New Era Pump Systems Syringe HEATER-KIT-1LG User manual

Publication #800-01 Revision 6-H0.14 12/25/20

SyringeHeater.com

SyringePump.com

Syringe Heater

Thermo-Kinetic Heat Clamping

Model: HEATER-KIT-1LG

HEATER-KIT-5SP

- Complete User Manual -

WAR

WARWAR

WAR

NING

NINGNING

NING

NOT FOR CLINICAL

NOT FOR CLINICALNOT FOR CLINICAL

NOT FOR CLINICAL

USE ON HUMANS

USE ON HUMANSUSE ON HUMANS

USE ON HUMANS

CAUTION

RISK OF

ELECTRIC SHOCK

CAUTION:

SURFACE OF HEATING

PADS WILL GET VERY

HOT

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 112/25/20

1.

General Information

Thank you for purchasing the Syringe Heater Kit. Please familiarize yourself with the Syringe Heater’s operation by reading this

user's manual. For future reference, record the serial number, located on the bottom identification label, and the date of purchase.

New Era Pump Systems Inc., located in Farmingdale, NY USA, can be contacted at:

Phone: (631) 249-1392 FAX: (707) 248-2089 Email: INFO@SYRINGEPUMP.COM

www.SyringePump.com www.SyringeHeater.com

This Operating Manual, and the Syringe Heater’s hardware, electronics, and firmware are copyrighted.

Copyright 2012-2020, all rights reserved.

1.1

Warnings

!

and Cautions

!

!

Read the user’s manual

!

Risk of electrical shock. Do not cut heating pads.

!

Surface of heating pads can get very hot

!

No user serviceable parts are inside.

!

Disconnect power from the heater when connecting or

disconnecting cables.

!

Do not immerse the heater control unit or pads in liquid

!

Install on a stable surface.

!

The heater can automatically start when the heater is

operating or when attached to an external control device.

!

Prevent liquids from entering openings.

!

Only connect to a power source as specified on

the power supply label.

!

Do not push objects of any kind into openings,

except for appropriate cables and connectors.

!

If the heater becomes damaged, do not use unless

certified safe by a qualified technician. Damage

includes, but is not excluded to, frayed cords and

deterioration in performance.

!

Discharge static from control cables before

connecting by touching the cable to ground.

1.2

Disclaimer

New Era Pump Systems Inc. makes no representations or warranties, expressed, statutory or implied,

regarding the fitness or merchantability of this product for any particular purpose. Further, New Era Pump

Systems Inc. is not liable for any damages, including but not limited to, lost profits, lost savings, or other

incidental or consequential damages arising from ownership or use of this product, or for any delay in the

performance of its obligations under the warranty due to causes beyond its control. New Era Pump

Systems Inc. also reserves the right to make any improvements or modifications to the product described in

this manual at any time, without notice of these changes.

New Era Pump Systems Inc. products are not designed, intended, or authorized for use in applications or as

system components intended to support or sustain human life, as a clinical medical device for humans, or

for any application in which the failure of the product could create a situation where personal injury or

death may occur.

All brand and product names used in this manual are the trademarks of their respective owners.

1.3

Warranty

New Era Pump Systems Inc. warranties this product and accessories for a period of two years, parts and

labor, from the date of purchase. The repaired unit will be covered for the period of the remainder of the

original warranty or 90 days, whichever is greater.

A return authorization number must be obtained from New Era Pump Systems Inc. before returning a unit

for repair. Warranty covered repairs will not be performed without a return authorization number. At the

option of New Era Pump Systems Inc., a defective unit will be either repaired or replaced.

This warranty does not cover damage by any cause including, but not limited to, any malfunction, defect or

failure caused by or resulting from unauthorized service or parts, improper maintenance, operation contrary

to furnished instructions, shipping or transit accidents, modifications or repair by the user, harsh

environments, misuse, neglect, abuse, accident, incorrect line voltage, fire, flood, other natural disasters, or

normal wear and tear. Changes or modifications not approved by New Era Pump Systems Inc. could void

the warranty.

The foregoing is in lieu of all other expressed warranties and New Era Pump Systems Inc. does not assume

or authorize any party to assume for it any other obligation or liability.

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 212/25/20

1.4

Packing List

Included in the Syringe Heater kit are the following items:

•Heater control box

•Primary heating pad, version 1LG or 5SP

•Version 1LG includes 2 releasable plastic ties

•Basic Operating Manual.

2.

Overview

The syringe heater controls the power to a heating pad regulated by a temperature sensor. It is controlled

from a microcontroller-based system which monitors and regulates the temperature on the heating pad.

Features:

♦User adjustable Thermo-Kinetic Heat

Clamping for precision regulation of

Set Point temperature.

♦Maximum temperature of 185 C

♦Non-volatile memory of all operating

parameters.

♦RS-232 bi-directional control, with built-in RS-232

network driver, for control from a computer. RS-232

network supports up to 100 heaters, pumps and other

devices from a single computer port.

♦Safety Features: Power Failure, Lock-Out, and Shut-Off

Timer Modes.

♦Selectable Temperature units of C or F (Celsius or

Fahrenheit)

3.

Setup

♦Attach the primary heating pad to the larger connector (8 pin) on the end of the heater control box.

♦Wrap the primary heating pad around the syringe body. Temperature will be measured near the point

where the wires are attached to the heating pad. Secure the heating pad to the syringe with the 2

releasable plastic ties (Pad 1LG).

♦Plug in the heater.

♦Use the Up and Down arrow buttons to adjust the temperature Set Point

♦To start heating the pad, simultaneously press the 2 ACTIVE buttons, and . The

ACTIVE LED will be lit. The heater will begin to regulate the temperature on the pad.

♦Press the button to stop heat regulation and exit Active Mode.

♦The temperature Set Point can be adjusted while in Active Mode.

ENTER

STOP

ENTER

STOP

SETUP

Temperature

Sensor

Primary

Heating Pad

1LG

Primary Heating

Pad Connector

Secondary

Heating Pad

Connector

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 312/25/20

SETUP

ENTER

STOP

ACTIVE

ACTIVE

OUT

ALARM

COMPUTER

PUMP

4.

User Interface

The controller will display, as the default display, the current

temperature of the primary heating pad, in the currently selected units,

C or F.

LEDs indicate the status of the heater.

ACTIVE Temperature Set Point is actively being

maintained

OUT

Heating pads are being powered. Flashing

indicates on/off power duty cycle to slow down

heating when near the Set Point

ALARM

Heating pad temperature is greater than 20

degrees C above the Set Point. Other system

alarms.

Keypad

Up / Down Arrow Buttons

Increases or decreases settings

By default, will change the temperature Set Point

Settings with decimal points

Press both buttons simulaneously to shift the decimal point.

SETUP Button

Displays the setup menu. Each press will display the next menu selection.

ENTER / STOP Button

When displaying the setup menu or changing a value, will select the entry or

save the new value. The display will blink when the new value is saved in

non-volatile memory.

Otherwise, will stop the heater. The Active LED will turn off. Temperature

will no longer be maintained.

Active Mode Buttons

Simultaneously press the SETUP and ENTER/STOP buttons. The Active LED

will turn on and the heatings pads will start heating until the temperature

reaches the Set Point.

5.

Setup Settings

Press the SETUP button to display the Setup Menu. Each press of the SETUP button will

display the next menu entry. All settings are saved in non-volatile memory. Pressing an Up or Down

arrow button will immediately select Temperature Clamping Set Point and will increment or decrement the

setting.

Press the ENTER button to select a menu entry or accept and enter a setting, exiting Setup

Configuration. A value being changed will be automatically entered after a few seconds time out period.

The display will blink to indicate the value has been entered and saved in non-volatile memory.

SETUP

SETUP

ENTER

STOP

ENTER

STOP

SETUP

ENTER

STOP

┌ACTIVE ┐

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 412/25/20

Press an Up or Down arrow button, or , to change a displayed setting.

The setup menu is as follows: Indicates that the display alternates between 2 displays.

Temperature Clamp Set Point

When active, the heater will heat the pads until the set point is

reached on the primary pad. Use the Fiine Tune settings to

control the regulation of the temperature clamping.

Alarm Set Point will be

20 degrees C (36 F) above

the Set

Po

int.

Fine Tune Temperature Set Point

Fine Tunes thermo-kinetic settings to improve regulation of

temperature Set Point clamping.

Press

to di

splay

the

F

ine Tune

settings sub

-

menu.

Slow Down Temperature Delta

Degrees below Set Point to begin heating slow down.

Heating duty cycle will be reduced based on degrees below

temperature set point and rate of temperature change.

Set to 0 to disable

. Default = 10.

Set Point heat clamping duty cycle

base percentage (Pc).

Hold duty cycle percentage is the base heat duty cycle percentage

to trickle charge the heaters to clamp the temperature setting.

Actual percentage will be dynamically adjusted up or down

according to temperature feedback

Set to 0 to disable.

Default = 10.

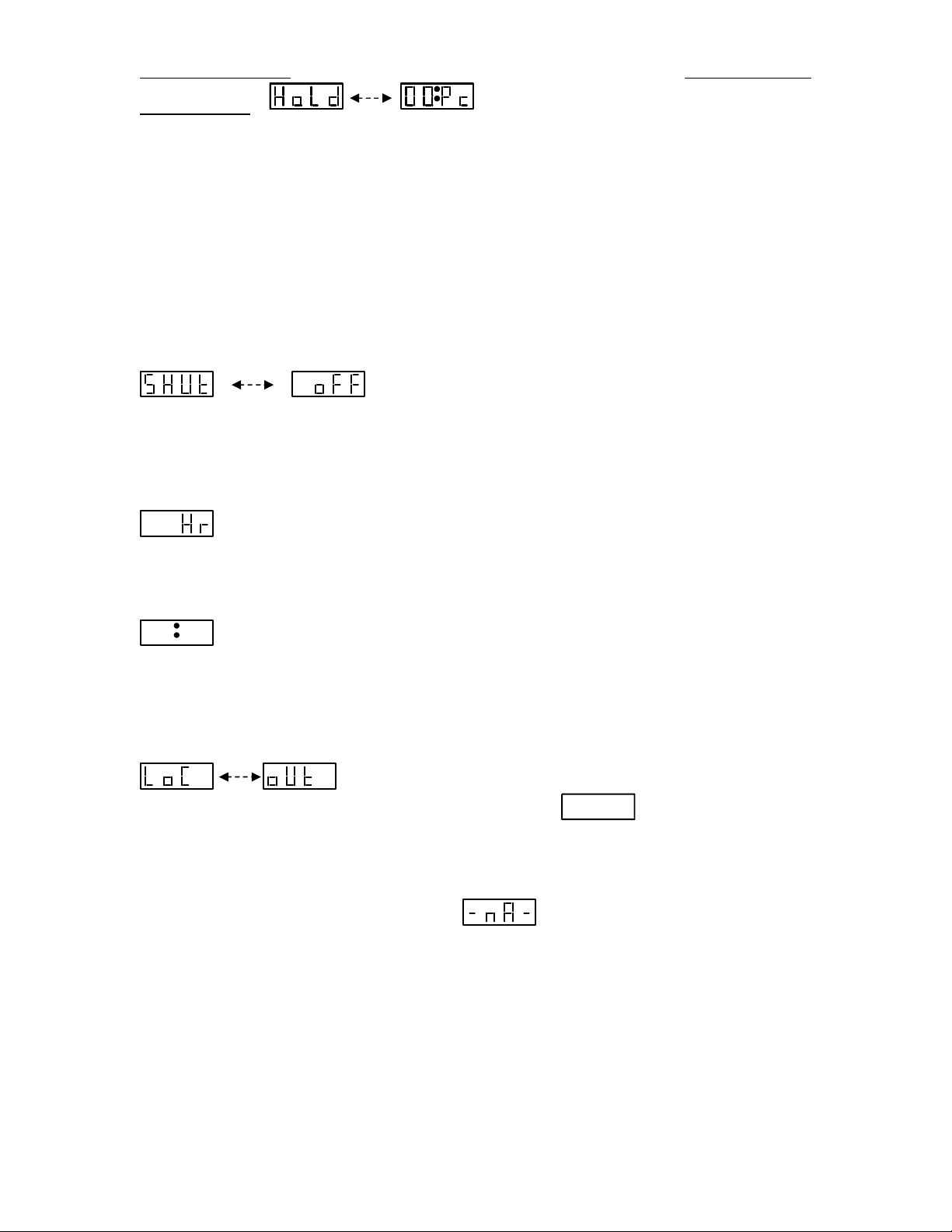

Inactivity Shut Off Timer

While the heater is in Active Mode, after set number of hours of

inactivity from the buttons or remote interface, the heater will

automatically stop, exiting Active Mode.

nn

Use arrow buttons to set shut off time, in hours.

Set to 0 to disable. Default = 0.

Power Failure Mode

n

When Power Failure Mode is enabled, if the heater loses power

while in Active Mode, the heater will power up in Active Mode

when power is restored. Alarm mode will override Active Mode.

Set to 1 to enable. Default = 0.

Enable Lock Out Mode

n

When enabled, pressing sets Lock Out Mode.

Set to 1 to enable. Default = 0.

nnnn

Set Lock Out code: use arrow keys to set blinking digit.

Press

or

to move to next digit.

Temperature Units

(Will not appear in Active Mode)

When the units are changed, all settings will change units without

being converted. Set temperature units: C or F (Celsius or

Farenheit). Default = C.

RS-232 Communications

Network Address.

nn

Sets the RS-232 network address for use with a network of

heaters and pumps connected to a computer. Default = 0.

ENTER

STOP

ENTER

STOP

SETUP

ENTER

STOP

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 512/25/20

System Reset

(Will not appear in Active Mode)

Resets all settings. First press to select.

Then set to

. Press again to reset all

settings to default settings. ‘0’ will exit reset without making any

changes.

n nn

Displays the firmware version. “n.nn” indicates version number.

6.

Operation

The heater constantly monitors and displays the temperature measured on the primary heating pad.

In Active Mode, the heater will apply power to the heating pads, as indicated by the OUT LED, until the

Set Point temperature is measured on the heating pad. In Thermo-Kinetic mode, the OUT LED will pulse

on and off, indicating a partial heating duty cycle.

6.1

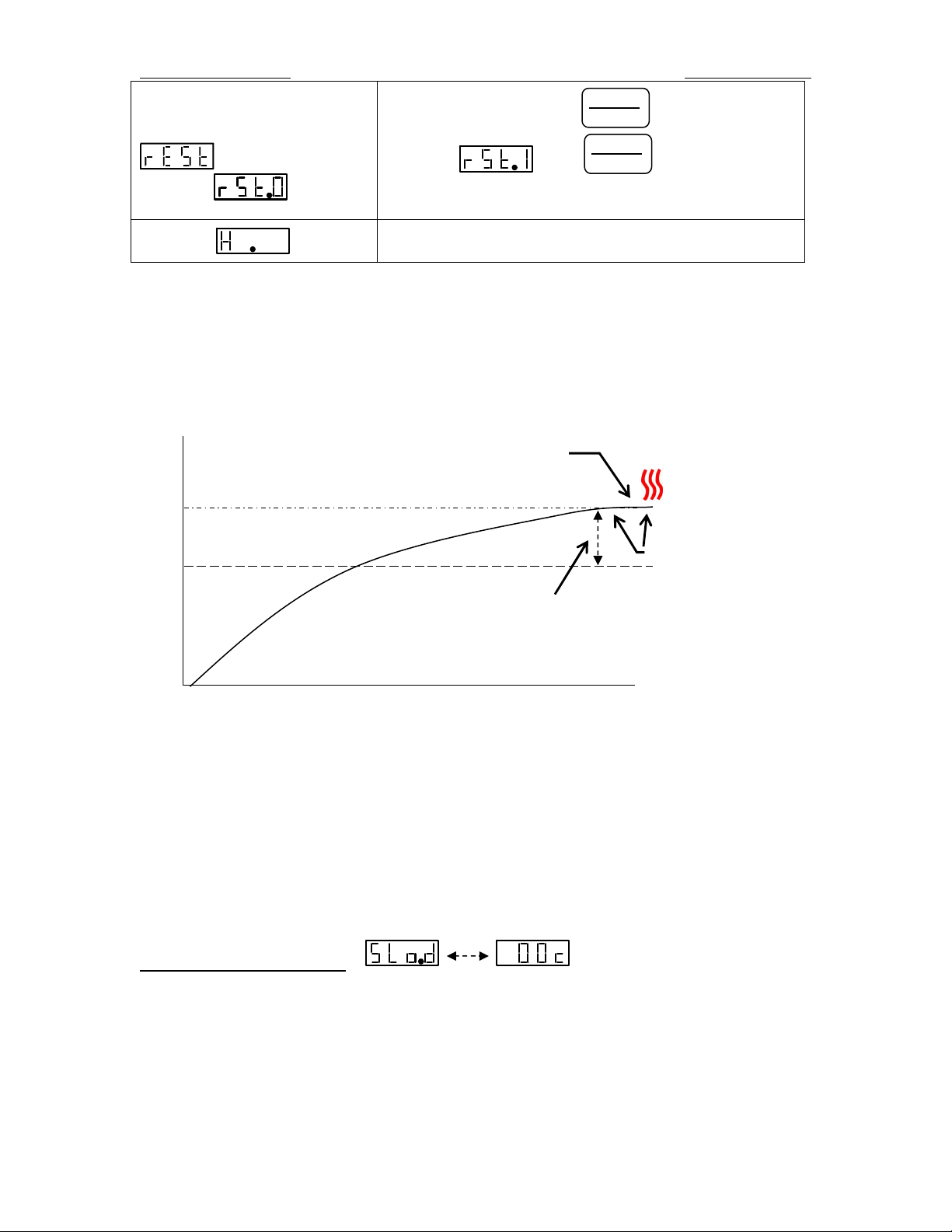

Thermo-Kinetic Mode

Setup settings “Slow Down Temperature Delta” and “Hold Percentage” configure Thermo-Kinetic Mode.

The default settings are 10 degrees C Slow Down Delta and 10% power Hold Heating percentage.

When Thermo-Kinetic Mode is off (settings set to 0), power to the heatings pads will remain on until the

Set Point is reached. Then turn on again when the termperature reduces to below the Set Point. This will

generaly cause large temperature swings. When power is turned off to the heating pads, the temperature

will continue to rise for several seconds.

Thermo-Kinetic Mode reduces the average power to the heating pads by dynamically reacting to changes in

the temperature measurement and rate of change. Then, when the Set Point is reached, the average power

applied to the heating pads will be reduced to a level that dynamically compensates for heat loss, clamping

the temperature at the Set Point. The average power is set by controlling the on/off power duty cycle of the

heating pads, as indicated by the pulse rate of the OUT LED.

Slow Down Temperature Delta

Set to the number of degrees below the Set Point to begin reducing the average power to the heating pads.

Increasing this number will minimize over shooting the Set Point. The larger the number, the longer it will

take to reach the Set Point. A good starting value is 10 degrees.

The average power will be linearly reduced in proportion to the temperature delta below the Set Point.

Then the power level will be adjusted based on the temperature change over time (temperature derivative).

ENTER

STOP

ENTER

STOP

Set Point

Slow Down

Temperature

Delta

Temperature

Hold Heating

Percentage

T

e

m

p

e

r

a

t

u

r

e

Heat Clamping

Thermo

ThermoThermo

Thermo-

--

-Kinetic Heat Clamping

Kinetic Heat ClampingKinetic Heat Clamping

Kinetic Heat Clamping

Heat Loss

Compensation

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 612/25/20

Hold Percentage

The Hold Percentage provides just enough power to the heating pads to compensate for heat loss, clamping

the temperature at the set point. The temperature hold heating percentage is used when the temperature is

within +/- 1 degree of the Set Point temperature.

The actual Hold Percentage is dynamically adjusted according to the measured temperature. When the

temperature settles below the Set Point, the adjusted percentage is incremented. When the temperatrue

settles above the Set Point, the adjusted percentage is decremented. These small changes in power will

slowly nudge the temperature towards the Set Point, while minimizing over/under shooting.

The Hold Percentage setting remains unaffected by the adjusted setting. The adjusted setting remains in

affect until the heater control box is powered off. A good starting value is 10 Percent.

6.2

Inactivity Shut Off Timer

When enabled, the heater will automatically exit Active Mode (stop heater) after set number of hours of

inactivity from the keypad or remote communications. The default is disabled (0 hours setting).

After selecting, use the arrow buttons to set the inactivity shut off time in hours. Set to 0 to disable timer.

The set time will be stored in non-volatile memory.

nn

During keyapd or remote inactivity while the heater is active, the display will periodically display the

inactivity time remaining until the heater exits Active Mode and stops heating the pad. The time will be

displayed in Hours and Minutes, or Minutes and Seconds if less then 1 hour remains.

nn

nn

6.3

Lock Out Mode

When enabled, Lock Out mode will lock out the keypad until the user defined lock out code is entered.

If any button is pressed while locked out, the display will show:

Pressing either arrow button will enter Lock Out code entry mode:

nnnn

. Any other button will

return to the previous display.

Use the arrow buttons to set the blinking digit. Press the Setup or Enter buttons to move to the next digit.

If the code entered is wrong, the display will show:

. Press any button to clear.

If the code is correct, the keypad will be unlocked, but the Lock Out setting will be unchanged. The next

time power is turned on, the keypad will be locked out. Use Setup mode to disable Lock Out mode.

RS-232 communications is not affected by Lock Out Mode.

The Lock Out code can be remotely set or queried with the Lock Out command:

LOC [ < 0 | 1 [<nnnn>] >

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 712/25/20

6.3.1 Lock Out Setup

Use the button to select Lock Out Mode:

n

, where ‘n’ indicates the current setting:

‘1’ enabled and ‘0’ disabled. Use the up and down buttons to select, then press

. If enabled, the currrent Lock Out code is displayed and can be changed.

To change the code, use the up and down buttons to change the blinking digit. Press

or

to move to next digit. After the last digit, the new code is entered.

The keypad will be immediately locked out upon entering the Lock Out code.

6.3.2 Default Code Bypass

If the lock out code is forgotten, the default code can be entered: While turning on power to the unit, press

and hold the Setup button . Lock Out code entry mode will be displayed. To unlock the

keypad, enter the bypass code:

1392

.

7.

Calibration

Heating pad calibration is performed through the RS-232 computer interface using the CAL command.

Calibration is performed by measuring the primary heating pad temperature at 2 temperatures: One at

room temperature, and one at a high set point of at least 25 C above room temperature. Measurements are

in Celsius units.

Notes on measuring the heating pad temperature:

Measure the temperature on the inner part of the primary heating pad curve, under the temperature sensor.

Only the primary heating pad, with a sensor, can be calibrated.

1)

Power on the syringe heater.

•Attach the computer cable (CBL-PC-PUMP-7) and start the terminal emulator PUMPTERM.EXE.

•Verify communications is established with the heater by pressing the ENTER key on the PC. A

response from the heater will indicate communications is established.

2)

Measure the low point temperature.

•Allow the temperature on the heating pad to reach room temperature for at least 1 minute.

•Measure the temperature on the heating pad.

•Very quickly, after reading the temperature, enter the low point temperature as a 1 to 3 digit Celsius

number (spaces are optional) with the following command:

CAL L nnn

3)

Measure the high point temperature.

•On the syringe heater, or from the PC, enter a temperature set point at least 25 degrees higher than

the room temperature. To set from the PC, use the SET command. For example, to set a 75 degree

set point (assuming C units set), enter:

SET 75

•Start the syringe heater by pressing the Active buttons, or from the PC, use the RUN command.

•Wait for the heating pad to reach the set point. Then wait 1 minute for the temperature to settle and

dissipate throughout the heating pad.

•Measure the temperature on the heating pad

•Very quickly, after reading the temperature, enter the high point temperature as a 1 to 3 digit Celsius

number (spaces are optional) with the following command:

SETUP

SETUP

ENTER

STOP

SETUP

ENTER

STOP

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 812/25/20

CAL H nnn

4)

Finalize the heating pad calibration.

•The calibration entry process can be repeated before the process is finalized, or the entries can be

ignored if the process is not finalized. Turning off power will discard the entries.

•To finalize the calibration, enter the command:

CAL

•If the calibration data was valid, the heater will respond with:

OK

•If there was an error in the calibration, the heater will respond with:

?NA

Performing a system reset will reset the calibration to the factory defaults.

8.

Alarms and Error Messages

8.1

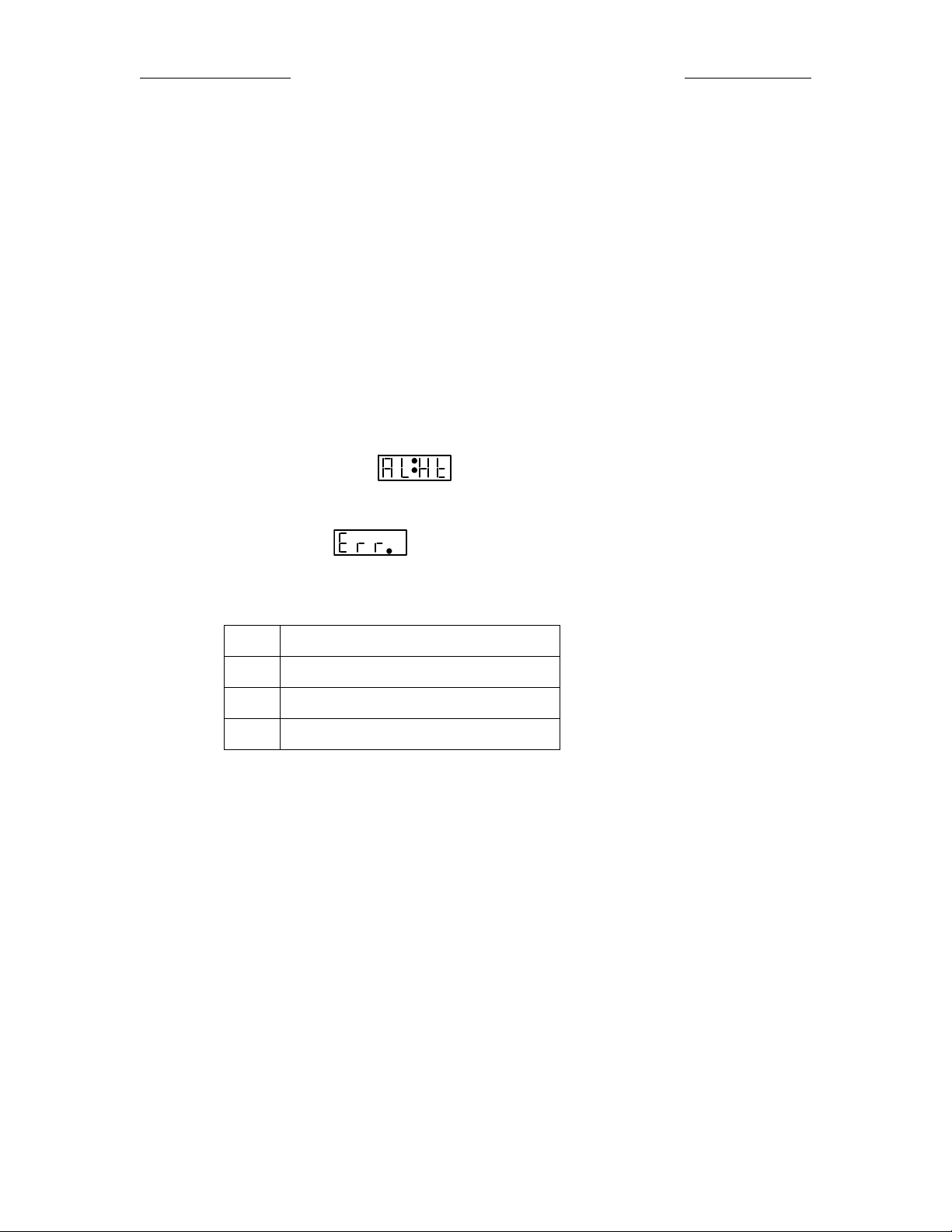

Alarm Mode

Alarm Mode is set when the measured temperature reaches the alarm level, 20 C (36 F) above the Set

Point. The heater will exit Active Mode, turning the “Active” LED off, the red “Alarm” LED on, and the

display will flash the alarm message:

Pressing any key will clear the message. Alarm Mode

is exited, turning the “Alarm” LED off, when the measured temperature reduces below the alarm level, or

the Set Point is raised above the alarm level.

8.2 Error Messages

Indicates a system fault, where 'n' is the fault code. The heater will exit Active Mode, turning the “Active”

LED off, the red “Alarm” LED on, and the error message will be displayed. The fault codes indicated by

'n' are:

n Description

1 Heater pad sensor differential

2 Control box internal temperature

3 Heater pad sensor minimum temperature

n

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 912/25/20

9.

RS-232 Communications

The syringe heater can communicate with any computer or device with an RS-232 communications port or

converter.

9.1

Connection and Networking

On the side of the heater are 2 square RJ-11 (“phone jack” style) sockets. Connect the RS-232

cable (CBL-PC-PUMP-7) into the socket labeled “Computer”. Connect the other end to the serial port on

the computer, converter cable, or other control device.

If the heater is part of a RS-232 network, connect a RS-232 network cable (CBL-NET-7) between the

socket labeled “Pump” on the heater and the socket labeled “Computer” on the next device in the network.

Repeat for each device in the network, connecting the “To Network” or “Pump” socket of one device to the

“Computer” socket on the next device in the network. Up to 100 devices can be networked together with a

computer. When communicating with a device in a multi-device network, each preceding device in the

network must be powered on.

Each device in the network needs a unique network address to identify the device to the computer.

Network addresses are from 00 to 99. If the network consists of only 1 device, set the device’s address to 0

(default setting). Also, each device needs to be set to the same baud rate as the computer. Use the ‘Setup’

function on the keypad to set the network address. See section 5, “Setup Settings”. The '*ADR' command

can also be used to set the network address.

The supported baud rate is 19,200.

9.2

RS-232 Protocol:

When the device is used in a multi-device network configuration, precede each command with a device

address. Devices will ignore all commands that do not have their defined network address. If the network

address is not specified in the command, the address will default to 0.

After a command is sent to the device, the device will not accept any further communications until the

current command has been processed. Completion of the command processing is indicated when the first

byte of the response packet is transmitted. While the user is changing data or configurations from the

keypad, command processing is delayed.

Communications to and from the device uses the following data frame:

Supported RS-232 Data Frame

Baud rate: 19,200

Frame: 10 bit data frame (8N1):

Start bit: 1

Data bits: 8

Stop bits: 1

Parity: None

Every command received by a device in the network is acknowledged by the device with a response packet

that includes a status character indicating the current operational state of the device.

9.2.1 RS-232 General Syntax Legend

The following syntax expansion legend is common to all syntax expansions:

Except where indicated, all command and response characters are ASCII data.

<float> => <f> [ <float> ] Floating point number. Maximum of 4 digits plus 1

decimal point. Maximum of 3 digits to the right of the

decimal point.

<on-off> => 1 On, enabled

0 Off, disabled

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 10 12/25/20

<count data> => <n> [<n>] Valid values: 1 to 99

<number data> => <n> [<n>] Valid values: 0 to 99

<text> => "any printable character" [<text>]

<f> => { <n> | . } Floating point digits

<n> => { 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 } Digits

<byte> => “one byte of any data”

( ) One byte of data expressed as (0xhh), where ‘hh’ is the

data in hexadecimal.

=> Is defined by. Syntax expands to next level of

expansion.

< > Non-terminal syntax expansion

[ ] Optional syntax

{ } Required syntax

| Or. Choose one of the syntax options.

λNone. Syntax expands to nothing (lambda production).

" " Description of syntax expansion

9.2.2 RS-232 Protocol: Basic Mode

Command packet syntax (to device):

<basic command protocol> => <command data> <CR>

Response packet syntax (from device):

<basic response protocol> => <STX> <response data> <ETX>

In the “Basic” communications mode, a master-slave protocol is used, whereby the device will only

transmit in response to a received command.

When the device receives the <basic command protocol>, <command data> will automatically be stripped

of all space and control characters and all text will be converted to upper case. This simplifies

communications with the device when commands are being manually typed in from a generic terminal

emulator.

9.2.3 RS-232 Protocol: Basic Mode Common Syntax

<transmitted data> => { <command data> | <response data> }

<command data> => [<address> | * ] [<command>] To device

<response data> => <address> <status> [ <data> ] From device

<status> => { <prompt> | <alarm> } Operational state of device

<prompt> =>

S Heater Stopped

H Heater Active

A Heater Alarm

<alarm> => A ? <alarm type> Alarm

<alarm type> =>

R System reset (power was interrupted)

H High temperature alarm, relative to set point.

D Heater pad sensor differential fault

I Control box internal temperature fault

M Minimum sensor temperature fault

<address> => <n> [ <n> ] Device network address, 0 to 99

* System command (overrides network address)

<data> => <text> Response to command

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 11 12/25/20

<CR> => (0x0D) Carriage return

<STX> => (0x02) Start of packet transmission indicator

<ETX> => (0x03) End of packet transmission indicator

<length> => <byte> Number of bytes remaining in packet, including this byte

9.3

Command Errors and Alarms

If a command received by the device is not recognized or the data is invalid, an error message will be in the

<data> field of the response packet following the <prompt> field. The following are the error responses:

<command error> => ? <error>

<error> =>

λ

Command is not recognized (‘?’ only)

NA Command is not currently applicable

OOR Command data is out of range

COM Invalid communications packet received

IGN Command ignored due to a simultaneous new Phase start

When an alarm occurs, the alarm must be acknowledged before any data is changed or the device is started.

Alarms are acknowledged by the user clearing the alarm message on the keypad, or the alarm status being

sent in response to any valid RS-232 command.

9.4

RS-232 Command Set

A packet without a command is interpreted as a status query. The addressed device responds with a status

only response packet.

Except where noted, a setting command without its parameter queries the command setting. The response

packet data will include the requested data. In general, the query response data will be in the same format

as the parameter for setting the command. For example, the query temperature setpoint command ‘SET’

will respond with ‘<nnn>‘ as the response ‘<data>‘.

Otherwise, the command is a set command. If the data was set, a status only response packet will be sent.

If the data was not set, the response packet will include an error (<command error>) message indicating

why the data was not set.

All commands are upper case. Spaces are optional. Lower case letters are converted to uppercase when

received.

9.5

RS-232 Commands

<command> =>

HEATING COMMANDS

START ACTIVE HEATING MODE

RUN Starts active mode, turning on the heater.

Active LED will be lit.

STOP ACTIVE HEATING MODE

STP Exits active mode. Stops heating the heating pads.

Active LED will be off

TEMPERATURE QUERY

TMP Query primary heating pad temperature in currently set units.

Query response: <nnn>

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 12 12/25/20

HEATING SET POINT

SET [ <nnn> ] Set/Query Heating set point in currently set units.

Maximum value: 185C or 365F

Query response: <nnn>

THERMO-KINETIC MODE FINE TUNE SLOW DOWN DELTA

FTS [ <nnn> ] Set/Query Fine Tune Slow down temperature delta setting.

Query response: <nnn>

THERMO-KINETIC MODE FINE TUNE HOLD PERCENTAGE

FTH [ <nnn> ] Set/Query Fine Tune temperature base hold percentage.

Query response: <nnn>

CALIBRATION

CAL [{ L | H } [<nnn>] ] Heating pad calibration. See calibration section for details.

TEMPERATURE UNITS

UNT [ C | F ] Set/Query temperature units.

Query response: {C | F}

GENERAL SETUP COMMANDS

Shut Off Timer Mode

SOT [ <nn> ] Set/Query inactivity shut off timer setting, in hours. Set to 0 to disable.

Query response: {nn}

POWER FAILURE MODE

PF [ 0 | 1 ] Set/Query Power Failure mode.

0 = Disable; 1 = Enable

Query response: {0 | 1}

LOCK OUT MODE

LOC [ { 0 | 1 [<nnnn>] } ] Set/Query Lock Out mode.

0 = Disable; 1 = Enable

<nnnn> = Lock out code

Query response: {0 | 1 <nnnn>}

NETWORK ADDRESS

ADR [ <nn> ] Set/Query RS-232 Network Address.

<nn> = 0 to 99

Query response: <nn>

FIRMWARE VERSION

VER Query firmware version.

Query response: NE800V<n>.<nn>

SYSTEM RESET

RESET Reset all parameters to factory defaults.

New Era Pump Systems Inc.

www.SyringeHeater.com

Model HEATER-KIT-1

Publication #1200-01 13 12/25/20

10.

Accessories

10.1

Additional Heating Pads

Only the primary heating pad has a temperature sensor. Additional heating pads do not have temperature

sensors. The additional heating pads will heat when the primary heating pad heats. Each heating pad must

be the same type as the primary heating pad. The following are part numbers for ordering additional

heating pads:

Type Base Model Replacement

Primary Pad

Second Heating Pad Third and Additional

Heating Pads

Large

HEATER

-

KIT

-

1LG

HEATER

-

PAD1

-

1LG

HEATER

-

PAD2

-

1LG

HEATER

-

PAD

3

-

1LG

Small

HEATER

-

KIT

-

5SP

HEATER

-

PAD1

-

5

SP

HEATER

-

PAD2

-

5SP

HEATER

-

PAD3

-

5SP

Heating Pad Sizes

HEATER-PADx-1LG

HEATER-PADx-5SP

Type Large: Curved rectangular for syringes

10 mL and larger

Small: Long strip for wrapping small syringes

and tubing

Heating Area L 9 cm x W 7.5 cm (3.5” x 3.0”) L 50 cm x W 1.5 cm (20.0” x 0.625”)

Overall Length L 9 cm x W 7.5 cm (3.5” x 3.0”) L 74 cm x W 1.5 cm (29.13” x 0.59”)

Cord Length 54 cm (21”) Attached at end of pad 90 cm (36”) Attached at middle of pad

10.2

RS-232 Network Cables

RS-232 Network Primary Cable

7 foot cable Part #: CBL-PC-PUMP-7

25 foot cable Part #: CBL-PC-PUMP-25

Cable to connect the first device of an RS-232

network to a standard PC’s serial port with a

DB-9M connector.

RS-232 Network Secondary Cable

7 foot cable Part #: CBL-NET-7

25 foot cable Part #: CBL-NET-25

Cable to connect additional devices, after the

first, to an RS-232 network.

USB to RS-232 Converter Cable

Part #: CBL-USB232

Creates a virtual RS-232 port through a USB

port. Attaches to the RS-232 Network Primary

Cable to allow communication through a PC’s

USB port. Includes a CD with software drivers.

11.

Specifications

Power requirements: 120 VAC 60Hz, North

American style plug

Maximum temperature setting:

185 C (365 F)

Power consumption: 0.33 A (One heating pad) Selectable temperature units: C (Celsius) or F (Fahrenheit)

Accuracy +/- 2% measured at the sensor

Controller case dimensions: L 4.625” x W 2.5” x H 1.5” (11.7475 cm x 6.35 cm x 3.81 cm)

RS-232 Protocol: Baud Rate: 19,200; Data Frame: 8N1; Address Range: 00 to 99 (100 devices)

This manual suits for next models

1

Table of contents