Charmhigh CHM-T48VB User manual

长沙常衡机电设备有限公司

http://www.charmhigh.net

1

Charmhigh Automatic Chip

Mounter(CHM-T48VB)Operating

Manual

2016

CHARMHIGH TECHOLOGY LIMITED

Technology Versus Future-V1.0-2016

2016-06-01

Charmhigh-V1.0-2016 |

2

All Rights Reserved

Catalogue

1. REVISION HISTORY......................................................................................................... 4

2. INSTALL THE MACHINE .................................................................................................. 5

3. PRODUCT LIST................................................................................................................. 6

4. HARDWARE REQUIREMENTS AND COMPATIBLE SOFTWARE................................. 7

4.1. HARDWARE REQUIREMENTS.......................................................................................... 7

4.2. COMPATIBLE SOFTWARE ............................................................................................... 7

5. NOTICES ........................................................................................................................... 8

6. TECHNICAL PARAMETERS ............................................................................................ 9

7. MECHANICAL STRUCTURE.......................................................................................... 10

8. BOOT THE MACHINE..................................................................................................... 12

9. RUN ................................................................................................................................. 13

9.1. EDIT WORK FILE......................................................................................................... 13

9.1.1. Component ....................................................................................................... 14

9.1.2. Material Stack ................................................................................................... 17

9.1.3. Batch................................................................................................................. 20

9.1.4. IC Tray............................................................................................................... 23

9.1.5. PCB Calibration ................................................................................................ 24

9.2. LOAD WORK FILE........................................................................................................ 26

10. TEST ............................................................................................................................ 28

11. SET .............................................................................................................................. 30

11.1. SYSTEM SET........................................................................................................... 31

11.2. VACUUM DETECTION SET........................................................................................ 34

11.3. BACKUP/RESTORE.................................................................................................. 35

12. FILE.............................................................................................................................. 37

12.1. GENERATE CSV FILE.............................................................................................. 37

12.1.1. By Altium Designer........................................................................................ 37

12.1.2. By Protel........................................................................................................ 39

12.2. FILE CONVERT........................................................................................................ 42

12.2.1. Material Stack ............................................................................................... 44

12.2.2. Component.................................................................................................... 44

12.2.3. Batch............................................................................................................. 45

13. LOG.............................................................................................................................. 47

14. SYSTEM LOG.............................................................................................................. 48

15. QUICK START............................................................................................................. 48

Charmhigh-V1.0-2016 |

4

All Rights Reserved

1. Revision History

No.

Date

Description

Version

1

2016-06-01

Create document

V1.0

Charmhigh-V1.0-2016 |

5

All Rights Reserved

2. Install the Machine

Open the packing cases, take out the SMT machine, placed it on a strong table;

Check if the machine is in good condition, check the list of products, if you have

any questions please contact us;

Please read this manual carefully before use SMT machine;

There's any problem in use, welcome to contact.

Charmhigh-V1.0-2016 |

6

All Rights Reserved

3. Product List

No.

Parts

Quantity

Remarks

1

SMT machine

1

-

2

nozzles

4

503,504,505,506

3

USB flash disk

1

8G

4

power cord

1

-

Charmhigh-V1.0-2016 |

7

All Rights Reserved

4. Hardware Requirements and Compatible Software

4.1. Hardware Requirements

All equipment are built-in, don't need other external devices.

4.2. Compatible Software

Compatible with Protel99se,Altium Designer.

Charmhigh-V1.0-2016 |

8

All Rights Reserved

5. Notices

(1) Keep the machine away from humidity and dust, otherwise may cause electric

shock or fire;

(2) Do not place the machine in the platform of instability or tilted, otherwise the

vibration of the machine when working may lead to lower precision, even personal

injury caused by overturned;

(3) Don't disassembling machine, or may be led to the decrease of the accuracy or

machine damage;

(4) Don't use hand to touch the moving parts, otherwise it may damage the machine

or cause personal injury;

(5) New machine components containing volatile substances, it need to maintain

good ventilation in the first few days using;

(6) The power cord can only be used for the machine, otherwise may damage the

other electrical appliances;

(7) Ensure the power supply meet machine nominal requirements;

(8) Ensure the power supply socket with good grounding;

(9) Keep the machine away from flammable and explosive goods;

(10) Place the nozzles and other small accessories in out of the reach of infants and

young children;

(11) Don't let the pull needle in the stretched state for a long time, or it could be

damaged;

(12) Don't put machine direct exposure to sunlight or bright light, otherwise may cause

the machine precision reduce or damage to the machine.

Charmhigh-V1.0-2016 |

9

All Rights Reserved

6. Technical Parameters

model

CHM-T48VB

PCB area

10mm×10mm~355mm×355mm

X,Y axis stroke

510×460mm

Z axis stroke

15mm

number of nozzle

2

material stack number

ordinary material stack 58, IC material stack up to 14

visual support

dual cameras

Motor drive

Closed-loop servo high voltage drive system(Ensure the

accuracy of operation)

Z axis back position

detection

Yes

Pull needle auto return

Yes

Leak detection method

Vacuum detection、Visual inspection

LCD Screen

7 inch Industrial LCD screen

Board

Independent research and development of industrial computer

motherboard

System

Embedded Linux system

need external air pump

no(built-in mute air pump)

need external PC

No need

power supply

220V(110V), 50Hz

power

250W

weight

65Kg

volume of packaging

0.41m3

Charmhigh-V1.0-2016 |

10

All Rights Reserved

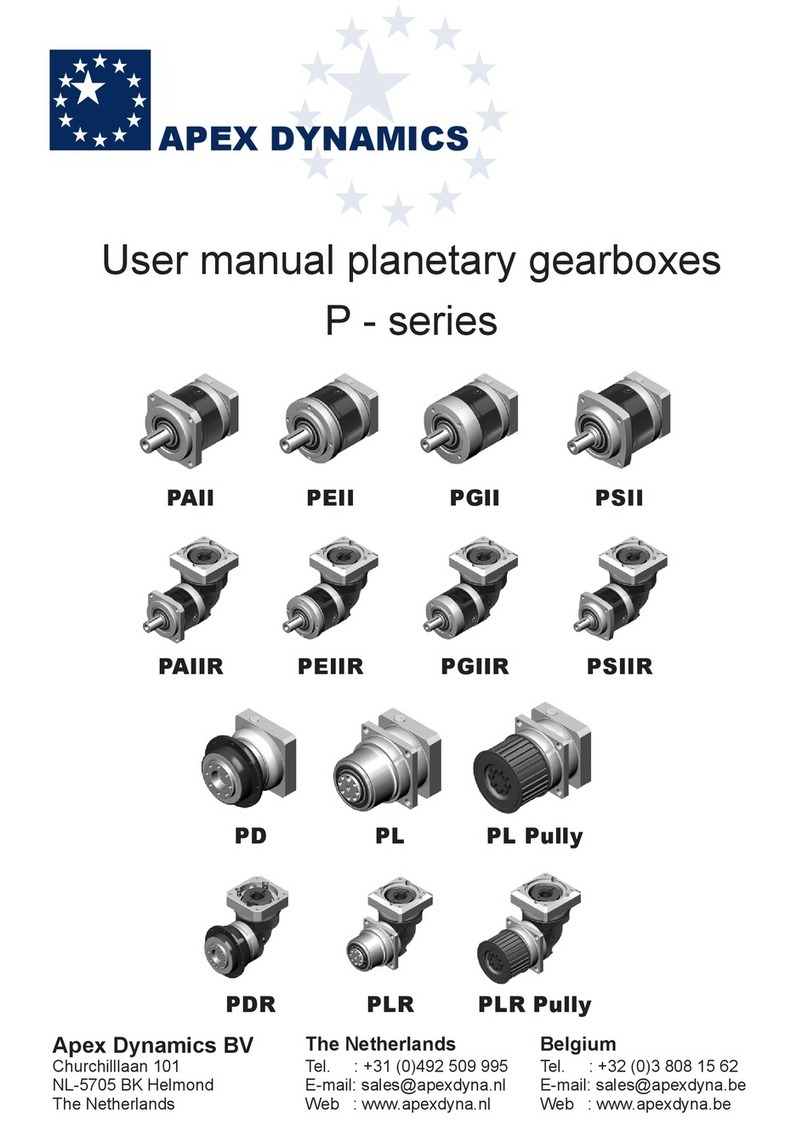

7. Mechanical Structure

The figure below shows the machine structure as a whole.

tape placing

area A

nozzle

pull needle

ordinary material

stack A

Belt receiving

wheel A

IC tray (PCB) clamping area

down camera

power

PCB clamping area

up camera

touch screen

USB emergency stop

power switch

IC material stack

tape placing

area A

ordinary material

stack B

Belt receiving wheel B

Figure.7-1

(1) Nozzle: Support two nozzles, the nozzle 1 is on the left, nozzle 2 is on the right,

used for absorbing materials;

(2) Pull needle: Used for pulling tape, note, don't let the pull needle in the stretched

state for a long time, or it could be damaged;

(3) Down camera: Used for observing the material stack, PCB and components;

(4) Up camera: Used for calibrating the components position, angle, so as to improve

placement accuracy;

(5) IC tray (PCB) clamping area: Used for fixing the IC tray or PCB;

(6) PCB clamping area: Used for fixing PCB, let PCB close to left, top spring should

be compacted;

(7) Ordinary material stack A\B: Place tape packaging materials;

(8) Belt receiving wheel A\B: Used for collecting film;

(9) Tape placing area A\B: Used for placing tape;

(10)IC material stack: Used for placing the larger IC;

(11)Touch screen: Used for manipulating and control the machine;

(12)USB interface: Used for connecting the USB storage device;

(13)Emergency stop switch: Emergency stop after press down, machine normal

Charmhigh-V1.0-2016 |

11

All Rights Reserved

work when clockwise rotation and bounce;

(14)Power switch: Note, open this button to boot, shutdown should first close the

software through the touch screen, and then close the button.

Charmhigh-V1.0-2016 |

12

All Rights Reserved

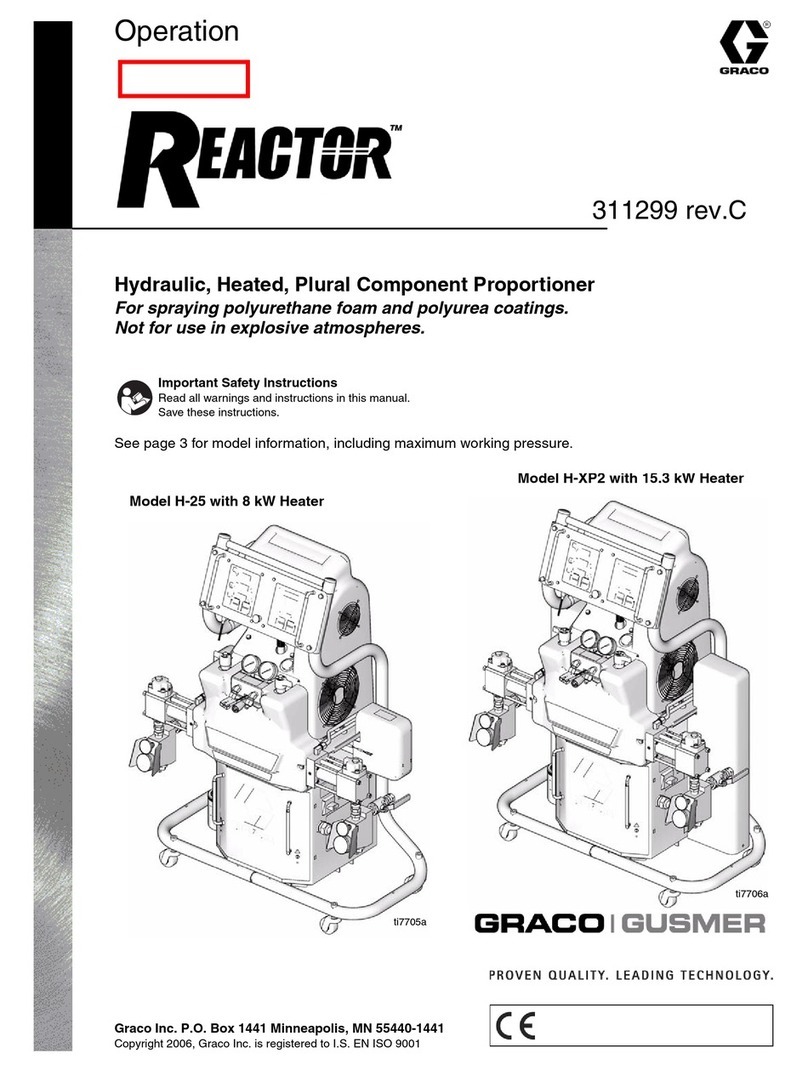

8. Boot the Machine

Open the machine power switch, wait for the machine to self check and loading the

operating system, when machine start complete, display screen as shown below.

Figure.8-1

(1) Alarm:Used for viewing current alarm and cause;

(2) Run: Used for loading working files and control the machine running etc.;

(3) Test: Used for testing each function module respectively;

(4) Set: Used for setting various parameters that machine work required;

(5) Log: Used for viewing the record information;

(6) System Log: Used for viewing the log of system;

(7) Files: Used for managing and convert work file.

Charmhigh-V1.0-2016 |

13

All Rights Reserved

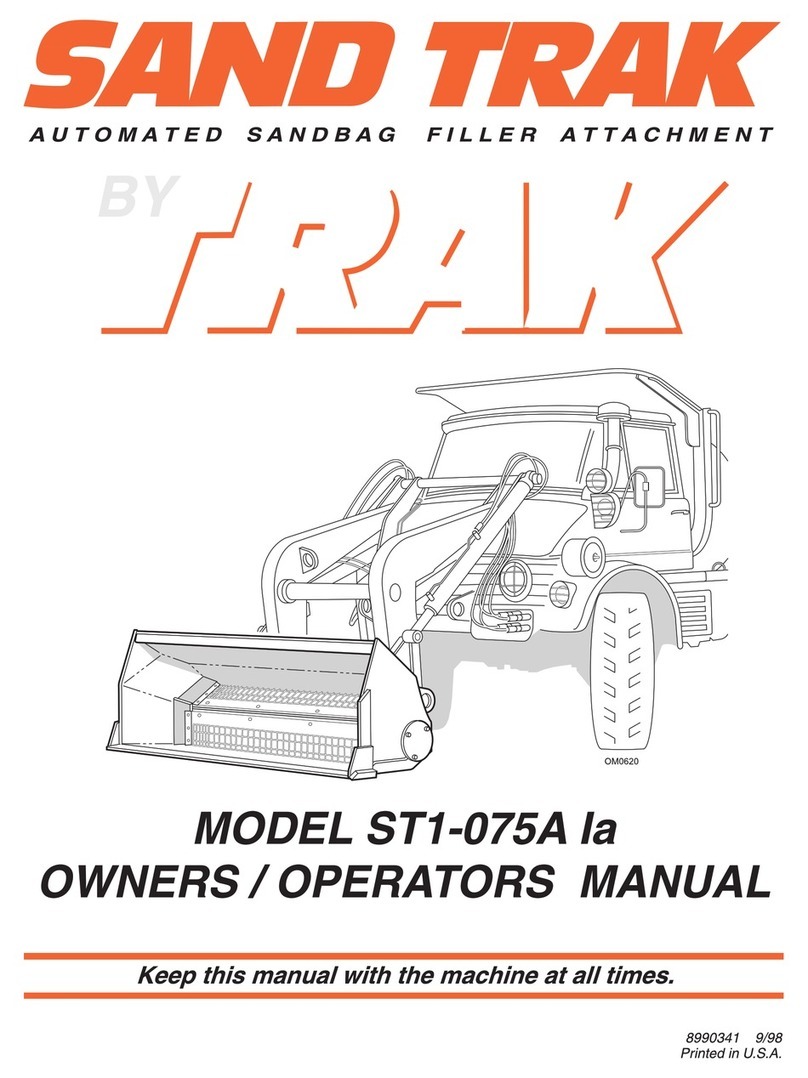

9. Run

The machine needs to select a work file to run, from the main screen, click on the run

button to enter the screen as shown below, through this screen can manage work file.

Figure.9-1

(1) Work file list: The middle of the screen displays a list of existing work files in the

system, click to select the work file, the upward double arrow on the right used for

paging up, upward single arrow used for selecting previous line, downward arrow

vice versa.

(2) New: Create a new work file;

(3) Delete: Delete the selected work file;

(4) Edit: Edit the selected work file;

(5) Load: Load the selected work file to run;

(6) Back: Click left arrow button on the upper right corner of the screen to return to

the previous level screen, other screen similarly.

9.1. Edit Work File

The work file editing screen shown as below, can edit component, material stack,

batch, IC tray and PCB calibration respectively.

Charmhigh-V1.0-2016 |

14

All Rights Reserved

Figure.9-2

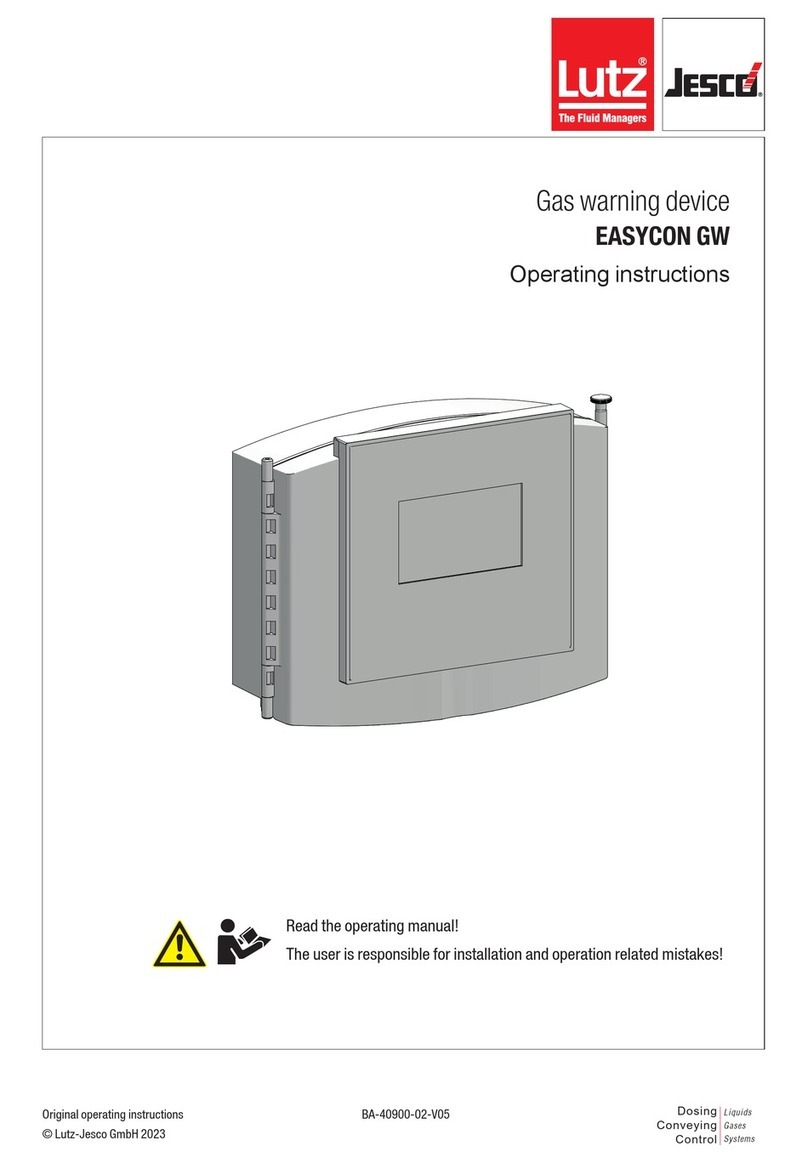

9.1.1.Component

The screen as shown above, used for managing device in PCB.

(1) Component list: Show all components contained in the selected work file, green

indicates enables vision calibration, orange indicates disable vacuum testing,

purple indicates enables vision calibration and disable vacuum testing, gray

indicates skip the device;

(2) Add: Add a component to the end of the list;

(3) Insert: Insert a new component before the currently selected row;

(4) Delete: Delete the selected component;

(5) Edit: To edit the selected component, see below for details;

(6) Save: If you edit the component in the list, the save button will flash, prompt the

information changed and has not been saved yet, click to save and stop flash.

9.1.1.1. Edit

The popup screen as shown below, the top left of the screen displays the current

component‟s line number (start from 0),the arrows on both sides, used for selecting a

component before or after, also can click the middle button popup keyboard to input

device line number directly.

Charmhigh-V1.0-2016 |

15

All Rights Reserved

Figure.9-3

(1) Comp. ID: Set component ID number, component ID number can not repeat in

the same work file;

(2) MStack: Set the specified component‟s material stack, when specifying a new

material stack, the material stack list in work file will automatically add a new

similar material stack;

(3) Speed: Set the component speed, set to 0 indicate use system speed, tips,

reduce speed properly when mount IC can improve the accuracy, e.g. 50%;

(4) Height: Set component height, smaller values represent lower height, and the

nozzle down more; Note,in order to adapt the 1.6 mm height PCB board, the

factory default height is 0.5 mm. Do some adjust for different thickness boards.

(5) Angle: Set component rotation angle, counterclockwise is positive, clockwise is

negative;

(6) Designator: Component designate information, such as R1, R2, C1, U1 etc.;

(7) Comments: Component annotation information, such as 0402,0805;

(8) MHead: Select nozzle, e.g. nozzle 1;

(9) Coord. X: Component coordinate X, generally do not need to modify if it is

generated in work file;

(10) Coord. Y: Component coordinate Y, generally do not need to modify if it is

generated in work file;

(11) Skip comp.: Check indicate not mount;

(12) Vacuum detect: Check indicate not throw material due to vacuum insufficient,

Charmhigh-V1.0-2016 |

16

All Rights Reserved

note, no material detection still effective, i.e. if the current position is not get the

material, it will do it one more time, if still failed then pull the tape one time and try

two times, if pull tape two consecutive times (in 3 position, total try 6 times) all

failed, then the machine alarm and stop, we suggest open this function when

mount such as cylindrical component;

(13) Enable vision: Check indicate calibrate component with vision, note, enable

vision can improve precision when mount IC;

(14) Coord. set: Setting component coordinate use down camera or nozzle, see

details below.

9.1.1.2. Coordinate Setting

Screen shown as below.

Figure.9-4

(1) Coordinate: Coordinate offset display in the upper left corner;

(2) MHead\Vision: Switchover coordinate set mode among nozzle and vision, the

figure below shows the screen that set coordinate by nozzle, in this mode user

need to check position by eye;

Charmhigh-V1.0-2016 |

17

All Rights Reserved

Figure.9-5

(3) Move: In the left side of the window four arrows control the mount head moving

in four directions respectively, movement speed can changed by H/L button, L

indicate low speed, H indicate high speed;

(4) Enlarge: zoom up the image;

(5) Find Target: Locating component position automatically, principle explains as

follows, the algorithm search from the image center to around, the first searched

close graph is deemed to the target which marked with red rectangle. Note, the

border of the target must be clear and closed, silk printing is found generally;

capture target is just auxiliary function, silk printing position not always be the

right position of component since the deviation of process technology, user

should set coordinate according to the position of footprint;

(6) Auto. center: Move nozzle to the center of target if target was captured;

(7) MHead n(n is MHead number): When use nozzle to positioning, click this button

then specified nozzle press down, for the convenience of observation;

(8) Apply: Click to apply changes.

9.1.2.Material Stack

Screen show as below, in this page can manage different kinds of component‟s place

position.

Charmhigh-V1.0-2016 |

18

All Rights Reserved

Figure.9-6

(1) Material stack list: Display all material stack that the work file contained;

(2) Add: Add a new one to the end of the list; tape packaged material use ID 1 to 29,

bulk IC use ID 60 to 79, IC tray use ID 80 to 99(see details below);

(3) Insert: Insert a new one to the position that before current selected material stack;

(4) Delete: Delete selected material stack, note, all of components that use this

material stack in the component list will be deleted too;

(5) Edit: Edit selected material stack, screen show as below.

Figure.9-7

Charmhigh-V1.0-2016 |

19

All Rights Reserved

a) Stack ID: Set current material stack ID, value can‟t repeat, all of components‟ ID

that use this material stack in the component list will be changed too;

b) Feed: The center distance between two successive components in the tape, unit

is millimeter;

c) Ec size X\Y: The size of components in this stack, unit is millimeter;

d) X\Y offset: Material stack coordinate adjustment;

e) Height: Functionally just like corresponding item in component edit, all of

relevant component will be changed;

f) Speed: Functionally just like corresponding item in component edit, all of

relevant component will be changed;

g) Comments: Set material stack comments;

h) Skip comp.: Functionally just like corresponding item in component edit, all of

relevant component will be changed;

i) Vacuum detect: Functionally just like corresponding item in component edit, all

of relevant component will be changed;

j) Enable vision: Functionally just like corresponding item in component edit, all of

relevant component will be changed;

k) Coord. set: Functionally just like corresponding item in component edit, see

figure below, there will appear a pull needle button in the top right corner of the

window when set coordinate by nozzle, click it then machine will pull tape one

time, in order to make the component in a certain place, then calibrating the feed

place of material by camera or nozzle, see figure below, adjusting the tape let the

red circle touches the blue line, the place of green rectangle is just the suggested

feed place.

Charmhigh-V1.0-2016 |

20

All Rights Reserved

Figure.9-8

Figure.9-9

9.1.3.Batch

Batch is that splicing a number of same PCBs to mount together, but just need one

Table of contents

Other Charmhigh Industrial Equipment manuals