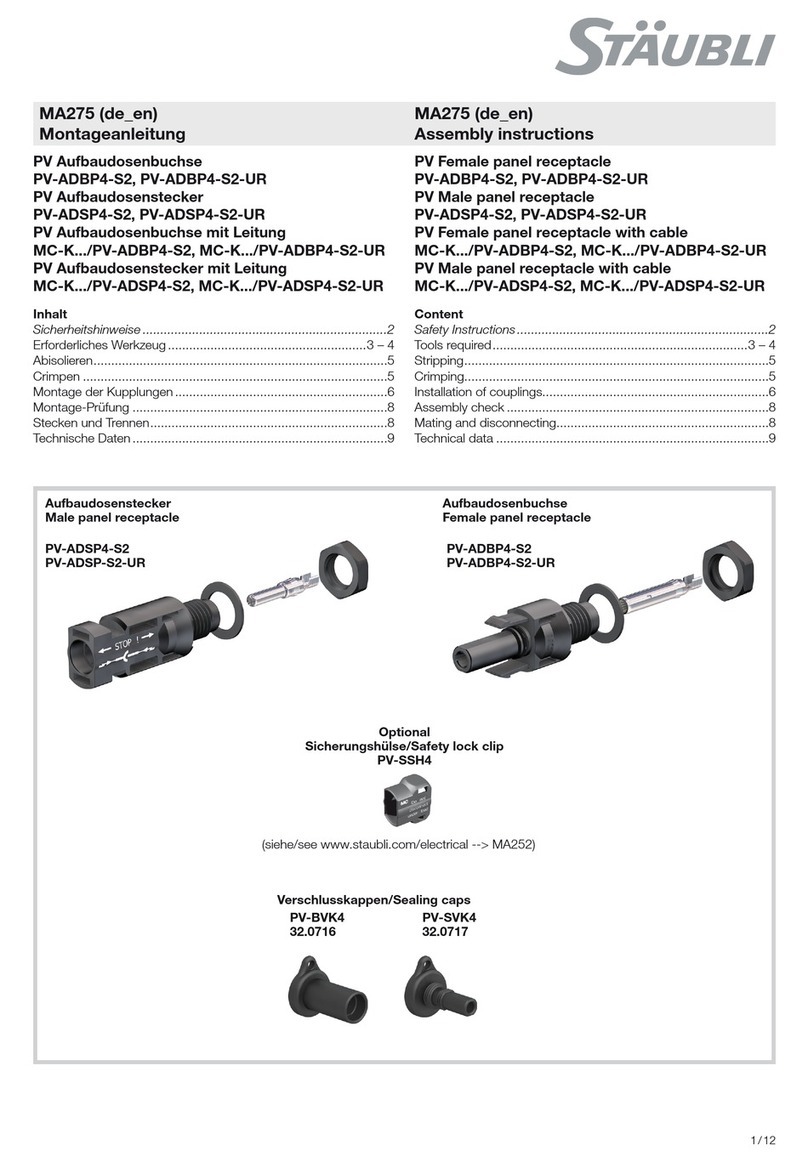

Staubli

Staubli MA275 Assembly instructions

Piranha

Piranha MegaFab P-120 Instructions and parts manual

Pfeiffer Vacuum

Pfeiffer Vacuum FullRange PKR 251 operating instructions

ITW

ITW Tapcon SA27 Operator's safety & operating instruction manual