NEUGART HLAE Series User manual

Instruction manual Hygienic Design Planetary Gearbox

1 Table of contents

1 GB_ 100225294 / Rev. status "004"

1Table of contents

1Table of contents 1

2About this document 2

2.1 Warnings 2

2.2 Notes and accentuations 3

3Safety 4

3.1 Intended use 5

3.2 Non-intended use 6

3.3 Personnel qualification 6

3.4 General safety instructions 7

3.5 Standards/directives 8

4Description 9

4.1 Technical data 10

4.2 Accessories 10

4.3 Lubrication 11

4.4 Rating plate 11

4.5 Approved detergents 12

5Storage, transport 13

6Installation 14

6.1 Conditions governing the location 14

6.2 Preparing the installation 14

6.3 Installing the motor on the gearbox 15

6.4 Installing the gearbox 17

7Commissioning 19

7.1 Measuring the surface temperature 19

8Cleaning 20

9Maintenance / repair 21

9.1 Lubrication 21

9.1.1 Determining the pot life of the lubricant 21

9.2 Seals 22

10 Troubleshooting 23

11 Disposal 23

12 Service 23

Instruction manual Hygienic Design Planetary Gearbox

2 About this document

GB_ 100225294 / Rev. status "004" 2

2About this document

This instruction manual describe the installation and commissioning of the NEUGART

Hygienic Design Planetary Gearbox with the designation HLAE. The instruction manual

contain the chapters Technical data, instruction as well as information on intended use /

maintenance and care of the product.

The machine operator must guarantee and ensure that these instructions are read and

understood by any person who is entrusted or commissioned with the installation,

operation or maintenance of the product. These instructions must be kept in an

accessible place in the vicinity of the machine so that they can be immediately consulted

as and when required.

Persons working in the machine surroundings must also be familiarised with the safety

instructions.

2.1 Warnings

Warnings point out specific dangers and specify measures for avoiding the danger.

Warnings are categorised in three levels:

Warning

word

Meaning

Danger

Immediately threatening danger for life and health

Warning

Possibly threatening danger for life and health

Caution

Possibly threatening danger of light injuries or damage to property

Warnings are structured as follows:

Danger

Type and source of the danger

Action to avoid the danger

Instruction manual Hygienic Design Planetary Gearbox

2 About this document

3 GB_ 100225294 / Rev. status "004"

2.2 Notes and accentuations

The following signs and icons are used in these instruction manual:

Warning icon. This icon points out dangers and warnings.

Information icon. Here you receive particularly important information you should

heed for a correct and safe installation of the gearbox.

Action. Here an action is required from you.

Instruction manual Hygienic Design Planetary Gearbox

3 Safety

GB_ 100225294 / Rev. status "004" 4

3Safety

This chapter describes the safety instructions you have to heed for a safe and hazard-

free use of the Hygienic Design Planetary Gearbox. It points out possible sources of

danger and necessary safety measures.

Observe the technical data!

Observe the technical data and the installation details (rating plate and documentation).

If the permissible technical data are exceeded, permanent damage to the product may

occur and the warranty claim will be forfeited.

Draw up risk assessment after installation into the machine!

The machine manufacturer must draw up a risk assessment for the machine and take

suitable measures to prevent unexpected movements from causing personal injuries or

damage to property. Additional requirements on specialised personnel may possibly

arise from the risk assessment.

Secure feather key!

Remove or secure any shaft feather keys, if the gearbox is started up without coupled

load to prevent the feather key from being flung out and the associated injury hazard.

Avoid contact between dissimilar metals!

The gearbox casing consists of stainless steel. Prevent the gearbox from coming into

direct contact with more active metals such as aluminium or steel so as to prevent

contact corrosion. Contact corrosion may cause damage to the gearbox surfaces, which

in turn can lead to contamination of the end product.

Note: Please also select the corresponding tools for this.

Instruction manual Hygienic Design Planetary Gearbox

3 Safety

5 GB_ 100225294 / Rev. status "004"

3.1 Intended use

The gearboxes have been in particular designed for use in machines in food, cosmetic,

pharmaceutical, medical and similar applications with highest demands on the

cleanability of the machine (hygiene design).

Operation of the HLAE gearboxes is permitted in applications with indirect contact to

foodstuffs.

You may only operate the gearboxes taking into consideration the ambient conditions

defined in this documentation.

Operation of the HLAE gearboxes is permitted in environments with detergents taking

into consideration the conditions defined in chapter 4.5.

Do not exceed permissible operating data.

Only start up the gearbox once the machine into which the gearbox is installed as a

component complies with the provisions of the directives and statutory provisions to be

applied (see Chapter 3.5).

Hygienic design uses

A hygienic design use comprises among others also the connection to the motor and to

the application. It is therefore important that on the part of the customer the

corresponding measures in terms of the hygienic design are taken into consideration. In

order to achieve this, we propose the following measures:

Gearbox:

The gearbox can be mounted in any position. There are no restrictions in this

regard.

Connection to the motor:

To seal the motor flange, an O-ring in the motor's A-bearing shield must be

provided according to hygienic design.

Use the sealing screws according to hygienic design provided by the motor

manufacturer to fasten the motor.

Connection to the application:

To seal the gearbox flange, the O-ring included in the supply must be inserted

in the gearbox output flange.

Depending on the application, the optionally available sealing kit can be used

for sealing. Detailed installation instructions see Chapter 4.2 and 6.4.

To meet the 3-A Sanitary Standard for General Requirements for your

application, the gearbox must be located outside the product contact surface

with at least 1 in. (25.4 mm) clearance between the gearbox and the nearest

product contact surface with the clearance open for inspection.

Instruction manual Hygienic Design Planetary Gearbox

3 Safety

GB_ 100225294 / Rev. status "004" 6

3.2 Non-intended use

It is forbidden to operate the HLAE gearboxes in explosive

areas.

HLAE gearboxes may not be used in clean room applications.

It is forbidden to commission the gearbox if the machine into which it has been

incorporated does not comply with the country-specific provisions (standards /

directives) or laws.

3.3 Personnel qualification

Only qualified specialist staff may carry out work such as transport, installation,

commissioning and maintenance. Qualified specialist staff designates persons who are

acquainted with the transport, installation, assembly, commissioning and operation of

gearboxes and who are in possession of the minimum qualifications corresponding to

their occupation and have read and understood the instruction manual:

Transport: only by personnel with corresponding qualification / training in

handling the product.

Installation: only by specialists who have undergone training in machine

engineering.

Commissioning / maintenance: only by specialists with extensive

knowledge in the field of drive engineering. Specialist staff must also know and

heed the national regulations for the prevention of accidents.

Use of the machine: only by specialists with knowledge of the hygiene

regulations valid in the area of application.

Hygienic cleaning: only by instructed cleaning personnel, who are acquainted

with the specified detergents and cleaning cycles and observe these according

to protocol. Failure to observe these can lead to permanent damage to the

product. Likewise, all cleaning instructions and specifications mentioned in this

document must be heeded and observed.

Ensure that personnel has read and understood these instruction manual.

Instruction manual Hygienic Design Planetary Gearbox

3 Safety

7 GB_ 100225294 / Rev. status "004"

3.4 General safety instructions

Caution

Improper use, faulty installation and operation as well as inadequate maintenance may

lead to serious damage to property and personal injuries.

Heed the following safety instructions before commissioning the gearbox:

Do not carry out any modifications/conversions on the gearbox.

Do not carry out any other work on the gearbox then the one described in these

instruction manual.

Before making use of the gearbox, ensure that all sealing elements and shafts

have been correctly connected.

Ensure that possible sources of danger are covered/secured (e.g. rotating parts).

Observe the conditions for commissioning requested by the manufacturer.

Never use the gearbox with damaged parts.

Always provide for adequate convection at the gearbox during operation.

The gearbox may get very hot during operation. Allow the gearbox to cool down

before working on it. Pay attention to hot lubricants when opening the gearbox.

Only work on the gearbox once it has come to a standstill and the driving motor

has been switched off and secured against unintentional restart.

Have repairs within the guarantee period only performed by NEUGART.

Instruction manual Hygienic Design Planetary Gearbox

3 Safety

GB_ 100225294 / Rev. status "004" 8

3.5 Standards/directives

The CE-mark of conformity and the EC declaration of conformity are not necessary, as

these gearboxes are not considered to be a machine within the meaning of the EC

Machinery Directive 2006/42/EC, but a component.

Commissioning the gearbox within the scope of application of the EC Machinery

Directive is forbidden until it has been determined that the machine into which the

gearbox has been installed as component complies with the EC machinery directive.

HYGIENIC DESIGN

The HLAE series has been designed in accordance with the stringent design

specifications of the EHEDG (European Hygienic Engineering & Design Group)

committee.

In addition, the HLAE series complies with the 3-A Sanitary Standard for General

Requirements and is certified under the Replacement Parts and System Component

Qualification Certificate Program (RPSCQC).

FDA (Food and Drug Administration)

Only FDA-compliant materials are used for the gearbox.

NSF (National Sanitation Foundation)

It goes without saying that attention is also paid to the inside of the HLAE series so that

the lubricant is certified as suitable for use in foodstuffs.

Instruction manual Hygienic Design Planetary Gearbox

4 Description

9 GB_ 100225294 / Rev. status "004"

4Description

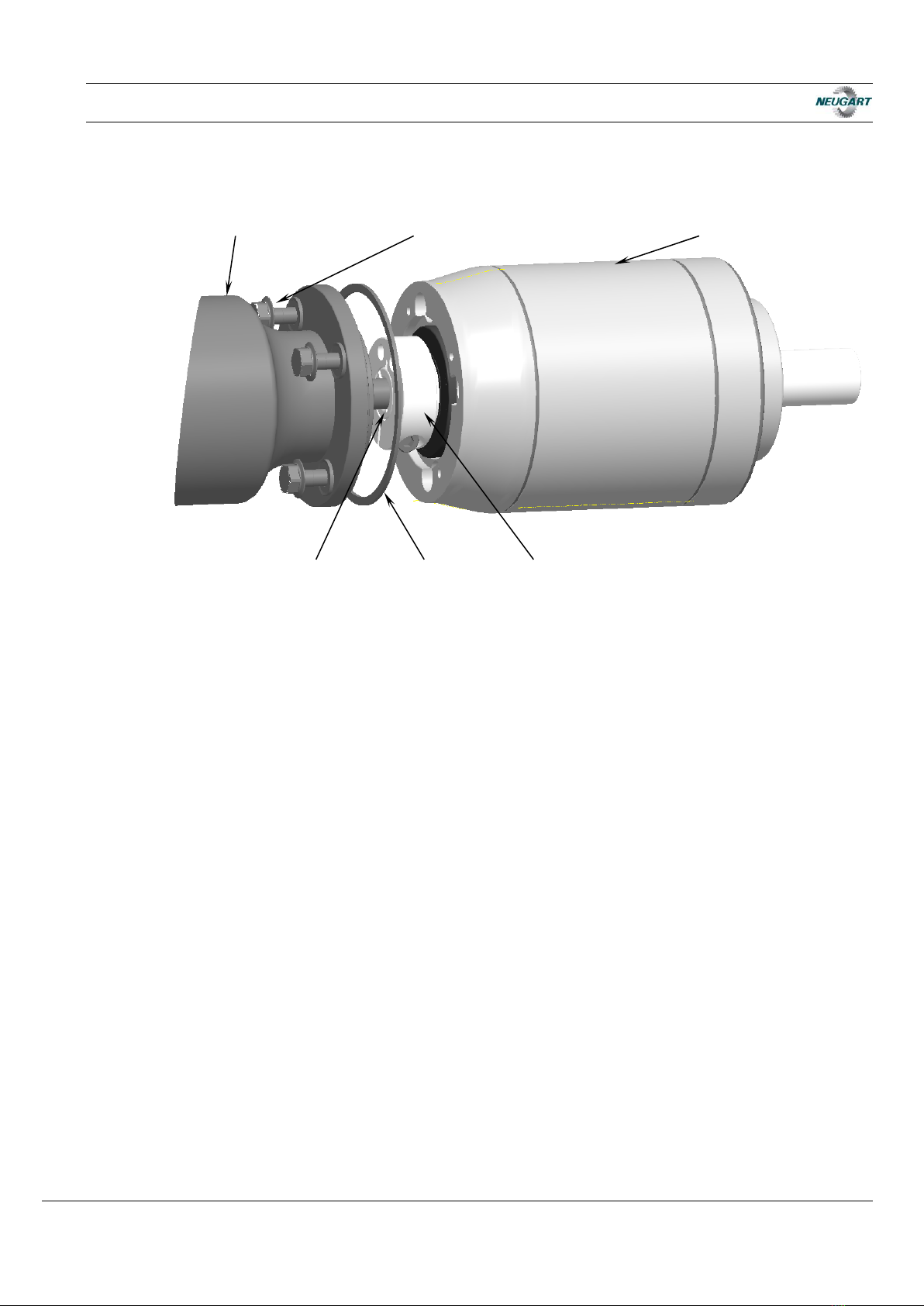

The HLAE is a planetary gearbox which has been developed with an optimised

cleanability in mind. The gearbox is available in 3 design sizes

(HLAE070, HLAE090, HLAE110) and a single- and double-stage design is offered for

each. The drive flange is adapted to the respective "hygienic design" motor. A reducing

bush is used between motor shaft and gearbox input shaft as necessary (this is then

included in the scope of supply). It is recommended to use the optional sealing kit on

the application side.

Hygienic design motor

Hygienic design

screws for fastening

the motor

O-rings with FDA

approval

(EPDM)

Gearbox contour

without dead spaces

Gearing components

from well-proven

gearbox series

Lubrication suitable

for use in foodstuffs

according to NSF (H1

approval)

Electro-polished

gearbox surface

Optional sealing kit

Fig. 1:

HLAE090 completely assembled

Instruction manual Hygienic Design Planetary Gearbox

4 Description

GB_ 100225294 / Rev. status "004" 10

4.1 Technical data

Gearbox series

HLAE070

HLAE090

HLAE110

Maximum permissible

operating temperature

-25°C to +90°C

Type of protection

IP69K

Rotation shaft sealing

O-rings

High-quality PTFE shaft sealing rings

EPDM (standard) / FFKM (on request)

Dimension sheet number

MB-4398

MB-4460

MB-4463

MB-4380

MB-4461

MB-4462

Additional technical data can be found on the Internet under www.neugart.com

4.2 Accessories

Sealing kit (output side)

For gearbox series

HLAE070

HLAE090

HLAE110

Item number

63911

63858

64130

O-ring EPDM O-ring EPDM

Mounting plate

Hygienic design

sealing washer

Hygienic design

screws

Fig. 2:

Sealing kit

Instruction manual Hygienic Design Planetary Gearbox

4 Description

11 GB_ 100225294 / Rev. status "004"

4.3 Lubrication

Only lubricants with H1 approval are used for the HLAE series. The amount of lubricant

is dimensioned such that lifetime lubrication is achieved (see Chapter 9.1).

4.4 Rating plate

The rating plate serves the explicit identification of the gearbox and must be legible at

all times (e.g. to allow the tracing of gearboxes by NEUGART).

The rating plate is laser-printed and must also be cleaned during the cleaning process.

1

2

3

5

4

6

Fig. 3: Example rating plate

1 Product key

4 Serial number

2 Type

5 Transmission ratio

3 Design size

6 Month/year of construction

Instruction manual Hygienic Design Planetary Gearbox

4 Description

GB_ 100225294 / Rev. status "004" 12

4.5 Approved detergents

During several exacting test series, the HLAE's resistance against the following industrial

detergents was tested under the toughest conditions:

Products by ECOLAB

P3-topax 19

P3-topax 12

P3-topax 52

P3-topax 56

P3-topax 66

P3-topax 990

P3- topactive OKTO

P3-topactive DES *

* P3-topax 12, P3-topax 56, P3-topactive DES are usable according to the material

suitability test carried out with the respectively more aggressive medium.

Test setup:

The material suitability test has been carried out by Ecolab in accordance with test

method 40-1. During this test, the surfaces of the gearbox materials were placed into

the respective detergent at a 3% concentration at a temperature of 21°C.

After successfully passed material suitability test, the compatibility with the detergents

specified is given.

This should correspond to approx. 2500 cleaning cycles with respectively 15 minutes

contact to the detergent or approx. 1500 cleaning cycles with cleaning and subsequent

disinfection.

Neugart can only provide a guarantee for the gearbox service life if the tested

detergents are used. Other detergents than the ones mentioned can be tested and

where appropriate approved by Neugart on request.

Instruction manual Hygienic Design Planetary Gearbox

5 Storage, transport

13 GB_ 100225294 / Rev. status "004"

5Storage, transport

Max. 2 years at –30° C to +60° C, dry, inside the original packaging.

Please observe the guarantee period according to our general terms and conditions.

Restrict the storage time to a minimum.

The seals will age if you store the gearbox at temperatures >60° C or expose it to

direct sunlight or ultraviolet light and ozone.

Storage temperatures up to 85° C are allowed for short periods (approx. 2 weeks).

However, already during this short period, temperatures >60° C may lead to

premature ageing of the seals. The seals should therefore be checked before using the

gearbox.

Caution

Gearbox damage due to improper transport

Do not drop the gearbox.

Only transport the gearbox inside its packaging.

Protect packaging and contents from humidity.

Storage

Transport:

Instruction manual Hygienic Design Planetary Gearbox

6 Installation

GB_ 100225294 / Rev. status "004" 14

6Installation

6.1 Conditions governing the location

Observe the following information for a smooth operation and an as long as possible

service life of the gearbox:

Provide adequate convection for the gearbox.

Pay attention that the gearbox is able to adequately dissipate heat via the output

flange.

The motor and other external heat sources can heat up the gearbox. Obtain

information about occurring motor temperatures from the respective manufacturer.

Adhere to the restrictions demanded by the respective type of protection of the

gearbox (see Chapter 4.1, Technical data).

6.2 Preparing the installation

So as to be able to use the gearbox without any restrictions, it is important to prevent

any dents, scratches or other damages to the product while assembling and handling

the product. Background: An increased formation of germs is to be expected inside the

dent caused by a scratch.

Observe the information with regard to contact corrosion (Chapter 3)

Before installing or mounting the product, first check the enclosed accessories for

completeness and check that the product does not exhibit any damages.

Before commissioning, the entire installation must be cleaned once according to

cleaning specification to avoid contamination of the first production batch.

Instruction manual Hygienic Design Planetary Gearbox

6 Installation

15 GB_ 100225294 / Rev. status "004"

6.3 Installing the motor on the gearbox

Ensure that

the motor does not exceed the maximum permissible motor weight for the

gearbox,

the concentricity and axial run-out tolerance "N" according to DIN 42955 is

observed on the motor side.

Motors with smooth shaft and B5-flange are to be preferred. During installation,

the motor manufacturer's specifications with regard to safety and the use of

screw locking varnish must be observed.

Install the motor according to the motor installation instructions enclosed in the gearbox

packaging.

1. Check that it is geometrically possible to install motor and gearbox.

2. Install the motor pinion that is included in the supply (gearbox sun gear with

deep groove ball bearing) on the cleaned motor shaft. Fix the clamping screw

with the specified tightening torque.

Caution: The specified installation dimension MUST be observed as failure to

do so will result in immediate damage to the components.

3. Place the sealing element enclosed by the motor manufacturer into the groove

between motor flange and gearbox provided on the "Hygienic Design motor".

4. Introduce the motor pinion parallel to the axis in vertical position carefully into

the gearing by means of slight turning movements.

Caution: Improper handling can damage the gearing.

5. Now fix the motor on the gearbox with the motor-side sealing screws. Fix the

screws with the tightening torque specified by the motor manufacturer.

Caution

The work steps specified in the motor installation instructions must be observed. You

can also download the motor installation instructions under www.neugart.com.

Installation

Instruction manual Hygienic Design Planetary Gearbox

6 Installation

GB_ 100225294 / Rev. status "004" 16

Hygienic design

motor

Hygienic design screws

with sealing washer

Hygienic design planetary

gearbox

Reducing bush

Motor-side

sealing

Motor pinion

Instruction manual Hygienic Design Planetary Gearbox

6 Installation

17 GB_ 100225294 / Rev. status "004"

6.4 Installing the gearbox

The gearboxes can be used in any installation position. The thickness of the

application plate may be varied within the specified limits.

Caution

Gearbox damage due to objects getting pressed or knocked against the

shaft

Only fasten couplings, washers, gear wheels, chain wheels, etc. on the shaft with

suitable clamping sets.

Caution

Gearbox damage due to sealing leak

Make sure that the seals on the gearbox do not get damaged or soiled during

installation.

Assemble the motor according to the motor installation instructions enclosed in the

gearbox packaging.

1. Check that it is geometrically possible to install the gearbox on the application.

2. Thoroughly clean / degrease the flange face and centring on the gearbox (no

aggressive detergents)

3. Clamp the enclosed O-ring into the groove intended for this purpose between

output flange and application plate.

Note: pull the O-ring onto the casing. Once the gearbox rests against the

application plate (see item 4 and 5), carefully slide the O-ring into the groove.

4. Carefully introduce the gearbox parallel to the axis into the application centring.

Caution: the O-ring may not be crushed or pushed out of position in doing so.

5. Fix the gearbox on your application using suitable sealing screws. Observe the

tightening torques intended for this purpose and use a suitable screw locking

device.

Note: We recommend the optionally available sealing kit, which comprises the

matching sealing screws (see Chapter 4.2).

6. When the sealing kit is used, the mounting plate (including matching O-rings)

must be installed on the application side subsequent to point 4 using the sealing

screws intended for this purpose (as described in point 5).

Note: Insert the O-ring in mounting plate and application in the groove

intended for this purpose and if necessary, fix for installation with a suitable

adhesive agent.

Instruction manual Hygienic Design Planetary Gearbox

6 Installation

GB_ 100225294 / Rev. status "004" 18

If due to the application, there are still gaps or dead spaces, these must be sealed

accordingly.

O-ring EPDM

O-ring EPDM

Mounting plate

O-ring EPDM

Sealing washer

hygienic

Hygienic design

screws

Instruction manual Hygienic Design Planetary Gearbox

7 Commissioning

19 GB_ 100225294 / Rev. status "004"

7Commissioning

Ensure that ...

all components are correctly interconnected.

the ambient temperature ranges within the specification.

all seals are free of dirt / ice to prevent these from being damaged when they are

loosened.

none of the parameters specified for the gearbox are exceeded (e.g. limit torque,

speed, etc. in the controller).

nobody is staying in the danger zone.

7.1 Measuring the surface temperature

Caution

Gearbox damage due to overheating

Exceeding the maximum permissible temperature of the gearbox will lead to gearbox

damage.

Ensure that during operation the maximum permissible temperature of the gearbox is

not exceeded.

Ensure that the equipment is switched off if the max. permissible temperature is

exceeded and consult NEUGART. This can for instance be implemented by means of

motor current monitoring.

Measure the temperature on the casing centre at maximum load. (preferably by means

of contact measurement)

The gearbox has reached a stationary thermal state if the temperature increase does

not exceed 2° C/h.

Danger

The surface temperature may reach up to 90°C

Risk of burns: Take corresponding precautions!

With the measured temperature you can determine the lubricant's pot life (see Chapter

9.1.1).

This manual suits for next models

3

Table of contents

Other NEUGART Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Petol

Petol HYDRA-TORK U1344 operating manual

Siemens

Siemens SIMATIC NET SCALANCE W788-x operating instructions

spotzero

spotzero Sea Xchange XTC II User manual and installation guide

Engcon

Engcon EC204 user manual

ApenGroup

ApenGroup PCH Series Maintenance and service manual

Hasco

Hasco Loc Check A5900/ Series manual