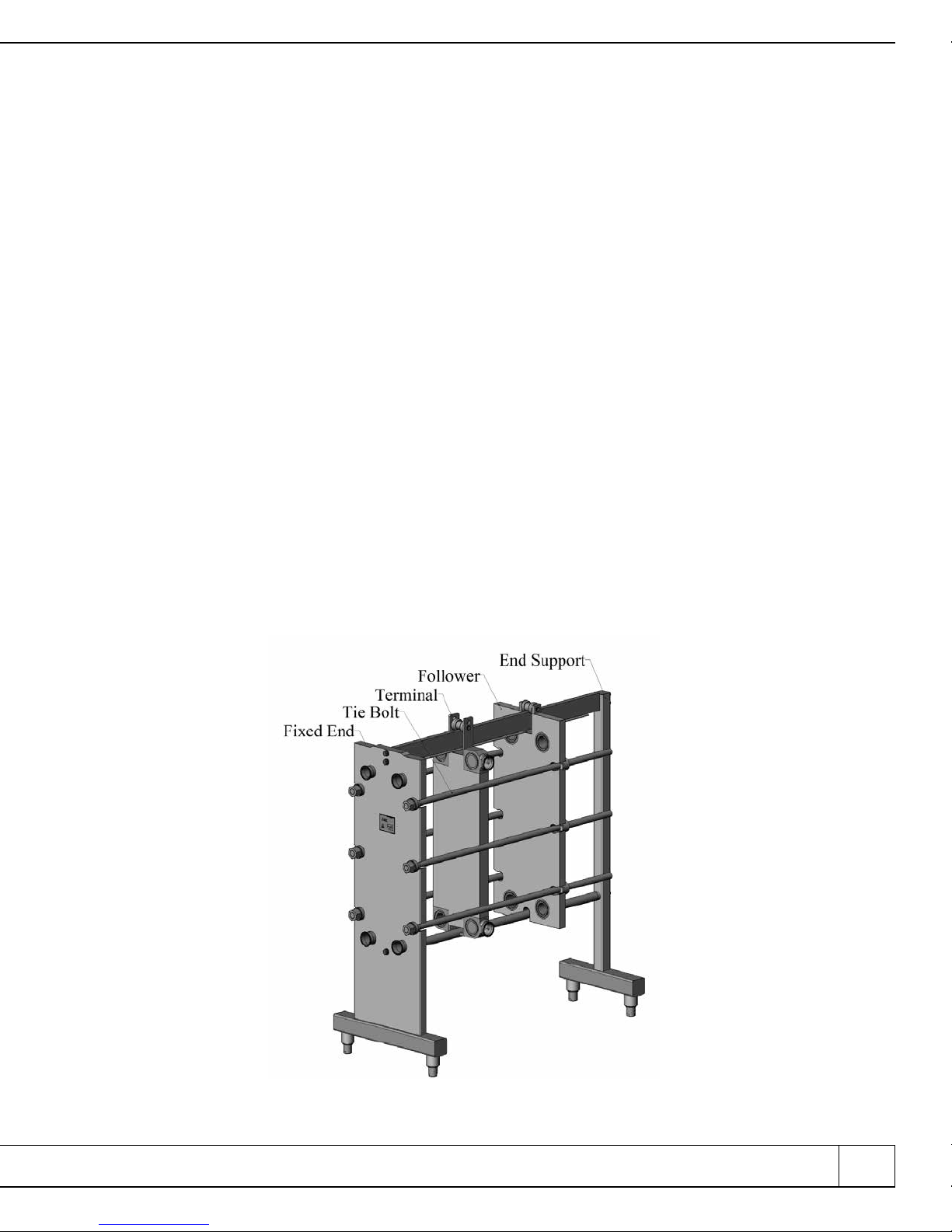

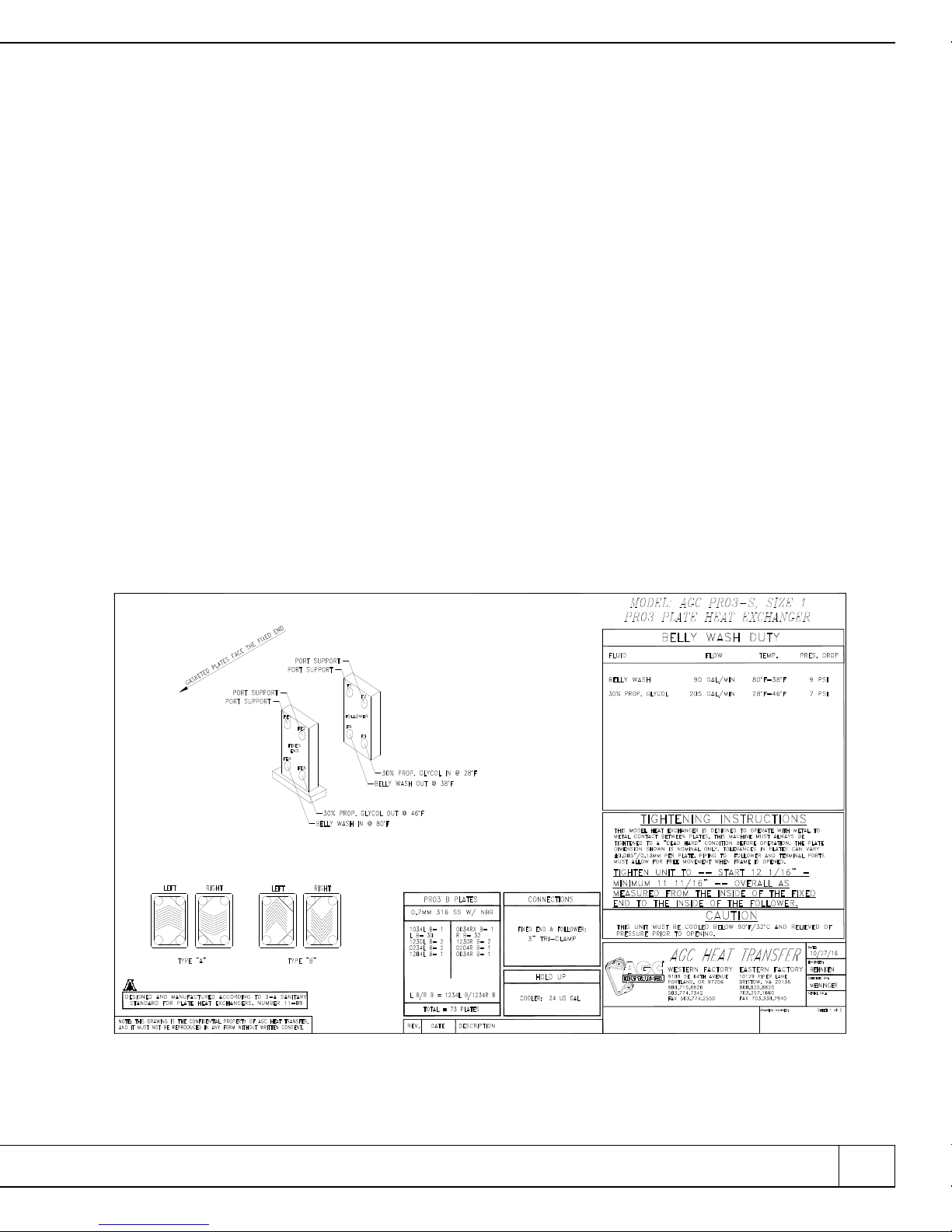

Figure 3

Wrench Space Requirement

800.825.8820 eastern I888.489.8820 central I 800.715.8820 western Iwww.agcheattransfer.com 3

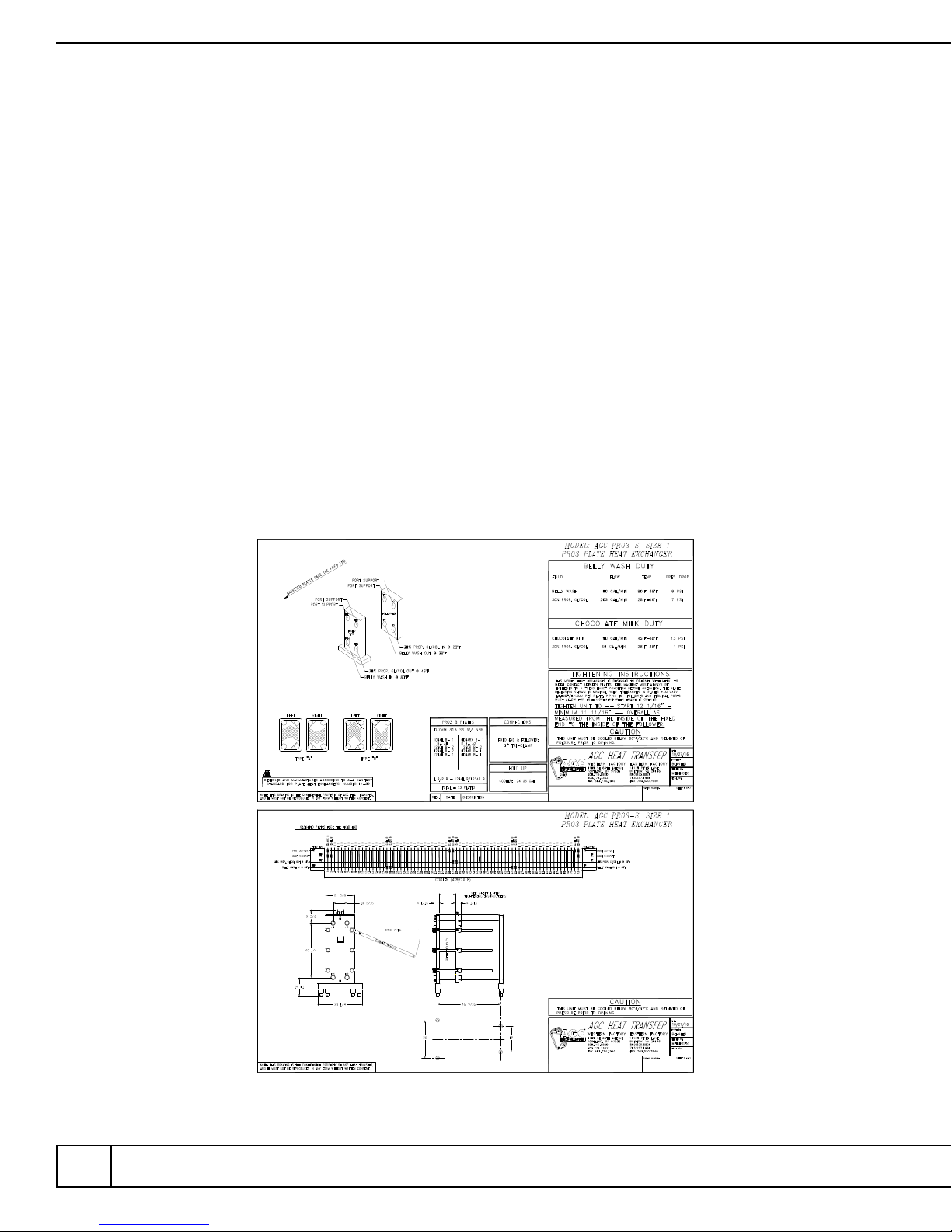

Page one shows the unit serial number, the duty, plate type, plate count, gasket type,

connection type, connection size, and the tightening dimension. Revisions are also listed

on page one. Page two of the drawing shows how the fluids pass through the heat

exchanger. (The ProFlow manual describes how to read this flow diagram). If the unit is

small, such as the unit in figure two, a front and side view of the heat exchanger will be shown

as well. For larger units the front and side views are shown on page three or page four

.

The second document in the drawing package is a plate punching diagram. This

diagram will show you how to identify each Pro3 plate either by its configuration number

(stamped at the top of each plate) or by looking at the plate noting which ports have been

opened. Since the Pro3 plate is a vertical flow plate, each plate can be used for either a right

or left hand plate. The ProFlow manual explains how these plates are used in greater detail.

The final document in the drawing package is the ProFlow manual. The ProFlow

manual has information about the AGC Heat Transfer product line and a more in-depth

discussion about plate heat exchangers in general

.

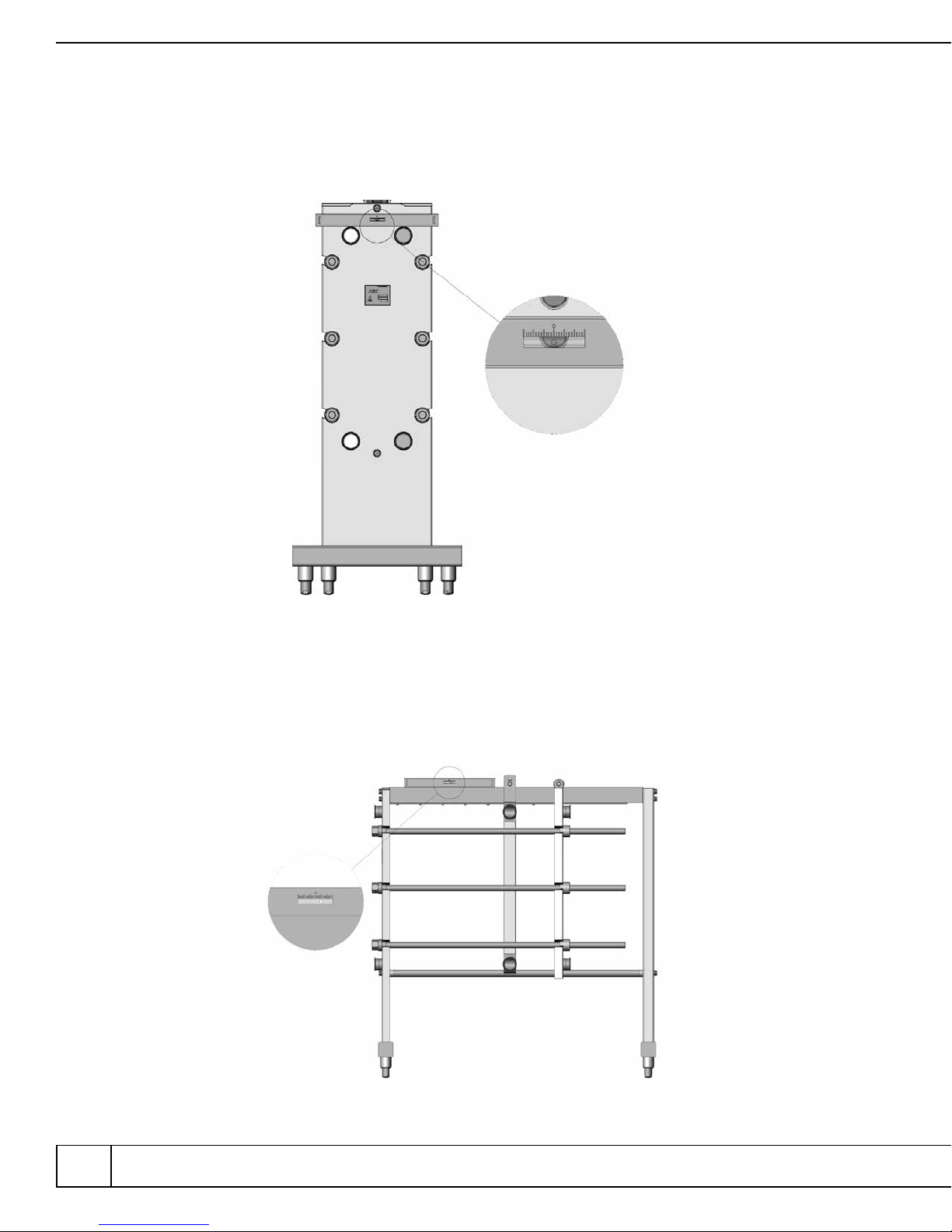

Frame Placement:

Locate the Pro3 frame on a firm flat surface capable of supporting the press and all of

its contents when full. If possible, the frame should remain strapped to the shipping skid

until it is near its final location. Once the press is positioned cut the metal bands holding it

to the shipping skid and, using an appropriately sized lifting strap, carefully lift the press off

the skid. The top rail can be used as a lifting point. Never lift the press by the tiebolts or

port nozzles. These bolts are in slots and are not designed to support the weight of the

frame for lifting. When locating the heat exchanger, ensure that adequate space is left

around the frame for maintenance and for plate installation/removal. Also include enough

space to allow the AGC Fat Boy™wrench to fully swing. See figure 3.