NEW VISTA NV1294 User guide

900-D North Macon Street | Baltimore, Maryland 21205

410-342-3820 | FAX 410-342-7324

www.newvistacorp.com

USE AND MAINTENANCE GUIDE

RT HANDHELD THREAD UNIT

Version 1.0 –February 2021

2

CONTENTS

CONTENTS...................................................................................................................... 2

GENERAL DESCRIPTION .................................................................................................. 3

Standard Kit

Customized Unit

METHOD OF OPERATION................................................................................................ 3

MODEL FEATURES .......................................................................................................... 4

Adjustable Torque Clutch

Type FP Tool Chuck and Tool Adapters

Rocker Trigger

Two Speed Gear Drive

Battery Powered

Tool Adapter Overview................................................................................................... 5

Type FP Chuck and Compliant Tool Adapters

FP Tool Adapter for Tapered Shank Tools

FP Tool Adapter for Reversible Tools

FP Tool Adapter for Straight Shank Tools

FP Socket Adapter Tool

Type J Chuck and Tool Adapters

J Tool Adapter for Ring Tools for external threads

J Tool Adapter for BH Gages

J to FP Adapter

Tool Changeover

To Engage a Tool Adapter

To Remove a Tool Adapter

Stop Collars for Depth Verification

GAGE RECOMMENDATIONS............................................................................................ 9

OPERATING INSTRUCTIONS ............................................................................................ 9

Getting Started

TORQUE ADJUSTMENT ................................................................................................... 9

Procedure

3

GENERAL DESCRIPTION

The RT Thread Unit is a cordless Thread Verification Unit for mechanically checking threads or

light thread chasing.

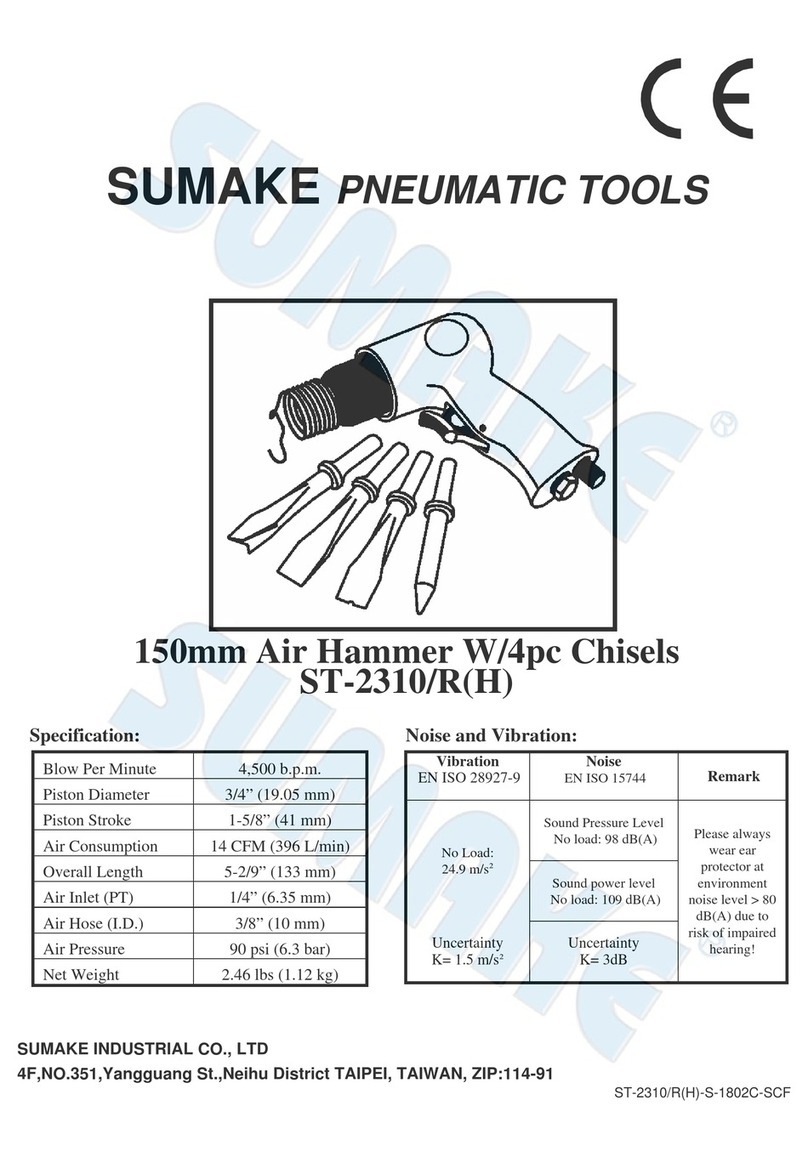

Standard Kit

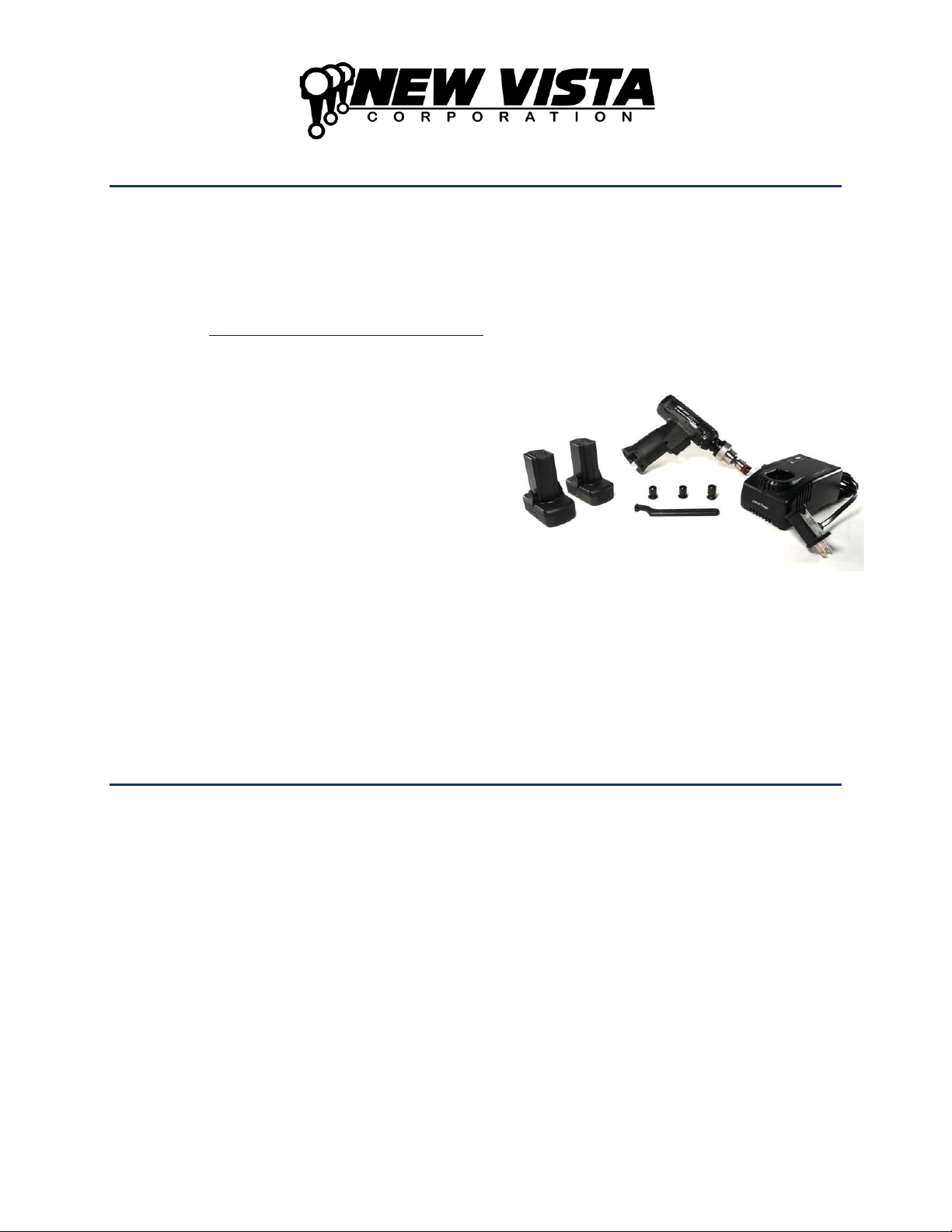

The RT Thread Unit can be purchased as a standard Kit from New Vista directly or through our

online store: https://www.newvistacorp.com/shop. The Kit comes with everything needed to start

verifying threads using standard taper shank gages. Each Kit includes the following:

•One RT Thread Unit equipped with a

type FP chuck

•Three taper shank gage tool adapters

(for handle sizes no. 0, 1, and 2)

•One torque adjustment tool (a spanner

wrench for 1-1/2” diameter circle with a

7/32” pin)

•Two 14.4V rechargeable lithium-ion

batteries

•One battery charger

Customized Unit

The RT Thread Unit can be customized to meet a wide variety of applications including, but not

limited to, left-hand threads, external threads, restricted-access situations, large threads, and

unique gaging needs. Please contact us to discuss your application.

METHOD OF OPERATION

To operate the unit, place the gage member or cleanout tool at the start of the thread. Align the

axis of the tool with the axis of the hole, push the unit firmly and pull the rocker trigger in the

forward direction. To reverse out of the threaded hole push the rocker trigger in the reverse

direction.

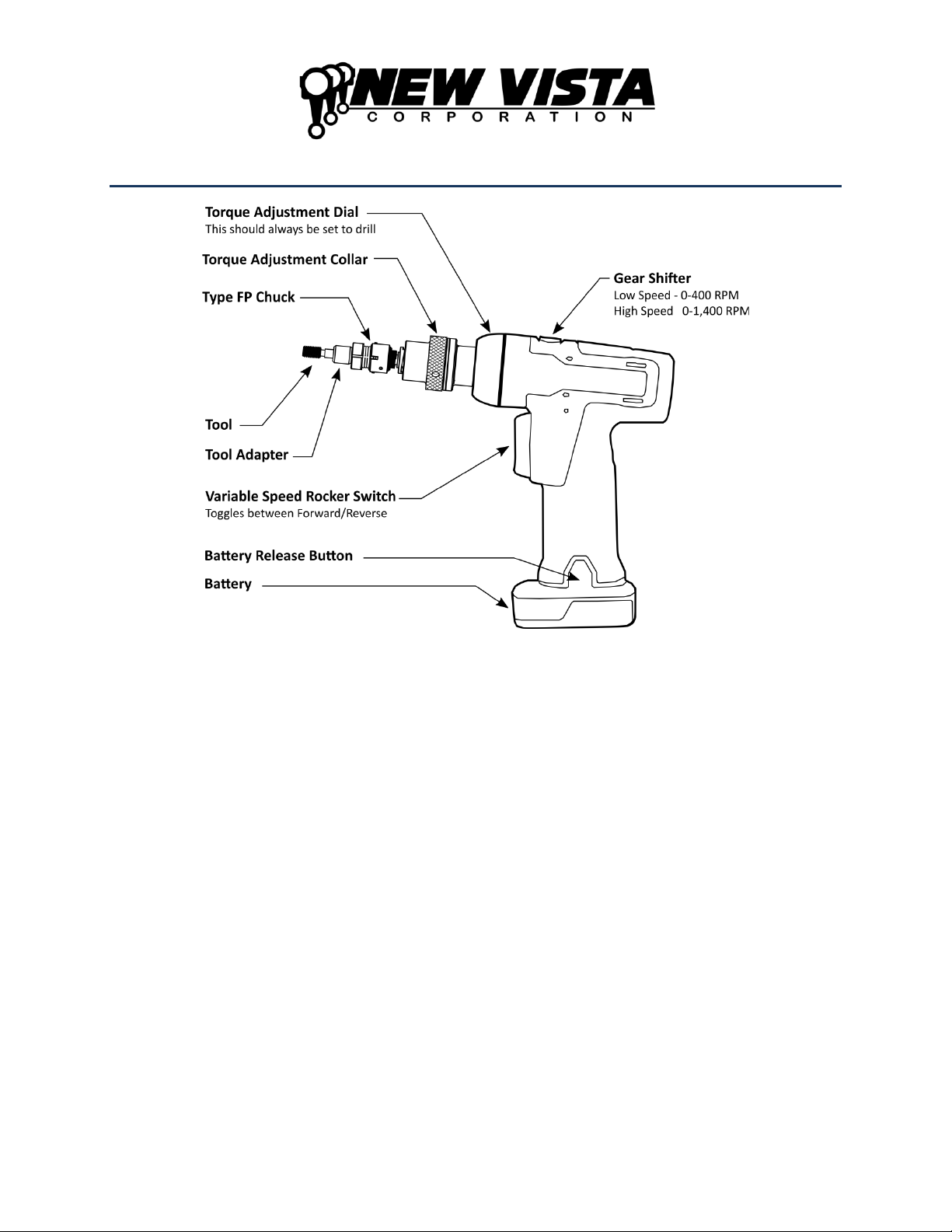

Figure 1

RT Kit Contents

4

MODEL FEATURES

Figure 2

Adjustable Torque Clutch

The RT Thread Unit comes with a 62020AC New Vista clutch. This sensitive, patented clutch

allows the thread tool to stop harmlessly if there is an obstruction in the thread. The torque in

reverse is always at maximum power to minimize the chance of a tool becoming jammed in a

hole. The forward torque is easily adjustable.

Type FP Tool Chuck and Tool Adapters

The FP chuck, along with the matching FP Tool Adapters, allows for tool changes that take less

than 4 seconds. These compliant tool adapters prevent jamming from misalignment and will

follow the existing thread. FP Tool Adapters are available for three of the most common tool

shank styles: taper, straight, and reversible (fully-threaded).

Custom tool adapters are available to accommodate ring gages or dies for external threads, and

our type BH tool adapters for larger threads sizes or especially deep threads.

Rocker Trigger

The variable-speed rocker trigger gives the user full control over speed and direction, making it

easy to enter a hole and switch to reverse.

5

Two Speed Gear Drive

Two speeds to accommodate your needs:

•Low speed: 0 to 400 RPM

(Typically used for the largest thread sizes or where more torque is required.)

•High speed: 0 to 1,400 RPM

(Default setting for most applications.)

Battery Powered

The RT is powered by a 14.4V Lithium-ion battery that is easily sourced from Snap-on Tools:

https://shop.snapon.com, Item#: CTB8174.

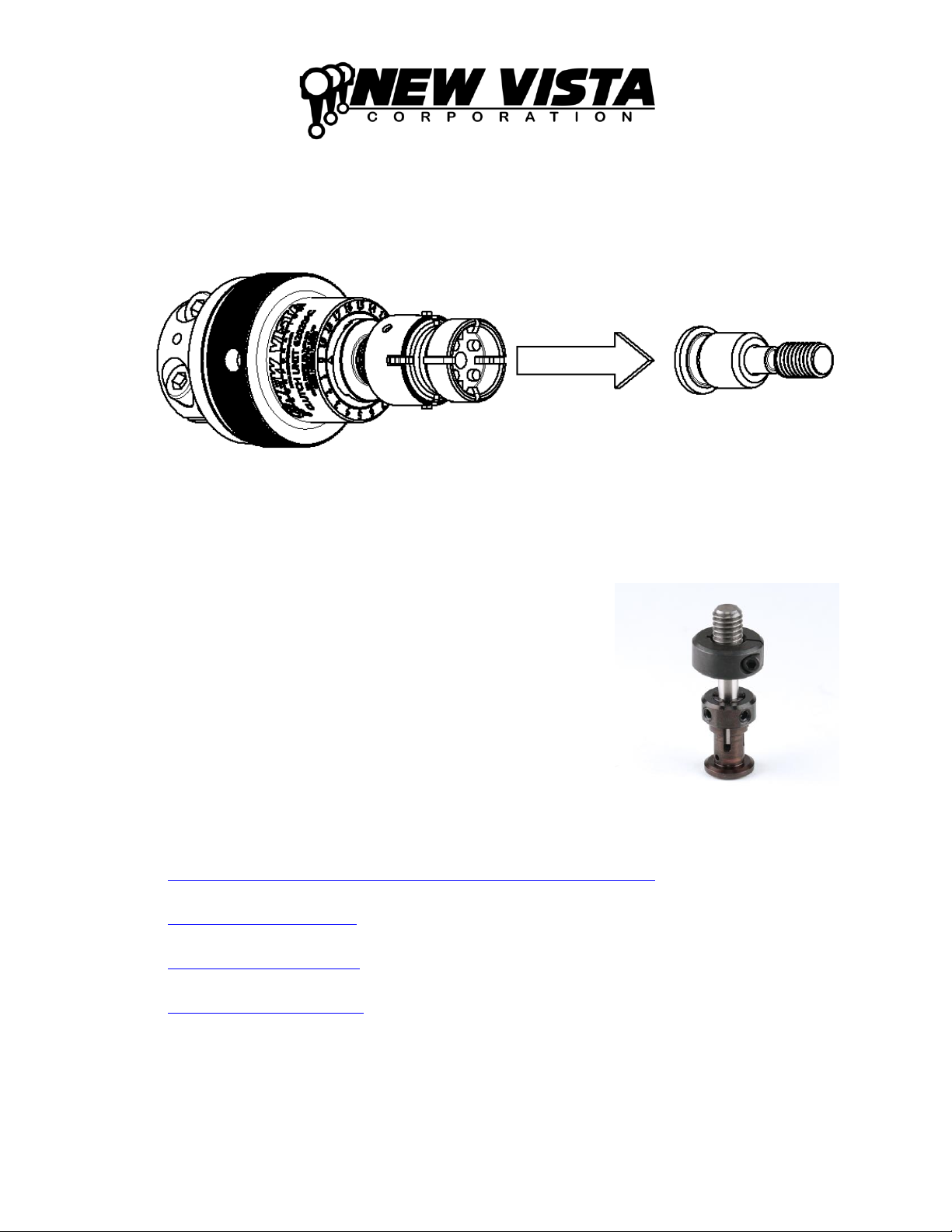

Tool Adapter Overview

Type FP Chuck and Compliant Tool Adapters

This is the standard chuck included in the RT Kit. It allows for

tools to be changed in seconds. All Type FP Tool Adapters provide

compliance. Custom sizes are available for special order. Contact

us with your requirements for application assistance.

FP Tool Adapter for Tapered Shank Tools

We offer five sizes of tool adapters for tapered shank gages/tools.

Taper Size 00

Metric Threads (M3, M3.5)

ANSI Threads (#4, #5, #6)

Taper Size 0

Metric Threads (M4, M5)

ANSI Threads (#8, #10, #12)

Taper Size 1

Metric Threads (M6, M7, M8, M9)

ANSI Threads (1/4”, 5/16”)

Taper Size 2

Metric Threads (M10, M11,M12)

ANSI Threads (3/8”, 7/16”, 1/2”)

Taper Size 3

Metric Threads (M14, M15, M16,

M17, M18, M20)

ANSI Threads (9/16”, 5/8”, 3/4”)

Figure 3

FP Type Chuck

Figure 4

Tapered Shank Gage shown with an

FP Tool Adapter for tapered shank

gages.

6

FP Tool Adapter for

Reversible Tools

FP Tool Adapter for

Straight Shank Tools

FP Socket Adapter Tool

Figure 5

Reversible (Full-Threaded) Gage shown

with an FP Tool Adapter for Reversible

Gages.

Figure 6

Straight-Shank Gage shown with an FP

Tool Adapter for Straight-Shank Gages.

Figure 7

FP Socket Adapter Tool

Reversible (Fully-Threaded)

tool adapters are available in

the following sizes:

Metric Threads: (M5, M6,

M8, M10, M12)

ANSI Threads: (#12, 1/4",

5/16”, 3/8”, 7/16”, 1/2”)

Other sizes are available upon

request.

Tool adapters to accommodate

straight shank tools are

available in 3/16” and 1/4”

sizes. Other sizes are available

upon request.

The FP Socket Adapter Tool

attaches to a standard 3/8”

Socket wrench. It is useful for

extracting a gage that has

become jammed in a thread.

This may happen if the clutch

torque is set at too high a

value for the size of thread.

Type J Chuck and Tool Adapters

This is a custom chuck that accommodates gages for large

threads, external threads, or deep threads. Type J Chucks and

Tool adapters are custom ordered and are not available in the

standard kit. Please contact us for application assistance.

Figure 8

Type J Chuck End

7

J Tool Adapter for Ring Tools

for external threads

J Tool Adapter for BH Gages

J to FP Adapter

Figure 9

These compliant tool adapters can

accommodate ring gages for thread

verification and dies for light chasing of

threads.

Figure 10

Type BH Gages allow for compliance in

larger size gages or in especially deep

threads.

Figure 11

This adapter allows standard type FP

tool adapters to be used on an RT

equipped with a Type J chuck.

Tool Changeover

Both Type FP and Type J tool adapters are designed to be easily changed.

To Engage a Tool Adapter

Align shaft of chuck with the hole in the center of the toolholder then push the tool adapter into

the chuck. Twist the tool adapter in either direction while you are pushing. This helps the drive

pins align with the slots in the toolholder

Figure 12

Twist the tool adapter while inserting it into the chuck.

8

To Remove a Tool Adapter

Pull the tool adapter away from the chuck along the chuck’s axis of rotation.

Figure 13

Pull the tool adapter along the chuck’s axis.

Stop Collars for Depth Verification

Most of the aforementioned tools can be fitted with a stop collar

to verify that the desired depth has been attained. To adjust the

stop collar, simply loosen its screw(s), reposition the collar, and

retighten the screw(s). If the tool has a non-threaded pilot, be

sure to take it into account when setting the depth.

Stop collars are available in many styles. We generally

recommend the split, clamping-style collars. Collars are

available from Misumi with a urethane damper on one side that

helps to prevent marring of the part surface.

Stop collars (shaft collars) are easily obtained from many

sources. Some recommended sources are:

•McMaster-Carr:

https://www.mcmaster.com/stop-collars/clamping-shaft-collars-9

•Misumi:

https://us.misumi-ec.com

•Fastenal:

https://www.fastenal.com

•Grainger:

https://www.grainger.com

Figure 14

GO Gage with Stop Collar

9

GAGE RECOMMENDATIONS

The RT Thread Unit can be used with standard off-the-shelf thread gages and tools.

For typical GO and NO GO thread verification applications we recommend grinding a 45º

chamfer that is equal to 50% of the gage’s major diameter on the end of the gage. This should

remove the cleanout groove on the end of the gage and allow for easier thread engagement.

Figure 15

Gage Chamfering Recommendations

OPERATING INSTRUCTIONS

Getting Started

1. Adjust the torque as necessary.

2. Attach the proper thread tool and tool adapter.

3. Adjust the stop collar to proper depth if you are using one.

4. Use the RT Thread unit as you would a handheld screwdriver.

TORQUE ADJUSTMENT

The torque adjustment collar, located behind the tool adapter, changes the torque setting. This

controls the amount of torque required to make the internal mechanism slip in the

clockwise/forward direction (for right hand threads).

The torque should be adjusted to a level that simulates the torque an operator would output with

a hand gage. You can contact New Vista for recommended torque settings by thread size. In the

counter clockwise/reverse direction (for right hand threads), the unit will apply the full torque

available from the motor to unscrew the tool. This ensures that a tool that has stalled during the

cycle can be unscrewed in reverse.

10

The torque collar is designed to turn stiffly so that a preset torque level it will not change. In

most cases adjustment will require a spanner wrench (included).

Note:

For standard RT Kit Units this setting has not been preset at the factory and

should be set to a torque appropriate for your application.

For custom units this setting is adjusted at the factory and should be tested on-site

before performing any adjustments.

Measuring the torque setting is accomplished by locking two nuts on the thread gage member

and using a torque wrench to measure the stall torque of the clutch. The torque should be

adjusted in small increments and tested to achieve the desired value.

Warning:

We highly recommend that you remove the battery from the unit while

setting the torque.

Do not run the tool in the reverse direction while performing this procedure. The

clutch only slips in one direction. The full torque of the unit will be exerted if the

unit is jogged in the reverse.

Procedure

1. Use a small torque wrench with a range of at least 0-45 in-lbs. (0-5N-m).

2. Remove the battery from the unit.

3. Lock two nuts on the thread gage. Install a matching socket on the torque wrench.

4. With one hand hold the torque wrench with the socket holding the nuts and measure the

torque setting by turning the wrench in the forward (clockwise for right-hand threads)

direction. The actual torque is read while the

clutch is slipping.

5. To adjust the clutch setting, turn the knob to

the required setting. Turning the knob

clockwise increases the amount of torque

needed. If the collar is too hard to turn by hand

use the included spanner wrench.

6. Remove the nuts from the gage.

Torque Adjustment Collar

Use included spanner wrench to

turn.

11

This page intentionally left blank

Table of contents