Netafim NETAJET 4G User manual

INSTALLATION MANUAL

V 002.01 - DECEMBER 2020

NETAJET

™4G

© COPYRIGHT 2020, NETAFIM™

NO PARTS OF THIS PUBLICATION MAY BE REPRODUCED, STORED IN AN AUTOMATED DATA FILE OR MADE PUBLIC IN

ANY FORM OR BY ANY MEANS, WHETHER ELECTRONIC, MECHANICAL, BY PHOTOCOPYING, RECORDING OR IN ANY

OTHER MANNER WITHOUT PRIOR WRITTEN PERMISSION OF THE PUBLISHER.

ALTHOUGH NETAFIM™TAKES THE GREATEST POSSIBLE CARE IN DESIGNING AND PRODUCING BOTH ITS PRODUCTS

AND THE ASSOCIATED DOCUMENTATION, THEY MAY STILL INCLUDE FAULTS.

NETAFIM™WILL NOT ACCEPT RESPONSIBILITY FOR DAMAGE RESULTING FROM THE USE OF NETAFIM'S PRODUCTS

OR THE USE OF THIS MANUAL.

NETAFIM™RESERVES THE RIGHT TO MAKE CHANGES AND IMPROVEMENTS TO ITS PRODUCTS AND/OR THE

ASSOCIATED DOCUMENTATION WITHOUT PRIOR NOTICE.

FOREIGN LANGUAGES

In the event that you are reading this manual in a language other than the English language, you

acknowledge and agree that the English language version shall prevail in case of inconsistency or

contradiction in interpretation or translation.

CONTENTS

6

7

7

8

9

9

9

9

9

10

10

11

11

11

11

12

12

13

13

14

16

18

20

22

24

26

26

26

27

27

28

Use of symbols

Introduction

General instructions

Safety instructions

Safety instructions when using acid/chemicals

Description

Features

Highlights

Advantages

Operating principle

Main components

Analog dosing channel

Dual dosing channel

Capabilities

Service

Maintenance

Add-ons

Dimensions

Weights

Modes

Main parts of the NetaJet™ 4G and its infrastructure

BP PL mode

BP ST mode

High-flow mode

Octa - 8-channel mode

IL PL mode

IL ST mode

On-site preparations

Infrastructure requirements

Pump house (Filter house / Fertilizer house) requirements

The water distribution system

The fertilizer/acid tanks and lines

Hydraulic infrastructure preparation

Location of inlet, outlet and fertilizer/acid line connectors

Continued on the next page

CONTENTS

Continued

29

29

30

30

31

32

33

35

35

37

39

41

42

Recommended flow meter pulse rate

Electrical preparation

Installation

Unpacking and placement

Hydraulic installation

Electrical installation

System operation

Preparations for running the NetaJet™ 4G

Running the NetaJet™ 4G

Dosing calibration

Calculation of dosing channel opening percentage

Simulation with a 10-liter (2-US-gallon) bucket of water

Calibration of the NetaJet™ 4G while irrigating

System calibration

Commissioning

Warranty

6 NETAJET™4G INSTALLATION MANUAL

USE OF SYMBOLS

ELECTRICAL HAZARD

Vontains instructions aimed at preventing bodily injury or direct damage to the NetaJet™ 4G

and/or the infrastructure in the presence of electricity.

WARNING

Contains instructions aimed at preventing bodily injury or direct damage to the crops, the

NetaJet™ 4G and/or the infrastructure.

CAUTION

Contains instructions aimed at preventing unwanted system operation, installation or conditions

that, if not followed, might void the warranty.

ATTENTION

Contains instructions aimed at enhancing the efficiency of usage of the instructions in the

manual.

NOTE

Contains instructions aimed at emphasizing certain aspects of the operation of the system or

installation.

SAFETY FOOTWEAR

Vontains instructions aimed at preventing foot injury.

TIP

Provides clarification, tips or useful information.

ACID HAZARD

Contains instructions aimed at preventing bodily injury or direct damage to the crops, the

product and/or the infrastructure in the presence of acid.

PROTECTIVE EQUIPMENT

Vontains instructions aimed at preventing damage to health or bodily injury in the

presence of fertilizers, acid or other chemicals.

EXAMPLE

Provides an example to clarify the operation of the settings, method of operation or installation.

The values used in the examples are hypothetical. Do not apply these values to your own

situation.

The symbols used in this manual refer to the following:

NETAJET™4G INSTALLATION MANUAL 7

INTRODUCTION

General instructions

• Installation must be performed by authorized technicians only.

• Refer to your supervisor if problems occur during the installation procedure.

• Installation should be performed on a hard, leveled floor or on a flat, hard, leveled plate.

• Do not apply force or pressure on components during the installation procedure.

• Verify that field components work properly.

• Make sure fertilizers and acid are on site at the time of installation.

Electricity

•

Ensure that a suitable electrical power supply is available in the vicinity of the installation for the NetaJet™ 4G

electrical connection (see Electrical preparation, page 29).

•

Ensure that an electrical socket is available in the NetaJet™ 4G vicinity, for installation and for service purposes.

Safety instructions

•All safety regulations must be applied.

•Ensure that the installation is carried out in a manner that prevents leaks from the NetaJet™ 4G,

the fertilizer/acid tanks and lines, the peripherals and the accessories (contaminating the

environment, soil or ambient area).

•When using acid, always observe the acid manufacturer's safety instructions.

•Electrical installation and troubleshooting should be performed by an authorized electrician only.

•The electrical installation must comply with the local safety standards and regulations.

•Installation should be performed by authorized technicians only.

•Protection provided by the equipment can be impaired if the equipment is used in a manner other than

that specified by the manufacturer.

CAUTION

Read the safety instructions section before beginning installation of the NetaJet™ 4G dosing unit.

WARNING

In agricultural environments - always wear protective footwear.

CAUTION

When opening or closing any manual valve, always do so gradually, to prevent damage to the

system by water hammer.

WARNING

Always use protective equipment, gloves and goggles when handling fertilizers, acid and

other chemicals!

NOTE

The maximum sound level produced by the equipment does not exceed 70dB.

WARNING

Measures must be taken to prevent fertilizer infiltration of the water source, to avoid water pollution.

8 NETAJET™4G INSTALLATION MANUAL

INTRODUCTION

Safety instructions when using acid/chemicals

ACID HAZARD

When using acid - always observe the acid manufacturer's safety instructions.

WARNING

Always use protective equipment, gloves and goggles when handling fertilizers, acid and

other chemicals!

WARNING

Exceeding the recommended acid concentrations will damage the dosing channels.

WARNING

Substances

such as chemicals for pest/disease control might be corrosive and damage the

NetaJet™ 4G. When using any substance

other than

fertilizers or acids not exceeding the

concentrations in the table above, always observe the manufacturer's instructions for corrosivity.

In case of any doubt, contact your local Netafim™ representative.

CAUTION

High concentrations of some fertilizer combinations might induce crystallization in the NetaJet's

lower manifold and cause clogging of the pipes.

These combinations should never be used in any

concentration in the dual dosing channel (Octa mode only)!

Fertilizer combinations prone to induce crystallization:

•

Calcium nitrate + ammonium sulfate => calcium sulfate

•

Calcium nitrate + potassium sulfate => calcium sulfate

•

MKP + calcium nitrate => calcium phosphate

•

MAP + calcium nitrate => calcium phosphate

•

Phosphoric acid + calcium nitrate => calcium phosphate

When injecting these fertilizer combinations:

•

Make sure to dilute each fertilizer to the allowed concentration in the fertilizer tank prior to injection

through the NetaJet™ 4G.

•

Immediately after each injection of any of the fertilizer combinations above, flush the NetaJet™ 4G

with clean water for at least 2 minutes.

In case of doubt regarding the use of any

combination of

fertilizers, contact your local Netafim™

representative.

ATTENTION

When dosing acid, use a dosing channel fitted with the appropriate components according to

the type

and concentration of acid used*:

For pH correction

For maintenance of drippers

Type of dosing channel

Diaphragm

and O-rings

Nitric acid

(HNO3)

Phosphoric

acid

(H3PO4)

Sulfuric acid

(H2SO4)

Potassium

hydroxide

(KOH)

Acetic acid

(CH3COOH)

Hydrochloric

(HCl)

Hydrogen

peroxide

(H2O2)

Chlorine (as

(hypochloride

For diluted acid EPDM <3% <85% <30% <35% <30% <10% <30% <1%

For concentrated acid

Viton <40% <85% <90% <10% <5% <33% <50% <10%

% is by weight at 21oC (70oF)

*The table indicates the resistance of the dosing channel components to acid,

and is not a recommendation to use the acids mentioned.

NETAJET™4G INSTALLATION MANUAL 9

DESCRIPTION

Features

•The NetaJet™ 4G realizes Netafim’s “grow more with less” concept. Based on Netafim’s unique

Nutrigation™ technology, it controls the amount of water and fertilizers used, optimizing resource

utilization for each specific crop and soil/substrate type.

•The NetaJet™ 4G is extremely accurate and reliable, preventing water and fertilizer waste while reducing

environmental pollution.

•The NetaJet™ 4G ensures very precise and homogeneous nutrient dosing for greenhouse crops.

•The NetaJet™ 4G is a modular CE-compliant dosing system that easily integrates with multiple

Netafim™ and third-party control and monitoring systems.

•

The NetaJet™ 4G always injects a uniform quantity of nutrients while performing perfect EC and pH control.

•The NetaJet™ 4G can accommodate a wide variety of dosing channels for fertilizer and

concentrated/diluted acid.

•The NetaJet™ 4G accommodates a wide variety of system pumps, peripherals and accessories to meet

a vast range of applications and infrastructure constraints.

Highlights

•Equipped with Netafim's unique innovative

analog dosing channels for very accurate and

reliable EC/pH control.

•

Provides fast and accurate fertilizer and acid control.

•State-of-the-art technology with unique static

mixing chamber

•Short control cycle

•Efficient water, fertilizer and energy consumption

•Guaranteed EC and pH control

•Almost completely maintenance-free Venturi

operations – no moving parts

•Highly accurate dosing channels

•

Fast and efficient Nutrigation™ recipe adjustments

•Multi-lingual capabilities

•Made by Netafim™

Advantages

•Easy system installation and maintenance

•In-house developed offering

•Versatile flow capacity

•Covers all applications ranging from greenhouse in soil, to very intensive soilless media

•Requires minimal investment with rapid ROI

Operating principle

The NetaJet™ 4G doses the various fertilizers and acids into a homogeneous solution in its unique

HidroMix static mixing chamber and injects it into the irrigation water main line.

The suction of the fertilizers and acid in the dosing channels is based on the Venturi principle. This requires

a pressure differentiation - available on the main line or supplied by the main line pump or the NetaJet's

dosing booster.

Main components

•HydroMix static mixing chamber

•A compensation channel with a pressure regulator

•Factory-installed PRV at the inlet and a PSV at the

outlet

•Selectable analog dosing channels

•Dual EC/pH monitoring and control

•Quick-action dosing valves

•Wide range of integrated accessories and

peripherals

•High-quality components and PVC piping

•Aluminum, corrosion-resistant frame with

adjustable legs

10 NETAJET™4G INSTALLATION MANUAL

DESCRIPTION

Analog dosing channel

The NetaJet™ 4G is the first fertilizer-dosing system equipped with Netafim's unique innovative analog

dosing channel.

The analog dosing channel is the long-awaited solution for very accurate and reliable EC/pH control for

Nutrigation™ of high-value greenhouse crops.

The analog dosing channel is equipped with a servo motor capable of continuous variable opening from 0

to 100%. This unique feature allows unprecedented precise and seamless Nutrigation™.

Advantages

•Ultra-high precision

•Smooth and stable hydraulic operation

•No fluctuations

•Fast EC/pH set-point reaching

•Short stabilization time

•Enables short Nutrigation™ cycles

•No risk of cavitation damage to the booster

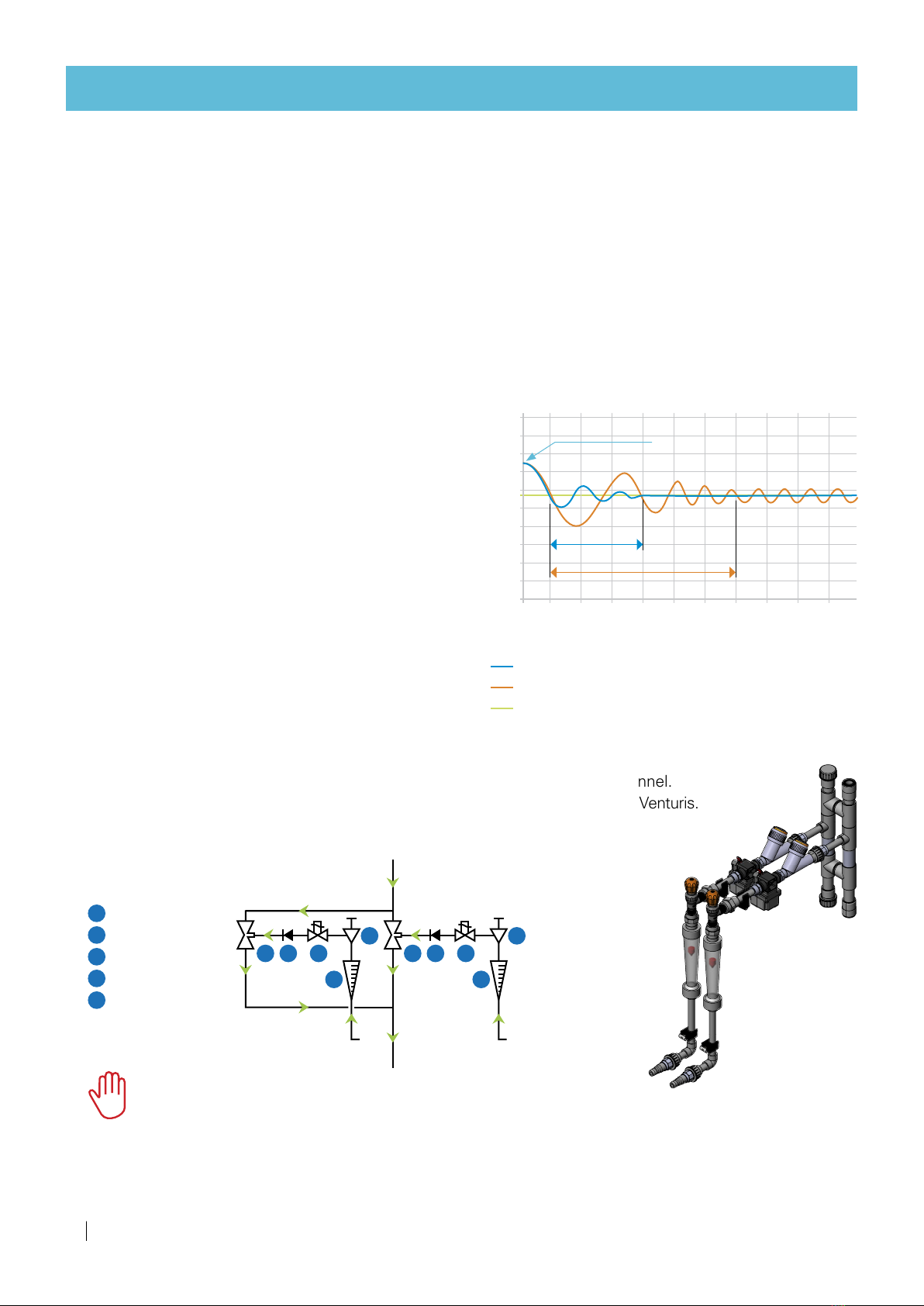

Stabilization time

The analog dosing channel offers the benefit of a

significantly shorter stabilization time compared with

the digital (pulsating) dosing channel (up to 50%).

This is particularly beneficial when performing short

Nutrigation™ cycles typical of greenhouse crops.

•X = Analog (continuous-variable) dosing channel

•Y = Digital (pulsating) dosing channel

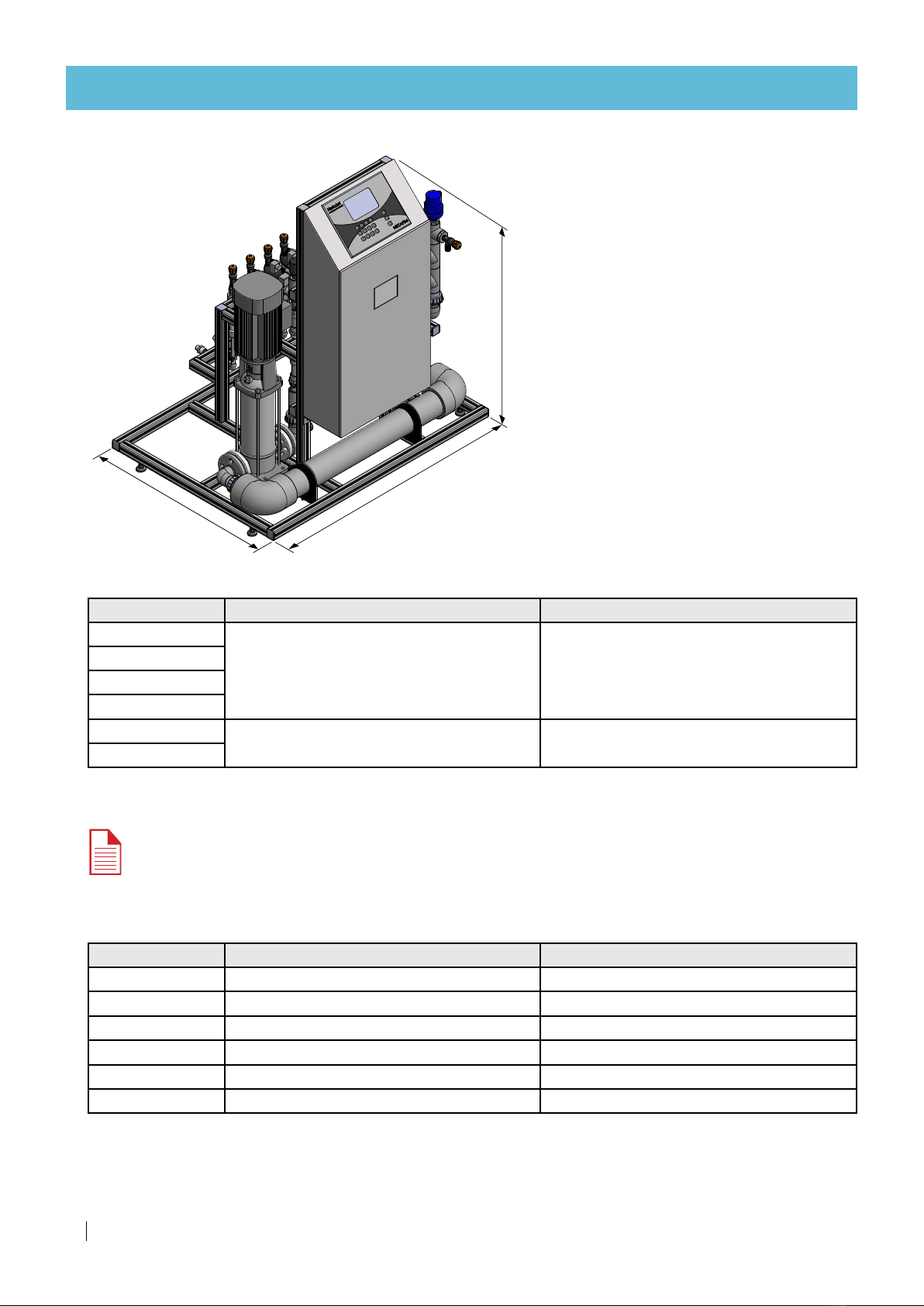

Dual dosing channel

The NetaJet™ 4G Octa mode (8 dosing channels) includes 3 dual dosing channel.

The dual dosing channel is applicable with 50 l/h (13 GPH) and 600 l/h (158 GPH) Venturis.

Dual dosing channel schematic diagram

pH

Time (sec)

10

9

8

7

6

5

4

3

2

1

0

205

0

X

Y

Source water

352510 403015 45 50

Analog (continuous-variable) dosing channel

Digital (pulsating) dosing channel

pH set point

Digital (ON/OFF) vs. analog dosing channel

performances

ARotameter

BNeedle valve

CDosing valve

DCheck valve

EVenturi

A

B

CDE

A

B

CDE

CAUTION

There are fertilizer combinations that should never be used in any concentration in the dual dosing

channel! (see CAUTION, page 8)

NETAJET™4G INSTALLATION MANUAL 11

DESCRIPTION

Capabilities

NetaJet™ 4G modes fed by a pressurised main line are suitable for a vast range of main line pressures

•Standard: 2.5 - 5.8 bar (36.5 - 84.0 PSI)

•High pressure: 5.8 - 7.5 bar (84.0 - 108.5 PSI)

For main line pressures lower than 2.5 bar (36.5 PSI), consult Netafim™.

NetaJet™ 4G modes fed by a storage tank

The water level in the storage tank should not be higher than 5 meters (16.4 feet) above the NetaJet™ 4G

inlet.

Various dosing channel configuration options

•Most modes: Up to 5 highly accurate dosing channels of various types,

from 50 l/hr (13 GPH) up to 600 l/hr (158 GPH) each.

•Octa mode: Up to 8 highly accurate dosing channels of various types,

from 50 l/hr (13 GPH) up to 600 l/hr (158 GPH) each.

•High-flow mode: Up to 5 highly accurate dosing channels of various types,

from 50 l/hr (13 GPH) up to 1000 l/hr (264 GPH) each.

Service

The NetaJet™ 4G utilizes modular construction, making servicing a simple and quick process.

The dealer keeps a small quantity of interchangeable components on hand, for replacement on site within

a few minutes.

Maintenance

To prevent failures and extend the life cycle of the NetaJet™ 4G, regular maintenance must be carried out

by the user, such as periodic rinsing of filters and calibration of the EC and pH sensors.

Regular maintenance of the NetaJet™ 4G is a time- and cost-efficient process requiring no special tools or

skills.

Add-ons

You can extend the functionality of your NetaJet™ 4G by means of the the wide variety of useful add-ons.

All the add-ons are easy to connect to the NetaJet™ 4G - here are a few examples:

Fertilizer meter with electric output

Enables continuous reading of fertilizer dosing. Useful in applications where the costumer wants a broader

indication of fertilizer flow in addition to the EC and pH readings. Installed externally, controlled and

monitored by the

NetaJet™ 4G

NMC Pro controller.

Stock selection

Enables the dosing of multiple fertilizers through a single dosing channel (in cases where simultaneous

dosing is not required). Available in a wide variety of configurations, from a single channel with 2 fertilizers

to as many channels and fertilizers as required. Installed externally, controlled and monitored by the

NetaJet™ 4G

NMC Pro controller.

For further information on the NetaJet™ 4G add-ons, consult Netafim™.

12 NETAJET™4G INSTALLATION MANUAL

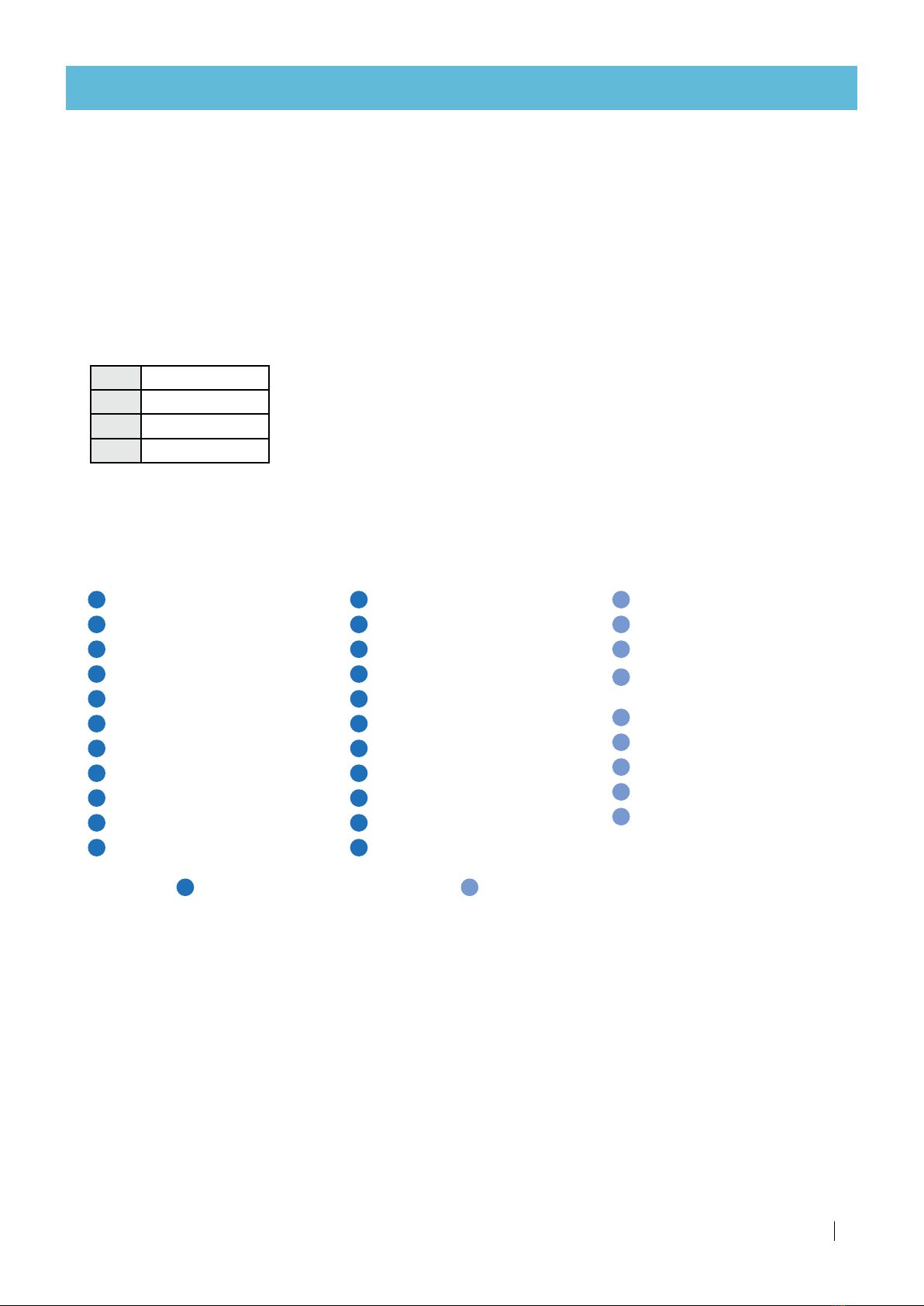

Dimensions

NETAJET 4GBPPL

H

D

W

External

dimensions

Mode

NetaJet™ 4G

external dimensions (W/D/H*)

Package dimensions (W/D/H**)

BP PL

123/90/134 cm (48/35.5/53") 131/112/158 cm (52/44/62")

BP ST

High-flow

Octa - 8-channel

IL PL

112/125/134 cm (44/49/53") 142/142/158 cm (56/56/62")

IL ST

*The height varies by ±1 cm (±0.5") according to the adjustment of the legs.

**The package height includes the pallet height of 15 cm (6").

NOTE

Allow 20 cm (8") arround the

NetaJet™ 4G for inlet, outlet and fertilizer pipes connections.

Weights

Mode

Net weight Packed weight

BP PL

130 -150

kg (

287-331

lbs)

180-200

kg (

397- 441

lbs)

BP ST

90-100

kg (

199-221

lbs)

140 -150

kg (

309-331

lbs)

High-flow

221-235

kg (

487-518

lbs)

255-275

kg (

562-606

lbs)

Octa - 8-channel

200 -215

kg (

441- 474

lbs)

275-295

kg (

606-650

lbs)

IL PL

130 -150

kg (

287-331

lbs)

180-200

kg (

397- 441

lbs)

IL ST

150 -190

kg (

331-419

lbs)

200-240

kg (

441- 529

lbs)

The weight ranges in the table above are order of magnitude only -

final weights, depending on the selected dosing booster, will be issued with the product order.

DESCRIPTION

NETAJET™4G INSTALLATION MANUAL 13

DESCRIPTION

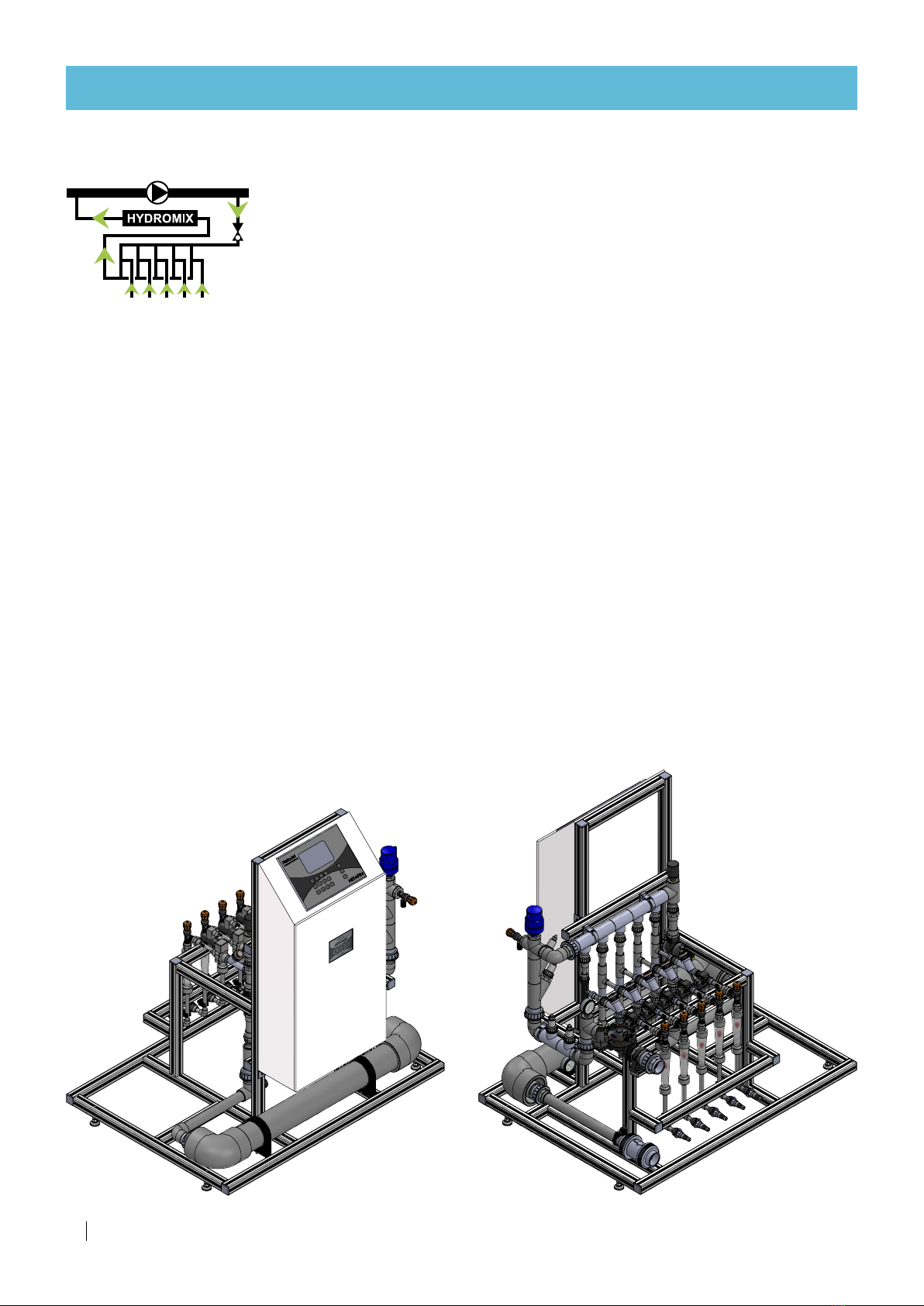

Modes

•

BP PL

: Bypass system for pressurized-line water source; 5 dosing channels (see page 14)

•

BP ST

: Bypass system for storage-tank water source; 5 dosing channels (see page 16)

•

High-flow

: High-flow bypass system for pressurized-line water source; 5 dosing channels (see page 18)

•

Octa - 8-channel

: Bypass system for pressurized-line water source; 6-8 dosing channels (see page 20)

•

IL PL

: Inline system for pressurized-line water source; 5 dosing channels (see page 22)

•

IL ST

: Inline system for storage-tank water source; 5 dosing channels (see page 24)

Legend:

BP

Bypass

IL

Inline

PL

Pressurized line

ST

Storage tank

Main parts of the NetaJet™ 4G and its infrastructure

The list below presents the main parts of the NetaJet™ 4G and the parts of the infrastructure required for

the operation of the NetaJet™ 4G various modes.

1Dosing channel + Venturi

2Dual dosing channel + Venturis

3

Inlet

pressure gauge

4Outlet pressure gauge

5

Lower

manifold pressure gauge

6Main line pressure gauge

7Sampling outlet

8Controller

9EC/pH transducer

10 Dosing booster switchbox

11 pH sensor

12 EC sensor

13 Dosing booster

14 Check valve

15 Pressure switch

16

Pressure sustaining valve (PSV)

17 Pressure reducing valve (PRV)

18 Air release valve

19 Mixing chamber

20 Compensation channel

21 Onboard main line pump

22 Upper manifold filter

23 Main line pump

24 Main line filter

25 Main line water meter

26

Main line

pressure sustaining valve (PSV)

27 Manual valve (isolation)

28 Irrigation valve

29 Fertilizer/acid filter

30 Manual valve (fertilizer)

31 Fertilizer/acid stock tank

Color code:

Supplied (part of the NetaJet™ 4G) Not supplied (part of infrastructure).

14 NETAJET™4G INSTALLATION MANUAL

DESCRIPTION

BP PL mode

Bypass system for pressurized-line water source.

Operating principle:

The pressure differential required to generate fertilizer suction via the Venturis

is produced by a booster pump integrated in the NetaJet™ 4G. This mode of

operation, where the lower manifold is under low pressure (around 0 bar/PSI),

permits the use of high-efficiency Venturis with high suction capacity and low

motive flow consumption.

Suitable for main line flow rate:

20-120 m³/h (90-500 GPM)

Flow limitation depends on the fertilizer injection rate and the size of the Venturis.

Suitable for main line pressure:

•Standard: 2.5-5.8 bar (36.5-84.0 PSI)

•High pressure: 5.8-7.5 bar (84.0-108.5 PSI)

For main line pressures lower than 2.5 bar (36.5 PSI), consult Netafim™.

Dosing channels:

Accommodates a wide variety of highly accurate dosing channels for fertilizer and concentrated/diluted acid:

•Up to 5 dosing channels of various types, from 50 l/hr (13 GPH) up to 600 l/hr (158 GPH) each.

•Optional - Concentrated acid channel, 50 l/h (13 GPH).

Total fertilizer/acid suction capacity - up to 3000 l/h (792 GPH).

Controller:

NMC-Pro (Operation with third-party controllers is optional. Consult Netafim™.)

EC/pH:

Precise single or dual monitoring and control - selectable by customer.

Front view Back view

16 NETAJET™4G INSTALLATION MANUAL

DESCRIPTION

BP ST mode

Bypass system for storage-tank water source.

Operating principle:

For systems operating at low pressure - from an on-ground reservoir or a storage

tank [max. height: 6 meters (20 feet)].

The main line pump also serves as dosing booster pump.

Suitable for main line flow rate:

15-100 m³/h (66-440 GPM)

Flow limitation depends on the fertilizer injection rate and the size of the Venturis.

Suitable for main line pressure:

The water level in the storage tank should not be higher than 5 meters (16.4 feet) above the NetaJet™ 4G inlet.

Dosing channels:

Accommodates a wide variety of highly accurate dosing channels for fertilizer and concentrated/diluted acid:

•Up to 5 x 50-600 l/hr (13-158 GPH)

•Optional - Concentrated acid channel, 50 l/h (13 GPH)

Total fertilizer/acid suction capacity - up to 3000 l/h (792 GPH).

Controller:

NMC-Pro (Operation with third-party controllers is optional. Consult Netafim™.)

EC/pH:

Precise single or dual monitoring and control - selectable by customer.

Front view Back view

18 NETAJET™4G INSTALLATION MANUAL

DESCRIPTION

High-flow mode

High-flow bypass system for pressurized-line water source

Operating principle:

The pressure differential required to generate fertilizer suction via the Venturis

is produced by a booster pump integrated in the NetaJet™ 4G. This mode of

operation, where the lower manifold is under low pressure (around 0 bar/PSI),

permits the use of high-efficiency Venturis with high suction capacity and low

motive flow consumption.

Suitable for main line flow rate:

80-400 m³/h (350-1760 GPM)

Flow limitation depends on the fertilizer injection rate and the size of the Venturis.

Suitable for main line pressure:

•Standard: 2.5-5.8 bar (36.5-84.0 PSI)

•High pressure: 5.8-7.5 bar (84.0-108.5 PSI)

Dosing channels:

Accommodates a wide variety of highly accurate dosing channels for fertilizer and concentrated/diluted acid:

•Up to 5 x 50-1000 l/h (13-265 GPH)

•Optional - Concentrated acid channel, 50 l/h (13 GPH)

Total fertilizer/acid suction capacity - up to 5000 l/h (1320 GPH).

Controller:

NMC-Pro (Operation with third-party controllers is optional. Consult Netafim™.)

EC/pH:

Precise single or dual monitoring and control - selectable by customer.

Front view Back view

20 NETAJET™4G INSTALLATION MANUAL

DESCRIPTION

Octa - 8-channel mode

Bypass system for pressurized-line water source, with 8 dosing channels.

Operating principle:

The pressure differential required to generate fertilizer suction via the Venturis is

produced by a booster pump integrated in the NetaJet™ 4G. This mode of operation,

where the lower manifold is under low pressure (around 0 bar/PSI), permits the use

of high-efficiency Venturis with high suction capacity and low motive flow consumption.

Suitable for main line flow rate:

20-120 m³/h (90-500 GPM). Flow limitation depends on the fertilizer injection rate and the size of the Venturis.

Suitable for main line pressure:

•Standard: 2.5-5.8 bar (36.5-84.0 PSI)

•High pressure: 5.8-7.5 bar (84.0-108.5 PSI)

Dosing channels:

Accommodates a wide variety of highly accurate dosing channels for fertilizer and concentrated/diluted acid:

•Up to 8 x 50-600 l/h (13-158 GPH)

•Optional - Concentrated acid channel, 50 l/h (13 GPH)

Total fertilizer/acid suction capacity - up to 4800 l/h (1268 GPH).

CAUTION

The Octa mode (8 dosing channels) includes 3 dual dosing channels. There are fertilizer combinations

that should never be used in any concentration in the dual dosing channel! (see CAUTION, page 8)

Controller:

NMC-Pro (Operation with third-party controllers is optional. Consult Netafim™.)

EC/pH:

Precise single or dual monitoring and control - selectable by customer.

Front view Back view

Other manuals for NETAJET 4G

1

Table of contents

Other Netafim Farm Equipment manuals