Neutronics NTRON Mini-ICS User manual

Process Instruments

Engineered Solutions for Gas Detection and

A

nalysis

MODEL Mini-ICS

OXYGEN ANALYZER / CONTROLLER – PERCENT RANGE

OPERATIONS MANUAL

MODE

NORMAL FAULT LOW FLOW O2ALARM

20.9

PERCENTOXYGEN

MODEL Mini-ICS O2Controller

Neutronics

!

Reference Manual for

Installation and

Operation Instructions

Manual Part Number: 5-06-4900-53-0

Document Control Number: MN-A-0031

Revision Level: B – ECO 7822

Revision Date: April 14, 2006

A DIVISION OF

456 Creamery Way, Exton, PA 19341

www.neutronicsinc.com

Table of Contents

TABLE OF CONTENTS....................................................... III

FOR YOUR SAFETY:........................................................ VII

WELCOME

1CHAPTER 1 – INTRODUCTION AND OVERVIEW......................... 1-1

................................................................ VIII

1.1 GENERAL ........................................................... 1-1

1.2 FEATURES .......................................................... 1-2

1.3 SYSTEM HARDWARE OVERVIEW ............................................. 1-3

1.3.1 Main Board.................................................... 1-3

1.3.2 Relay Board................................................... 1-3

1.3.3 Power Supply.................................................. 1-3

1.3.4 Display Board................................................. 1-3

1.3.5 Control Panel................................................. 1-4

1.3.6 Chassis....................................................... 1-4

1.4 SYSTEM INPUTS AND OUTPUTS ............................................ 1-6

1.4.1 Oxygen Sensor Input........................................... 1-6

1.4.2 Flow Switch Status Input...................................... 1-6

1.4.3 O2Alarm Relay Output ......................................... 1-6

1.4.4 Inert Gas Control Relay Output................................ 1-6

1.4.5 Fault Relay Output............................................ 1-7

1.4.6 Remote Calibration Relay Output............................... 1-7

1.4.7 Analog Voltage Output......................................... 1-7

1.4.8 Analog Current Output:........................................ 1-7

1.4.9 Range ID Output............................................... 1-8

1.4.10 Service Port.................................................. 1-8

1.5 FRONT PANEL USER INTERFACE ........................................... 1-1

1.5.1 The “UP” Pushbutton........................................... 1-1

1.5.2 The “DOWN” Pushbutton......................................... 1-1

1.5.3 The “MODE” Pushbutton......................................... 1-1

1.5.4 7-Segment Alphanumeric Display................................ 1-1

1.5.5 Normal Indicator LED.......................................... 1-1

1.5.6 O2Alarm Indicator LED ........................................ 1-1

1.5.

1.5.

2CHAPTER 2 – SYSTEM INSTALLATION AND START-UP.................. 2-3

7Low Flow Indicator LED........................................ 1-1

8Fault Indicator LED........................................... 1-2

2.1 INSTALLING THE ANALYZER .............................................. 2-3

2.1.1 Step 1 – Locate and Mount the Analyzer unit................... 2-4

2.1.2 Step 2 – Install the Oxygen Sensor............................ 2-5

2.1.3 Step 3 – Install the Analyzer................................. 2-5

2.1.3.1 Oxygen Sensor Input....................................... 2-8

2.1.3.2 Flow Switch Status Input.................................. 2-8

2.1.3.3 Oxygen Alarm Relay Outputs................................ 2-8

2.1.3.4 Inert Gas Control Relay Outputs........................... 2-9

2.1.3.5 Fault Relay Outputs....................................... 2-9

2.1.3.6 Remote Calibration Relay Outputs.......................... 2-9

2.1.3.7 Analog Voltage Output.................................... 2-10

2.1.3.8 Analog Current Output.................................... 2-10

2.1.3.9 Range ID Output.......................................... 2-10

2.1.3.10 RS-232 Service Port..................................... 2-11

2.1.3.11 Battery Backup.......................................... 2-11

2.1.3.12 Mains Power............................................. 2-12

2.2 STARTING UP AND COMMISSIONING THE SYSTEM ............................... 2-13

2.2.1 STEP 1 – Power Up the unit................................... 2-13

2.2.2 STEP 2 – Calibrate the Unit.................................. 2-15

2.2.3 STEP 3 –Set Alarms, and Inert Gas Control Limits............. 2-15

2.2.3.1 Set Oxygen Alarm Level................................... 2-15

2.2

2.2

3CHAPTER 3 – ANALYZER OPERATION................................ 3-1

.3.2 Set High Inert Gas Control limit......................... 2-15

.3.3 Set Low Inert Gas Control limit.......................... 2-15

3.1 SYSTEM ORGANIZATION ................................................. 3-1

3.2 USER MODES ........................................................ 3-1

3.2.1 CALIBRATE Mode................................................ 3-1

3.2.1.1 When to calibrate......................................... 3-1

3.2.1.2 What gases to use......................................... 3-1

3.2.1.3 Procedure for calibrating the Model Mini-ICS.............. 3-2

3.2.2 SET O2ALARM Mode ............................................. 3-3

3.2.3 SET HIGH INERT GAS CONTROL LIMIT Mode......................... 3-3

3.2.4 SET LOW INERT GAS CONTROL LIMIT Mode.......................... 3-3

3.2.5 VIEW ACTIVE FAULTS Mode....................................... 3-3

3.3 RUN MODES ......................................................... 3-5

3.3.1 NORMAL Mode................................................... 3-5

3.3.2 O2ALARM ACTIVE Mode .......................................... 3-5

3.3.

3.3.

4CHAPTER 4 – MAINTENANCE AND TROUBLESHOOTING................... 4-1

3INERTING CONTROL ACTIVE Mode.................................. 3-6

4FAULT ACTIVE Mode............................................. 3-7

4.1 SYSTEM SETUP ....................................................... 4-1

4.1.1 System Setup via Front Panel Keypad........................... 4-1

4.1.1.1 User Setup 1: ICS and O2 Alarm Relays Failsafe/Non Failsafe.4-2

4.1.1.2 User Setup 2: O2 Alarm Relays Ascending Trip.............. 4-2

4.1.1.3 User Setup 3: Analog Voltage Output Setting............... 4-2

4.1.1.4 User Setup 4: Analog Current Output Setting............... 4-2

4.1.1.5 User Setup 5: Display Range Setup......................... 4-2

4.1.1.6 User Setup 6: RS-232 Baud Rate............................ 4-2

4.1.1.7 User Setup 7: Serial Output Format........................ 4-2

4.1.1.8 User Setup 8: Sensor Disconnect Detection Test............ 4-3

4.1.1.9 User Setup 9: Minimum Analog Output Voltage Concentration. 4-3

4.1.1.10 User Setup 10: Maximum Analog Output Voltage Concentration4-3

4.1.1.11 User Setup 11: Minimum Analog Output Current Concentration4-3

4.1.1.12 User Setup 12: Analog Current Full Scale................. 4-3

4.1.1.13 User Setup 13: Set Current Year. ** NOT ACTIVE FOR THIS

RELEASE** 4-4

4.1.1.14 User Setup 14: Set Current Month. ** NOT ACTIVE FOR THIS

RELEASE** 4-4

4.1.1.15 User Setup 15: Set Current Day. ** NOT ACTIVE FOR THIS RELEASE**

4-4

4.1.1.16 User Setup 16: Set Current Hour. ** NOT ACTIVE FOR THIS

RELEASE** 4-4

4.1.1.17 User Setup 17: Set Current Minute. ** NOT ACTIVE FOR THIS

RELEASE** 4-4

4.1.1.18 User Setup 18: Factory Setup Restore..................... 4-4

4.1.2 System Setup via Service Port................................. 4-4

4.1.2.1 RS-232 Service Port Interfacing with HyperTerminal in Microsoft

Windows 95 or later................................................ 4-4

4.1.2.2 Troubleshooting Your HyperTerminal Interface.............. 4-5

4.1.2.3 Organization of RS-232 Serial Data........................ 4-5

4.1.2.4 Standard Level Access..................................... 4-6

4.1.2.5 Advanced Level 1 Access................................... 4-9

4.1.2.6 Advanced Level-2 Access................................... 4-9

4.1.2.7 SETTING UP THE MODEL Mini-ICS – The RS-232 User Setup Menu4-10

4.1.2.8 System Information Display............................... 4-10

4.1.2.9 (U20) Alarm and Relay Setup Menu......................... 4-10

4.1.2.10 (U30) Analog Output Setup Menu.......................... 4-12

4.1.2.11 (U04) Display/Analog Output Range....................... 4-15

4.1.2.12 (U50) RS-232 Serial Setup Menu.......................... 4-15

4.1.2.13 (U60) Front Panel Locks Menu............................ 4-16

4.1.2.14 (U70) Auto Calibration Setup Menu....................... 4-17

4.1.2.15 Sensor Disconnect Test.................................. 4-18

4.1.2.16 Set Time-of-Day and Date ** NOT ACTIVE FOR THIS RELEASE**4-19

4.1.2.17 Averaging Window Size................................... 4-19

4.1.2.18 Auto Return to Run Mode Time............................ 4-19

4.1.2.19 Return all Settings to Factory Delivered Settings....... 4-19

4.1.3 Change factory settings via Hardware Jumpers................. 4-20

4.1.3.1 Analog Voltage Output.................................... 4-20

4.2 ROUTINE PERIODIC MAINTENANCE ......................................... 4-22

4.3 TROUBLESHOOTING .................................................... 4-23

4.3.1 Fault Codes.................................................. 4-23

4.3.1.1 Fault Code 0 – Constant Memory Error..................... 4-23

4.3.1.2 Fault Code 1 – Low Flow.................................. 4-23

4.3.1.3 Fault Code 2 – Sensor disconnected....................... 4-23

4.3.1.4 Fault Code 4 – Low Sensor Limit higher than Low ICS Limit 4-23

4.3.1.5 Fault Code 5 – High ICS Limit lower than Low ICS Limit... 4-24

4.3.1.6 Fault Code 6 – Unstable Calibration Sample............... 4-24

4.3.1.7 Fault Code 7 – Sensor Calibration signal high............ 4-24

4.3.1.8 Fault Code 8– Sensor Calibration Signal Low.............. 4-24

4.3.1.9 Fault Code 9 – Sensor Analog-to-Digital Converter Time-Out4-24

4.3.1.10 Fault Code 10 – Sensor Operating Signal Low............. 4-25

4.3.1.11 Fault Code 11 – Calibration Period too Short............ 4-25

4.3.1.12 Fault Code 17 – Bad cell Calibration Coefficient........ 4-25

4.3.1.13 Fault Code 18 – Main-board EEPROM corrupted............. 4-25

4.3.1.14 Fault Code 27 – Auto Calibration Mode active............ 4-25

4.3.1.15 Fault Code 28 – Calibration Mode active................. 4-25

4.3.1.16 Fault Code 29 – Manual Relay Control active............. 4-25

4.3.1.17 Fault Code 30 – User Setup Mode active.................. 4-26

4.3

4.3

5CHAPTER 5 – APPENDICES........................................ 5-1

.1.18 Fault Code 31 – Factory Setup Mode active............... 4-26

.1.19 Fault Code 32 – Program Starting........................ 4-26

5.1 APPENDIX A – SPARE PARTS LIST ........................................ 5-1

5.2 APPENDIX B - SPECIFICATIONS .......................................... 5-2

5.3 APPENDIX C – ANALYZER FACTORY CONFIGURATION SETTINGS5-5

5.4 APPENDIX D – FRONT PANEL HOT-KEY FUNCTIONS............................ 5-7

5.5 APPENDIX E – WARRANTY ............................................. 5-8

INTENDED USE FOR THE MODEL MINI-ICS....................... 5-8

5.6 APPENDIX F – REFERENCE DRAWINGS ..................................... 5-9

5.7 APPENDIX G – MOUNTING CONFIGURATIONS ................................ 5-10

5.7.1 Wall Mount Enclosure......................................... 5-10

5.7.2 Rack Mount Enclosure......................................... 5-11

5.7.3 Explosion Proof Enclosure.................................... 5-12

For Your Safety:

PLEASE READ THIS MANUAL IN ITS ENTIRETY BEFORE ATTEMPTING

INSTALLATION OR OPERATION! Attempting to operate the

Model 1100 without fully understanding its features and

functions may result in unsafe conditions

• Always use protective eye wear and observe proper safety procedures

when working with pressurized gases.

• Properly dispose of the Oxygen sensor according to the MSDS and local

policies when it has expired.

• Ensure the MODEL Mini-ICS has been properly calibrated before use.

• Never expose the analyzer chassis or sensor to water, high humidity or

moisture. The analyzer chassis is not watertight.

• Never expose the MODEL Mini-ICS to flame or high temperatures. Never

expose the Model Mini-ICS analyzer to flammable gases or vapors. The

Mini-ICS is not rated Intrinsically Safe.

• Ensure the analyzer unit is mounted in an area with free airflow to

prevent the chassis from exceeding the operating temperature

specifications. Do not mount the analyzer or sensor against hot

surfaces. Do not block the ventilation louver on the analyzer

chassis.

WELCOME

Thank you for purchasing the Model Mini-ICS

Analyzer for percent range Oxygen measurement.

The Model Mini-ICS Compact Analyzer is a user friendly, microprocessor

controlled Oxygen measuring instrument. It has many features to offer the

user, which will be described in this manual. We recommend that all

personnel who use this instrument read this manual to become more familiar

with its proper operation.

For further detail regarding the maintenance and in-field service of the

Model Mini-ICS analyzer, please contact the Neutronics Inc. Application

Engineering Department. If you have questions or comments, we would like

to hear from you.

Neutronics Inc. Customer Service Department

456 Creamery Way

Exton, PA 19341

Tel: 610) 524-8800 ext 136

Toll Free: (800) 378-2287 ext 136 (US only)

Fax: (610) 524-8807

EMAIL: [email protected]

Visit us at www.neutronicsinc.com

Equipment Serial Number:

(For faster service, please have this number ready if for any reason you need to contact

us about your instrument)

Copyright ©2003 Neutronics Inc.

This work is protected under Title 17 of the US Code and is the sole property of

Neutronics Inc. No part of this document may be copied or otherwise reproduced, or

stored in any electronic information retrieval system, except as specifically permitted

under US copyright law, without the prior written consent of Neutronics Inc.

1 CHAPTER 1 – INTRODUCTION AND OVERVIEW

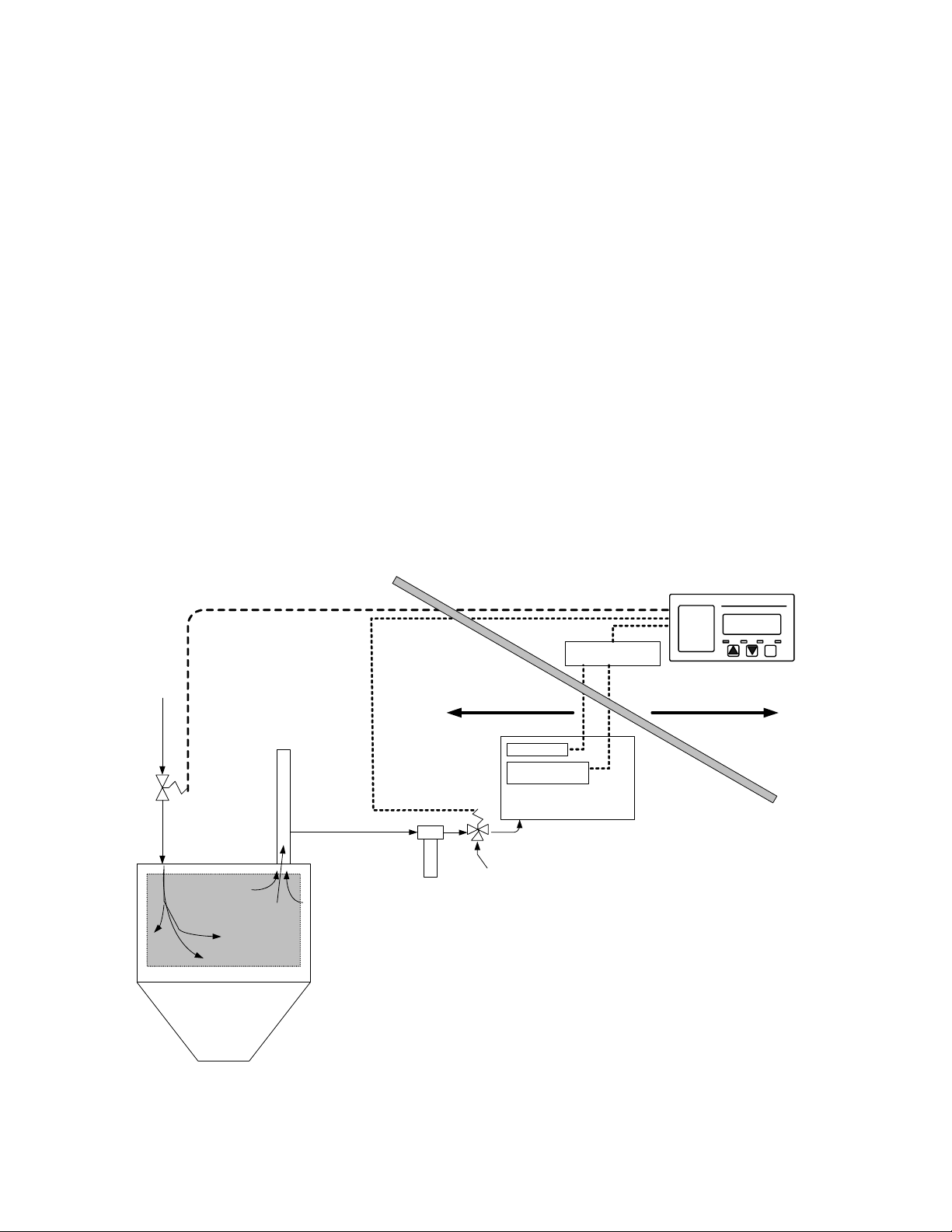

sensor

1.1 General

The Model Mini-ICS [Inert Gas Control System] analyzer by Neutronics

offers a cost effective solution in a small package for industrial

process Oxygen measurement and inert gas control applications for flash-

fire/explosion prevention, or product quality. The Model Mini-ICS is a

custom analytical instrument, designed to accurately measure 0.1 to

50.0% Oxygen, and provide direct control of Oxygen levels in your

process by controlling inert gas purging.

At the heart of the analyzer is a remote-mounted Neutronics zero-

maintenance, disposable galvanic Oxygen sensor. Remote mounting allows

the sensor to be installed close to a process sampling point for the

fastest response time possible. Neutronics also offers a variety of

process sampling and sample conditioning solutions for

reliability and longevity.

Pre-Filter

Sample Conditioning

Package

O2 Sensor

Loss of Sample

Sensor

Inert Gas Input

(Nitrogen)

Vent

Analyzer (Control Module)

Safety Barriers

SAFE AREAHAZARDOUS AREA

Inert Gas

Control Valve

Remote

Cal

Solenoid

Valve

1100-ICS

Gas Head-Space

Industrial Mixer,

Centrifuge, Reactor,

Blender, etc.

Figure 1

–

Complete process Oxygen

m

onitor and control system example

Manual Part Number:

5-06-4900-53-0 Revision Level: B

ECO 7822 Revision Date:

April 14, 2006 Page

1-1

System Installation and Startup

1.2 Features

The Model Mini-ICS analyzer module is designed to be flush mounted to a

panel or console. Packaging options available from Neutronics Inc.

include General Purpose and Explosion Proof surface-mount enclosures,

and custom rack-mount designs. Because of the small size of the Model

Mini-ICS analyzer, the basic panel-mount unit can be integrated into a

variety of equipment or control panels.

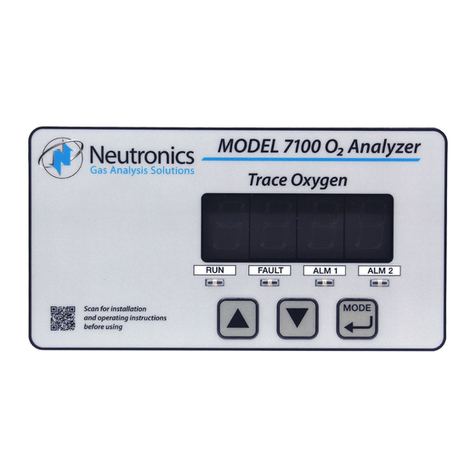

Figure 2 – analyzer

MODE

NORMAL FAULT Low Flow O2 Alarm

20.9

PERCENTOXYGEN

MODEL Mini-ICS O2Analyzer

Neutronics

Color Coded LED’s:

NORMAL = Green

FAULT = Yellow

Low Flow = Red

O2 Alarm = Red Large Buttons

for Ramp Up and

Ramp Down for

Display and

Mode Control

Large Mode Select

Button for easy

scrolling through

menu options

Large LED

Digital Display

Reference Manual for

Installation and

Operation Instructions

!

Other Features Include:

• User-adjustable Oxygen Alarm with relay output for process control use

• User-adjustable Inert Gas Control function with relay output for

process control use. Inert Gas Control features user-adjustable high

and low set point hysteresis

• Loss of Flow indication for extractive process sampling applications

• Double Redundant system configuration backup file, with automatic

repair function

• Convenient Remote calibration relay output for “one-man” calibration

in applications where the Oxygen sensor is a long distance from the

Mini-ICS Analyzer

• Two Analog Outputs: 4-20 mA AND 0-1, 0-5, or 0-10 VDC

• Auto Ranging or Fixed Range Oxygen Measurement (VDC output provided

for auto-range identification)

• Bi-directional RS-232 Serial Interface for connection to a PC,

terminal, or printer

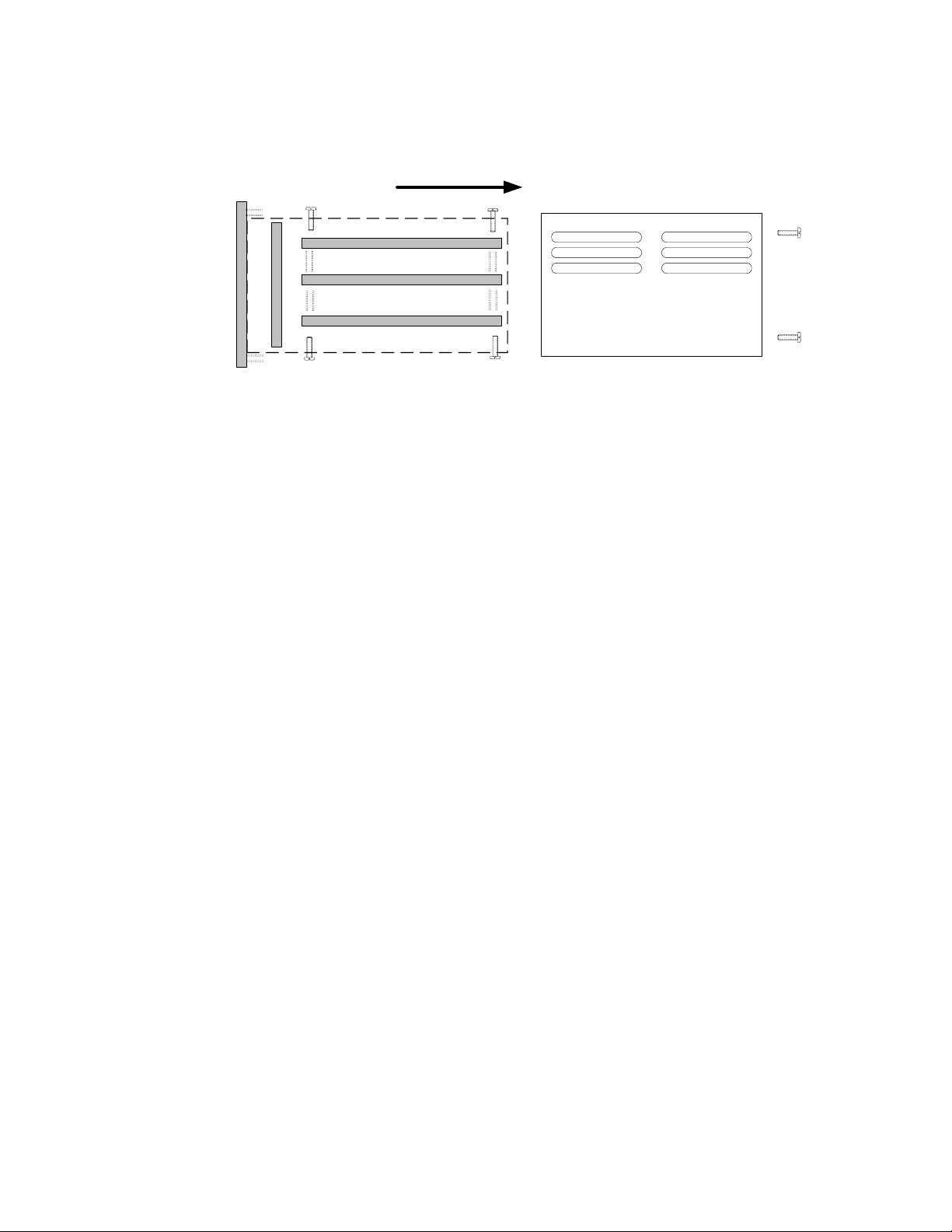

System Hardware Overview

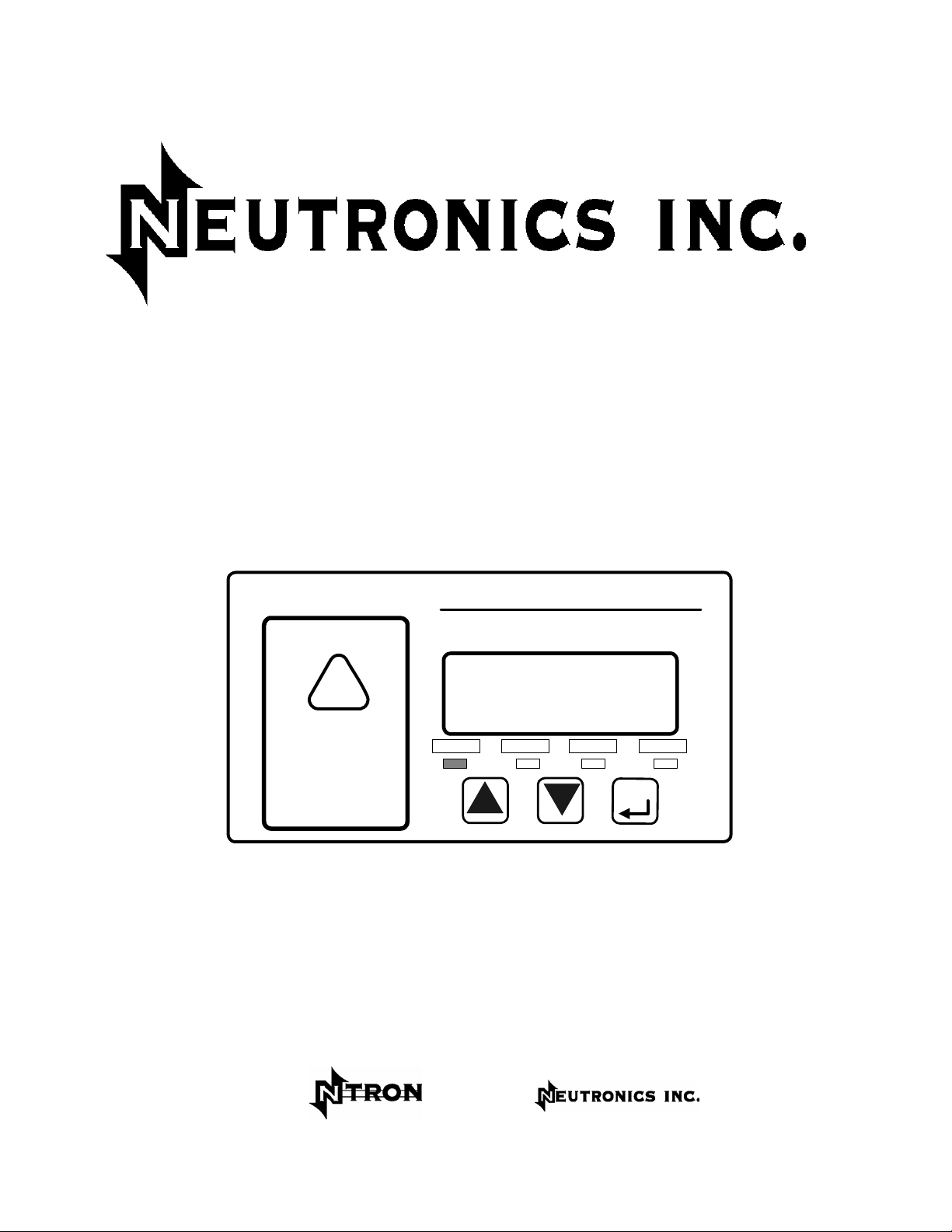

1.3 System Hardware Overview

Chassis

Power Supply Board

Relay Board

Main Board

Display

Board

Control

Panel

Figure 3 – basic analyzer

1.3.1Main Board

The main board houses the microprocessor, and supporting electronics for

controlling the operation of the Model Mini-ICS Analyzer. The main

board receives the sensor signal and flow switch inputs, and provides

the control and display functions of the analyzer.

1.3.2Relay Board

The Relay Board houses relay contacts for all of the Alarm and Control

features of the Mini-ICS. The relays are mapped discretely to each

alarm or control function to provide electrical outputs for reporting,

and process control use.

1.3.3Power Supply

The power supply board is designed to take 110/220 VAC, 50/60 Hz (90-264

VAC, 47-63Hz). as input. The supply is internally fused directly on the

board. An optional 24VDC (10-30 VDC) power supply is available for

installations where a DC voltage is required to power the Model Mini-

ICS. A 12VDC battery-backup power input (battery not provided) is also

provided to act as a back up in case of main power failure.

1.3.4Display Board

The Display board is designed to generate a digital indication of the

concentration of Oxygen, and error codes. The display is a 7-segment,

¾” Alphanumeric LED for easy viewing from a distance.

System Installation and Startup

1.3.5Control Panel

The Control Panel serves as the main user interface. The Control Panel

features the keypad (ramp-UP, ramp-DOWN, and MODE keys) and the status

LED’s. The control panel is designed to be splash and water-resistant.

At the four corners of the panel are the #8-32 mounting studs, which

allow flush mounting of the instrument to a control or equipment panel.

The gasketed panel is suitable for NEMA type 4 / IP20 environments when

properly installed.

1.3.6Chassis

The chassis is manufactured of specially coated steel. It is designed

to provide a general level of protection against mechanical damage from

the local environment. It is also an important component of the ESD

shielding design. Since the Model Mini-ICS is a flush mounted system,

the portion of the instrument housed in the chassis will be located

behind the control panel or embedded within the customer equipment

enclosure. The enclosure is general purpose and is not watertight.

Analyzer

Electronics

Package is

inserted here

Figure 4 – analyzer

System Hardware Overview

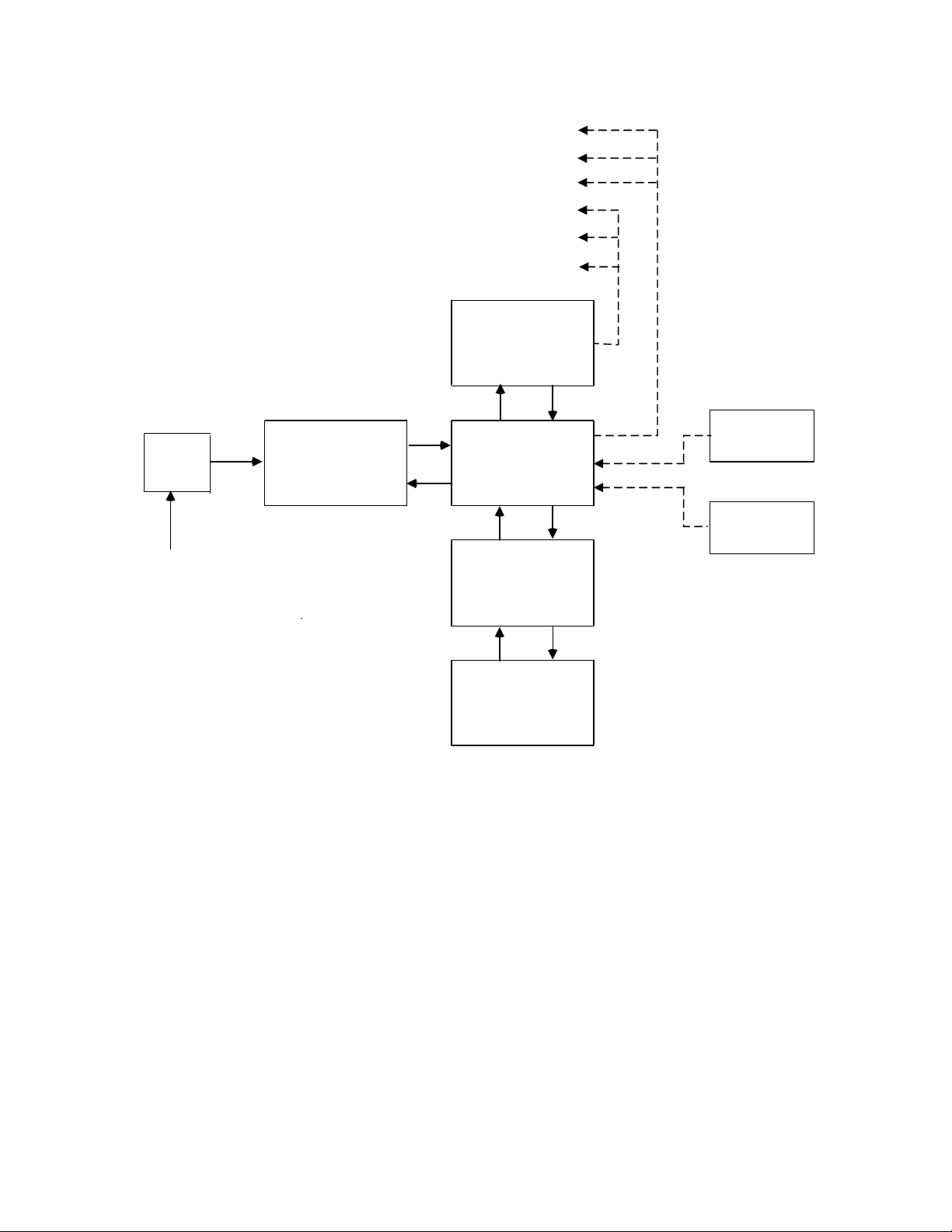

Relay Board

RS 232 COM Line

Mains Power

Input

Power

Supply Main Board

Display

Board

Contr ol

Panel

Line

Filter

Fault andRemoteCalibration Relay Outputs

O2Alarm & Inert Gas Control Relay Outputs

Range IDOutput

Analog Voltage Output

Sensor

4-20 mA Output

Flow

Switch

Figure 5 – analyzer system configuration

System Installation and Startup

1.4 System Inputs and Outputs

1.4.1Oxygen Sensor Input

The Oxygen Sensor electrical input is used to indicate the Oxygen level

concentration in a process vessel headspace, or a process gas stream.

Sensors are available to measure the Oxygen concentration in percent by

volume or partial pressure in the ranges from 0.1% to 25.0%, and 0.1% to

50.0%. All available Neutronics Inc. Sensors are Intrinsically Safe,

remote-mounted devices, and may be interfaced through electrical safety

barriers for hazardous applications,

1.4.2Flow Switch Status Input

The Flow Switch Status electrical interface is used to indicate the flow

status of sample gas from the process to the Oxygen Sensor, for

extractive applications where a Neutronics Inc. Sampling System has been

provided. A closed flow switch indicates sufficient sample flow. An

open Flow Switch indicates that sample flow has dropped below the

mechanical set point of the Flow Switch. In this flow condition, the

Oxygen reading may not be representative of the process Oxygen level.

Neutronics Inc. Flow Switches are Intrinsically Safe, and may be

interfaced through electrical safety barriers for hazardous

applications.

1.4.3O2Alarm Relay Output

The Oxygen Alarm relay is mapped to the O2Alarm setpoint, and is

provided for process control use. The user may set the level at which

the O2Alarm activates (section 3.2.2). The O2Alarm may be configured

as ascending (highest Oxygen level allowable) or descending (lowest

Oxygen level allowable) activation. The relay output may be configured

for fail-safe (relay coil de-energized in alarm state) or non fail-safe

(relay coil energized in alarm state) activation. Factory default

settings are ascending, and fail-safe (Appendix C, Factory

Configuration). The O2Alarm relay contacts are form C (DPDT), voltage-

free.

1.4.4Inert Gas Control Relay Output

The Inert Gas Control (ICS) relay is mapped to the Inert Gas Control

high and low limit setpoints, and is provided for process control use.

The user may set the levels at which Inert Gas Control activates (high

limit setpoint), and de-activates (low limit setpoint). The relay

output may be configured for fail-safe (relay coil de-energized in alarm

state) or non fail-safe (relay coil energized in alarm state)

activation. The factory default setting is fail-safe (Appendix C,

Factory Configuration). The ICS relay contacts are form C (DPDT),

voltage-free.

System Hardware Overview

The purpose of the ICS relay is to control the flow of inert gas to the

process being monitored, to keep Oxygen levels in the process within an

acceptable range at all times. Purging the process with inert gas

lowers the Oxygen concentration in the process. The Mini-ICS Analyzer

will activate the ICS relay when the Oxygen concentration rises to the

High ICS limit setpoint. It will deactivate the ICS relay when the

Oxygen concentration falls below the Low ICS limit (sections 3.2.3 and

3.2.4).

1.4.5Fault Relay Output

The Fault relay output is used to indicate that there is at least one

system fault active on the Model Mini-ICS Analyzer (section 4.3.1 –

fault codes and definitions). The Fault relay contacts are Form B

(SPST), voltage-free.

Note: The user can configure the ICS relay to activate on certain Fault

conditions for process safety applications (sections 4.1.2.9, and

Appendix C).

1.4.6Remote Calibration Relay Output

The Remote Calibration relay is used to activate a valve that flows

calibration gas to the sensor during gas calibration. This is a

convenience item for applications where the sensor/sampling system is a

long distance from the analyzer. The Calibration relay is mapped to the

analyzer Calibration function. It activates whenever the user initiates

a gas calibration routine by entering CAL mode (section 3.2.1), closing

off the flow of process gas and introducing calibration gas to the

Oxygen Sensor. The Remote Calibration relay contacts are Form B (SPST),

voltage-free.

1.4.7Analog Voltage Output

The Analog Voltage output is used to indicate to a remote device (user

control system, chart-recorder, etc.), the displayed Oxygen

concentration in dynamic electrical potential. The Analog voltage can

vary from 0 volts for minimum-scale-deflection, to either 1, 5 or 10

volts full-scale. The Analog voltage output is scaled according to the

analyzer’s active range, and must be used in conjunction with the Range

ID voltage when the Analyzer is configured for auto-ranging (section

1.4.9).

1.4.8Analog Current Output:

The Analog Current output is used to indicate to a remote device (user

control system, chart-recorder, etc.), the displayed Oxygen

concentration in dynamic electrical current flow. The minimum scale

deflection may be set to either 0 mA or 4 mA. Full-scale is fixed at 20

mA. The Analog current output is scaled according to the analyzer’s

active range, and must be used in conjunction with the Range ID voltage

when the Analyzer is configured for auto-ranging (section 1.4.9).

System Installation and Startup

1.4.9Range ID Output

To remotely detect the present range of Oxygen concentration, the Model

Mini-ICS features a 0-10 volt Auto-Range Identification output. The

Range ID output is used in conjunction with the Analog Voltage and

Analog Current outputs when auto-ranging is used. It provides an

indication of the Analog outputs’ current full-scale. There are four

voltage levels are used in the Mini-ICS:

• For a Full Scale of 1%, the Range ID output is 5.63 Volts

• For a Full Scale of 10%, the Range ID output is 6.25 Volts

• For a Full Scale of 25%, the Range ID output is 6.88 Volts

• For a Full Scale of 50%, the Range ID output is 7.50 Volts

• For a Manual Scale, the Range ID output is 9.30 Volts

1.4.10 Service Port

The Service port provides a user-friendly means of digital

communications with the Model Mini-ICS Analyzer. Through this port, the

unit may be configured, calibrated, and queried for most functions. The

RS-232 port may also be programmed to send out information on a timed

basis for users who prefer to use digital instead of Analog interfacing

with the analyzer. In addition, the service port may be used with a PC

based computer (such as a portable notebook computer) over a standard

bi-directional RS-232 serial interface.

1.5 Front Panel User Interface

1.5.1The “UP” Pushbutton

The “UP” pushbutton can be used to program the Mini-ICS Analyzer via the

front panel. This momentary push-button soft key is used to enter

incremental information. Its function is menu-driven.

1.5.2The “DOWN” Pushbutton

The “DOWN” pushbutton can be used to program the Mini-ICS Analyzer via

the front panel. This momentary push-button soft key is used to enter

decremental information. Its function is menu-driven.

1.5.3The “MODE” Pushbutton

The “MODE” pushbutton can be used to program the Mini-ICS Analyzer via

the front panel. This momentary push-button soft key is used to

navigate the operational modes available through the front panel. Its

function is menu-driven.

1.5.47-Segment Alphanumeric Display

The 7-Segment alphanumeric display feeds back information from the Mini-

ICS to the user via the front panel. The primary purpose of the 7-

Segment display is to show the Oxygen concentration readout. It is also

used for feedback information during modes of operation, Fault codes,

and operational mode indications, such as setup and calibration.

1.5.5Normal Indicator LED

The purpose of the NORMAL Indicator LED is to inform the user via the

front panel that the Model Mini-ICS is measuring the concentration of

the sample gas and updating the display and outputs accordingly, and has

not detected any Alarm, or Fault conditions.

1.5.6O2Alarm Indicator LED

The purpose of the O2Alarm Indicator LED is to inform the user via the

front panel that the O2Alarm and its associated relay are in active

mode.

1.5.7Low Flow Indicator LED

The purpose of the Low Flow Indicator LED is to inform the user via the

front panel that the sample gas flow from the process to the Oxygen

sensor is below the mechanical set point of the flow switch. Since Low

Flow is considered a system Fault condition, when the Low Flow LED is

active, the Fault relay will also be active

Manual Part Number:

5-06-4900-53-0 Revision Level: B

ECO 7822 Revision Date:

April 14, 2006 Page

1-1

System Installation and Startup

1.5.8Fault Indicator LED

The purpose if the Fault Indicator LED is to inform the user via the

front panel that at least one system fault, other than the Low Flow

Fault is active. Note that when the Fault Indicator LED is active, the

Fault relay will also be active.

Installing the Analyzer

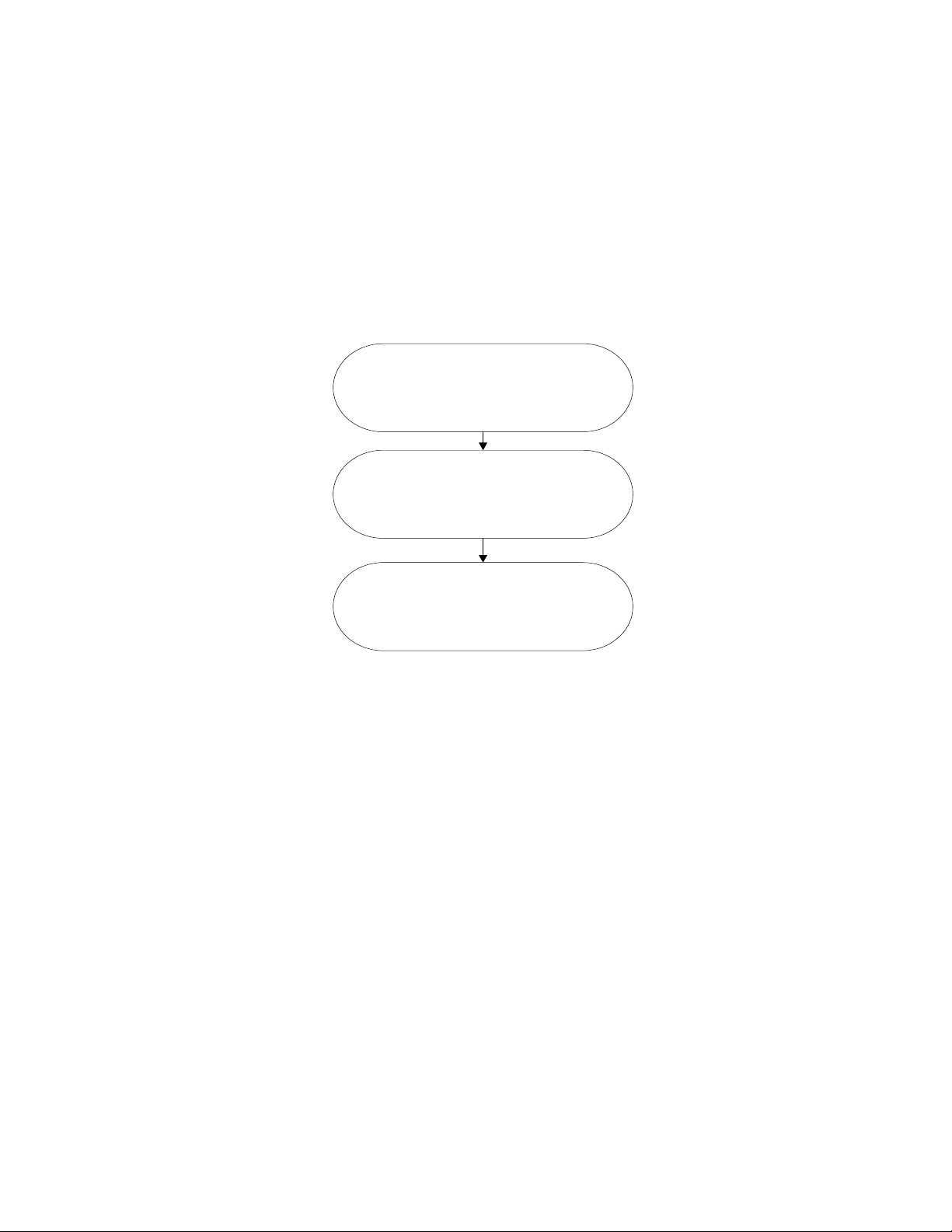

2 CHAPTER 2 – SYSTEM INSTALLATION AND START-UP

2.1 Installing the Analyzer

STEP 1:

LOCATE THE ANALYZER...

PANEL CUTOUT

STEP 2:

INSTALL THE SENSOR…

Sampling Package

STEP 3:

INSTALL TH ALYZERE AN

Figure 6 – installation outline

Manual Part Number:

5-06-4900-53-0 Revision Level: B

ECO 7822 Revision Date:

April 14, 2006 Page

2-3

System Installation and Startup

2.1.1Step 1 – Locate and Mount the Analyzer unit

The Model Mini-ICS is designed to be mounted flush to the surface of

equipment or on a control panel. Select a suitable location for the

Model Mini-ICS analyzer unit where the digital display and status LED’s

will be easy to read, and the interface buttons on the display panel

will be easy to access.

The analyzer should not be exposed to water, adverse temperature, or

shock. Ensure the analyzer unit is mounted in an area of free airflow to

prevent the chassis from exceeding the operating temperature

specifications. Do not mount the analyzer or sensor against hot

surfaces. Do not block the ventilation louver on the analyzer chassis.

To maintain a watertight seal on the control panel, ensure that all

burrs and deformities at the cutout and mounting holes are removed

before insertion of the analyzer unit into the cutout. Ensure that a

proper seal is made at the gasket on the model Mini-ICS control panel.

Installation of the analyzer chassis requires four clearance holes for

the #8-32 threaded studs and a cutout in the control panel to allow the

chassis to slide flush to the panel. Make sure there are no burrs or

sharp edges in the cutout or mounting-holes, which would interfere with

the gasket on the analyzer control panel. The gasket ensures a

watertight seal around the control panel. The control panel, when

properly installed is suitable for NEMA Type 4, IP66 environments. The

rear electronics enclosure is suitable for NEMA Type 1, IP 20

environments.

2.91"

6.20"

6.62"

2.75"

PANEL CUTOUT & DRILL PATTERN

.169 DIA. HOLE

4 PLACES

Figure 7 – analyzer

Table of contents

Other Neutronics Measuring Instrument manuals

Neutronics

Neutronics YELLOW JACKET 68945 User manual

Neutronics

Neutronics ULTIMA ID PRO RI-700H User manual

Neutronics

Neutronics 7100E User manual

Neutronics

Neutronics QUICK DETECT User manual

Neutronics

Neutronics MINI ID User manual

Neutronics

Neutronics ULTIMA ID User manual

Neutronics

Neutronics UltimaID User manual