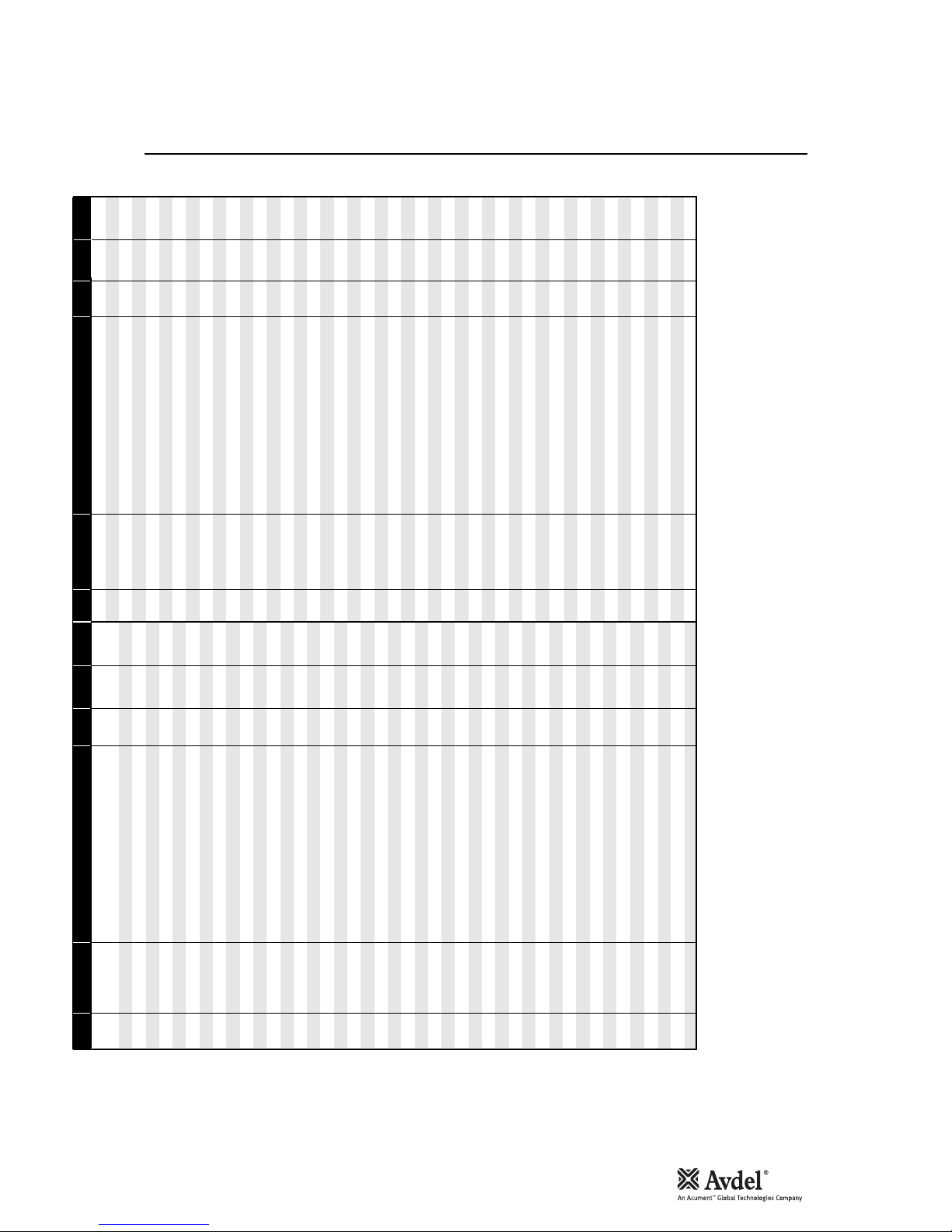

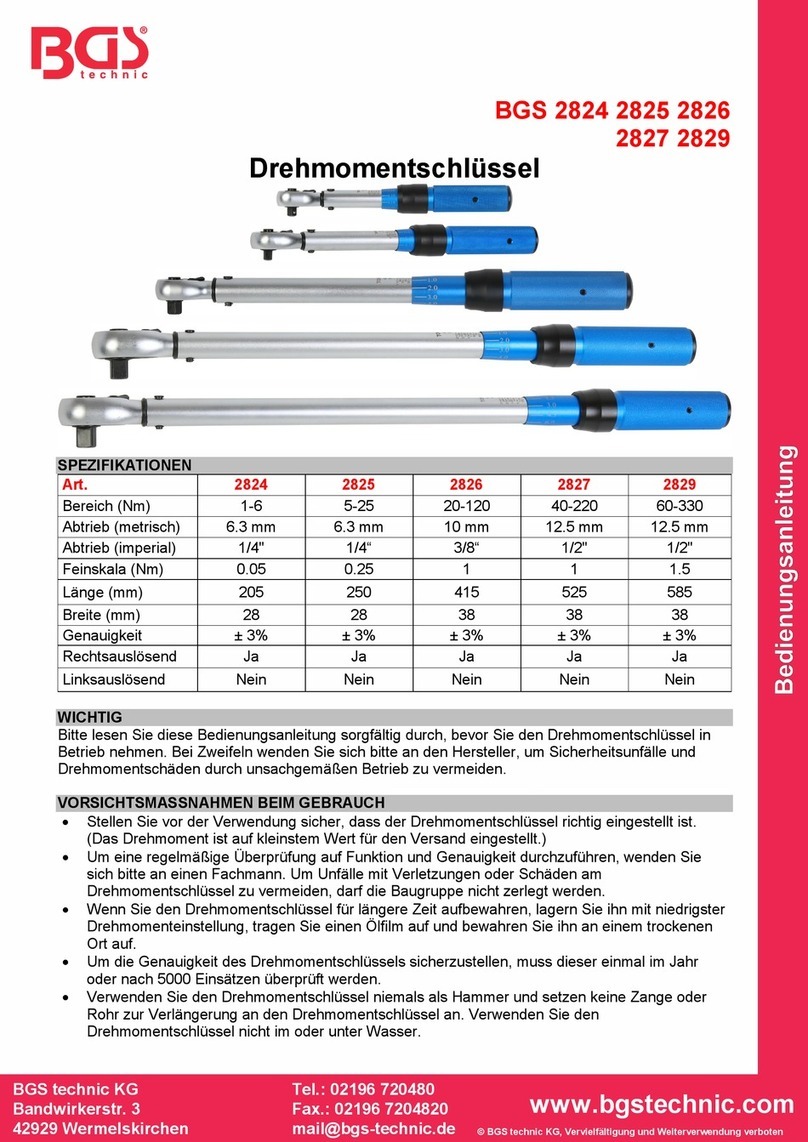

45 07001-00652 Pozi screw 8 ✔50

46 07007-01954 Battery 1 ✔1

47 71600-02022 Battery retainer spring 1 ✔10

48 07007-01957 Dowel pin 1 ✔50

49 07003-00353 O-ring 1 ✔50

50 07003-00351 O-ring 2 2

51 71600-03202 Pump block 1 2

52 07002-00156 Steel washer 3 ✔50

53 71600-02024 Nose tip spanner 1 ✔10

54 71600-02025 Vent screen 1 9

55 07007-01956 Outlet check valve 1 5

56 07007-00365 O-ring (housing) 1 5 8

57 07003-00359 O-ring for item 55 1 5

58 07003-00355 Bonded seal 1 4

59 71600-02019 Valve seat 1 4

60 71600-02029 Compression spring 2 4

61 71600-02017 Valve needle 1 4

62 07003-00354 O-ring 1 4

63 07003-00352 O-ring 1 4

64 71600-02018 Threaded sleeve 1 4

65 71600-02020 Trigger plate 1 4

66 71600-02021 Pin 1 4

67 07004-00104 Circlip 2 ✔50

68 07004-00103 Circlip 1 ✔50

69 07002-00157 Steel shim washer 1 4

70 07007-01958 Inlet check valve 1 5

71 07003-00349 O-ring 1 3

72 07003-00170 O-ring 1 3

73 71600-03310 Reservoir 1 3

74 71600-03304 Reservoir adapter 1 3

75 71600-02013 Seal screw 1 ✔1

76 07003-00358 O-ring 1 5

77 07007-01965 Battery charger - 220/240V~50Hz (UK) 1 ✔1

07007-01966 Battery charger - 220/240V~50Hz (Europe) 1 ✔1

07007-01967 Battery charger - 220/240V~50Hz (Australia) 1 ✔1

07007-01968 Battery charger - 110V~60Hz (USA, Canada) 1 ✔1

07007-01969 Battery charger - 100V~50/60Hz (Japan) 1 ✔1

78 07007-01980 Filter 1 3

79 07007-01960 Storage case 1 ✔1

80 07900-00759 Tool Instruction Manual - UK version 1 ✔1

81 71600-02031 Collector lid buffer 1 9

82 07003-00371 'O' Ring 1 3

83 71600-02035 Blank serial number label 1 ✔50

84 07003-00373 Energised PTFE seal 1 2

85 07003-00372 Energised lip leal 1 2

1 71600-02004 Lid torsion spring 1 ✔ 50

2 71600-02003 Collector lid 1 9

3 71600-03130 Motor & gearbox assembly 1 1

4 71600-03110 Contact holder 1 1

5 71600-03110 Electrical control circuit 1 1

6 07004-00102 Circlip 1 ✔ 50

7 71600-02016 Cylinder cap 1 7

8 71600-02015 Piston sleeve 1 7

9 07003-00350 O-ring 1 8

10 71600-02012 Compression spring 1 7

11 07001-00650 Socket csk head screw 1 ✔ 50

12 07003-00364 O-ring (piston) 1 8

13 07003-00361 Piston bearing ring 1 8

14 07003-00243 Piston seal 1 8

15 07003-00273 Rod seal 1 8

16 07003-00362 Cylinder bearing ring 1 8

17 07003-00363 O-ring (cylinder) 1 8

18 71600-02011 Piston 1 7

19 07003-00277 O-ring 1 ✔50

20 71210-02101 Jaw spreader housing 1 ✔1

21 07001-00654 Button head screw 2 ✔3&650

22 07003-00194 Bonded seal 2 ✔3&650

23 07001-00646 Socket cap head screw 1 ✔ 50

24 71600-02009 Housing 1 ✔1

25 07001-00647 Socket cap head screw 2 ✔ 50

26 07002-00155 Steel washer 1 ✔50

27 71600-02014 Switch bracket 1 ✔10

28 07001-00648 Slotted cheese head screw 2 ✔ 50

29 07001-00651 Socket cap head screw 4 ✔ 50

30 07001-00645 Socket cap head screw 1 ✔ 50

31 71600-02026 Locknut 1 ✔10

32 71600-02010 Cylinder 1 6

33 71600-02023 Nose tip holder 1 9

34 71600-03403 Trigger lever 1 4

35 71600-03203 Compression spring 1 2

36 71600-03201 Plunger 1 2

37 07003-00366 O-ring 1 2

38 07001-00649 Socket cap head screw 4 ✔ 50

39 07003-00360 Bonded seal 1 5

40 71600-03401 Trigger button 1 4

41 71600-02002 Left moulding 1 9

42 71600-02028 Case label RH 2 ✔ 10

43 71600-02001 Right moulding 1 9

44 71600-02027 Case label LH 1 ✔ 10

ITEM PART Nº DESCRIPTION QTY SPARES ITEM PART Nº DESCRIPTION QTY SPARES

MIN

ORDER QTY MIN

ORDER QTY

Note

1Motor, Gearbox and Electrical Assembly (part number 71600-99602). These items are only available as a complete assembly kit unless a minimum order quantity is stated.

2Pump Assembly Kit (part number 71600-99601). These items are only available as a complete assembly unless a minimum order quantity is stated.

3Reservoir Assembly Kit (part number 71600-99608). These items are only available as a complete assembly kit unless a minimum order quantity is stated.

4Trigger Mechanism Kit (part number 71600-99606). These items are only available as a complete assembly kit unless a minimum order quantity is stated.

5Housing Hydraulic Kit (part number 71600-99607). These items are only available as a complete kit.

6Cylinder Assembly Kit (part number 71600-99603). These items are only available as a complete assembly kit unless a minimum order quantity is stated.

7Piston Assembly Kit (part number 71600-99604). These items are only available as a complete assembly kit unless a minimum order quantity is stated.

8Head Seal Kit (part number 71600-99605). These items are only available as a complete assembly kit unless unless a minimum order quantity is stated.

9Body Moulding Assembly Kit (part number 71600-99600). These items are only available as a complete assembly kit unless a minimum order quantity is stated.

✔These items are available as individual spares subject to the minimum order quantity - refer to Avdel sales.