New Cosmos Electric SDM-73 User manual

SDM-73

Portable Oil Steel Dust Checker

Model SDM-73

Instruction Manual

Please keep this instruction manual available for quick reference

when needed.

Before use, carefully read this instruction manual and fully

understand the content.

Instruction Manual No.: SDM-73CEET

- TABLE OF CONTENTS -

1. Introduction

2. Features

3. Safe Operation

4. Component Names and Functions

4-1. Exterior View

4-2. Component Names and Functions

5. Operation Procedures

5-1. Installing Batteries

5-2. Battery Check

5-3. Measurement

5-4. Collection of Oil Sample

6. Troubleshooting

7. Specifications

8. Warranty

Appendix

1. Measuring Principle

2. Metal Materials Measurable

3. Practical Use

1

1

2

3

4

5

6

7

9

10

12

13

14

15

16

1

1. Introduction

We thank you for purchasing the Portable Oil Steel Dust Checker Model

SDM-73 for the measurement of steel dust in the lubricating oil.

The Oil Steel Dust Checker employs a magnetic balance type

electromagnet induction method as the measuring principle, and is a

useful simplified diagnosis tool for the inspection of the abrasion status

of the bearings and gears, cylinders, etc.

The steel dust can be measured simply by collecting from the oil

sample in a sampling syringe.

This Manual describes the specifications, functions and operating

instructions, carefully read and thoroughly understand this manual

before operating the Oil Steel Dust Checker SDM-73.

2. Features

The employed magnetic balance type electromagnetic induction

method is a highly sensitive for the detection of the abrasion in

the initial stage.

Suitable for diagnose of irregularity in the ultra slow speed

revolution range where diagnosis by vibration method is difficult.

Very simple operation.

Only requiring the sampling container to be filled with the sampled

oil and inserted for instant measurement.

Compact portable instrument and useful for field measurement.

2

3. Safe Operation

Read and understand the contents of the manual before operating the

instrument. The following safety symbols are used in this manual and must be

observedwithoutfail:

!

Warning

WARNING indicates a situation, which if not avoided,

could result in malfunction or abnormal performance of

theinstrument.

!

Caution

CAUTION indicates a situation, which if not avoided may

cause damage to the instrument, or an accurate

measurementmaynotbeobtained.

Memo MEMOindicates operationaladviceandorinstructions.

!

CAUTION

▪This instrument is not explosion-proof. It must be used in a safe

location.

▪Removethebatteriesand storetheinstrument if it isnot be usedfora

longtime.

▪Do not disassemble or modify the instrument or change the structure

or electric circuits.

▪Do not leave the instrument in high-temperature or highly humid

places.

▪Keep the instrument away from radical temperature or humidity

changes, walkie-talkie, mobile phone, or its performance may be

adverselyaffected.

▪Do not drop, hit, or apply a strong mechanical shock to the

instrument,or itsperformancemaybeadverselyaffected.

▪This instrument is not drip-proof. Keep the instruments away from

water.

▪Do not wipe the instrument with a wet cloth or cloth containing a

solvent.Wipetheinstrumentgentlywithasoftclothwhenitis dirty.

▪Be sure to keep the sampleinsert port clean.Correct reading cannot

be obtained when it is smeared with oil, etc. as there is an optical

sensor to detect the sampling syringe. (Wipe away a smear with a

cottonswab orsoftcloth.)

3

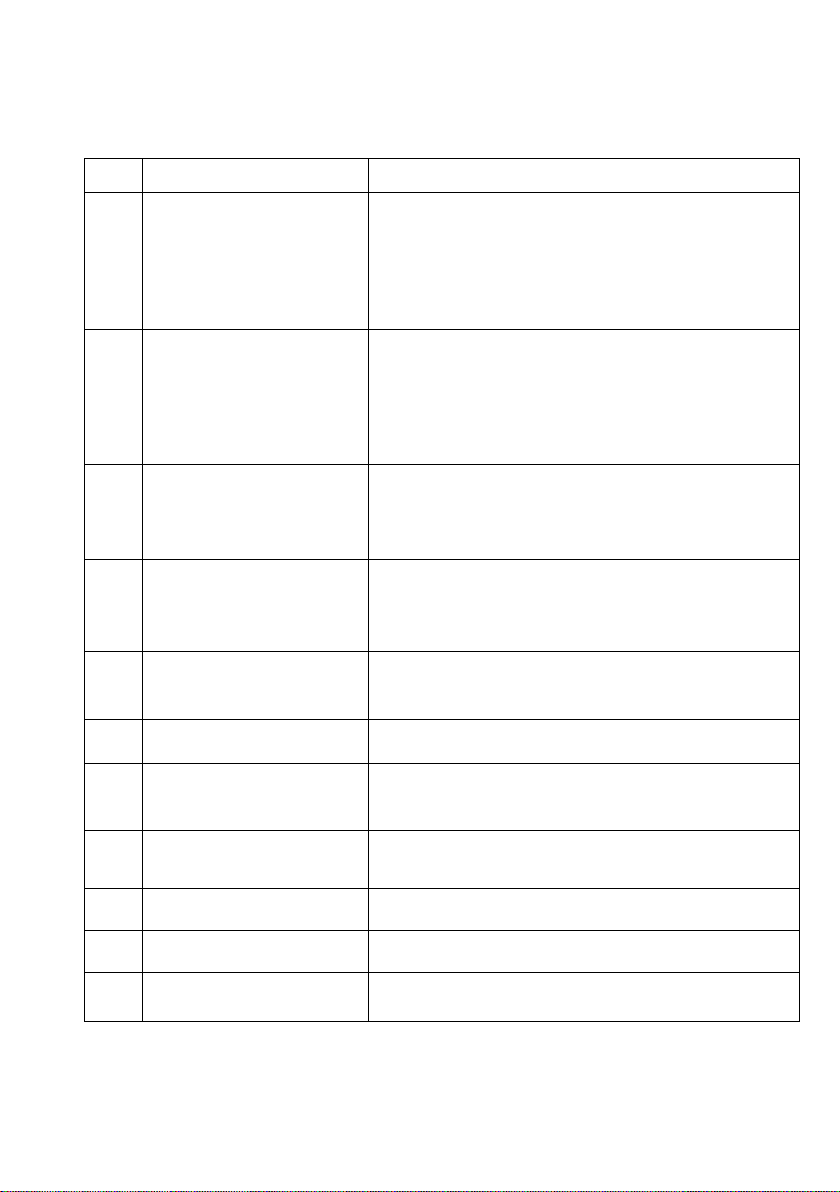

4. Component Names and Functions

4-1.Exterior View

4

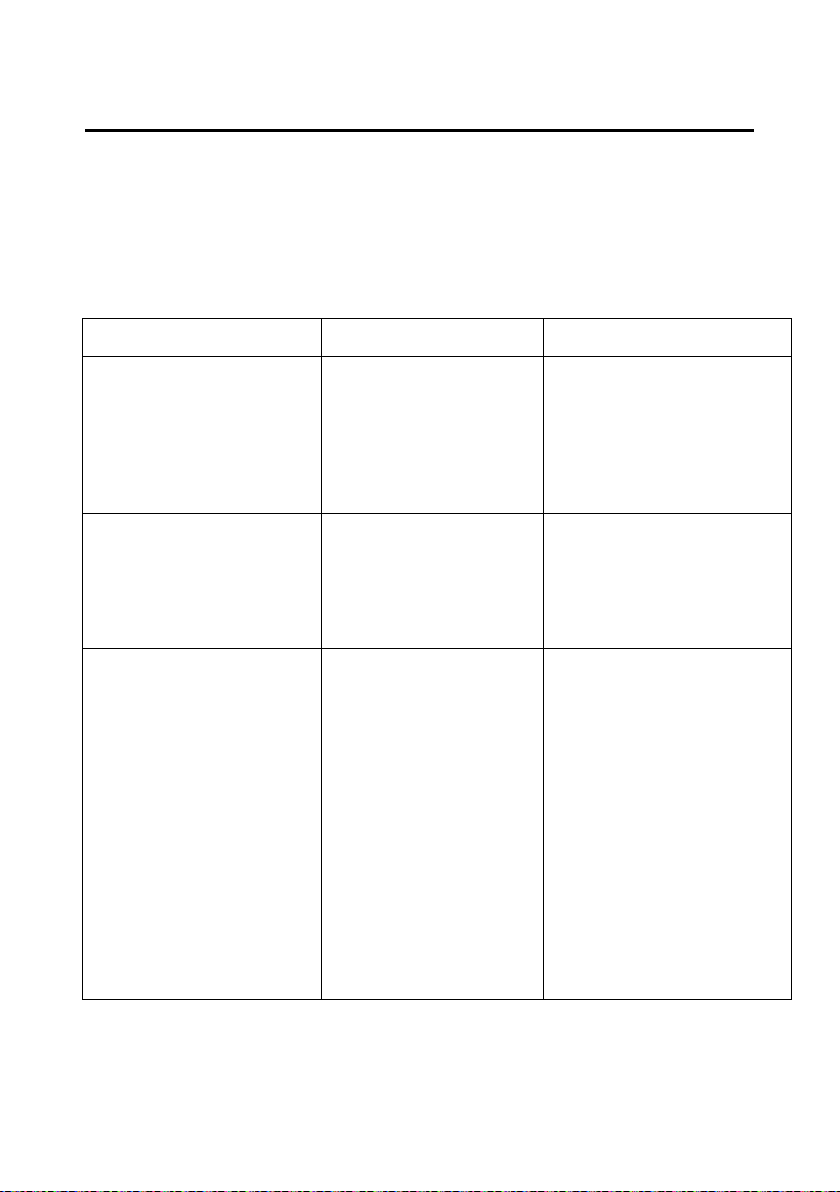

4-2. Component Names and Functions

No.

Controls Functions

1 Change-over

selector switch

Rotate the switch to “MEAS” position to

commence measurement, with the sampling

syringe removed from the instrument.

To check the voltage level of the batteries,

rotate the switch to “BATT” position.

2 Sample insert port

Insert port for sampled oil.

The measurement of the steel dust is

conducted when the sampling syringe is

inserted, while the selector switch is set at

“MEAS” position.

3 BATTERY alarm lamp

To indicate the low battery status, when the

battery voltage becomes lower than 3.6V,

the alarm lamp will turn ON.

4 LCD display The display will indicate a digital reading of

the steel dust in the sampled oil. Also, to

indicate the reading of battery voltage.

5 DC jack The exclusive jack to accept the plug of the

AC Adapter.

6 Calibration date label Label to indicate calibration date.

7 Battery compartment The battery compartment accommodates 4

AA size dry batteries.

8 Sampling syringe

(2ml) A syringe to collect sampling oil.

9 Oil collection nozzle A nozzle for oil collection.

10

Syringe holder

11

AC adapter

for 100V AC Exclusive AC adapter. (Option)

5

5. Operation Procedures

5-1. Installing Batteries

Open the battery compartment cover located on the lower right side

of the instrument, press and slide off the cover, secure a fresh set

of 4 AA size (LR6) alkaline dry batteries, and carefully observe the

battery polarity illustration inside the battery compartment to make

sure that the batteries are installed correctly. It is recommended

that a fresh new set of batteries be installed; do not use a set of

partial used and new batteries.

To close the battery compartment, place the cover on the batteries

leaving an opening of about 10mm, and while pressing the cover

downward push it forward to close the compartment.

6

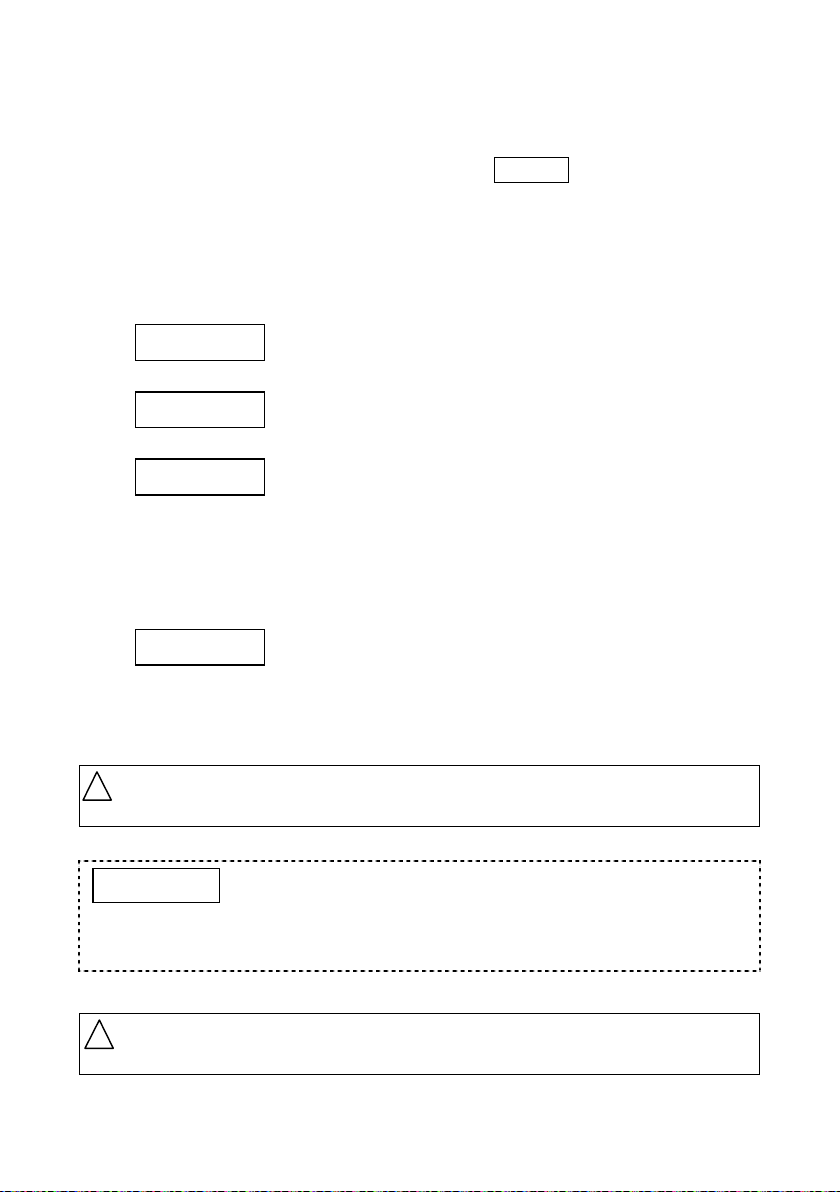

5-2. Battery Check

Rotate the selector which from the “OFF” position to the “BATT”

position, the LCD display will indicate - - - - for a period of 2-3

seconds, then the voltage of the battery will be displayed.

Examples of battery voltage display.

(Battery voltage = 5.6V)

can be operated if the voltage is higher than 3.6V

the BATTERY alarm lamp will turn ON if the

voltage is lower than 3.6V and instrument can

not be operated. Secure a fresh set of batteries

and make replacements.

when the battery voltage drops below 3.2V, the

BATTERY alarm lamp will commence to blinking

with an audible buzzer sound.

Warning

Measurement conducted under low battery condition

will not provide an accurate or reliable reading.

In case the battery voltage should drop below 3.2V

during measurement at “MEAS”

mode, the

BATTERY alarm lamp will turn ON and the audible

alarm will sound.

b 5. 6

b 3. 6

b 3. 6

b 3. 2

Caution It is recommended to

replace the batteries with a

fresh set of 4AA size (LR6) alkaline batteries.

!

Memo

!

7

5-3. Measurement

1) Rotate the selector switch to “MEAS” and shift to the

measurement mode.

2) Check to see that the display

indicates 0.000 then insert the

sampling syringe with syringe

holder containing the sampled oil

into the sample port.

(Refer to 5.4 regarding procedures

for the collection of oil sample.)

3) An audible beep will sound for 2-3

seconds after the sampling syringe

with the holder has been inserted

indicating the measurement has

been completed, and the reading is

held, read and record the reading.

4) When the sampling syringe with the holder is removed from the

sample port, the display will return to zero 0.000 by the auto

zeroing adjustment function.

(Remove the syringe and holder together.)

5) After the measurement has been completed, make sure to return

the selector switch to “OFF” position.

8

Caution

Always insert the sampling syringe with holder, and remove them together

gently. Do not apply an impact when inserting the sampling syringe with

holder. If the insert is too slow, the reading may drift and may not be

accurate. In such case pull out the sampling syringe with the holder once

andreinsertforthemeasurement.

After the sampling syringe with the holder has been inserted for

measurement, do not move the instrument until the “BEEP” sound for the

completion of the measurement. If the instrument is moved the

measurementmaydrift.

Caution

This instrument employs the electromagnetic induction method as the

measuring principle, and should not be operated in the vicinity where a

strongelectromagneticwaveisgenerated.

(Example: inverter controlled motor, welding machine, electric spark

machine) It is recommended to conduct measurement in a location not

effectedbysuchelectricalequipment.

Do not operate the instrument in a location where walkie-talkie or cellular

phonemaybeused.

During measurement, do not use or place a metal tool (object) near the

sampleport.

If the collected sample oil is of high temperature, allow it to cool to normal

room temperaturebeforemeasurement.

Memo

Readings may vary when the size of steel dust is big or when steel dust

concentration is high, as the dust in the sampling oil shall be gradually

settled. In this case, shake the syringe and mix them well before

measurement. It is recommended to measure the value, placing the

instrumenthorizontally.

Readings obtained from sampling oil with steel dust generated under

normal wear are relatively stable. And readingsobtained from theoil with

steel dust generated under abnormal wear may vary, because size of dust

particleisnotequal anditaffectsthemeasurement.

Measure the value at least 3 – 4 times and take an average or maximum

value,asthereadingobtainedat1st measurementmay benotcorrect.

!

!

9

5-4.CollectionofOilSample

1) Collect the oil sample (approx. 10-30ml) from rotating portion of the

machinery and put it in asampling bottle. Collect the sampling oilfrom near

bottom sincesteel dust tendstosettle nearbottom.

2) Shake and mix the oil sample in the sampling bottle well. When the oil

viscosityishigh,stirtheoilwellbeforemeasurement.

3) After mixing the oil sample, collect 1.5ml oil sample in the syringe with oil

collection nozzle. Collect slightlylarger amount than 1.5ml, and remove the

airinsidethesyringeandadjusttheamountequalto1.5ml.

4) Remove the oil collection nozzle and wipe the tip of syringe with paper

towel,thenfitacap.

5) After shaking the syringe andmix the oil samplewell beforemeasurement.

Carryout themeasurementrightaftermixingtheoilsample.

Memo Syringe is a consumable part. Pay attention to the following.

When removing the oil sample stuck on the scale on the syringe, the scale may

vanish depending on the type of oil. Do not to put oils on the scale on the

syringe.

Discharge the oil sampleinthe syringe to thesampling bottle after measurement.

When it is kept in the syringe, the syringe may be deformed depending on the

typeofoil.

Do not put the tip of the syringe downwards after collecting the oil sample in the

syringe,sincesteeldustsmaysettleinthetipofthesyringe.

The syringe canbe used for the measurement 5-10 times. Replace the syringe

withanew onewhenthescalegrowsfaintandhardtoread 1.5ml scale.

Syringe

Sampling bottle

Oilcollectionnozzle

Oil sample

Cap

Syringe holder

10

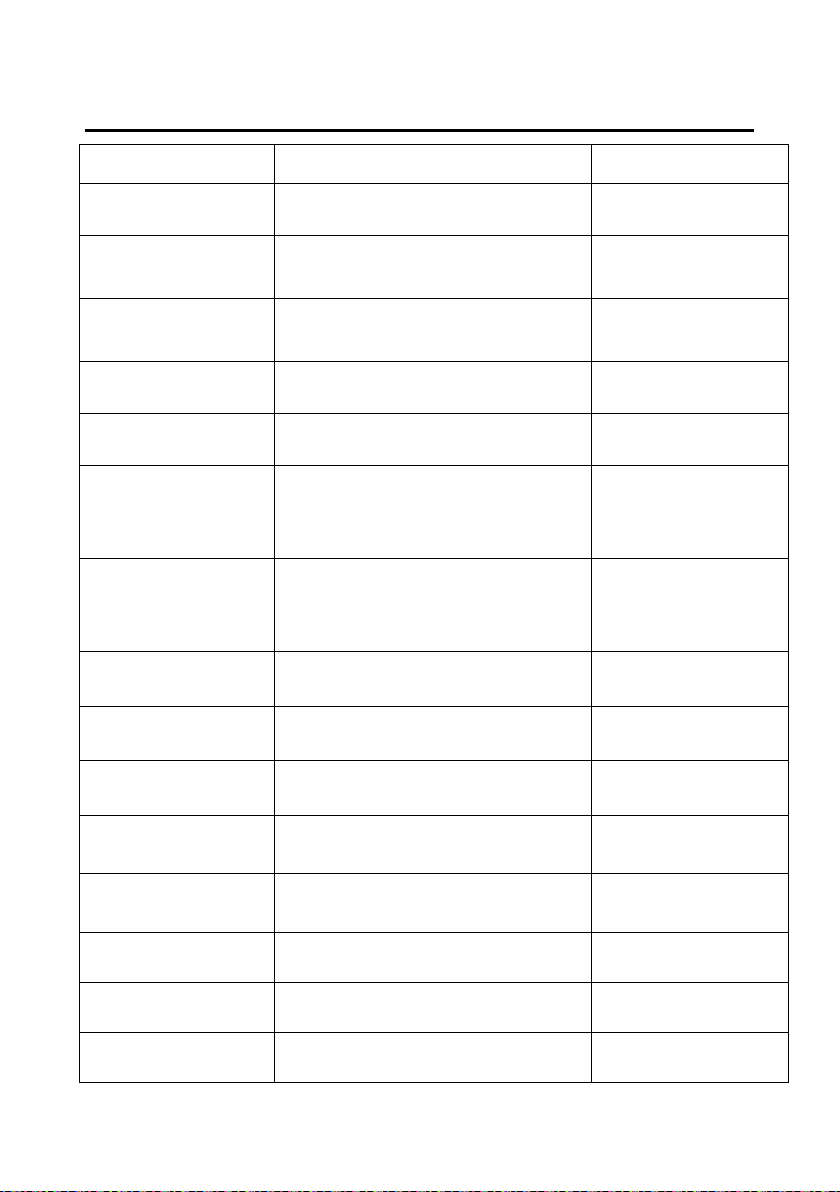

6. Troubleshooting

Problems, which may be experienced during the use of the Oil Steel

Dust Checker SDM-73, are listed in the table below, together with

indications of probable cases and recommendations for corrective

actions. Contact our authorized distributor if your problem is not listed or

when the remedy fails to correct the problem.

Problem Cause Remedy

No indication appears on

the display when the

selector switch is set at

“BATT” or “MEAS” using

fresh set of batteries.

Bad battery

contacts.

The polarities of the

battery are not

correctly installed.

Take out the batteries

and reinstall. (page 5)

Reinstall the batteries

with the polarity

correctly positioned.

(page 5)

The battery alarm lamp

turns ON when selector

switch is set at “BATT”

or

“MEAS” using fresh set

of batteries.

The battery may be

installed with the

polarity in wrong

position.

Reinstall the batteries

with the polarity

correctly positioned.

(page 5)

The reading of the

display does not stabilize

or is not held when the

sampled oil is inserted.

The reading is held at an

unstable condition.

The sampled oil is of

high temperature

and cannot be

measured.

Measurement

conducted nearby a

source of strong

electromagnet wave.

(Inverter controlled

motor, etc.)

Cellular phone or

walkie-talkie used

while conducting

measurement.

Allow the sampled oil

to cool off and conduct

measurement. (page 8)

Move away from the

source of

electromagnet wave.

(page 8)

Turn OFF the cellular

phone or walkie-talkie

and perform

measurement. (page 8)

11

Flashing - - - - is

indicated on the LCD.

Turned Power ON

with the sampling

syringe with holder

inserted in the

instrument.

Remove the sampling

syringe with holder

from the instrument.

Even after the sampled

oil removed from the

sample port, the display

will not return to zero, or

flashing - - - - is

indicated.

No reading is obtained

after the sampled oil is

inserted in the

instrument.

Optical sensor to

detect the sampling

syringe is smeared

with oil, etc.

Only the sampling

syringe is removed

while the syringe

holder is in the

instrument.

Wipe away a smear

near the sample insert

port with a cotton swab

or soft cloth.

Always remove the

sampling syringe

together with the

syringe holder.

12

7. Specifications

Items Specifications Remarks

Model SDM-73

Measuring principle

Magnetic balance type

electromagnetic induction method.

To measure Concentration of iron particles in

the oil.

Measurement range

0 – 19999 ppm weight ratio

Display 4 1/2 digit liquid crystal display

Minimum resolution

1 ppm 0 ppm indicated

when the value is

less than 5 ppm.

Accuracy ±(10 %rdg + 10 dgts)

The analyzed value of standard oil

by atomic absorption method

%rdg =

measured value%

Zero adjustment Automatic adjustment

Sample volume 1.5 ml

Power requirement 4 AA size dry batteries

Battery life 30+ hours of continuous operation

using alkaline

batteries

Operating

temperature 0 to 40 degrees C

Dimensions 84W x 40D x 190H (mm)

Weight Approximately 480g

Approval CE (EMC Directive 2004/108/EC)

13

8. Warranty

New Cosmos Electric Company Limited (New Cosmos) offers the

following as the sole and exclusive limited warranty available to

Customer.

This warranty is in lieu of, and customer waives, all other warranties of

any kind or nature, expressed or implied, including without limitation,

any warranty for merchantability or fitness for a particular purpose. The

remedies set forth herein are exclusive.

New Cosmos warrants to the original purchaser and no other person or

entity (customer) that gas detection product supplied by New Cosmos

shall be free from defects in materials and workmanship for a period of

one (1) year from the date of purchase. This warranty does not include

consumables, such as fuses, filters, etc. Certain other accessories not

specifically listed here may have different warranty periods.

After examination of allegedly defective product return to New Cosmos,

with freight prepaid, should the product fail to conform to this warranty,

customer’s only remedy and New Cosmos’s only obligation shall be, at

New Cosmos’s sole option, replacement or repair of such

non-conforming product or refund of the original purchase price of the

non-conforming product. In no event will New Cosmos be liable for any

other special, incidental or consequential damages or losses of any kind

whatsoever, including but not limited to, loss of anticipated profits and

any other loss caused by reason of non-operation of the product.

This warranty is valid only if the product is maintained and used in

accordance with New Cosmos’s instructions and /or recommendations.

New Cosmos shall be released from all obligations under this warranty

in the event repairs or modifications are made by persons other than its

own or authorized service personnel or if the warranty claim results

from physical abuse or misuse of the product.

14

Appendix

Reference Materials

1. Measuring Principle

The measuring principle of the magnetic balance electromagnetic

induction method is shown in the illustration below, the magnetic

circuit sensor is composed of an exciter coil connected to the both

sides of the detection coil, the magnetic field generated by both

exciter coils are blanketed in the vicinity of the center detection coil.

Normally, the center detection coil does not generate an induction

voltage, on the other hand when the sampled oil containing iron

particles is inserted into the exciter coil, the magnetic field is offset

by the magnetic permeability variation, and an induction voltage is

generated in the detection coil. The induction voltage can measure

the concentration of the iron particles in the sampled oil.

Amplifier

circuit

Transmission

circuit

Sampled grease

Exciter coil 1

Output

Detection coil 2

Exciter coil 2

15

2. Metal Materials Measurable

Table 1 of Metal Materials that can be Measured

(○:Measurable, ×:Not measurable)

Metal and Materials Magnetism Measurable

Remarks

Iron, nickel, cobalt Ferromagnetism ○

Aluminum, chrome,

manganese, titan,

stainless steel

(SUS-304, SUS-316)

Para magnetism ×

Copper, silver, lead,

zinc, tin Diamagnetic ×

Iron oxide (α-Fe2O3)

Ferruginous

(Hydroxide iron) Para magnetism ×*1

Iron oxide

(γ-Fe2O3, Fe3O4) Ferromagnetism ○

Sodium, calcium,

lithium, molybdenum Para magnetism ×*2

*1: Iron oxide has several isomers, as can be noted from the table

above there are substance that can be measured with the Oil Steel

Dust Checker and substance that can not be measured. Specially in

case the environment allows the oxidation of iron particles easily

and where the collected sample contains red rust the measurement

conduct may indicate a reading lower than the actual concentration.

16

3. Practical Use

1) Management and Simplified Diagnosis of Oil Lubricated Bearings &

Gears

To be used to diagnose the steel dust contents in the oil used for

lubrication of low speed rotation to high speed rotation machinery.

Most useful for the diagnosis of the abrasion of the bearing and

gears used at low speed rotation and difficult to diagnose with the

vibration method, and to improve the accuracy of diagnosis when

jointly used with the vibration method for medium and high speed

rotation machinery.

Preliminary diagnosis for SOAPmethod, ferrography method, etc.

Useful tool for preliminary diagnosis as a cost saving for

maintenance.

Example of various use

Pumps & Motors Agitators Fan-blower・Compressor Cooling tower・Air fin cooler

Mixer・Kneader Rotary drier Paper-marking machinery Mill・Crusher・Refiner

Metal rolling machinery Conveyor Crane・Hoist・Lift Civil engineering machinery

Rolling stock・Elevator Escalator・Parking tower

Transportation Moving sidewalk

17

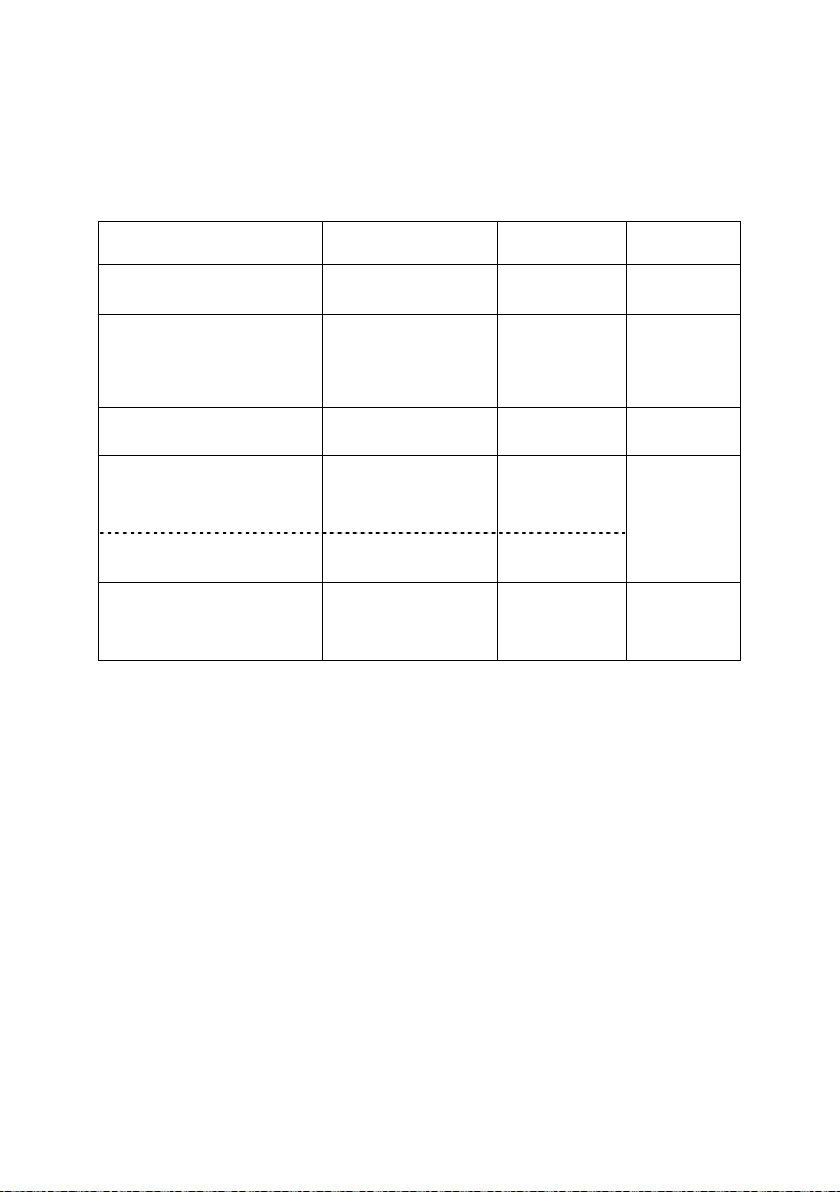

2) Criterion

The following table is an example of the criterion.

This criterion is relatively strict in order to carry out appropriate

corrective lubrication improvements, to detect the abnormal trend at

an early stage.

The criterion for the small sized machine is three times higher than

the one for the large sized machine. It is because oil bath type

lubrication and less filtering are frequently employed on the small

sized machine.

It is recommended to establish a suitable criterion to your machine,

by collecting the data and tendency from the machine although it

may sometimes be difficult as there are so many types of machines

and applications.

Table 3 Criterion of the Steel Dust Concentration in the Oil

Criterion (ppm)

Large sized

machine Small sized

machine Countermeasure

Normal

value Less than 30

Less than 100

Management of steel dust contents

in the oil at normal cycle

Precaution

value 30- 100 100- 300 Repeat lubrication and remeasure

the steel dust concentration 1

month later.

Irregular

value More than 100

More than 300

Countermeasure for improvement

of lubrication, precision diagnosis at

short cycle management.

Manual Revision History

Edition No. Date Change

SDM-73 CEET June, 2008

Additional copies of this operation manual are available.

Contact the following address for ordering information.

Distributor: Manufacturer:

New Cosmos Electric Co., Ltd.

2-5-4 Mitsuiya-naka,

Yodogawa-ku,

Osaka 532-0036, Japan

TEL: +81-6-6309-1505

FAX: +81-6-6308-8129

http://www.new-cosmos.co.jp/en/index.html

Table of contents

Other New Cosmos Electric Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Solartron Mobrey

Solartron Mobrey MRL800 Installation & maintenance manual

Emerson

Emerson Micro Motion TA Series installation manual

Kinvent

Kinvent K-Grip user guide

Thorne & Derrick

Thorne & Derrick Kamstrup ULTRAFLOW 54 Installation

PCB Piezotronics

PCB Piezotronics ICP 333B30 Installation and operating manual

STONEX

STONEX R6 Series user manual