Neutronics ULTIMA ID PRO RI-700H User manual

456 Creamery Way, Exton, PA 19341

www.neutronicsinc.com

Thank you for purchasing the

Ultima ID Pro

.™

Proper registration will enable us to send you periodic notification of product updates and other important

announcements. Registering your product will also allow us to contact you in the unlikely event that it will need

adjustment or modification. Please take the time to register your new product at our web site:

http://www.neutronicsinc.com/productregistration

You will find the product serial number inside of the battery cover of the main unit and on the outside of the carton

box.

If you would like to register by phone, have any operational questions regarding your new purchase, find the

location of the distributor in your area, or for any other questions, please call 800-378-2287 (in PA: 610-524-8800).

Thank You.

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 1-2

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 1-3

ULTIMA ID PRO™

Model RI-700H HVAC/R REFRIGERANT ANALYZER

OPERATION MANUAL

Manual Part Number: 5-06-7000-70-0

Manual File MN-A-0190 Rev. D

Revised: December 8, 2010

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page v

Table of Contents

TABLE OF CONTENTS ................................................................................................................................................V

FOR YOUR SAFETY: ...................................................................................................................................................VI

ANALYZER WARNINGS.............................................................................................................................................VI

WELCOME ................................................................................................................................................................VIII

1INTRODUCTION AND OVERVIEW .................................................................................................................. 1-9

1.1GENERAL .......................................................................................................................................................1-9

1.2FEATURES ....................................................................................................................................................1-10

1.3ULTIMA ID PRO COMPONENTS.......................................................................................................................1-11

Ultima ID Pro Base Unit......................................................................................................................... 1-11

Low Side Vapor Sample Hose ................................................................................................................ 1-11

AC Power Adapter................................................................................................................................. 1-12

Control Panel......................................................................................................................................... 1-13

Back Panel Connections........................................................................................................................ 1-13

Hard Shell Storage/Carrying Case ........................................................................................................ 1-14

2ULTIMA ID PRO OPERATION ......................................................................................................................... 2-1

2.1FIRST USE ......................................................................................................................................................2-1

Battery Installation (Optional) ................................................................................................................ 2-1

2.2TURNING ON THE UNIT....................................................................................................................................2-2

2.3CALIBRATION..................................................................................................................................................2-2

2.4VAPOR SAMPLING...........................................................................................................................................2-3

2.5LIQUID SAMPLING...........................................................................................................................................2-3

2.6VIEWING THE TEST RESULTS ...........................................................................................................................2-4

2.7CONTAMINATED BLEND REFRIGERANTS ...........................................................................................................2-4

2.8PURE BLEND REFRIGERANTS ..........................................................................................................................2-4

2.9BLENDS WITH INCORRECT COMPONENT RATIOS ................................................................................................2-5

2.10PRINTING THE TEST RESULTS..........................................................................................................................2-5

3MAINTENANCE & TROUBLESHOOTING ....................................................................................................... 3-6

3.1SETTING THE LCD CONTRAST..........................................................................................................................3-6

3.2CHANGING THE WHITE PLASTIC SAMPLE FILTER ..............................................................................................3-6

3.3REPLACING THE SAMPLE HOSE .......................................................................................................................3-7

3.4CHANGING THE PRINTER PAPER ......................................................................................................................3-7

3.5SOFTWARE UPDATES ......................................................................................................................................3-8

3.6ERROR MESSAGES ..........................................................................................................................................3-8

APPENDICES .......................................................................................................................................................... 3-9

3.7SPARE PARTS LIST .........................................................................................................................................3-9

3.8APPENDIX B-SPECIFICATIONS........................................................................................................................3-9

3.9APPENDIX E–WARRANTY .........................................................................................................................3-10

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page vi

For Your Safety:

PLEASE READ THIS MANUAL IN ITS ENTIRETY BEFORE ATTEMPTING

INSTALLATION OR OPERATION! Attempting to operate the Ultima ID Pro without

fully understanding its features and functions may result in unsafe conditions

•Always use protective eye wear and observe proper safety procedures when working with

pressurized gases.

Read and understand the entire manual BEFORE attempting to operate the instrument.

Analyzer Warnings

•Refrigerant Blend Warning: The HVAC industry is ever evolving new refrigerants. Many of

these new blends can be identified and/or profiled using the Ultima ID Pro. A list of tested

refrigerants and their characteristics is provided in the appendix of this manual.

•Sample Filter Warning: Replace the sample filter of the instrument AS SOON AS RED SPOTS

OR DISCOLORATION BEGIN TO APPEAR ON THE OUTSIDE DIAMETER OF THE WHITE

ELEMENT. Failure to properly maintain and replace the sample filter will result in severe

damage.

•Sample Input Warning: The instrument includes two hose assemblies. One for High Side Liquid

sampling and one for Low Side Vapor Sampling. Failure to use the correct hose on the proper

sample port may result in incorrect readings and/or damage to the instrument. DO NOT

attempt to introduce liquid or samples heavily laden with oil into the Low Side sampling hose.

•Damage caused to the instrument due to the use of the wrong hose on the wrong port will void

the warranty!

•Battery Charger Warning: When charging the optional battery with the 1000mA charger, the

charger will become warm. If the charger becomes hot, unplug the charger immediately!

When charging multiple battery packs, allow the charger to cool between each battery.

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page vii

General Cautions

•Always inspect the sample hose before each use. Replace the hose if it appears cracked, frayed,

obstructed or fouled with oil.

•ALWAYS turn the compressor off before connecting the instrument to an air conditioning

system.

•Always wear eye and skin protection when working with refrigerants. Escaping refrigerant

vapors will present a freezing danger.

•To reduce the risk of electrical shock, do not disassemble the instrument; do not use the

instrument in wet or damp areas.

•DO NOT direct refrigerant vapors venting from hoses towards the skin.

•DO NOT disassemble the instrument. There are no serviceable components internal to the

instrument and disassembly will void the warranty.

•ALWAYS place the Analyzer on a flat and sturdy surface.

•DO NOT utilize any other hose other than those supplied with the instrument. The use of other

hose types will introduce errors into the refrigerant analysis and instrument calibration.

•ALWAYS verify that the refrigerant to be tested from the Low Side does not contain or will not

emit heavy loads of oil or liquid.

•NEVER admit any sample into the instrument at pressures in excess of 500 psig.

•NEVER obstruct the air intake, sample exhaust or case vent ports of the instrument during use.

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page viii

WELCOME

Thank you for purchasing the ULTIMA ID PRO Refrigerant Analyzer.

The Ultima ID Pro is the most advanced refrigerant analyzer ever designed for determining the purity of

common gaseous refrigerants. It has many features to offer the user, which will be described in this manual.

We recommend that all personnel who use this instrument read this manual to become more familiar with

its proper operation.

For further information regarding the application, operation or spare parts, please contact the Neutronics

Inc. Customer Service Department. If you have questions or comments, we would like to hear from you.

Neutronics Inc.

456 Creamery Way

Exton, PA 19341

Tel: 610) 524-8800

Toll Free: (800) 378-2287 (US only)

Fax: (610) 524-8807

Visit us at www.neutronicsinc.com

Copyright ©2010 Neutronics Inc.

This work is protected under Title 17 of the US Code and is the sole property of Neutronics Inc. No part of this document may

be copied or otherwise reproduced, or stored in any electronic information retrieval system, except as specifically permitted

under US copyright law, without the prior written consent of Neutronics Inc.

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 1-9

1INTRODUCTION AND OVERVIEW

1.1 General

Contamination and mislabelling of refrigerants either in storage cylinders or air conditioning systems can

lead to component corrosion, elevated head pressures and system failures when utilized by unsuspecting

technicians. The ability of the technician to determine refrigerant type and purity is severely hampered

by the presence of air when attempting to utilize temperature-pressure relations. The development of

various substitute refrigerants further complicates the ability of a technician to identify refrigerant purity

based upon temperature-pressure relationships. The substitute refrigerant blends can also introduce a

flammability hazard to the technician and the ultimate end user of the air conditioning system.

The Neutronics Ultima ID Pro Refrigerant Analyzer provides a fast, easy and accurate means to determine

refrigerant purity in refrigerant storage cylinders or directly in air conditioning systems. The instrument

utilizes non-dispersive infrared (NDIR) technology to determine the weight concentrations multiple of

refrigerant types. Refrigerant purity is displayed on the LCD Screen. The user must determine acceptable

levels of purity based on their recovery or use standards.

The instrument is supplied complete with a ¼” Flare Vapor sampling hose, a ¼” Flare Liquid sampling

assembly, a 100/240 VAC power transformer, built in printer, and all required plumbing housed within a

rugged, portable, storage case.

Sample gas is admitted into the instrument through one of the two supplied sampling hoses and

presented to the sensing device. The instrument provides the user with direct percent by weight

concentrations. Note that the instrument does not consider air to be a contaminant.

The instrument interfaces with the user with an LCD graphic display, status indicator lamps, push button

communication switches and an alarm horn. Alarm indications are provided to alert of instrument fault

conditions. Direct percent by weight concentrations of the sample refrigerant is provided on the display

as well as user directions and prompts. An on-board printer is provided to print an on-the-spot analysis

report.

The Neutronics Ultima ID Pro Refrigerant Analyzer provides the refrigerant technician with excellent

knowledge of refrigerant type and purity as well as protection against refrigerant contamination and

potential flammability.

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 1-10

1.2 Features

The Ultima ID Pro Refrigerant Analyzer is the most advanced portable instrument ever manufactured for

determining the purity of gaseous refrigerants for the HVAC-R market.

Features Include:

•Advanced ergonomic design

•Rugged rubberized hand grips

•Large graphic display with on-screen instructions

•Fast 60 second test time

•Built in printer for instant analysis report

•Vapor or Liquid Sampling ability

•Internal, rechargeable battery (optional) for cordless operation in any location

•Hard shell carry/storage case

•Remote Software Update port

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 1-11

1.3 Ultima ID Pro Components

Ultima ID Pro Base Unit

The Ultima ID Pro base unit houses the Graphic Display, Infrared Bench, Electrical Connections, and

Optional Printer Module. These components require no maintenance, therefore there are no serviceable

components internal to the instrument, and disassembly will void the warranty.

Low Side Vapor Sample Hose

The 6-foot (1.8 meter) Low Side Vapor Sample Hose is constructed of a polyurethane tube. A Brass flow

restrictor acts to reduce pressure at the sample connection point and reduce the introduction of harmful

oil into the machine. The maximum inlet pressure is 500 psig. The hose is provided with an instrument

inlet port mating connector on one end and a ¼” SAE female flare coupling nut on the service end.

Control Panel Sam

p

le Filter

Printer

User Interface

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 1-12

High Side Liquid Sample Hose

The 6-foot (1.8 meter) High Side Sample Hose is constructed of a polyurethane tube with an oil reservoir.

A Brass flow restrictor acts to transform Liquid refrigerant to Vapor at the sample connection point while

the Oil Trap Syringe collects oil and provides a means of expulsion after the test is complete. The

maximum pressure is 500 psig. The hose is provided with magnet for attaching it to the tank and an

instrument inlet port mating connector on one end and a ¼” SAE female flare coupling nut on the service

end.

AC Power Adapter

The Ultima ID Pro is powered via a 100/240 VAC 50/60 Hz power transformer. This transformer is

included with each unit and converts a standard 100/240 VAC 50/60 Hz wall outlet to 12VDC to power

the device. An optional internal and rechargeable battery kit is available separately. Note: Use of any

other power source may cause damage to the unit and void the warranty.

Service End

(

1/4 SAE Flare Nut

)

Analyzer End

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 1-13

Control Panel

The Control Panel serves as the main user interface. The Control Panel features three soft key buttons

that change their function as the instrument changes modes. The current function for each button is

displayed by the soft key label at the bottom of the graphic display. Red and Green LED’s at the top of the

Control Panel are used for visual status indications.

Back Panel Connections

The connections located on the back panel are illustrated below.

CAUTION: The sample outlet port should never be obstructed. Keep the sample outlet port free and

clear at all times. Do not operate near open flame.

Green LED Red LED

Soft Key

Buttons

Sample Inlet

Sample Outlet Battery Charge Port

12VDC Power Input

(AC Adapter)

Power

On/Off

Graphic

Display

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 1-14

Hard Shell Storage/Carrying Case

The hard shell storage/carrying case is custom fit to the Ultima ID Pro. It provides rugged protection for

the instrument as well as convenient storage for all components. The enclosure is general purpose and is

not watertight.

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 2-1

2ULTIMA ID PRO OPERATION

2.1 First Use

Battery Installation (Optional)

The Ultima ID Pro has, as an option, an internal rechargeable battery. If your Ultima ID Pro is

equipped with the optional rechargeable battery, you must first install and charge the battery prior

to use. NOTE: The Ultima ID Pro can be operated with or without the battery using the supplied

AC adapter. Refer to Section 2.2 for instructions.

To install the optional battery, remove the battery cover from the back of the unit by unscrewing

the two screws as shown below.

OR OPENED CONTAINERS OF GASOLINE.

at least 18 inches above to floor.

Use this equipment in locations with mechanical ventilation that

provides at leat four air changes per hour or locate the equipment

DATECODE:

NEUTRONICS INC. MODEL No: UID

(610) 524-8800, www.NeutronicsInc.com

456 Creamery Way, Exton, PA, 19431 USA

WARNING-TO REDUCE THE RISK OF FIRE:

DO NOT USE THIS EQUIPMENT IN THE VICINITY OF SPILLED

LISTED 6P03

Design Pressure: 300 psig

Refrigerant Type: R-12, R-134a

R

Miscellaneous Refrigerant Equipment

12 VDC, 1A; Design Pressure: 300 psig

CFC-12 (R-12) or HFC-134a (R-134a)

(R-134a).

For Accuracy, see Manual.

detect 2% or greater of air in HFC-R134a

to 98% purity. Also this equipment will

to Meet SAE J1771 to identify

Refrigerant Diagnostic Tool Design

Certified by Intertek Testing Services (ITS)

SAE J1771 CERTIFICATION

Inside of the Ultima ID Pro battery compartment, locate the male plug on the left side. Slide the

nylon strap around the battery. Insert the battery module into the compartment aligning the

female connector of the battery module with the male plug in the battery compartment. Replace

the cover and snug the screws.

Note: Charge the battery for a minimum of 4 hours with the supplied charger prior to first

use. The Battery cannot be charged with the standard power adapter.

Battery Cover Screws

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 2-2

To remove the battery, simply tug gently on the nylon strap, being sure to pull straight up, until

the battery is dislodged. The battery may be charged either inside of the unit or independent of the

unit.

2.2 Turning On the Unit

Connect the included AC power supply to the 12VDC power input jack on the back of the unit.

Plug in the AC power supply to a 100 – 240 VAC outlet. (Note: If the optional battery module is

installed and charged, the AC power supply is not required.) Press the left, soft key, power button

and the splash screen shown in (Figure 1) will appear for approximately three seconds followed

immediately by the screen in (Figure 1A) and then by the warm up screen for 3.5 minutes (Figure

2). After the warm up, the calibration screen may be shown if it is required (Figures 3 and 4).

TO CHANGE

SETTINGS OR

REPLACE PAPER

ROLL PRESS SET

FOR OTHER HELP

PRESS HELP

SET HELP DONE

2.3 Calibration

Air calibrations are only required periodically. A reminder to perform air calibrate will appear

after the unit has been powered up 30 times after the last air calibration. The air calibration

can be delayed (skipped) until it is convenient to allow the unit to cool down for at least 4

hours and be placed in a refrigerant-free environment. (Figures 3 and 4). When calibrating, the

unit willbring fresh air into the unit via an internal pump. This fresh air purges any excess

refrigerant and ensures accurate test results. Calibration requires that the hose be disconnected

from the refrigerant cylinder or air conditioning system. (Figure 5).

CALIBRATING

THIS WILL ONLY

TAKE 50 SECONDS

REFRIGERANT-FREE

AREA

3 – POWER UP AND

SELECT AIR CAL

WHEN PROMPTED

CAL BACK SKIP

AIR CALIBRATION IS

NEEDED SOON

1 – POWER DOWN

UNIT FOR 4 HOURS

2 – MOVE UNIT TO

REFRIGERANT FREE

AREA

WARMING UP

PLEASE WAIT

ULTIMA ID PRO

SOFTWARE VERSION

XXX XX.XXX

Figure 1 Figure 2

Figure 4 Figure 5Figure 3

Figure 1A

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 2-3

When the unit is ready for gas testing, the unit will display the screen shown in (Figure 6).

Connect the hose to the tank and press test. The Ultima ID Pro will display the screen shown in

(Figure 7). If you wish to change any of the factory default settings, refer to section 3.

2.4 Vapor Sampling

Vapor sampling is the most common process used for identifying refrigerants using the Ultima ID

Pro. It is a simple process requiring the operator to take these 4 steps:

1) Connect the vapor sampling hose to instrument and then to the Low Side Vapor port of

the system or cylinder.

2) Open the low side valve of the cylinder and press test.

3) Disconnect the hose from the cylinder.

4) Disconnect the hose from the Ultima ID Pro for storage.

2.5 Liquid Sampling

Liquid sampling is an option that is exclusive to the Ultima ID Pro. It permits the user to flash

liquid into vapour for introduction into the analyzer. To use the liquid sampling assembly, follow

these seven steps:

1) Inspect the liquid sampling assembly and ensure that the plunger on the oil trap

syringe is completely depressed.

2) Connect the appropriate end of the hose to the instrument and the opposite end of the

liquid sampling assembly to the High Side Liquid port of the system or cylinder. Affix

the oil trap syringe vertically to the tank with the magnet.

3) Open the high side valve of the cylinder. The liquid sample will exit the tank and be

flashed to vapour by the hose assembly. As the liquid is flashed, the plunger on the oil

trap syringe will begin to rise and the flashed refrigerant sample will travel into the

analyzer.

4) Wait for the plunger on the oil trap syringe to expand past the outlet port.

5) Press test on the Analyzer.

6) Upon completion of the test, close the valve on the cylinder, disconnect the hose from

the inlet of the oil trap syringe, depress the plunger on the oil trap syringe to expel the

trapped oil.

7) Inspect the hose for signs of oil and replace the hose restrictor if necessary.

8) Disconnect the hose from the Ultima ID Pro

TESTING

THIS WILL ONLY

TAKE 60 SECONDS

ANALYZING THE

REFRIGERANT

READY

1 - CONNECT HOSE

2 - OPEN VALVE

3 - PRESS TEST

HELP TEST

Figure 6 Figure 7

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 2-4

2.6 Viewing the Test Results

Upon completion of the test, the Ultima ID Pro will display a screen similar to that shown in (Figure

8). Pressing the “More” button will display the screen shown in (Figure 9).

2.7 Contaminated Blend Refrigerants

The Ultima ID Pro includes the ability to detect and analyze the composition of many common

R400 Series refrigerants in addition to R134a, R22 and Hydrocarbons. In the event that the

Ultima ID Pro determines that the primary refrigerant in the system or cylinder is one of the

measured refrigerants, the results will display as follows in (Figure 10). Pressing the “MORE”

button will display the detail screen shown in (Figure 11). If the blend or refrigerant mixture is not

recognized, the screen shown in (Figure 12) will be displayed.

2.8 Pure Blend Refrigerants

The Ultima ID Pro has the ability to Identify the following refrigerants: R408A, R409A, R417A,

R421A, R421B, R422A, R422B, R422C and R427A. In addition, the instrument can both,

Identify and Analyze the component content of pure R134a, R22, R404A, R407C and R410A.

Analysis of analyzed pure blend refrigerants will yield additional data regarding the composition of

the refrigerant sample. The Ultima ID Pro will display the blend refrigerant type as shown in

(Figure 13). Pressing the “MORE” button will display the detail screen shown in (Figure 14).

RESULTS

UNKNOWN

REFRIGERANT

BACK PRINT DONE

RESULTS

R410A 98.7%

R22 1.3%

BACK PRINT DONE

RESULTS

R410A

CONTAMINATED

BACK MORE

RESULTS

R22 97.0%

R410A 3.0%

BACK PRINT DONE

RESULTS

R22

CONTAMINATED

BACK PRINT MORE

Figure 8 Figure 9

Figure 10 Figure 11 Figure 12

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 2-5

2.9 Blends with Incorrect Component Ratios

The Ultima ID Pro has the ability to detect blend ratios that have been altered by contamination.

As stated above, the blends that can be identified and analyzed are R404A, R407C and R410A. If

one of these refrigerant blends have incorrect component ratios, it will be displayed as shown

below: (Figure 15). To see the component concentrations press “MORE.” (Figure 16).

2.10 Printing the Test Results

The test results can be printed by selecting the “PRINT” button. After the print is complete,

carefully tear off the printout and the unit will return to the previous screen. Additional printouts

may be made following the same procedure. To exit the test, press the “EXIT” button. (Figures 17,

18, & 19,) show sample printouts for various test results.

(NOTE) Care must be taken when tearing off the printed results to leave a clean edge.

Neutronics Inc.

Refrigerant

Analyzer

UNKNOWN

REFRIGERANT

(Date)

(Technician)

Neutronics Inc.

Refrigerant

Analyzer

R410A = 100.00%

R125 = 49.8%

R32 = 50.2%

(Date)

(Technician)

Neutronics Inc.

Refrigerant

Analyzer

R22 = 100.0%

(Date)

(Technician)

RESULTS

COMPONENTS OF

R410A

BACK MORE

RESULTS

100%

R410A

BACK MORE

Figure 17 Figure18 Figure 19

Figure 13 Figure 14

Figure 15 Figure 16

RESULTS

R125 60.0%

R32 40.0%

BACK PRINT DONE

RESULTS

R410A 100.0%

R125 50.0%

R32 50.0%

BACK PRINT DONE

Manual Part Number:

5-06-7000-70-0

Manual File:

MN-A-0190 Rev. D

Revision Date: December 8, 2010 Page 3-6

3MAINTENANCE &TROUBLESHOOTING

3.1 Setting the LCD Contrast

The Ultima ID Pro features an adjustable LCD contrast for use in varying light conditions. To

adjust the contrast, press the “HELP” button on the “Ready to Air Cal” screen as shown in Section

2.2,(Figure 1A). The screen will display several options as shown in (Figure 20). Pressing the

“SET” button will display the options in (Figure 21).

TO CHANGE

SETTINGS OR

REPLACE PAPER

ROLL PRESS SET

FOR OTHER HELP

PRESS HELP

SET HELP DONE

TO FEED IN A

NEW PAPER ROLL

PRESS FEED

PRESS SET TO

ADJ LCD CONTRAST

SET FEED DONE

3.2 Changing the White Plastic Sample Filter

When inspecting the sample filter, look completely around the entire outside diameter of the white

filter element located inside of the clear plastic housing. Look for red spots or the beginnings of

discoloration on the white outside diameter of the element. Do not look into the round ends of the

white element for red spots or discoloration. The round ends of the filter may always appear red. If

red spots or discolorations are discovered on the outside diameter, the sample filter requires

replacement to prevent the influx of particulate and oil mists into the instrument.

Obtain a replacement filter, part number 6-02-6000-08-0. Remove the existing filter from the

retaining clip of the instrument by pulling straight up and out. CAREFULLY remove the flexible,

black rubber tubing connections from both ends of the existing filter. DO NOT allow the tubes to

slip back into the internal portion of the case. Discard the existing filter in an environmentally

friendly manner.

Install the tube ends onto the barbs of the replacement filter, taking note to align the flow arrow of

the filter with the flow arrow of the instrument top panel. CAREFULLY slide the tubing back into

the internal portion of the instrument and seat the new filter into the retaining clip. Inspect the

sample hoses for signs of oil entrapment. Replacement of the sample filter usually requires

cleaning or replacement of the sample hoses.

Figure 20 Figure 21

Table of contents

Other Neutronics Measuring Instrument manuals

Neutronics

Neutronics QUICK DETECT User manual

Neutronics

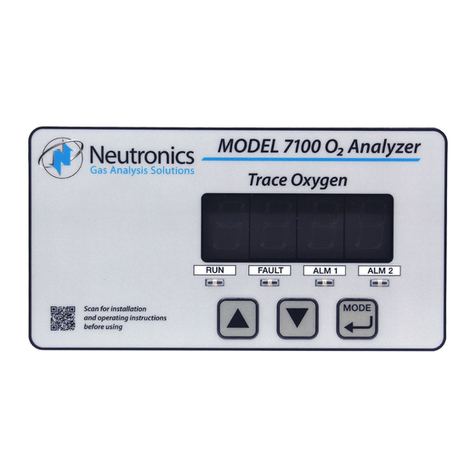

Neutronics 7100E User manual

Neutronics

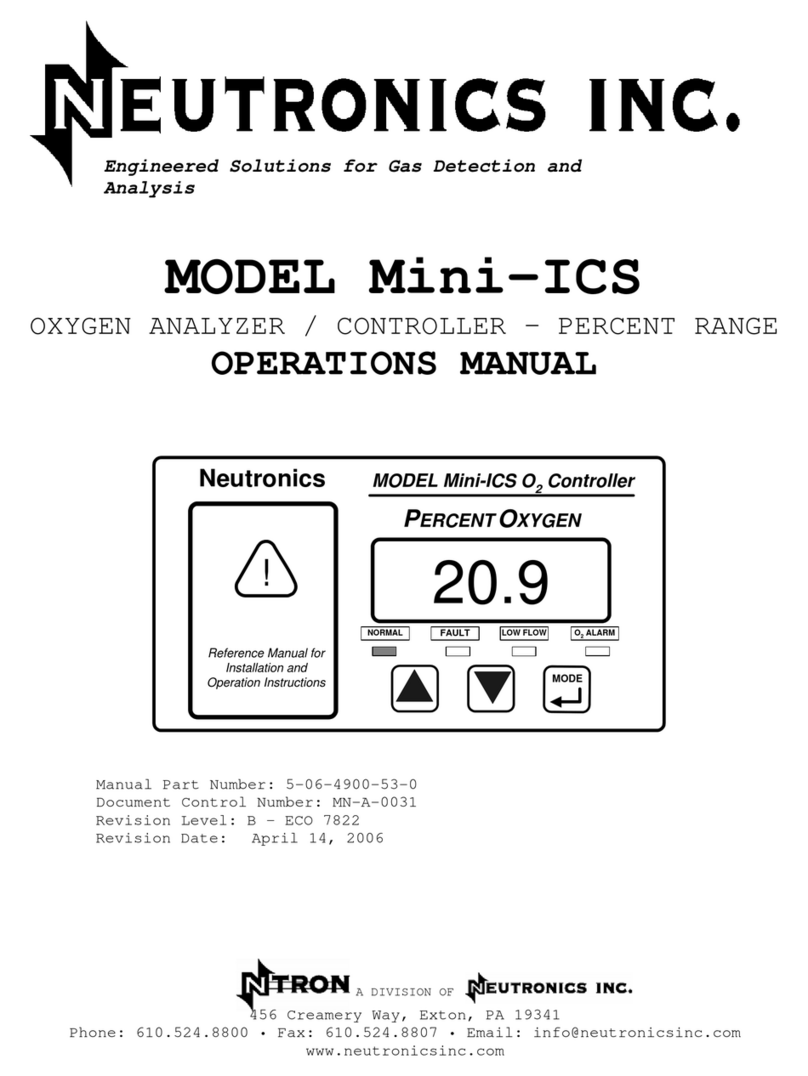

Neutronics NTRON Mini-ICS User manual

Neutronics

Neutronics YELLOW JACKET 68945 User manual

Neutronics

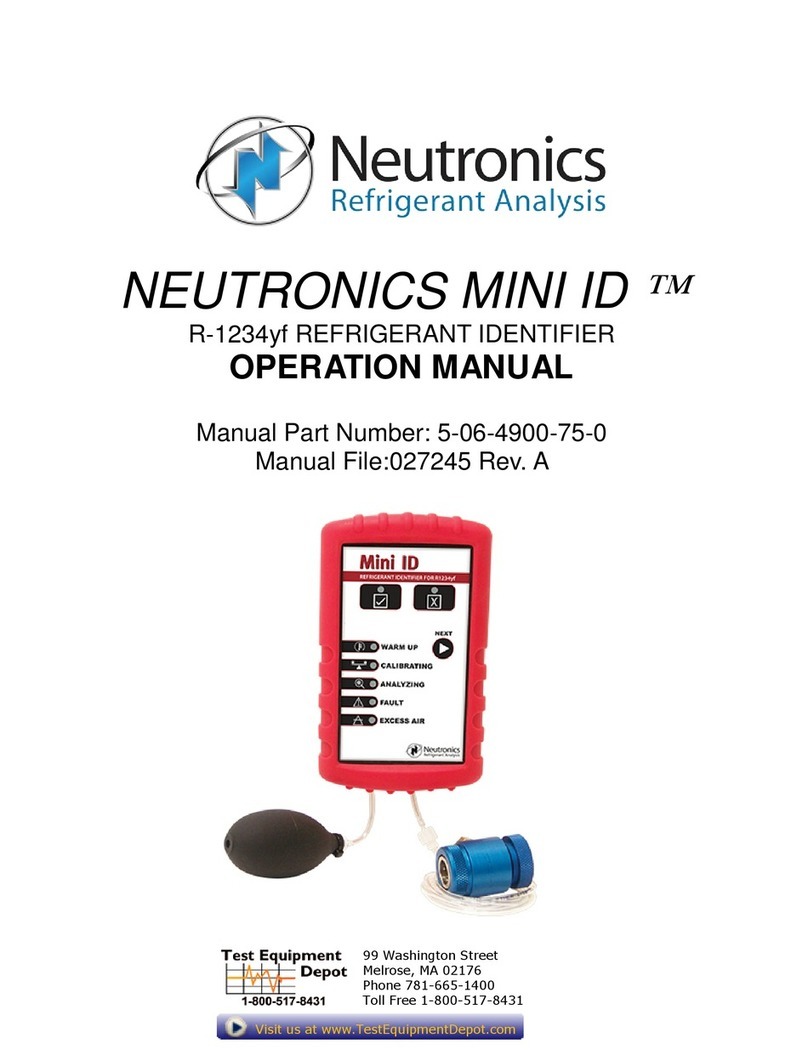

Neutronics MINI ID User manual

Neutronics

Neutronics UltimaID User manual

Neutronics

Neutronics ULTIMA ID User manual