Neutronics QUICK DETECT User manual

QUICK DETECT™

A/C SEALANT DETECTION KIT

OPERATION MANUAL

Manual Part Number: 5-06-7000-62-0

Manual File MN-A-0001 Rev. E

8

9

10

3

4

5

6

7

1

2

Flow

456 Creamery Way, Exton, PA 19341

www.neutronicsinc.com

Manual Part Number:

5-06-7000-62-0

Manual File:

MN-A-0001 Rev. E

Revision Date:

J

une 5, 2006 Page iii

Table of Contents

TABLE OF CONTENTS ...............................................................................................................................................III

FOR YOUR SAFETY: ....................................................................................................................................................V

WELCOME ..................................................................................................................................................................VI

1COMPONENT IDENTIFICATION ......................................................................................................... 1-1

1.1 TEST RIG ........................................................................................................................................................1-1

1.2 FLOW METER ASSEMBLY ................................................................................................................................1-1

1.3 SYRINGE ASSEMBLY........................................................................................................................................1-1

1.4 SENSING PLUG &SAFETY CAP ........................................................................................................................1-1

1.5 ADDITIONAL ITEMS..........................................................................................................................................1-2

2ASSEMBLING THE QUICK DETECT ................................................................................................... 2-3

2.1 FIRST USE ......................................................................................................................................................2-3

2.2 STEP 1–PREPARING THE SENSING PLUG........................................................................................................2-3

2.3 STEP 2–INSERTING THE SENSING PLUG .........................................................................................................2-3

2.4 STEP 3–INSTALLING THE SAFETY CAP............................................................................................................2-3

2.5 STEP 4–ATTACHING THE HOSE.......................................................................................................................2-4

2.6 STEP 5–ATTACHING THE FLOW METER ...........................................................................................................2-4

3TESTING FOR SEALANT .................................................................................................................... 3-5

3.1 PREPARING THE VEHICLE ................................................................................................................................3-5

3.2 TESTING THE VEHICLE WITH THE ENGINE OFF ...................................................................................................3-5

3.3 TESTING THE VEHICLE WITH THE ENGINE ON....................................................................................................3-5

3.4 MONITORING THE TEST....................................................................................................................................3-6

3.5 CHECKING THE TEST RESULTS .........................................................................................................................3-6

3.6 CLEANING THE SYSTEM ...................................................................................................................................3-6

4APPENDICES.......................................................................................................................................4-7

4.1 APPENDIX A-SPARE PARTS LIST ...................................................................................................................4-7

4.2 APPENDIX B-SPECIFICATIONS........................................................................................................................4-7

4.3 APPENDIX C-TROUBLESHOOTING ...................................................................................................................4-7

4.3.1 Low Flow Readings...................................................................................................................4-7

4.3.2 No High Side Service Port.........................................................................................................4-7

4.4 APPENDIX D–INTENDED USE .........................................................................................................................4-7

4.5 APPENDIX E-WARRANTY............................................................................................................................4-8

Manual Part Number:

5-06-7000-62-0

Manual File:

MN-A-0001 Rev. E

Revision Date:

J

une 5, 2006 Page iv

For Your Safety:

PLEASE READ THIS MANUAL IN ITS ENTIRETY BEFORE ATTEMPTING

INSTALLATION OR OPERATION! Attempting to operate the Ultima ID without

fully understanding its features and functions may result in unsafe conditions

TEST RIGS MAY CONTAIN LIQUID REFRIGERANT UNDER PRESSURE. Contact with

refrigerant may cause injury. Wear protective equipment, including safety goggles. Disconnect

test rig from A/C system with extreme caution.

CAUTION: RISK OF INJURY. THIS EQUIPMENT SHOULD BE OPERATED ONLY BY CERTIFIED

PERSONNEL. Operator must be familiar with A/C systems and refrigerant and dangers of

pressurized components.

Avoid breathing A/C refrigerant and lubrication vapor or mist. Exposure may irritate eyes,

nose and throat. Additional health and safety information may be obtained from refrigerant

and lubrication manufacturers.

Use this equipment in locations with mechanical ventilation that provides at least four air changes per

hour.

DO NOT OPERATE EQUIPMENT UNATTENDED. Equipment requires constant observation of

flow rate for the time period specified in procedure. Unattended operation may result in

excessive refrigerant discharge to the environment.

VERIFY SENSING PLUG CONNECTION INTO TEST RIG PRIOR TO TESTING. Incomplete

connection of sensing plug into coupler of test rig will result in sudden ejection from test rig

when connected to A/C system.

USE ONLY ORDINARY CLEAN TAP WATER IN THE WETTING OF SENSING PLUGS. Dirty

water or other fluid types may cause false indications of sealant presence.

DO NOT REMOVE SENSING PLUGS FROM SHIPPING BAGS UNTIL READY FOR USE. The

sensing plugs are sensitive to fouling from dirt, liquid, etc.

USE ONLY REPLACEMENT PARTS SUPPLIED BY NEUTRONICS INC. Use of non-authorized

replacement parts will void all warranties and may result in false or erroneous test results.

DO NOT UTILIZE QUICK DETECT SYSTEM WITHOUT SAFETY SHIELD. Use of system without

safety shield may result in accidental release of refrigerant charges.

DO NOT POSITION FLOWMETER BELOW LEVEL OF TEST PORT. Positioning of the flowmeter

below the level of the A/C test port may result in flowmeter flooding with liquid refrigerant, oil,

dye and sealant.

Manual Part Number:

5-06-7000-62-0

Manual File:

MN-A-0001 Rev. E

Revision Date:

J

une 5, 2006 Page v

Manual Part Number:

5-06-7000-62-0

Manual File:

MN-A-0001 Rev. E

Revision Date:

J

une 5, 2006 Page vi

WELCOME

Thank you for purchasing the QUICK DETECT A/C Sealant Detector.

The Quick Detect is designed to detect the presence harmful Type II sealants at the High Side service port of

the A/C System. The Quick Detect uses disposable cartridges in conjunction with flow measurement to

determine the presence of active sealant. We recommend that all personnel who use this instrument read

this manual to become more familiar with its proper operation.

For further information regarding the application, operation or spare parts, please contact the Neutronics

Inc. Customer Service Department. If you have questions or comments, we would like to hear from you.

Neutronics Inc.

456 Creamery Way

Exton, PA 19341

Tel: 610) 524-8800

Toll Free: (800) 378-2287 (US only)

Fax: (610) 524-8807

EMAIL: [email protected]

Visit us at www.neutronicsinc.com

Copyright ©2004 Neutronics Inc.

This work is protected under Title 17 of the US Code and is the sole property of Neutronics Inc. No part of this document may

be copied or otherwise reproduced, or stored in any electronic information retrieval system, except as specifically permitted

under US copyright law, without the prior written consent of Neutronics Inc.

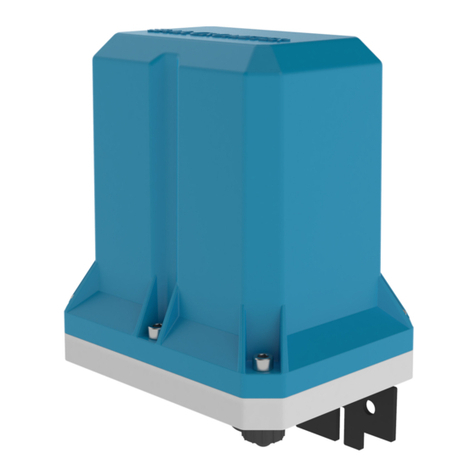

Component Identification

1COMPONENT IDENTIFICATION

1.1

si

Test Rig

Provides connection of sensing plug to the high

based A/C systems.

de or liquid service port of R134a or R12

1.2

Provides visu

Flow Meter Assembly

al indication of refrigerant leak flow rate.

1

2

3

4

5

1

2

3

4

5

1.3

Provides

Syringe Assembly

method for injection of water into sensing plugs ends

8

9

10

3

4

5

6

7

1

2

1.4

Sensing Plug ant detection function of

refriger

Sensing Plug & Safety Cap

provides seal

ant from test rig.

. Safety cap prevents accidental release

R134a Test Ri

g

R12 Test Ri

g

Sensing Plug (10) Safety Cap

Manual Part Number:

5-06-7000-62-0

Manual File:

MN-A-0001 Rev. E

Revision Date:

J

une 5, 2006 Page 1-1

Manual Part Number:

5-06-7000-62-0

Manual File:

MN-A-0001 Rev. E

Revision Date:

J

une 5, 2006 Page 1-2

.5 Additional Items

In addition t bing, a hook

for hanging t

1

o the item described in 1.1 – 1.4, the kit also includes a length of rubber tu

he flow meter, a carrying/storage case and an instruction manual.

Starting up and Commissioning the System

Manual Part Number: Manual File: Revision Date:

J

une 5, 2006 Page 2-3

NG THE QUICK DETECT

First Use

Prior to first use, identify each of the Quick Detect omponents as described in 1.1 – 1.6, locate the

oper coupler for an R12 or R134a

cipal to detect the presence of active sealant.

2ASSEMBLI

2.1

c

High Side (liquid) service port on the vehicle, and select the pr

vehicle.

2.2 Step 1 – Preparing the Sensing Plug

Type II sealants react with moisture and air to form a solid substance designed to seal leaks within

the A/c system. The Quick Detect uses this same prin

Prepare the sensing plug by injecting tap wa

included syringe. (See Figure 1) After injecting the wate

excess water leaving only a few small droplets inside.

ter into both ends of the sensing plug using the

r, shake the sensing plug once to remove

2.3 Step 2 – Inserting the Sensing Plug

Insert the non-ribbed end of the Sensing Plug into the appr

QD sleeve and inserting the Sensing plug. (See Figure 2) N

opriate test rig by pulling back on the

ote, the Plug must be fully inserted and

– Installing the Safety Cap

lide the safety cap completely over the Sensing Plug. (See Figure 3) The safety cap prevents any

accidental release of the Sensing Plug from the QD coupler during installation of the Quick Detect

onto the vehicle.

Figure 2Figure 1

the sleeve must return to its original position. Tug on the plug to ensure it is properly seated.

2.4 Step 3

S

5-06-7000-62-0 MN-A-0001 Rev. E

Manual Part Number:

5-06-7000-62-0

Manual File:

MN-A-0001 Rev. E

Revision Date:

Figure 3 Figure 4

2.5 Step 4 – Attaching the Hose

Attach one end of the hose to the Sensing Plug. (See Figure 4) Make sure the hose is completely

seated over all of the ribs on the end of the plug.

2.6 Step 5 – Attaching the Flow Meter

Attach the Flow Meter to the loose end of the hose. (See Figure 5) Make sure the hose is well

seated on the Flow Meter.

Figure 5

J

une 5, 2006 Page 2-4

Testing For Sealant

3TESTING FOR SEALANT

Manual Part Number: Manual File: Revision Date:

J

une 5, 2006 Page 3-5

Vehicle

et A/C system to the follow

the vehicle A/C system to operate for a minimum

ystem to

ine

3.1 Preparing the

Step 1: Start vehicle engine and s ing

of 2-

stabilize for

Off

settings:

Maximum cool

Lowest temperature setting

Highest fan speed

Step 2: Allow

minutes to ensure full circulation and mixing of refrigerant charge.

Step 3: Turn off vehicle engine and allow A/C s

3-minutes.

Note: For large capacity and dual A/C systems, it is advised to allow

a 5-minute stabilization period prior to testing.

3.2 Testing the Vehicle with the Eng

Connect the test rig assembly to the A/C system high side port

(vehicle engine should be off) and start timer. Installation of the test

rig should be made by pressing on the safety cap only.

o

th the Engine On

e Vehicle” before proceeding

/C system to the following settings:

onnect the test rig assembly to the A/C system high side port (vehicle engine should be on and

/C system running) and start timer. Installation of the test rig should be made by pressing on the

Check A/C system high-side flow rate as measured by the flow

meter. If the flow is above 1.5 on the flow meter then proceed t

step 3.4. If flow is below 1.5 then proceed to step 3.3.

3.3 Testing the Vehicle wi

Complete section 3.1 “Preparing th

Start vehicle engine and set A

Maximum cool

Lowest temperature setting

Lowest fan speed

C

A

safety cap only. Check A/C system high-side flow rate as measured by the flow meter. If flow is still

elow 1.5 then proceed to section four (4) for trouble shooting tips.

b

5-06-7000-62-0 MN-A-0001 Rev. E

Warranty

Manual Part Number:

5-06-7000-62-0

Manual File:

MN-A-0001 Rev. E

Revision Date:

J

une 5, 2006 Page 3-6

ained

test rig from the A/C system high side port.

ding, then sealant is present. If the flow

nt is NOT present.

After completion of the test, remove the flow meter from the system and allow any residual oil to

drain from the hose assembly.

3.4 Monitoring the Test

Observe flow meter reading for 3 minutes. Note that during the initial 30-60 seconds the flow rate

may rise due to water being pushed through the sensing plug. Note the highest reading obt

during the initial 60-seconds and compare to the reading obtained at the end of 3-minutes.

At the end of the 3-minute period, disconnect the

3.5 Checking the Test Results

If the flow drops 30% or more from the initial, stabilized rea

remains within 30%, sealant is NOT present.

Eg. Initial flow = 4.5, Final Flow = 2.5 Sealant is present.

Initial Flow = 4.5, Final Flow = 4.0 Seala

3.6 Cleaning the System

Appendix C – Factory Configuration Settings

4APPENDICES

Manual Part Number: Manual File: Revision Date:

J

une 5, 2006 Page 4-7

4.1

ER

Appendix A - Spare Parts List

PART NUMB DESCRIPTION

7-08-1000-51-0 Quick Detect Kit

7-08-1000-52-0 Quick Detect Spare Sensing Plugs (25)

Quick Detect Spare Parts Kit Items 1.2 thru 1.5

7-08-1000-53-0

4endix B - ns

REFRIGERANT TYPES:

.2 App Specificatio

R12, R134a

PRESSURE: 250 PSIG Max.

TEMPERATURE: 200°F

SEALANT TYPES: Type II

4.3 Appendix C - Troubleshooting

4.3.1 Low Flow Readings

Low flow rea

service port, reusing a sensing plug or clo

dings can be caused by several factors including low refrigerant charge, inoperable

gged tubes. If you encounter low flow readings after

a traditional High Side Service Port. The Quick

4.4 Appendix D – Intended Use

This product is designed for use on Mobile A/C Systems for the express purpose of detecting the

presence of active, Type II sealants at the High Side (Liquid) port of the A/C system.

attempting to conduct the test with a new sensing plug and the compressor and engine running,

add a small charge of refrigerant to the system and retest.

4.3.2 No High Side Service Port

A limited number of vehicles are produced without

Detect cannot be used on these vehicles.

5-06-7000-62-0 MN-A-0001 Rev. E

Warranty

4.5 APPENDIX E - Warranty

NEUTRONICS warrants, subject to the terms listed below, that the goods will be free from defects in

design, materials, and workmanship for a period of (1) one year from the date that the goods are

shipped to the buyer.

THE SOLE LIABILITY OF NEUTRONICS FOR ALL PURPOSES SHALL BE TO REPAIR OR REPLACE,

AT THE SOLE OPTION OF NEUTRONICS, DEFECTS APPEARING WITHIN THE (1) ONE YEAR

PERIOD. NEUTRONICS SHALL HAVE NO OBLIGRATION FOR REPAIR OR REPLACEMENT

UNLESS NEUTRONICS HAS RECEIVED WRITTEN NOTICE OF THE ALLEGED DEFECT WITHIN

THE (1) ONE YEAR PERIOD AND THE DEFECTIVE GOODS ARE PROMPTLY RETURNED BY THE

BUYER, AT THEIR EXPENSE, TO NEUTRONICS AT: 456 CREAMERY WAY EXTON, PA 19341

USA, AND THE DEFECT OCCURS UNDER THE CIRCUMSTANCES OR PROPER USE IN

ACCORDANCE WITH ALL INSTRUCTIONS AND MANUALS PROVIDED TO THE BUYER.

NEUTRONICS WILL DELIVER THE REPAIRED OR NEW GOODS TO THE BUYER AT NEUTRONICS

EXPENSE. IN NO EVENT WILL NEUTRONICS BE LIABLE FOR ANY LOSS OR DAMAGE DIRECTLY

OR INDIRECTLY ARISING FROM THE DEFECTS OR FROM THE USE OF THE GOODS OR FROM

CONSEQUENTIAL OR INCIDDENTAL DAMAGES, WHETHER IN CONTRACT, TORT, OR

OTHERWISE, FOR PERSONAL INJURY OR PROPERTY DAMAGE OR ANY FINANCIAL LOSS.

Buyer shall be responsible for insuring that the goods are functioning properly at all times and

shall not use any goods which are not functioning properly. Buyer, therefore, agrees to indemnify

NEUTRONICS from and against all losses and claims to or by any person or property caused in any

manner by the goods or the use of the goods, including any expenses and attorney’s fees in

connection with all claims, demands, proceedings, or other expenses.

Any description of the goods contained in any documents to which these warranty provisions

relate, including any quotations or purchase orders relating to the goods being delivered to the

buyer, are for the sole purpose or identifying the goods, and any such description, as well as any

sample or model which may have been displayed to or seen by the buyer at any time, have not

been made part of the basis of the bargain and have not created or amounted to any express

warranty that the goods would conform to any such description or any such sample or model.

NEUTRONICS DOES NOT WARRANT THAT THE GOODS ARE FREE OF THE RIGHTFUL CLAIM OF

ANY THIRD PERSON BY WAY OF INFRINGEMENT OF PATENT OR OTHER PROPRIETARY

INFORMATION AND DISCLAIMS ANY WARRANTY AGAINST SUCH INFRIGEMENT.

It shall be the responsibility of the buyer to read carefully and abide by all instructions provided to

the buyer in the instruction manual or elsewhere. If the buyer, or the employees of the buyer, did

not abide by such instructions, then the alleged defect shall not be deemed to have arisen under

circumstances of proper use.

The terms of these warranty provisions shall apply to all products sold by Neutronics, except

sensing plugs, which are considered “consumable items”, and as such are covered by the terms of

these warranties for a single use or a period of (1) year, whichever comes first. No waiver,

alteration or modification of the terms of these provisions shall be valid unless in writing and

signed by an executive officer of NEUTRONICS.

EXCEPT AS SPECIFICALLY SET FORTH AND LIMITED IN THIS PARAGRAPH, NEUTRONICS, INC.

MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES AS TO

MERCHANTABILITY, OR AS TO THE FITNESS OF THE GOODS FOR ANY PARTICULAR USE OR

PURPOSE, AND ANY WARRANTIES SET FORTH IN THIS PARAGRAPH ARE IN LIEU OF SUCH

IMPLIED WARRANTIES OF MERCHNTABILITY AND FITNESS FOR PARTICULAR USE OR

PURPOSE.

Manual Part Number:

5-06-7000-62-0

Manual File:

MN-A-0001 Rev. E

Revision Date:

J

une 5, 2006 Page 4-8

This manual suits for next models

1

Table of contents

Other Neutronics Measuring Instrument manuals

Neutronics

Neutronics MINI ID User manual

Neutronics

Neutronics UltimaID User manual

Neutronics

Neutronics NTRON Mini-ICS User manual

Neutronics

Neutronics 7100E User manual

Neutronics

Neutronics YELLOW JACKET 68945 User manual

Neutronics

Neutronics ULTIMA ID User manual

Neutronics

Neutronics ULTIMA ID PRO RI-700H User manual