- 5 -

6 Technical Data

Table 1 Technical Data:

Size

TNM

LG

TKnom.

Pb72

[Nm]

TKmax

Pb72

[Nm]

TKnom.

Pb82

[Nm]

TKmax

Pb82

[Nm]

nmax

[rpm]

82 48 100 75 150 8000

97 96 200 150 210 7000

112 150 310 230 540 6000

128 250 500 380 650 5000

148 390 800 600 1350 4500

168 630 1300 980 1800 4000

194 1050 2000 1650 2400 3500

214 1500 3100 2400 4200 3000

240 2400 4800 3700 6200 2750

265 3700 7500 5800 8300 2500

295 4900 10000 7550 10500 2250

330 6400 13000 9900 14500 2000

370 8900 18200 14000 20000 1750

415 13200 27000 20500 27000 1500

480 18000 36000 28000 66000 1400

575 27000 54000 41000 97500 1200

Table 2

Technical Data RINGFEDER® TNM LG

Size

TNM

LG

d1

max

[mm]

d2

[mm]

d3

[mm]

d4

[mm]

d5

[mm]

d6

h8

[mm]

d7

[mm]

z

num-

ber

l1

[mm]

l2

[mm]

lG

[mm]

L

[mm]

S1

[mm]

S2

[mm]

m

[kg]

82-120 32 40 44,5 108 82 120 6,6 6 16 8 40 68 3,0 12 1,8

97-144 39 50 54,5 128 97 144 9,0 6 20 10 49 83 3,0 14 2,9

112-158 46 60 64,5 142 112 158 9,0 6 22 10 58 95 3,5 15 4,4

128-180 53 70 74,5 160 128 180 11,0 6 25 13 68 109 3,5 16 6,7

148-200 65 90 92,5 180 148 200 11,0 7 28 13 78 124 3,5 18 9,8

168-220 75 100 104,5 200 168 220 11,0 8 34 13 87 142 3,5 21 14,0

194-248 85 115 121,5 224 194 248 13,5 8 38 16 97 159 3,5 24 21,0

214-274 95 130 135,5 250 214 274 13,5 8 42 16 107 175 4,0 26 27,9

240-314 100 145 146,0 282 240 314 17,5 8 45 20 117 192 4,0 30 37,6

265-344 115 160 164,0 312 265 344 17,5 8 50 20 137 220 5,5 33 53,4

295-380 130 170 181,0 348 295 380 17,5 9 52 22 147 236 8,0 37 70,2

330-430 135 200 208,0 390 330 430 22,0 9 56 25 156 252 8,0 40 91,7

370-480 160 235 241,0 440 370 480 22,0 10 62 25 176 281 8,0 43 126,0

415-575 180 270 275,0 528 415 575 26,0 10 65 30 196 306 8,0 45 183,9

480-615 190 320 289,0 568 480 615 26,0 10 65 30 220 330 8,0 45 244,7

575-692 260 400 368 645 575 692 26,0 10 65 30 240 350 8,0 45 370,1

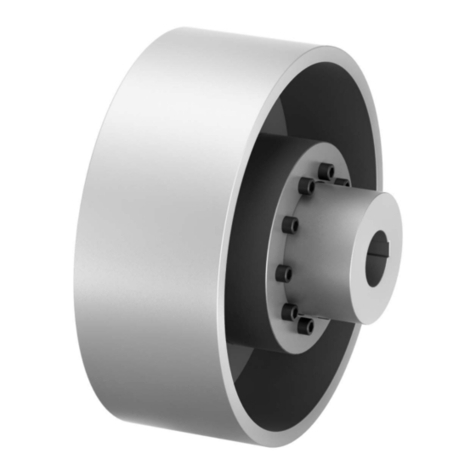

Fig. 2 RINGFEDER® TNM LG

RINGFEDER® TNM LG

BAWN 009-GBR-1