8

When operating the machine

Attention:

Whenever there is an instruction in the

manual telling the operator to turn the

machine off and to uncouple the tail shaft

from the tractor, the procedure for re-

coupling the tail shaft and starting the

machine again should occur only at the

endoftheoperation.

2.1- Avoid grease, oil or dust building-up on the

machine.

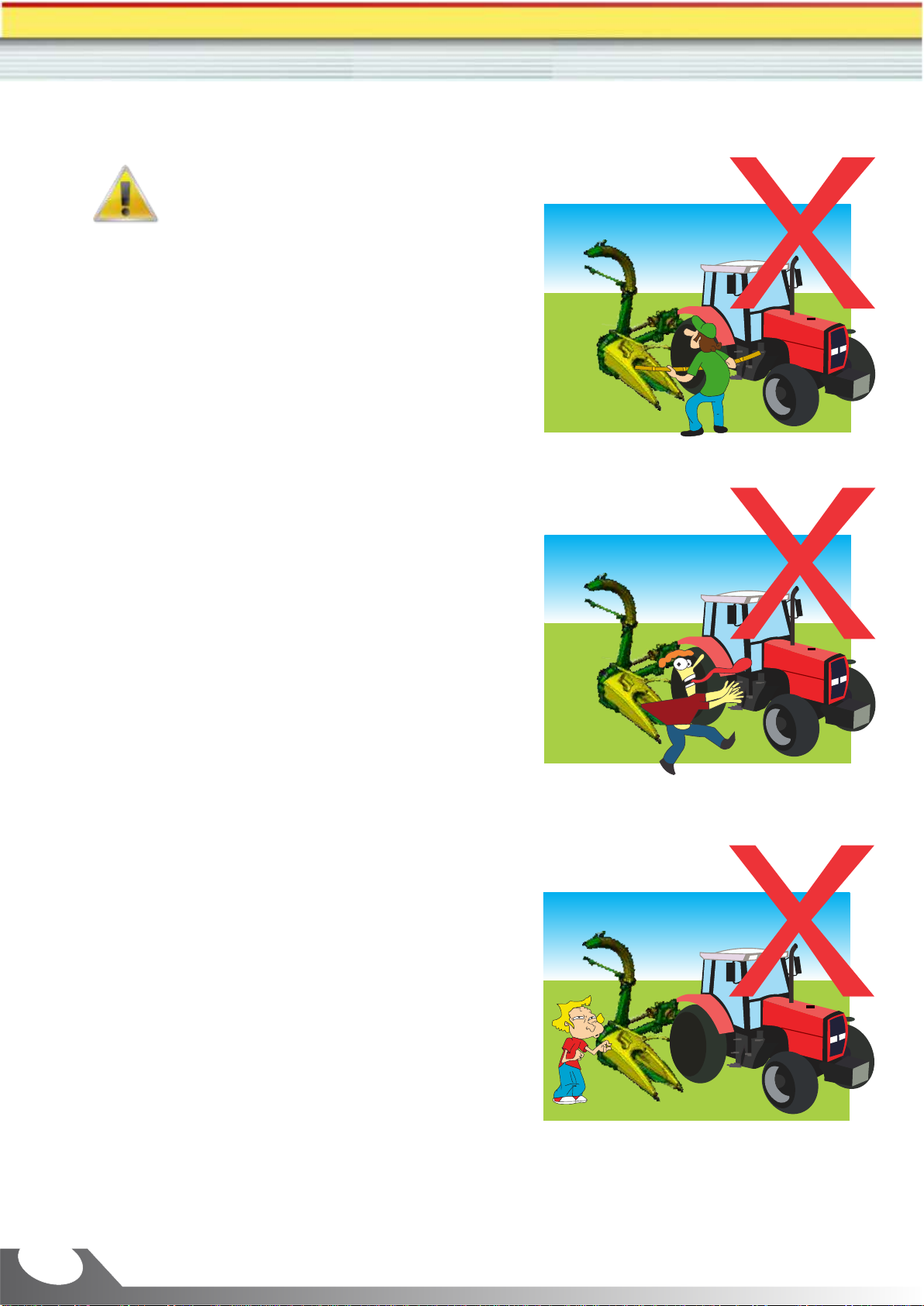

2.2-Neverfeedthemachinemanually.

2.3- Never attempt to adjust or repair components with

themachinerunning.

2.4-Donotturnontheequipmentwithoutsafeguards.

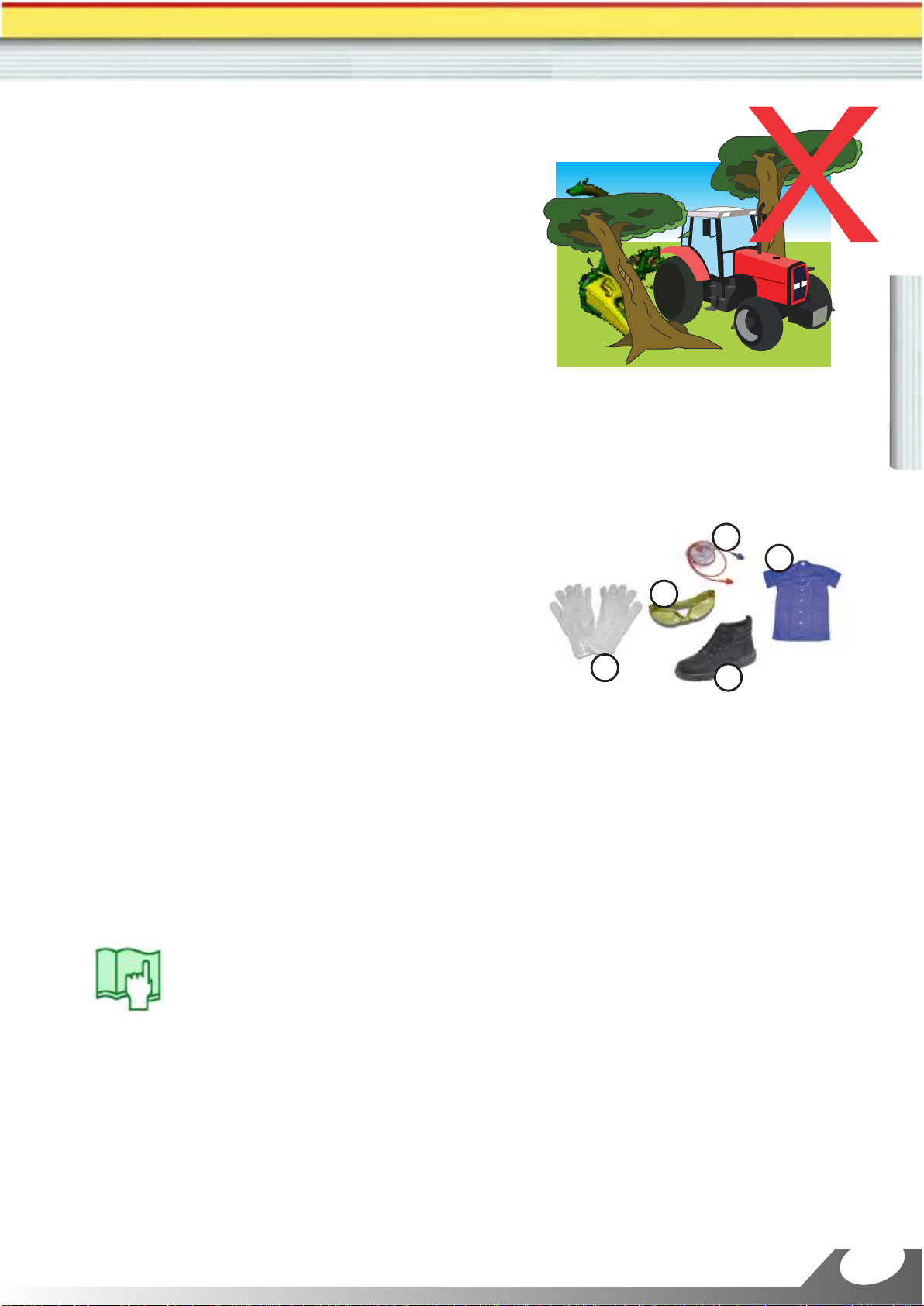

2.5- Loose clothes and long hair might be caught by

moving mechanisms. therefore, never get close or

operatethemachineinsuchconditions.

2.6- Whenever you move the machine out of the

harvestingprocess,lowertheoutletchute.

2.7- Keep the PTO turned on only when working, turn it

offduringmaneuversordisplacementsoutofwork.

2.8- Never allow unskilled people to operate the

machineorthetractor.

2.9-Donot allowchildrenorother peopletogetcloseto

the machine when it is in operation or during

maneuvers.

2.10- Never replace the cutting set gears with the

machineturnedon.

2.11- Do not couple the cardan to the PTO when it is

running.

2.12- Do not start or stop the engine with the PTO

running.

2.13-Neverremovethestickersfromthemachine.

2.14-Whencoupling thecardan for thefirst time, check

whetheritslengthisproper.Seesub-item7.9.