NEUGART PLE User manual

PLE |PLQE | PLPE | PLHE |PLFE | PFHE

WPLE |WPLQE |WPLPE |WPLHE | WPLFE

PSBN |PSN |PLN |PSFN |PLFN

WPLN |WPSFN |WGN

NGV

DSS No. 100225283

DSS-Rev.

012

Date 12.07.2023

Operating Manual Gearbox

Economy gearboxes

Precision gearboxes

Application-specific gearboxes

2

Operating Manual Gearbox

Contents

Contents

1 General notes 4

1.1 Personnel qualification 4

1.2 Description of the gearbox 4

1.3 Intended use 5

1.4 Reasonably foreseeable misuse 5

1.5 Warnings 5

1.6 Contents and use of the operating manual 6

1.7 Further applicable documents 6

2 Description of the gearbox 7

2.1 Nameplate 7

2.1.1 Nameplate with data matrix code 7

2.1.2 Nameplate with serial number 8

2.2 Lubrication with low temperature lubricant 8

3 Storage and transport 9

3.1 Bearings 9

3.2 Transport 9

4 Mounting 10

4.1 Attaching the motor to the gearbox by means of a clamping system (motor attachment) 10

4.1.1 Attaching the motor 11

4.1.2 Attaching the motor shaft with a clamping system 12

4.1.3 Determining the radial run-out, axial run-out and coaxiality tolerance of the motor 13

4.2 Attaching the motor to the gearbox by means of the drive pinion (direct motor mounting) 14

4.3 Attaching the drive unit to the gearbox by means of the drive shaft

(free drive shaft)

15

4.4 Installing the gearbox in the application 17

4.4.1 Application side attachment to steel or aluminum 18

4.4.2 General tightening torques on the application side

Mounting bolts 19

4.4.3

Modified gearboxes: Strength class of the application-side mounting bolts and

use of washers

19

4.5 Radial and axial run-out of the gearbox shaft end 19

5 Commissioning and operation 21

5.1 Technical specifications 21

5.2 Initial operation (Commissioning) 21

5.2.1 Determining the lubricant service life 24

5.3 Operation 25

5.3.1 Remedying operational malfunctions 26

5.4 Inspection and maintenance 27

5.4.1 Inspection intervals and inspection measures 27

5.4.2 Maintenance operations 28

5.4.3 Safety data sheets 28

6 Disposal (instructions regarding hazardous substances, composition) 29

7 Service and manufacturer information 30

7.1 Service 30

7.1.1 Address and return shipments: 30

7.1.2 Locations in the USA and China 30

7.2 Manufacturer (company name and address) 30

3

Overview of revisions

Revision Chapter Reason for revision Revised by

Operating Manual Gearbox

Overview of revisions

4

1 General Information

1.1 Personnel qualification

In particular, mounting, commissioning, operation, maintenance and disposal of the

gearbox require qualified specialists who, due to their training, knowledge and ex-

perience in the field of mechanics and drive technology, are able to assess the work

assigned to them, recognize possible hazards, particularly misuse, and take suitable

preventive and protective measures.

1.2 Description of the gearbox

The gearbox has input and output shafts for the non-positive and positive mounting

of electric motors. By means of mechanical transmission elements, speeds and

torques are converted or transmitted by the drive and the output shaft in a form-fit,

material-fit or friction-locked manner. The drive and output shaft can accommodate

external loads.

The gearbox has a partially closed or closed housing.

The drive and the output shaft are usually freely accessible.

The geometric characteristics and performance data of the gearbox are described

in its technical specifications.

Operating Manual Gearbox

General notes

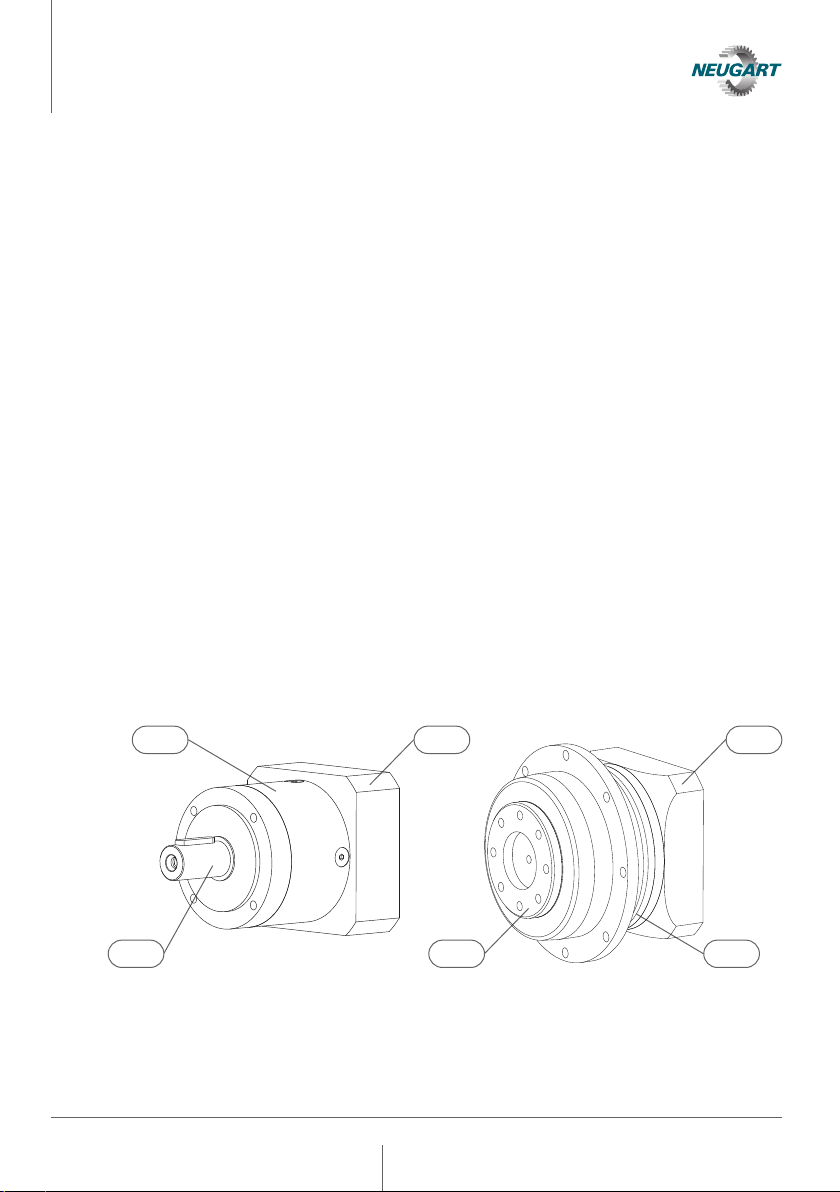

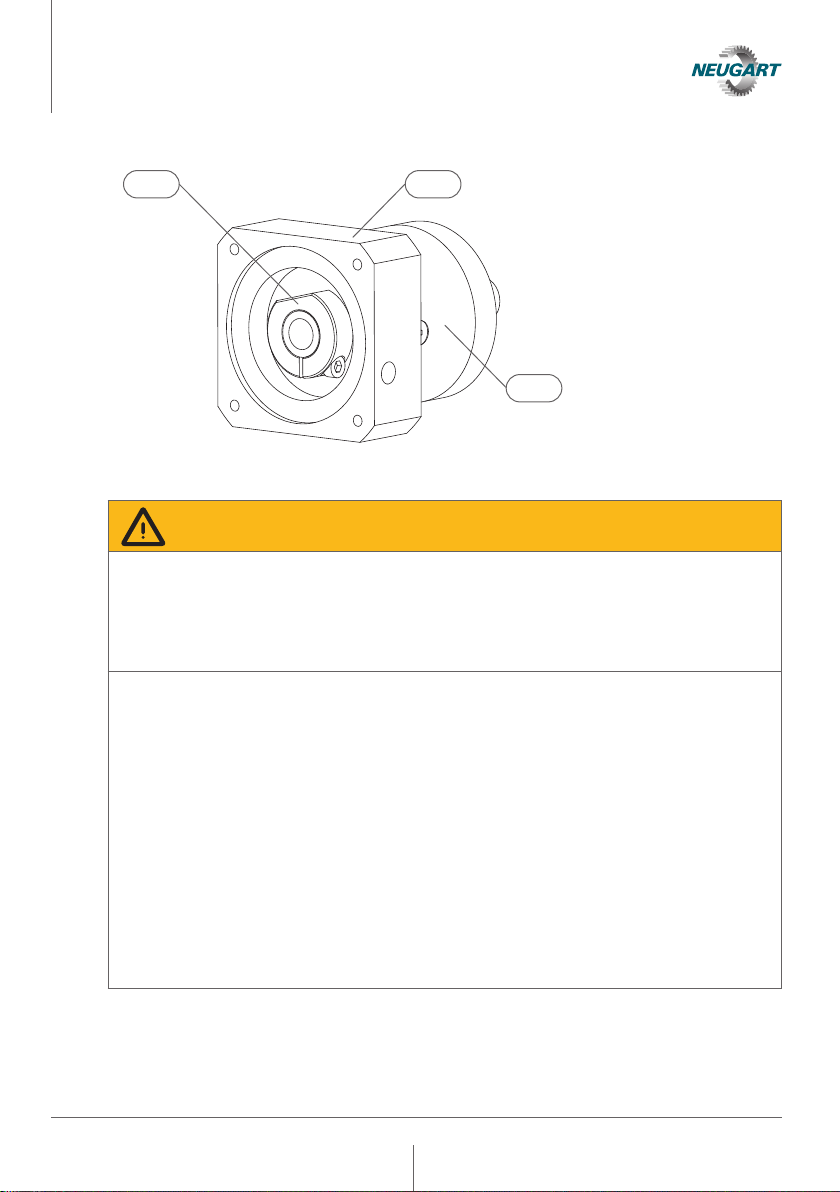

In the examples shown above, the following components of a planetary

gearbox are described:

1 Gearbox housing 3 Drive flange

2 Output shaft 4 Output shaft as flange output shaft

1

2

3 3

14

5

1.3 Designated use

The gearbox is intended exclusively for converting or transmitting torques, speeds

and for absorbing radial or axial loads in accordance with its technical specifications.

The gearbox may only be used for commercial and industrial reutilization.

1.4 Reasonably foreseeable misuse

Among other things, do not operate the gearbox in the following way:

• Without connecting element(s) on input or output shaft(s)

• Without monitoring and protective devices on the application side

• Outside the temperature range suitable for the lubricant

• Without consideration of the influence of the operating temperature on

the lubricant service life

• In potentially explosive atmospheres

• Outside the performance data provided in the technical specifications

Furthermore, interventions through technical modifications or conversions are not

permitted.

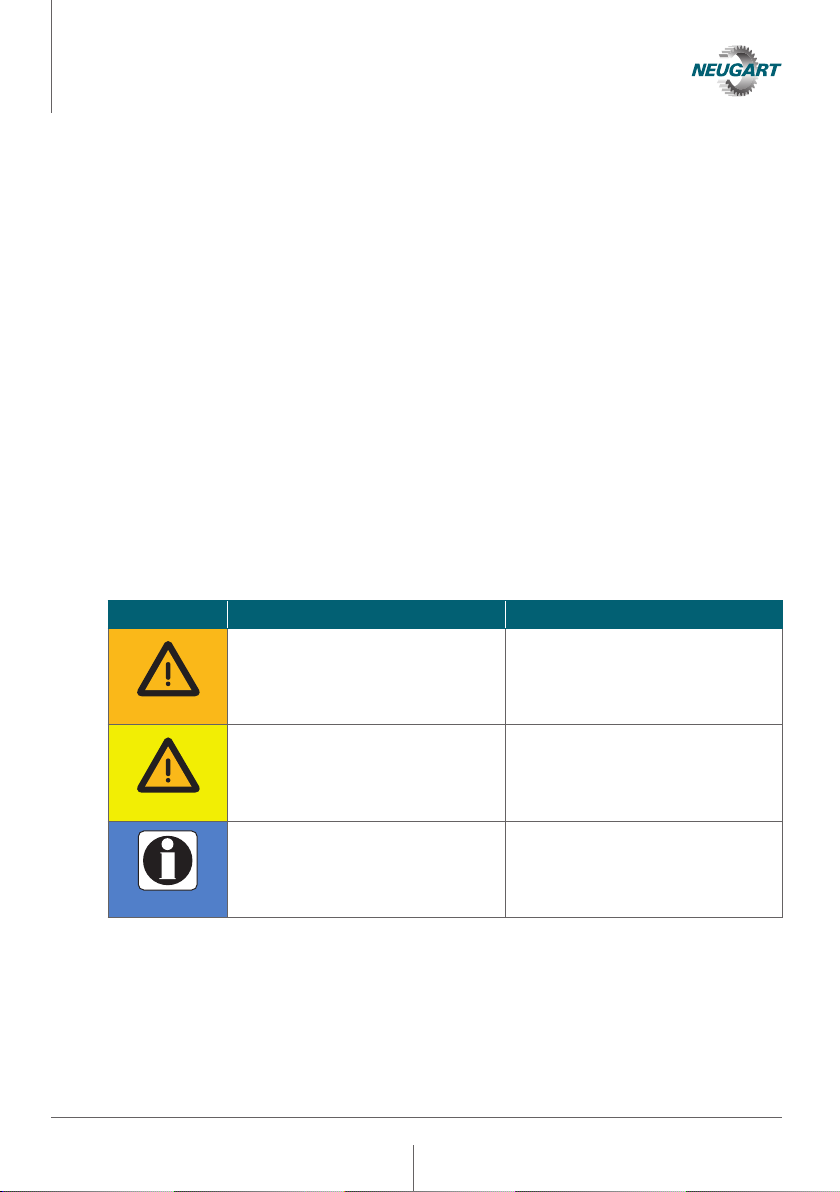

1.5 Warnings

Signal word

Explanation Consequences of non-compliance

Gefahr

Warning!

Possible imminent danger to life and

health

Serious injuries, including

death

Gefahr

Attention!

Possible imminent danger of property

or environmental damage

Damage to the drive system or its

environment

Information

Very important information: Simplifies

correct and safe installation and use of

the gearbox

Can lead to undesired developments

in the operating process

Operating Manual Gearbox

General notes

6

1.6 Content and use of the operating manual

This operating manual describes the conditions that must be met to ensure that the

gearbox can be started up properly without adversely affecting the safety and health

of persons. In addition, it contains specifications for all life phases of the gearbox.

The operating manual is only complete when with the further applicable documents.

If the operating manual refers to further applicable documents, these must be

observed.

The gearboxes described in this operating manual are based on a risk assessment

conducted in accordance with DIN EN ISO 12100: 2011-3.

1.7 Further applicable documents

• Technical specification (dimension spec sheet)

• Mounting instructions for the motor when mounted according to 4.1 as well as 4.2

Operating Manual Gearbox

General notes

7

Operating Manual Gearbox

Description of the gearbox

2 Description of the gearbox

2.1 Nameplate

The nameplate is affixed to the drive flange or the gearbox housing. For clear identi-

fication of the gearbox, the nameplate must also be legible at all times once installed

in a machine or system. There are two different versions of the nameplate, which are

explained in the following chapters 2.1.1 and 2.1.2.

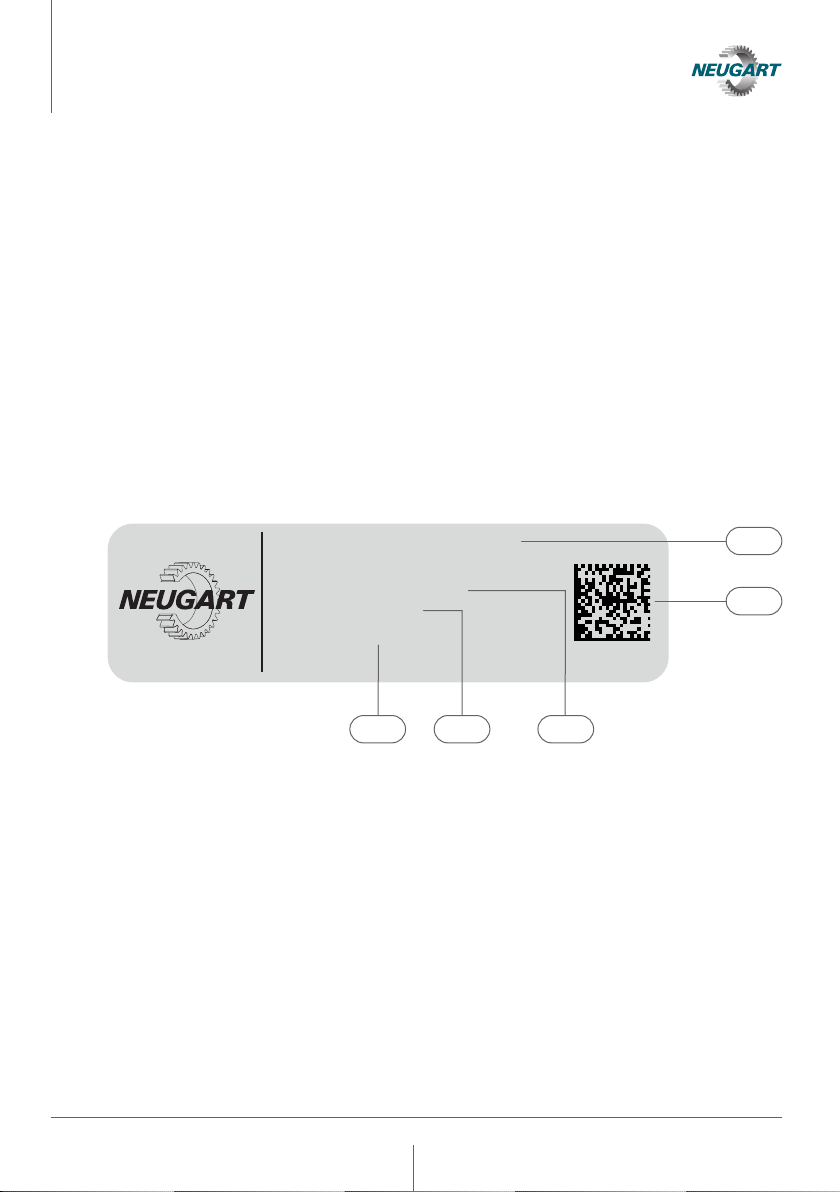

2.1.1 Nameplate with data matrix code

The following figure shows, by way of example. the nameplate of a PLE series

planetary gearbox with a data matrix code. The data matrix code links to the Online

Service, where more detailed product information can be accessed.

1 Product code (2 lines)

2 Data matrix code

3 Serial number

4 Article number

5 Production date: Calendar week / year

Made in Germany

PLE080-004-SSSA3AE-E19

/40/80/100/B5/M6

SN: MZRKPMCVRNB

AN: 100253786

DOP: 34/2022

5 4 3

2

1

8

Operating Manual Gearbox

Description of the gearbox

2.1.2 Nameplate with serial number

The following figure shows, by way of example, the nameplate of a planetary gearbox

from the PSN series with serial number:

1 Article number

2 Serial number

3 Product code (2 lines)

4 Production date: Month / year

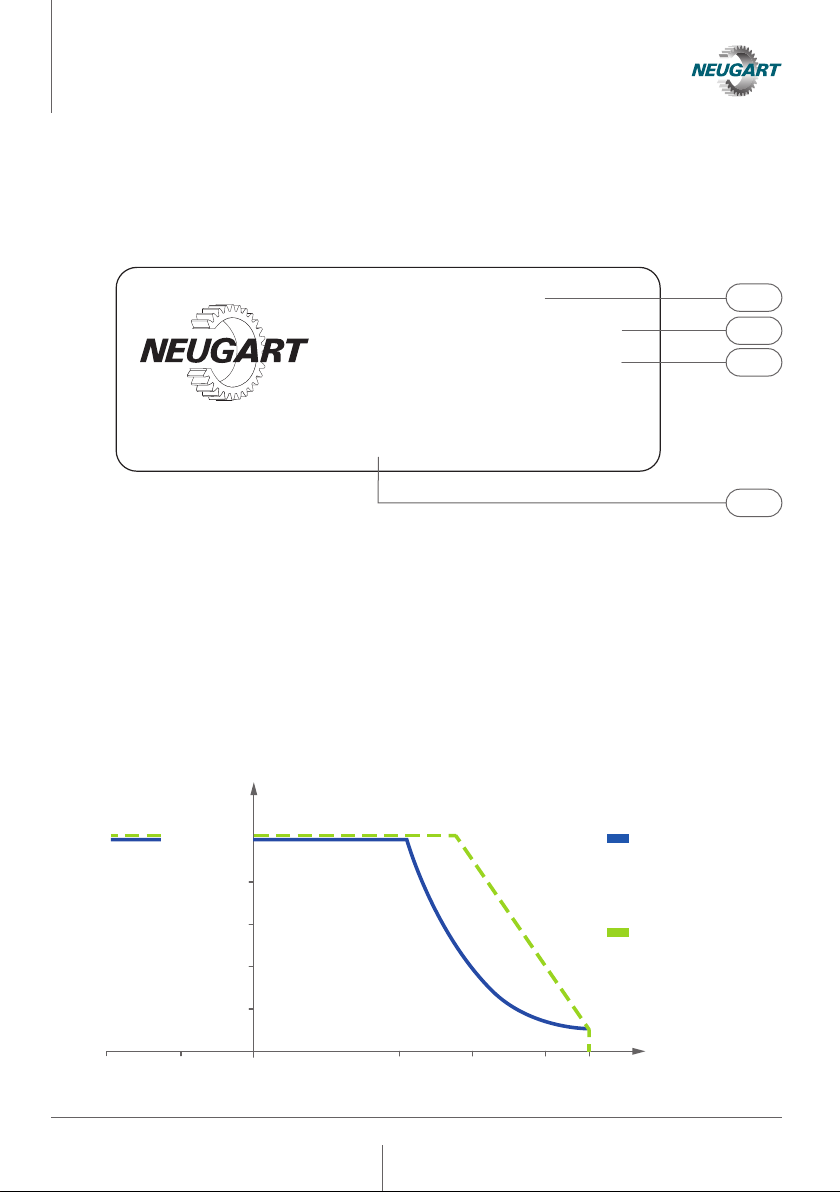

2.2 Lubrication with low-temperature lubricant

Please note that the use of a low-temperature lubricant leads to different

performance data. For further details, please refer to the following diagram.

Art−No. 123456789

F−No. 2170569−1 − 002

PSN090-005-SFSA3AD-Z14

/30/80/100/B5/M6

Made in Germany 06/2016 www.neugart.com

4

2

3

1

Tmin -20 0 20 40 60 80 Tmax °C

80% T2N

60% T2N

40% T2N

20% T2N

Nm

100% T2N

PLE, PLQE, PLPE,

PLHE, PLFE, PFHE,

WPLE, WPLQE, WPLPE,

WPLHE, WPLFE, NGV

PSBN, PSN, PLN,

PSFN, PLFN,

WPLN, WPSFN, WGN

9

3 Storage and transport

3.1 Storage

Gefahr

Caution!

Improper storage can damage the gearbox. This can lead to premature aging of the

lubricant and sealing elements, which can greatly reduce or shorten their service

life or sealing effect.

• Choose a dry storage location to avoid corrosion.

• The long-term storage temperature must be kept between 0 C and +40 C because

of the lubricant's storage life and the possibility of lubricant or seal aging.

• Direct sunlight or UV radiation accelerates the aging process of the seals and

results in premature wear.

• To ensure lubricant serviceability, the storage period must not exceed 1 year.

3.2 Transport

Gefahr

Caution!

When lifting and moving the gearbox, there is a risk of it falling if it is not properly

secured. When the gearbox is being moved, there is a pinch point hazard between

the gearbox and other application components.

• Keep the gearbox weight and gearbox dimensions listed in its technical specifica-

tions in mind.

• The gearbox must be lifted by means of suitable lifting aids which wrap directly

around the gearbox housing.

Operating Manual Gearbox

Storage and transport

10

Operating Manual Gearbox

Mounting

4 Mounting

Gefahr

Caution!

A damaged gearbox may no longer meet its technical specifications.

• The gearbox must not show any mechanical damage, corrosion, or lubricant

leakage.

• The sealing elements must be protected from compressed air and aggressive

cleaning agents. For cleaning, use cold cleaning agents based on a gasoline

hydrocarbon.

• The mounting or removal of output elements or motors by means of striking,

pressing or the like must be avoided in order to protect the bearings. Use pullers

or heat connecting elements to be attached.

• Do not install a damaged gearbox in the application.

• Do not operate a damaged gearbox.

Gefahr

Caution!

The gearbox may no longer fully meet the warranted performance characteristics

or the maximum permissible operating temperature may be exceeded if the mate-

rials used are not sufficiently thermally conductive or if the heat storage capacity is

insufficient due to undersizing or the ventilation is inadequate.

• The application-side materials and sizing for connection geometries must be

specified for sufficient heat flow and heat capacity (e.g. aluminum or steel and

plate size equal to twice flange size).

• Ventilation must be ensured by convection or forced-air ventilation.

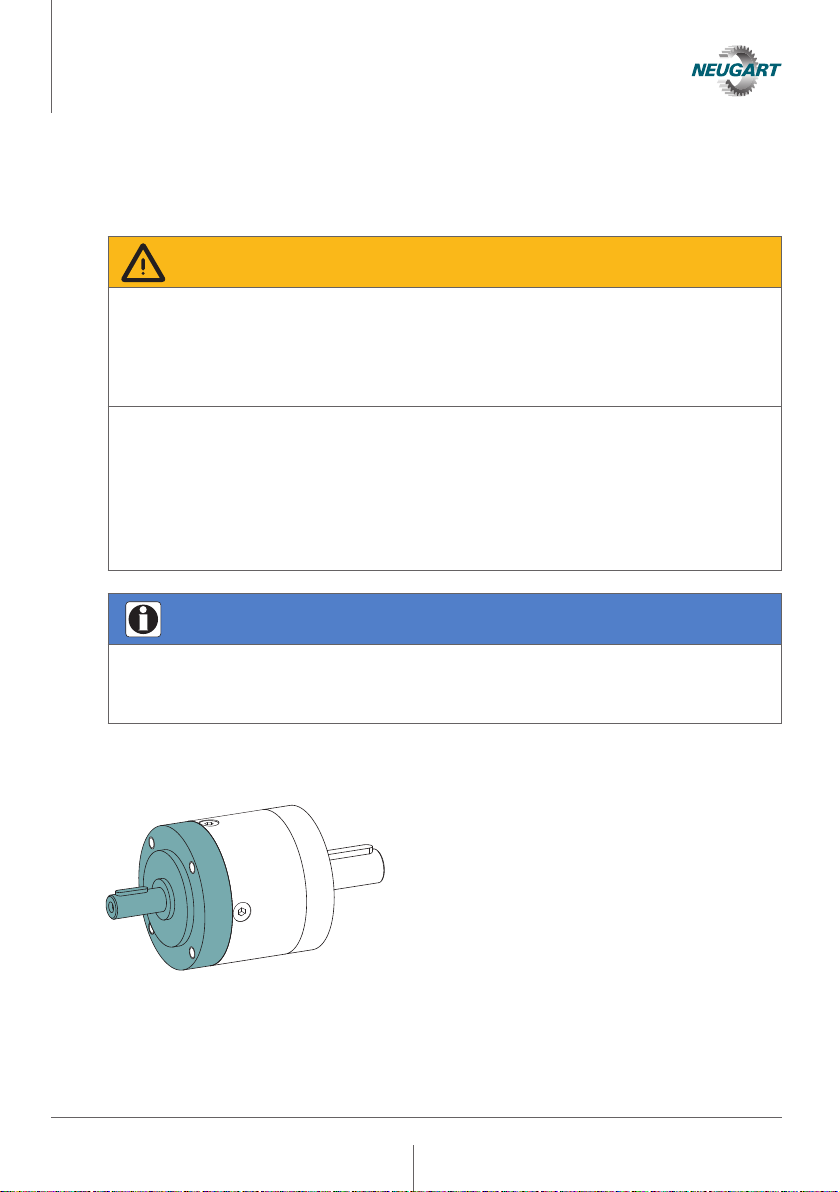

4.1 Attaching the motor to the gearbox by means of a clamping system

(motor attachment)

Information

If the gearbox is prepared for mounting a motor by means of a clamping system,

please refer to the mounting instructions supplied with the gearbox for detailed

information on mounting the motor to the gearbox.

11

Operating Manual Gearbox

Mounting

1 Clamping System

2 Drive flange

3 Gearbox housing

4.1.1 Attaching the motor

Gefahr

Warning!

Due to its weight, incorrect mounting or in the event of unacceptable deviation from

radial run-out and axial run-out tolerances., the motor can cause a gear compo-

nent or a connecting element to break. Among other things, this can result in a

loss of position in the power train, uncontrolled rotation or a blocking of the output

shaft.

• The permissible motor weight or bending moment given in the technical specifi-

cation must be observed.

• The mounting instructions for motor mounting must be observed.

• Carefully clean the component surfaces to be used for non-positive connection

and remove all residues.

• Radial run-out and axial run-out tolerances must be ensured when mounting

a motor based on the values of the technical specification and the measuring

method described in 4.1.3.1 to 4.1.3.5.

• Observe the bolt tightening torques of the motor manufacturer when fastening

the motor.

• Select a suitable torque tool with a minimum accuracy to DIN EN ISO 6789-1

Type II A to ensure the required tightening torque.

• The bolts must be secured against self-loosening through use of a threadlocker

(e.g. Loctite 245).

21

3

12

4.1.2 Attaching the motor shaft with a clamping system

Gefahr

Warning!

Insufficient cleaning of the friction-locked components or insufficient tightening

torque (TAK) of the clamping screw can lead to slippage in the clamping system

and to its failure. Excessive tightening torque of the clamping screw can lead to its

breakage and thus to failure of the clamping system. This can result in uncontrolled

rotation of the output shaft, among other things.

• The mounting instructions for motor mounting must be observed.

• To protect against plastic deformation, the clamping system must not be pre-

loaded without the shaft installed.

• Carefully clean the component surfaces to be used for non-positive connection

and remove all residues.

• Observe the specified tightening torque (TAK) in the mounting instructions to

avoid slippage in the clamping system or breaking the clamping screw.

• Select a suitable torque tool with a minimum accuracy to

DIN EN ISO 6789-1 Type II A to ensure the required tightening torque.

Gefahr

Warning!

A motor shaft diameter not matched to the clamping system can lead to slippage in

the clamping connection and to its failure. This can result in uncontrolled rotation

of the output shaft, among other things.

• Make sure that the tolerance of the motor shaft is matched to the gearbox.

• The tolerance for the motor shaft diameter can be found in the technical specifi-

cations.

Gefahr

Warning!

The clamping screw has specific characteristics. The use of a clamping screw other

than the original screw can lead to failure of the clamping connection.

• Use only the original screw.

• Use only a replacement part provided by Neugart.

Operating Manual Gearbox

Mounting

13

4.1.3 Determining the radial run-out, axial run-out and coaxiality tolerance of the motor

4.1.3.1 Radial run-out of the motor shaft end

The measuring probe is placed at the center

of the shaft end. The maximum and minimum

values are read on the measuring instrument

by slowly rotating the shaft. The measurement

may be performed with the motor in a hori-

zontal or vertical position, with the measuring

instrument mounted directly on the motor or

on a common base plate for the motor and

measuring instrument. The difference between

these readings must not exceed the values

given in the technical specifications of the

gearbox.

4.1.3.2 Coaxiality of flange centering with respect to the motor shaft

Using a fixture similar to the one shown in the

picture,the measuring instrument is mounted

on the shaft end at a distance of about 10 mm

from the mounting surface of the flange. The

maximum and minimum values are read on

the measuring instrument by slowly rotating

the shaft. It is recommended that the shaft

be oriented vertically when performing this

measurement. The difference between these

readings must not exceed the values given in

the technical specifications of the gearbox.

4.1.3.3 Axial run-out of the mounting surface of the flange with respect to the motor shaft

Using a fixture similar to the one shown in the

picture,the measuring instrument is mounted

on the shaft end at a distance of about 10 mm

from the mounting surface of the flange. The

maximum and minimum values are read on

the measuring instrument by slowly rotating

the shaft. It is recommended that the shaft

be oriented vertically when performing this

measurement. The difference between these

readings must not exceed the values given in

the technical specifications of the gearbox.

Operating Manual Gearbox

Mounting

E/2

10

10

14

Operating Manual Gearbox

Mounting

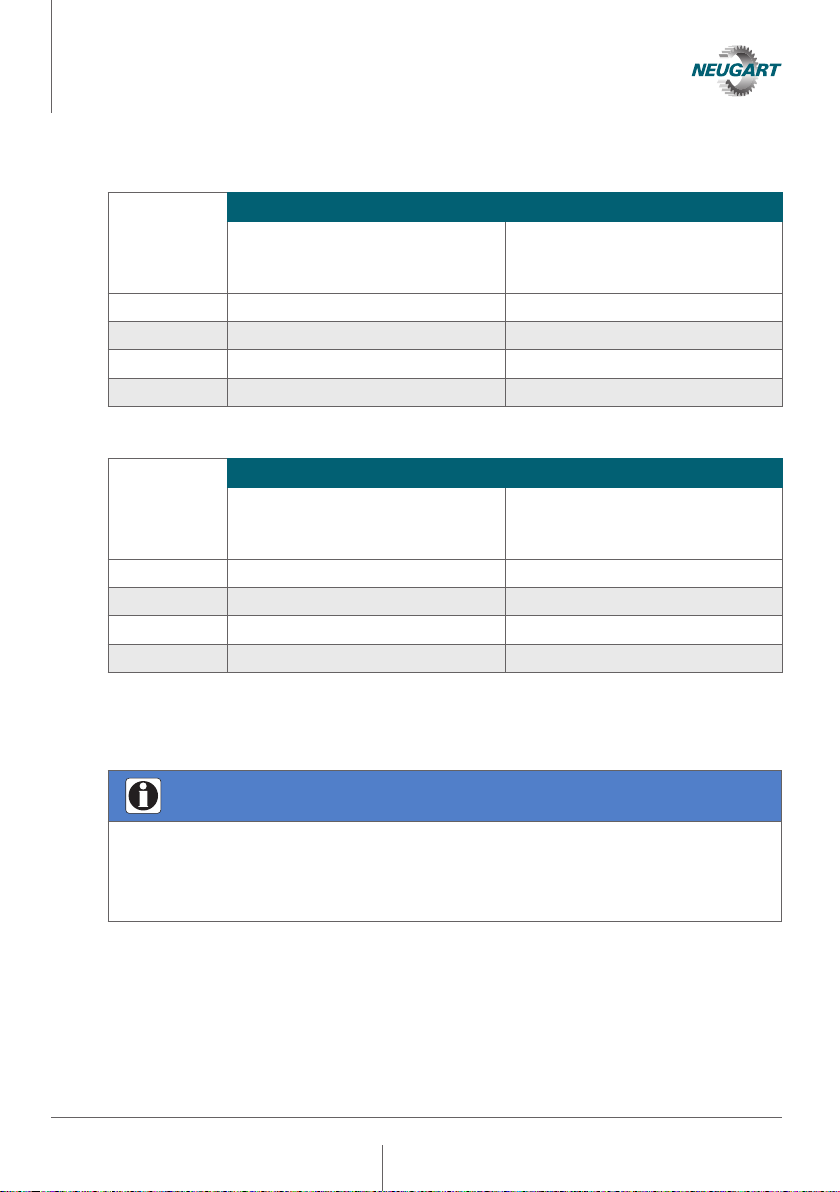

4.1.3.4 Radial run-out tolerance of the motor shaft

Nominal

motor shaft

diameter

[mm]

Radial run-out tolerance [mm]

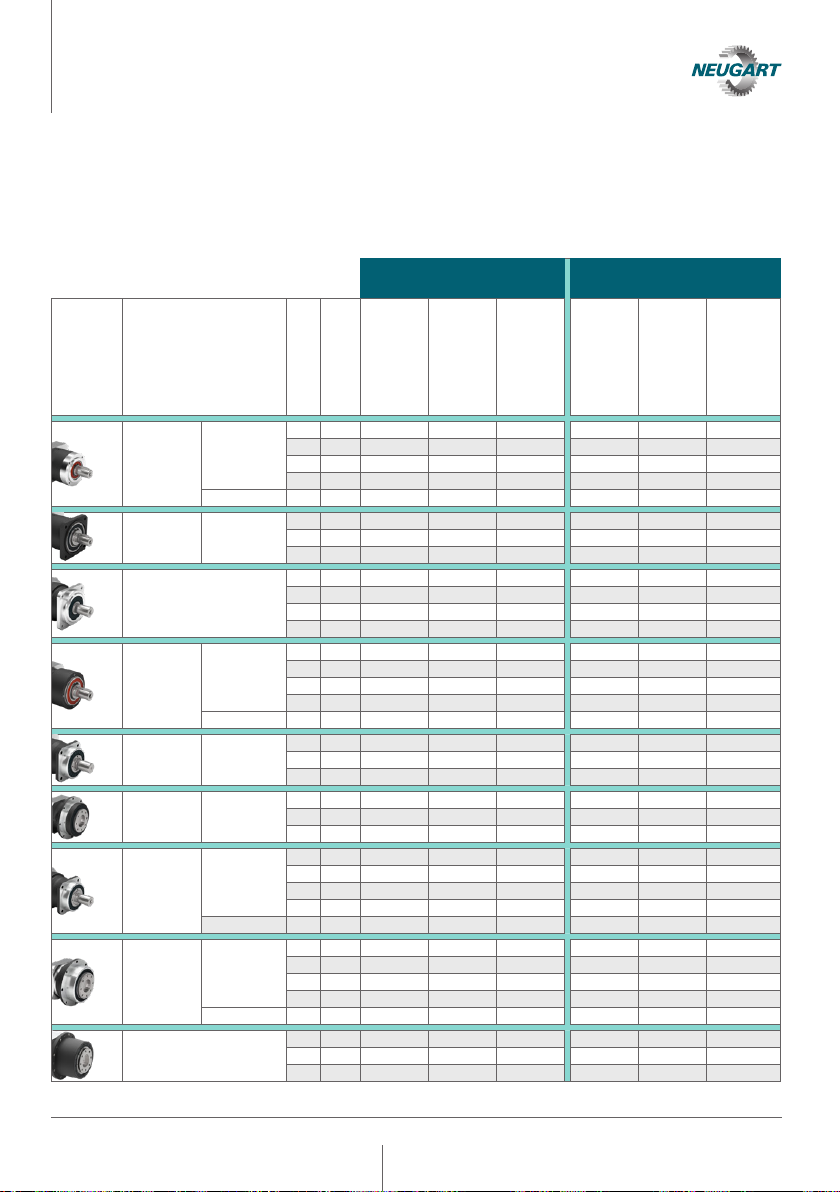

PLE, PLQE, PLPE, PLHE, PLFE, PFHE,

WPLE, WPLQE, WPLPE, WPLFE,

WPLHE, NGV

PSBN, PSN, PLN, PSFN, PLFN,

WPLN, WPSFN, WGN

0 — ≤10

0.03

0.015

>10 — ≤30

0.04

0.020

>30 — ≤50

0.05

0.025

>50 — ≤80

0.06

0.030

4.1.3.5 Axial run-out and coaxiality tolerance of the motor flange

Flange size/

Square

measure

[mm]

Axial runout and coaxiality tolerance [mm]

PLE, PLQE, PLPE, PLHE, PLFE, PFHE,

WPLE, WPLQE, WPLPE, WPLFE,

WPLHE, NGV

PSBN, PSN, PLN, PSFN, PLFN,

WPLN, WPSFN, WGN

0 — ≤40

0.06

0.03

>40 — ≤100

0.08

0.04

>100 — ≤230

0.10

0.05

>230 — ≤450

0.13

0.06

4.2 Attaching the motor to the gearbox by means of the drive pinion

(direct motor mounting)

Information

If the gearbox is prepared for mounting a motor by means of a drive pinion directly

connected to the motor shaft, please refer to the mounting instructions supplied

with the gearbox for detailed information on mounting the motor to the gearbox or

connecting the drive pinion to the motor shaft.

15

4.3 Attaching the drive unit to the gearbox by means of the drive shaft

(free drive shaft)

Gefahr

Warning!

Due to its weight, faulty mounting, a technically faulty connection between the

motor shaft and drive pinion or in the event of impermissible deviation from the

radial and axial run-out tolerances, the motor can cause breakage of torque-

transmitting gearbox components or slip in the connection. This can result in un-

controlled rotation or blocking of the output shaft, among other things.

• The permissible motor weight or bending moment given in the technical specifi-

cations must be observed.

• The instructions for motor and drive pinion mounting must be followed.

• The radial and axial run-out tolerances required in the motor and drive pinion

mounting instructions must be satisfied with the drive pinion attached.

• The design of the connection between the motor shaft and the drive pinion

must ensure the performance data of the technical specifications.

Information

If the gearbox is prepared for attachment of a drive unit by means of a drive shaft

mounted on the gearbox, the same mounting specifications listed in 4.4 apply to the

application connection on the input and output sides.

Operating Manual Gearbox

Mounting

16

Gefahr

Warning!

Incorrect connection or pretensioning of the drive-side connecting element can

cause breakage or slippage in the connection between the drive shaft and con-

necting element. This can result in breakage of a gear component or connecting

element, loss of position in the power train, or premature bearing failure. This can

result in uncontrolled rotation or blocking of the output shaft, among other things.

• If so indicated in the specifications, the gearbox must be connected to the appli-

cation with the flange geometry shown on the input and output sides.

• The permissible external loads listed in the technical specifications must be

observed.

• An uncontrolled introduction of external forces due to "overspecified" operating

conditions (e.g. additional application-side bearings for the drive shaft, excessive

belt tension when using a belt pulley) can lead to breakage of the drive shaft or

failure of the gearbox bearings. Suitable connecting elements must be used and

positional deviations must be avoided.

Operating Manual Gearbox

Mounting

17

4.4 Installing the gearbox in the application

Gefahr

Warning!

Incorrect attachment to the application can lead to misalignment or slippage in the

connection between the gearbox and application or gearbox shafts and connecting

elements. This can lead to breakage of a gear component, a connecting element

or loss of position in the power train, which can result in uncontrolled rotation or

blocking of the output shaft, among other things.

• Observe the strength class of the application-side mounting bolts and possible

use of washers according to 4.4.1

• Observe the tightening torques for the application-side mounting bolts and the

requirements in 4.4.1 and 4.4.2

• Select a suitable torque tool with a minimum accuracy to DIN EN ISO 6789-1

Type II A to ensure the required tightening torque.

• The bolts must be secured against self-loosening through use of a threadlocker

(e.g. Loctite 245).

• Non-positive connections must be made with suitable clamping sets and the

appropriate fit according to the shaft fits given in the technical specifications in

order to avoid slippage.

• Carefully clean the component surfaces to be used for non-positive connection

and remove all residues.

• The application-side flange geometry must be free of damage and residues.

• Uncontrolled introduction of external forces due to "overspecified" operating

conditions can lead to shaft breakage or failure of the gearbox bearings. Overspe-

cified operating conditions can include positional deviations between the gearbox

and the application, jamming in the case of direct connection to translational ap-

plications e.g. rack and pinion, additional application-side bearings for the input

or output shaft or excessive pretensioning of belts. Suitable connecting elements

must be used and positional deviations must be avoided.

Operating Manual Gearbox

Mounting

18

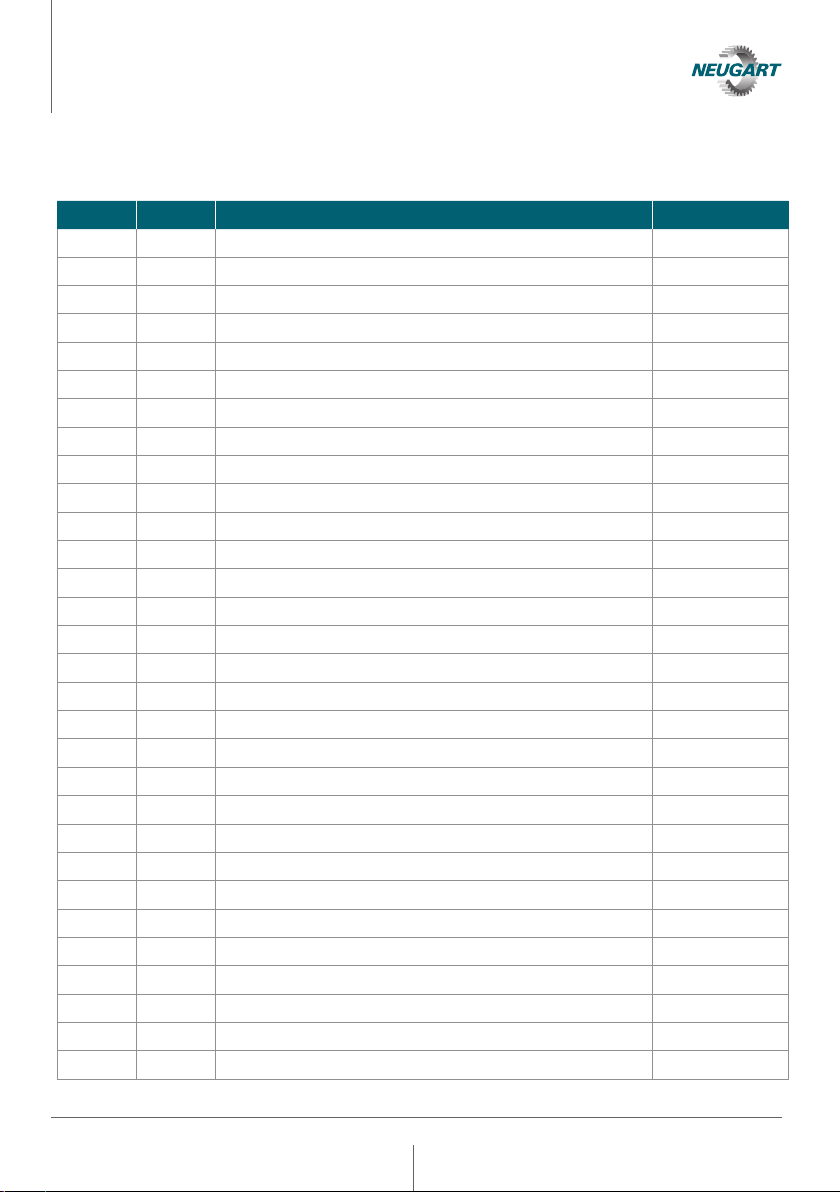

4.4.1 Application side attachment to steel or aluminum

Table 4.4.1 shows the strength class to be used and the tightening torque for the

application-side mounting bolts, as well as the use of washers for application-side

attachment to steel or aluminum.

Application-side

attachment to steel

Application-side

attachment to aluminum

Gearbox

(sample

image)

Series

Frame size

Bolt size

Mounting bolt

strength class

Washer required

Tightening-

torque

[Nm]

Mounting bolt

strength class

Washer required

Tightening-

torque

[Nm]

PLE WPLE

040 M4 10.9 no 3.8 10.9 yes 3.8

060 M5 10.9 no 7.5 10.9 yes 7.5

080 M6 10.9 no 12.9 10.9 yes 12.9

120 M10 10.9 no 61 10.9 yes 61

160 M12 12.9 no 123 12.9 yes 123

PLQE WPLQE

060 M5 12.9 yes 8.7 10.9 yes 7.5

080 M6 12.9 no 15.1 10.9 no 12.9

120 M8 12.9 yes 36 10.9 yes 31

PSBN

070 M5 12.9 yes 8.7 10.9 yes 7.5

090 M6 12.9 yes 15.1 10.9 yes 12.9

115 M8 12.9 yes 36 10.9 yes 31

142 M10 12.9 yes 72 10.9 yes 61

PLPE WPLPE

050 M4 12.9 no 4.4 12.9 yes 4.4

070 M5 12.9 no 8.7 12.9 yes 8.7

090 M6 12.9 no 15.1 12.9 yes 15.1

120 M8 12.9 no 36 12.9 yes 36

155 M10 12.9 no 72 12.9 yes 72

PLHE WPLHE

060 M5 12.9 yes 8.7 10.9 yes 7.5

080 M6 12.9 no 15.1 10.9 no 12.9

120 M8 12.9 no 36 10.9 no 31

PLFE

PFHE WPLFE

064 M4 12.9 no 4.4 10.9 no 3.8

090 M5 12.9 no 8.7 10.9 no 7.5

110 M5 12.9 no 8.7 10.9 no 7.5

PSN

PLN

WPLN

WGN

070 M5 12.9 yes 8.7 10.9 yes 7.5

090 M6 12.9 no 15.1 10.9 no 12.9

115 M8 12.9 no 36 10.9 no 31

142 M10 12.9 no 72 10.9 no 61

190 M12 12.9 no 123 10.9 no 105

PSFN

PLFN WPSFN

064 M4 12.9 no 4.4 10.9 no 3.8

090 M5 12.9 no 8.7 10.9 no 7.5

110 M5 12.9 no 8.7 10.9 no 7.5

140 M6 12.9 no 15.1 10.9 no 12.9

200 M8 12.9 no 36 10.9 no 31

NGV

064 M5 12.9 no 8.7 10.9 no 7.5

090 M6 12.9 no 15.1 10.9 no 12.9

110 M8 12.9 no 36 10.9 no 31

Operating Manual Gearbox

Mounting

19

4.4.2 General tightening torques on the application side

Tightening torques for the application-side mounting bolts [Nm]

Strength class

Mounting bolts M3 M4 M5 M6 M8 M10 M12 M16

10.9 1.6 3.8 7.5 12.9 31 61 105 257

12.9 1.9 4.4 8.7 15.1 36 72 123 300

General conditions for establishing the tightening torques

• Design of bolted connection in accordance with VDI 2230

• The total coefficient of friction for thread and head support is µ

total

=0.1

• Up to 90% of the bolt yield strength is used

• The max. permissible tightening torque minus the accuracy class of the

mounting tool (the accuracy class of the mounting tool must satisfy

DIN EN ISO 6789-1 Type II A at a minimum)

4.4.3 Modified gearboxes: Strength class of the application-side mounting bolts and use

of washers

Table 4.4.3 shows the strength class of the application-side mounting bolts to be

used for modified gearboxes, as well as the use of washers, for application-side

attachment on steel or aluminum. For painted gearboxes, we recommend the use of

washers to protect the paint layer.

Material

Gearbox side

Aluminum Aluminum Aluminum

Steel Steel Steel

Design

Gearbox side

Thread Holes Oblong

holes Thread Holes Oblong

holes

Application

side

of steel

Strength class

Mounting bolts 10.9 12.9 12.9 12.9 12.9 12.9

Washer

required no yes yes no no yes

Application

side

of aluminum

Strength class

Mounting bolts 10.9 10.9 10.9 12.9 10.9 10.9

Washer

required yes yes yes yes no yes

Operating Manual Gearbox

Mounting

20

Operating Manual Gearbox

Commissioning and operation

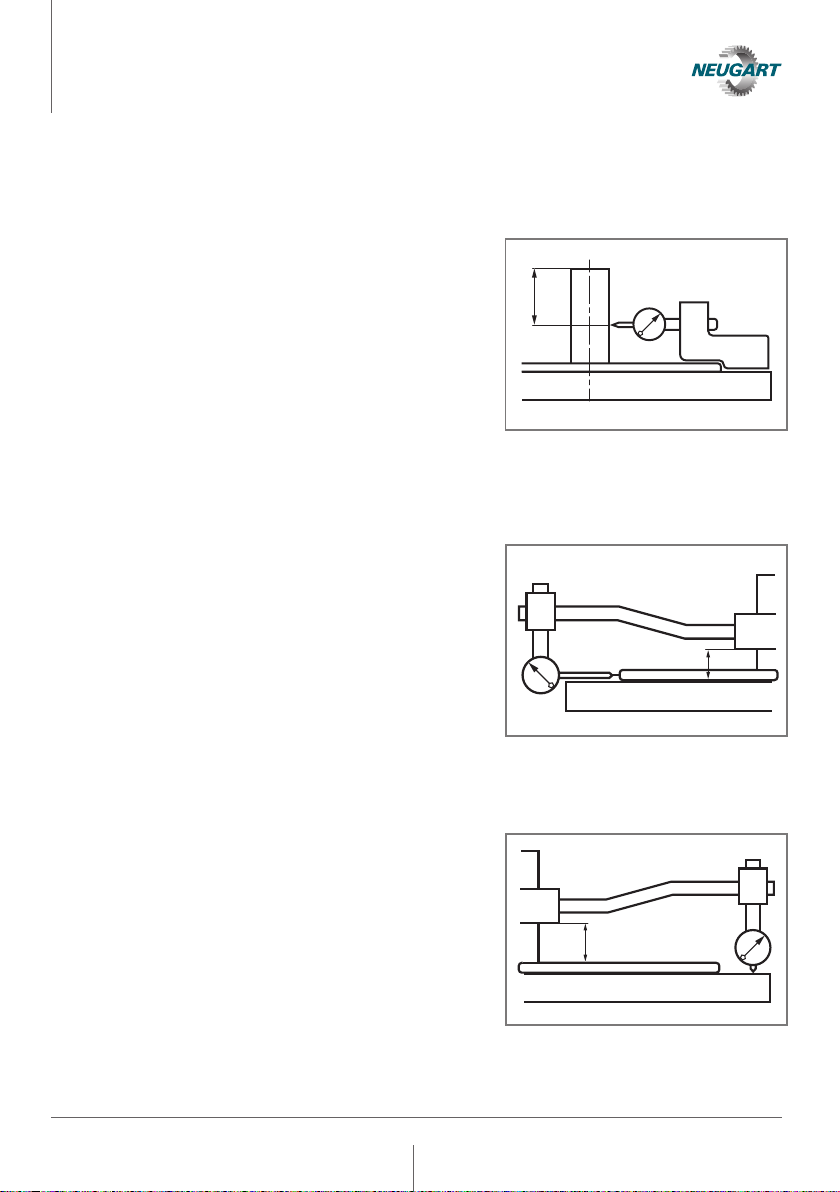

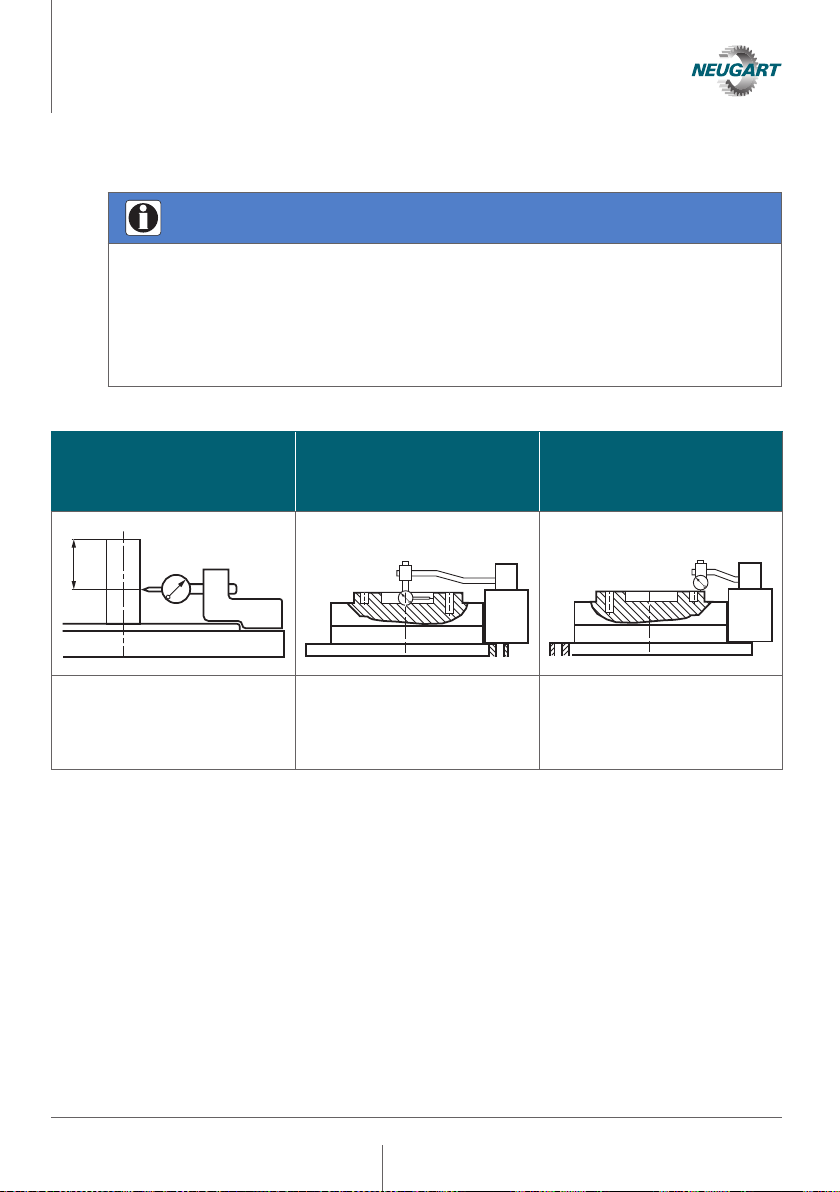

4.5 Radial and axial run-out of the gearbox shaft end

Information

If the technical specifications include data on the radial and axial run-out of the

output shaft, the measuring methods described below must be used. The measure-

ment may be performed with the gearbox in the horizontal or vertical position, with

the measuring instrument mounted directly on the gearbox or on a common base

plate for the gearbox and measuring instrument. The maximum and minimum

values are read on the measuring instrument by slowly rotating the shaft.

Radial run-out

of the gearbox shaft end

for stem shafts

Radial run-out

of the gearbox shaft end

for flanged shafts

Axial run-out

of the gearbox shaft end

for flanged shafts

E/2

The measuring probe is

placed at the center of the

shaft end.

The measuring probe is

placed at the center of the

inner centering diameter of

the flanged shaft.

The measuring probe is

placed at the outer edge of

the screw-on surface of

the flanged shaft.

This manual suits for next models

19

Table of contents

Other NEUGART Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Linn-High-Therm

Linn-High-Therm HT-1500-GT-VAC Special GRAPHITE operating instructions

Spirotech

Spirotech SpiroVent Superior S6 Series user manual

ABB

ABB AFS670 Safety instructions

Hydrotech

Hydrotech HSF2200 Series Operation & maintenance manual

Siemens

Siemens 3WN6 operating instructions

National Instruments

National Instruments VXIpc 770 Series user manual