NetGain Motors HyPer 9HV IS User manual

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 1 of 28

User Manual

HyPer 9HV IS™

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 2 of 28

Table of Contents

Warning and Caution ..............................................................................................................................................................4

Safety Information .............................................................................................................................................................. 4

DISCLAIMER: .......................................................................................................................................................................5

X144 Main Wiring Diagram.....................................................................................................................................................6

X144 K1 Wire Harness Pinout ................................................................................................................................................. 7

HyPer 9HV Motor Plug Wiring Instructions ............................................................................................................................8

HyPer 9HV Motor Plug Pinout.................................................................................................................................................9

Motor Encoder Pin Positions .............................................................................................................................................. 9

Motor Thermistor Pin Positions..........................................................................................................................................9

X144 Main Contactor Wiring.................................................................................................................................................10

12/24V Coil Driver, High Voltage Contacts, and Key Switch In.........................................................................................10

Compact Display Pinout........................................................................................................................................................11

Compact Display Mating Female Plug...............................................................................................................................11

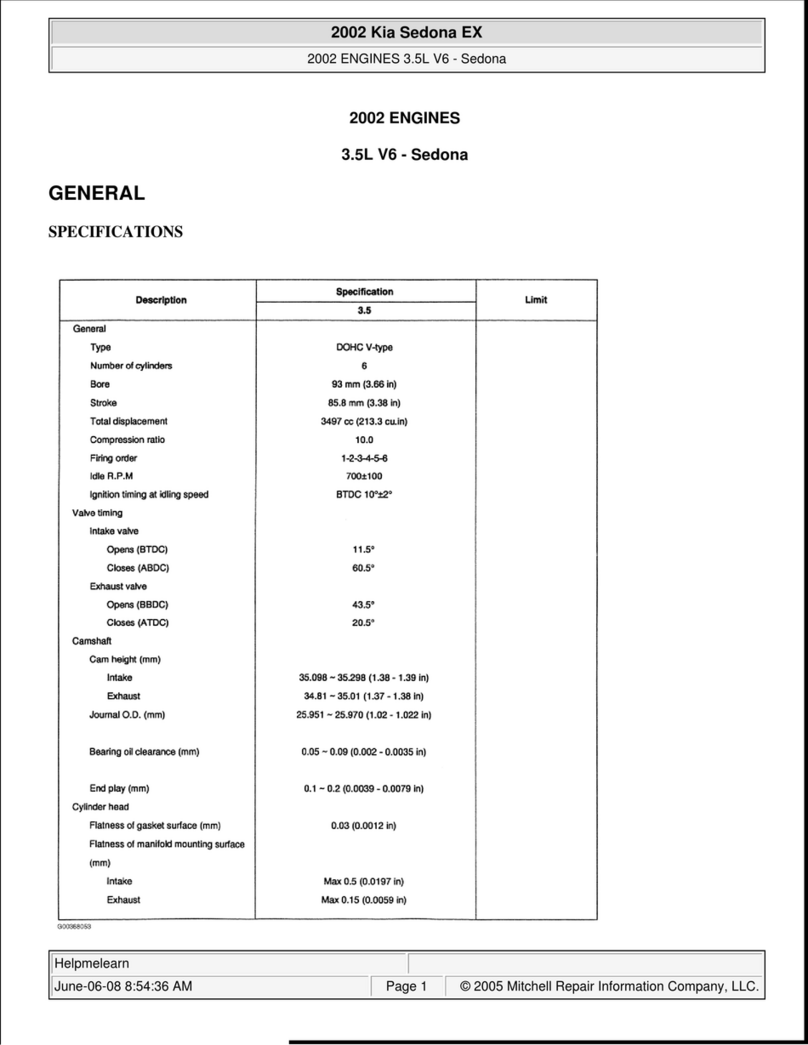

Controller Specifications.......................................................................................................................................................12

Controller Communication ...............................................................................................................................................12

Controller EMC..................................................................................................................................................................12

Controller Safety Certification ..........................................................................................................................................12

Controller Operating Environment Specifications............................................................................................................12

Pre-startup Steps ..................................................................................................................................................................13

Download SME Smarview Sys Program: ...........................................................................................................................13

Download* the Latest Controller Firmware: ....................................................................................................................13

Download* Your HyPer 9HV Clone File:............................................................................................................................13

Quickstart Guide ...............................................................................................................................................................13

Post-startup Steps.................................................................................................................................................................17

Throttle Mapping..............................................................................................................................................................17

Brake Regen Mapping.......................................................................................................................................................17

Regen on Neutral Operating Profiles................................................................................................................................17

Neutral Torque Mapping ..................................................................................................................................................18

Battery Mapping ...............................................................................................................................................................18

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 3 of 28

HyPer 9HV Motor Temperature Derating.........................................................................................................................18

X144 controller Temperature Derating.............................................................................................................................19

Signal: Inputs and Outputs................................................................................................................................................20

Controller I/O Table ..........................................................................................................................................................20

Diagnostic Code Guide..........................................................................................................................................................23

Additional Support............................................................................................................................................................28

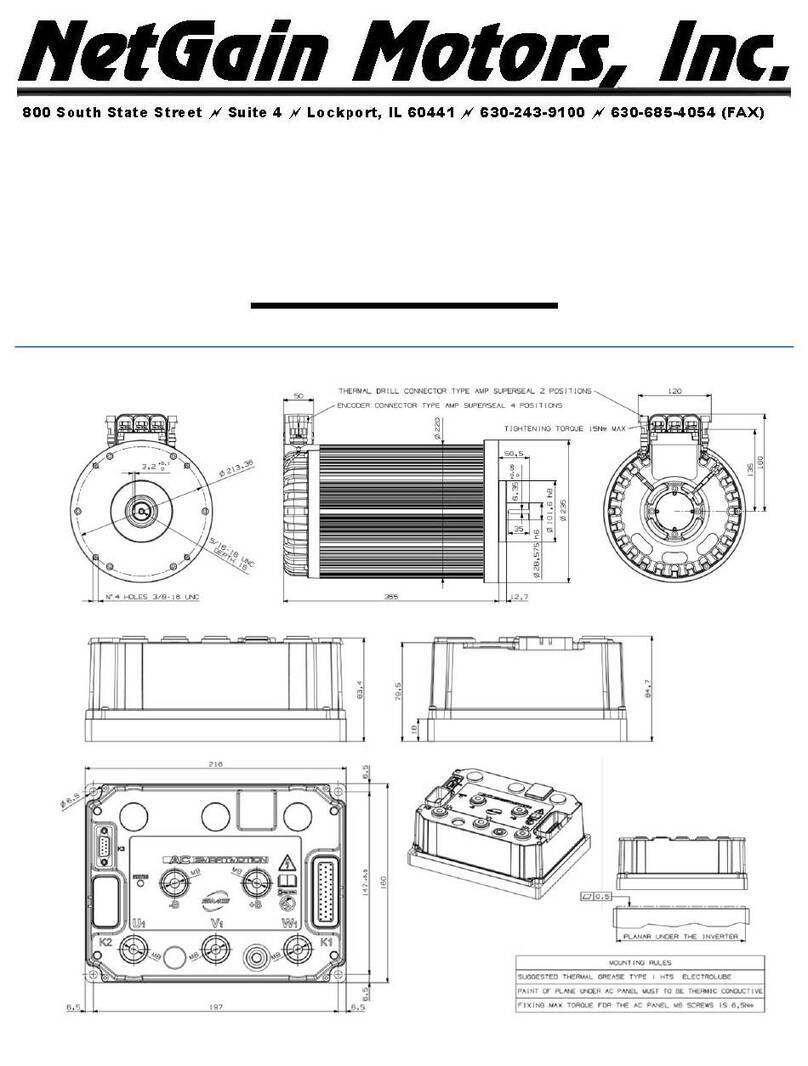

Figure 1 - Standard X144 Wiring Diagram.............................................................................................................................. 6

Figure 2 - Standard X144 Pin Order Assignment..................................................................................................................... 7

Figure 3 - Motor Plug Wiring Photo ........................................................................................................................................ 8

Figure 4 Compact Display Male Connector........................................................................................................................... 11

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 4 of 28

Warning and Caution

Safety Information

This is not an all-inclusive list. Use common sense and act responsibly, electric motor controllers and

motors are extremely powerful and could cause death, dismemberment or other serious injury if misused

or not safely handled!

Wear protective or safety equipment such as safety shoes, safety glasses and gloves when working with

motors and controllers.

Remove all metal jewelry and metal objects from hands, wrist, fingers, etc. before working on any

electric motor or controller.

Insulate any tools that are used in proximity to connection points that have any voltage potential to

prevent shorts if the tool is accidentally dropped onto the terminals/connections.

Use caution when operating any controller or motor. If you're not sure what you're doing, or do not feel

comfortable with the situation, find a knowledgeable person to advise you.

Make certain the motor and controller are disconnected from any power source before servicing. If any

doubt exists of the voltage that might exist, measure with proper metering devices that are in good

functional condition, and rated for the voltages that could exist.

Verify and re-verify proper wiring connections.

Take extreme caution around series-connected batteries to avoid placing hands across live connections. It

is generally good practice to avoid the use of both hands when working around high voltage circuits. This

reduces the risk of an accidental short across the chest cavity.

If working on an electric vehicle, make certain the vehicle is positioned securely with the drive wheels

safely clear of the floor and blocked up so that the drive wheels cannot make contact with the floor under

any circumstances. Block the non-drive wheels if they remain in contact with the floor so that the vehicle

cannot roll in either direction.

Motors and controllers must only be connected to a power source by knowledgeable and experienced

personnel.

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 5 of 28

Motors should NEVER be run without a load. Running a motor without a load could result in harm to

people or the motor. Absence of a load is considered misuse and could prove dangerous to anyone in the

vicinity and void the motor warranty.

Portions of the motor or controller may become hot and proper precautions must be taken.

Motors and controllers should never be operated beyond the limits established by the manufacturer.

Motors and controllers must not be modified in any manner; doing so will void warranty and could prove

extremely dangerous.

Motors are heavy and are likely to become damaged if dropped, or cause damage to anything they fall

upon (including people and body parts). Use extreme caution when working with motors!

Motors contain moving parts that could cause severe injury if the proper precautions are not taken.

Never touch an operating motor.

Do not defeat any safety circuits or safety devices.

Under no circumstances should you push in any contactor of an electric vehicle while the drive wheels are

in contact with the floor. Pushing in a contactor when the drive wheels are in contact with the floor can

cause serious property damage, personal injury or death.

DISCLAIMER:

NetGain Motors, Inc. has no control of third party installation procedure or the use of this motor and control

system. Accordingly NetGain Motors, Inc. assumes no liability for vehicle functionality or safety durring or after

third party installation of the motor and controller. It is the responsibility of the vehicle designer and component

installer to test and qualify their application and ensure proper safety and functionality. NetGain Motors, Inc

assumes no responsibility for this product in any use.

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 6 of 28

X144 Main Wiring Diagram

X144 ONLY!

12V-24V

Key Switch

For X1 wkring see:

HyPer 9 IS User

Manual

Figure 1 - Standard X144 Wiring Diagram

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 7 of 28

X144 K1 Wire Harness Pinout

Figure 2 - Standard X144 Pin Order Assignment

Must Be

Assigned

See Motor Plug

Wiring

Instructions for

Termination Steps

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 8 of 28

HyPer 9HV Motor Plug Wiring Instructions

1. Choose a location to fasten the Male 4P and 2P Receptacles from your HyPer Motor.

2. Route multipair cable atleast 6 inches from the motor case. Fasten this cable securely so it is restrained

from movement. Line cable up with motor’s Male Receptacles.

3. Using Cable Cutters - trim excess length from mulitipair cable, leave 4-6” extra to ensure cable will

reach motor Receptacles.

4. Using a co-ax stripper or scissors –carefully strip multipair black jacket atleast 4.5” from cable end.

This length should allow 4P and 2P wires to reach their respective Receptacle. Be careful not to cut into

the foil shilding or wire insulation underneath the jacket. A razor blade or X-acto knife can be used to

carefully slice a releif strip down the stripped jacket length, so it can be easily removed.

5. Slide ½” diameter heatshrink over multipair cable. Slide heatshrink past the newly exposed foil, and

rest heatshrink on remaining jacket material for future adhesion.

6. Slide ¼” diameter heatshrink over each of the 3 shileded twisted pairs. Rest heatshrink near jacket for

future adhesion.

7. Peal back 1.5” of foil shield and plastic wrap.

8. Slide yellow Plug Seals onto each wire with the smaller diameter end of each Seal facing the wire end.

9. Strip ¼” of insulation from the end of each 20awg wire.

10. Using an Open Barrell Crimper for “Amp” brand Pins –Crimp the provided “Strip Pins” onto the

copper of each wire.

11. Place pins in their proper position according to Motor Plug Pinout on the next page.

12. Fasten the red locking plate on the front of each plug. Verify all six pins are fully inserted.

13. Slide yellow Plug Seals into wire cavites.

14. Plug the newly assembled Plugs into the matching Male Plugs on your HyPer motor.

15. After the pre-start up steps are complete, and correct system operation is verified, apply heat to

heatshrink using a heat gun. Adhere the heatshrink as close to the plug as possible without putting strain

on the inserted wires.

Figure 3 - Motor Plug Wiring Photo

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 9 of 28

HyPer 9HV Motor Plug Pinout

Important: The Motor Encoder must be mounted securely and restrained from movement. Keep Encoder wires

as far as possible from High Voltage cables and the motor’s field.

Motor Encoder Pin Positions

Motor Encoder - 4 Position Connector

Pin

Name

Position

4

Encoder I/O Ground

K1-9

3

Encoder Cos 1

K1-33

2

Encoder Sin 1

K1-21

1

+5V Out

K1-35

Motor Thermistor Pin Positions

Motor Thermistor - 2 Position Connector

Pin

Name

Position

2

Motor Thermistor

K1-32

1

Analog Ground

K1-12

K1-9 K1-33 K1-21 K1-35

Included in HyPer 9HV IS:

Amp Superseal 4 POS

Plug Part# 282088-1

Pin Part# 282110-1

Seal Part# 281934-2

Included in HyPer 9HV IS:

Amp Superseal 2 POS

Plug Part# 282080-1

Pin Part# 282110-1

Seal Part# 281934-2

K1-12 K1-32

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 10 of 28

X144 Main Contactor Wiring

12/24V Coil Driver, High Voltage Contacts, and Key Switch In

X144 Main Contactor –External PWM

Terminal

Name

X144 Position

X2

Driver Output 1

K1-26

X1

Coil Return

K1-25

A2-

Controller HV+

B+ Terminal*

A1+

Precharge

B+ Precharge**

* This HV circuit should include proper fuses and disconnect switches.

Included in HyPer 9HV IS:

Gigavac 500+ Amp, 12-800Vdc

- 12/24V External PWM Coil

Part# GV200PA-1

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 11 of 28

Compact Display Pinout

Compact Display Mating Female Plug

Compact Display - 8 Position Connector

Pin

Name

Position

8

+12V Out

K1-10

7

I/O Ground

K1-12

6

Not Connected

N/A

5

LIN-BUS

K1-15

4

Digital Input 1

TBD

3

Digital Input 2

TBD

2

Digital Input 3

TBD

1

Digital Input 4

TBD

Figure 4

Compact Display Male Connector

Not Included in HyPer 9HV IS:

Econoseal .070 MK-II 8 POS

Plug Part# 2822393-1 or 174982-2

Pin Part# 171662-1 or 171630-1

Locking Plate Part Part# 174983

4 1

8 5

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 12 of 28

Controller Specifications

Controller Communication

•RS-232

•Lin Bus

•CAN:

oProtocol: CAN Open

oPhysical layer: ISO11898-2

oBaud rates: 1Mbps, 800kbps, 500kbps, 250kbps, 125kbps, 50kbps

Controller EMC

•EN12895 (Industrial Trucks –Electromagnetic Compatibility)

Controller Safety Certification

•EN1175-1 (Safety of Industrial Trucks –Electrical Requirements)

The vehicle Owner takes full responsibility of the regulatory compliance of the vehicle system with the

controller installed.

Controller Operating Environment Specifications

•Storage ambient temperature range: -40°C to +70°C

•Operating ambient temperature range: -40°C to +55°C

•Heatsink operating temperature range: -40°C to +95°C

oWith linear derating: +80°C to +95°C

•Protection Level: IP65

•Vibration: Tested under conditions suggested by EN60068-2-6 [5g, 10÷500Hz, 3 axes]

•Shock & Bump: Tested under conditions suggested by EN60068-2-27

•Cold & Heat: Tested under conditions suggested by EN60068-2-1

•Mechanical size: 210 x 160 x 85 [mm] • Weight: 3.5 kg

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 13 of 28

Pre-startup Steps

Download SME Smarview Sys Program:

http://www.go-ev.com/downloads/smartview_sys_dlr.zip

Download* the Latest Controller Firmware:

http://www.go-ev.com/downloads/clone_files/TAU_SYSYS_A01.D01.00A.bin

Download* Your HyPer 9HV Clone File:

http://www.go-ev.com/downloads/clone_files.html

*Not Compatible with Internet Explorer

Be sure your vehicle’s drive wheels are suspended from the ground upon initial powerup! Drive

wheels MUST NOT be in contact with any surface upon initial power up.

Controller MUST BE powered off at all times while working with the wire harness. DO NOT

adjust ampseal connectors or any wires while controller power is switched on.

Open High Voltage disconnect switch while working with High Voltage cables.

If a motor ever revs with no throttle applied, turn off the key switch immediately.

Quickstart Guide

The following number order sequence may be essential to your system and the Smartview program’s

operation. Please follow all steps carefully and in order. If a problem is encountered, ensure all steps were

followed correctly. If all steps are correct and a problem persists, please see Additional Support.

16. Follow the Wiring Diagram supplied by your dealer or shown above.

17. Fasten High Voltage Battery leads to the X144 controller’s B+ and B- terminals according to the Wiring

Diagram. This battery voltage must be within range: Minimum: 90V to Maximum: 180V.

18. Do not connect U,V,W motor leads until steps 4-18 are complete.

19. Before switching on the Controller, remove the 35pin connector.

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 14 of 28

20. On the motor encoder’s 4 Pin Ampseal connector - ensure the wires and connectors are restrained from

movement within the installation area. Also ensure that these wires do not intersect or contact High

Voltage cables or the motor’s field. Verify correct wiring of the encoder:

1. PIN1 is connected to K1-35 (+5V Out).

2. PIN2 is connected to K1-21 (Encoder Sin 1).

3. PIN3 is connected to K1-33 (Encoder Cos 1).

4. PIN4 is connected to K1-9 (Encoder I/O Ground).

21. Check that accessory voltage (12-24V) is connected to K1-24 (Key Switch In) when switching on the

Key. This is the only wire on connector K1 that will see voltage from an outside source.

22. Check that Contactor Positive Coil is connected to K1-25 (Coil Return).

23. Check that Contactor Negative Coil is connected to K1-26 (Driver Output 1).

24. Connect Amp 35 pin connector to controller plug K1.

25. Couple the supplied Null Modem Serial Cable to the supplied Serial-USB adapter.

26. Connect USB end to PC loaded with SME Smartview Smarview Sys software.

27. Connect female serial end to X144 controller’s male serial K3 port.

28. Open SmartView DLR Sys software.

29. Select Connection type: Normal or Wired. Then select the Serial Port your device driver was installed

on. 1. Your COM port number set is listed in the Windows Device Manager.

2. Verify that the COM port number is not already used by another software when SmartView is

opened.

30. Verify vehicle is in Neutral with wheels suspended from the ground. Then switch on X144 controller via

Key Switch, and ensure the controller’s Green or Red Status light is solid or blinking.

1. If Controller’s Status light is off, verify wiring.

2. If Smartview’s home screen options do not appear with a “Manage” block, verify steps 11-15

are followed in order.

31. Once communicating with the Controller, install the downloaded .bin Firmware by clicking on:

1. Mange Clone Firmware Update

2. Browse the Firmware Path and select the most recent Firmware release, which you have

downloaded.

3. Once this .bin file is selected and in the Firmware Path, Click PROGRAM.

32. Install your motor’s downloaded clone file by clicking on:

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 15 of 28

1. Mange Clone Load from file archive to controller

2. Navigate to the file location your downloaded Clone File was saved in. If no path was

selected when downloading the file from , the file will be in your “Downloads” folder. You

should only see files with the extension .clon

3. Select the .clon file matching your motor’s serial number.

4. Click OK, the clone file LOAD progress will reach 100%

5. The Home screen should appear atomatically with –Monitor, Diagnose, Configure, and

Manage blocks.

33. With the Controller switched on and the Main Contactor closed, Smartview’s home screen will be

active, click:

1. Monitor Real Time Data/Inputs –

a. Check that by pressing the Throttle, you are able to see the Analog Input 1 and 2

values increase. If not, check the wiring.

b. Verify that these values are always between 700mV-4600mV. If values are less

than <700mV or greater than >4600mV, please verify wiring.

c. If a throttle other than NetGain’s HEPA is being used, a custom throttle map is

required to match your throttle. Please refer to Post Startup Steps to adjust the

Throttle Mapping.

2. Monitor Real Time Data/Inputs –

a. Check that by selecting the Forward Direction, the Digital Input 2 (K1-5) swithes

on (light green). If not, check the wiring.

3. Monitor Real Time Data/Inputs –

a. Check that by selecting the Reverse Direction, the Digital Input 3 (K1-6) swithes

on (light green). If not, check the wiring.

4. Monitor Real Time Data/Inputs –

a. If a brake pressure transducer is installed, follow steps b. and c.

b. check that by pressing the Brake, you are able to see the Analog Input 3 value

increase. If not, check the wiring.

c. Verify that the starting input value is <900mV with no pressure on the brake

pedal. If starting value is >900mV, please refer to Post Startup Steps to adjust the

Brake Mapping.

34. Once steps 4-18 are complete

1. Turn off Key Switch and Disconnect High Voltage Supply.

2. Connect UVW cables to the

HyPer 9HV

™motor. Be sure the vehicle’s wheels are suspended

from the ground.

3. Re-connect High Voltage Supply.

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 16 of 28

35. The system should now be fully operational. You can now attempt to spin the motor:

1. Select the Forward Direction

2. Press the Throttle and notice the Motor driving

3. Press the Brake and notice the Motor braking

36. If the Motor is in Blocked Rotor condition (maximum Current and 0rpm, with possible high frequency

noise), switch off the Controller. This means that the encoder wiring or motor phases are wrong. Please,

check them.

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 17 of 28

Post-startup Steps

Throttle Mapping

All HyPer-Drive controllers require throttle signal from a 0-5V or 0-12V potentiometer. HyPer 9 Clone

Files come pre-programmed with a throttle map for the Prius Hall Effect Pedal Assembly. This pedal provides

an output of 1.60V-4.55V. A different potentiometer or pedal assembly will require different minimum and

maximum input values be programmed. A user may map any 0-5V thottle pedal to their prefference. Follow the

steps below to Map your Throttle Pedal.

1. On the Smartview DLR Sys home screen, select Configure Traction Throttle Map/s.

2. View the Analog Input signal from the Throttle. If the throttle is wired correctly, this should be

above 800mV without any pressure on the Throttle Pedal.

3. With power off and the vehicle in Neutral - Press on the Throttle pedal and note the change in this

Analog Input mV value.

4. Adjust the Forward and Reverse maps accordingly, starting from the lowest left capture point,

working right to the highest.

Brake Regen Mapping

Dynamic Brake Pedal Regen is pre-programmed in all HyPer 9HV Clone files. To utilize Dynamic

Brake Pedal Regen, a Brake Pressure Transducer must be installed in the system. This Transducer sends a 0-5V

signal that the X144 controller is programmed to transfer into Brake Regen Torque. Follow the steps below to

Map your Brake Pedal.

1. On the Smartview DLR Sys home screen, select Configure Traction Brake/s

Pedal/Handle Brake.

2. View the Analog Input signal from the pressure transducer. If a transducer is wired, this should be

above 300mV without any pressure on the brake pedal.

3. Press on the brake pedal and note the change in this Analog Input mV value.

4. Adjust the map accordingly, starting from the lowest left capture point, working right to the highest.

Regen on Neutral Operating Profiles

If the vehicle does not have a brake pressure transducer (or another type of 0-5V potentiometer to

control regen), Dynamic Brake Pedal Regen can not be used.

All systems have the option to use "Regen on Neutral", also known as Single Pedal Driving. Regen on

Neutral features are programmed into all HyPer 9HV clone files.

There are 3 separate operating profiles on each controller, each with a different Neutral Regen Torque

percentage. These can be cycled through via:

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 18 of 28

1. The Compact Display's (E/S/H) button.

or

2. Selector switches.

There three Regen on Neutral values shown below are pre-programmed into HyPer 9HV clone files. These

values can be adjusted to suit user preference.

•Profile 1 E (End Regen) : 0% (Coast)

•Profile 2 S(Some Regen) : 28%

•Profile 3 H(High Regen) : 40%

Neutral Torque Mapping

Follow the steps below to adjust these Neutral Regen Torque values.

1. On the Smartview DLR Sys home screen, select Configure Traction Torque Limits By

Other.

2. Under “Limit By Operating Profile” - adjust the Regen Torque by Neutral to suit your preference.

Battery Mapping

The X144 controller can accept high voltage power from any DC supply with limits between 62V-132V.

The controller can estimate a battery’s state of charge based off a specified Voltage Map. Follow the steps

below to Map your battery pack.

1. On the Smartview DLR Sys home screen, select Configure System Battery Datasheet.

2. Under “Type” – select Lead Acid or User Defined.

3. Enter your Battery Pack’s Capacity and Nominal Voltage.

4. Adjust the state of charge percentage levels based on the minumum and maximum charge values of

your Battery Pack.

HyPer 9HV Motor Temperature Derating

The HyPer 9HV Motor contains Permanent Magnets. These magnets are rated up to a temperature of

170°C. To ensure proper protection from overheating the magnets, the controller is programmed to derate

power based on the motor’s temperature.

Operating ambient temperature range: -40°C to +120°C

Linear power derating: +135°C (100% current) to +155°C (30% current)

Thermal Shut Down: +165°C

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 19 of 28

X144 controller Temperature Derating

To ensure proper protection from overheating, the controller is programmed to derate power based on its

heatsink temperature. Additional cooling methods, such as Liquid Cooling, may be required if your controller

is overheating under normal operation.

Operating ambient temperature range: -40°C to +55°C

Linear power derating: +80°C (100% current) to +95°C (50% current)

Thermal shut down: +95°C

HyPer 9HV IS User Manual Version 06

NetGain Motors, Inc.

Page 20 of 28

HyPer-Drive X144 Pre-Programmed I/O

Signal: Inputs and Outputs

•Digital Inputs: 9

•Analog Inputs: 5

•Digital Outputs (ON/OFF): 2

•Driver Outputs (PWM): 4

•Motor Speed/Position Sensor Inputs: 2 (A+B Channels/Sin+Cos Analog)

Controller I/O Table

Refer to following table for a complete X144 controller I/O capabilities. For a pinout of the wire harness included

in your HyPer 9HV IS, refer to Figure 2 –Standard Pinout Order Assignment. The following table lists the controller’s

pre-programmed capabilities.

K1 connector pin-out for AC-X1

Pin

Name

I/O

Specification

Typical function

1

GND

I/O Ground

Do not exceed 0.5A

Negative Logic Supply

2

CAN-L

CAN BUS

CAN-BUS 1 MBit/s max

CAN L (No internal termination

resistor)

3

CAN-L RES

CAN BUS

Connected to CAN-L with a series

120Ohm

Termination resistor

4

DIGITAL INPUT 1

Digital Input

VL<=2V,VH>=4.5V Resistor pull-

down(active high) or pull

up(active low) ON rated voltage

+12V/24V

TO BE ASSIGNED

5

DIGITAL INPUT 2

Digital Input

VL<=2V,VH>=4.5V Resistor pull-

down(active high) or pull

up(active low) ON rated voltage

+12V/24V

TO BE ASSIGNED

6

DIGITAL INPUT 3

Digital Input

VL<=2V,VH>=4.5V Resistor pull-

down(active high) or pull

up(active low) ON rated voltage

+12V/24V

TO BE ASSIGNED

7

DIGITAL INPUT 4

Digital Input

VL<=2V,VH>=4.5V Resistor pull-

down(active high) or pull

up(active low) ON rated voltage

+12V/24V

TO BE ASSIGNED

8

DIGITAL INPUT 5

Digital Input

VL<=2V,VH>=4.5V Resistor pull-

down(active high) or pull

up(active low) ON rated voltage

TO BE ASSIGNED

Table of contents

Other NetGain Motors Engine manuals

Popular Engine manuals by other brands

Siemens

Siemens SIMOTICS S-1FK7 operating instructions

Saito

Saito FG-73R5 instruction manual

Briggs & Stratton

Briggs & Stratton Intekt 825 Series Operator's manual

Briggs & Stratton

Briggs & Stratton 130000 950 Series Operator's manual

SkyReach

SkyReach BushCat Maintenance manual

Waterra

Waterra Waterra PowerPack PP1 manual

Bartec Varnost

Bartec Varnost 4KTC 250 manual

Applied Motion Products

Applied Motion Products TSM17C Hardware manual

Hyundai Seasall

Hyundai Seasall U125S Installation & operation guide

ACM

ACM TITAN 200 BME 115V installation manual

Kohler

Kohler LOMBADINI 15 LD 500 Use & maintenance

Roto

Roto 130 FSI operating instructions