Newgy Industries Robo-Pong 2040+ User manual

•Quick Set-Up, 545 ...........3

•Quick Set-Up, 1040+ ....... 4

•Quick Set-Up, 2040+ .......5

•Operation ....................... 7

•Robot Positions .............13

•Misc. Adjustments .........14

•Important Notices ..........16

•Take-Down, 2040+ ........17

•Maintenance ................19

•Accessories ................... 20

•Troubleshooting ............ 20

•Exploded Views ............23

•Parts List ....................... 25

•Training Log .................. 27

•Warranty & Repair

(Back Cover)

Important:

read operatIng

InstructIons

carefully

newgy table tennIs robot

OWNER'S MANUAL

For Models 2040+, 1040+ & 545

Manufactured under one or more of the following U.S. patents: 4,844,458;

4,854,588; 4,917,380; 5,009,421; 5,335,905; 5,383,658; 5,485,995; and

6,406,386. Also covered by multiple foreign patents/patents pending. Robo-Pong,

Pong-Master, Robo-Balls, and Newgy are trademarks of Newgy Industries, Inc.,

Tennessee, USA.

© January 2018

Newgy INdustrIes, INc.

teNNessee, usA

800-556-3949

615-452-6470

Newgy@Newgy.com

www.Newgy.com

14

4

2

© October 2018 by Newgy Industries, Inc.. This manual, including all photographs, illustrations and software, is protected by

International Copyright Law, with all rights reserved. The manual and any materials contained therein may not be copied

without the author's written permission.

DISCLAIMER

The manufacturer makes no warranties with respect to the contents of this manual, and expressly waives any implied warran-

ty for the particular purpose of sale or interest. The manufacturer reserves the right to make any amendments or changes to

the contents of this manual, and assumes no responsibility for notifying any individual of such amendments or changes. The

specifications and parameters provided in this manual are provided as is and subject to change without notice. The ultimate

power of interpretation belongs to Newgy Industries, Inc..

ADJUST HEAD ANGLE

Loosen the Brass

Knob on the right

side of the robot

(as you’re facing

it), and angle the head down as

far as possible and then re-tight-

en. Verify that the word “top-

spin” is at the top of the ball dis-

charge hole. (See Figures 4, 5, & 7

on pages 7 and 8 for more info.)

POSITION ROBOT ON TABLE

Position the robot in

the center of the

table close to the

endline as shown.

The robot’s head should be in line

with the centerline of the table

(Robot position 1, Figure 15, page 12).

NEWGY TABLE TENNIS ROBOT SYSTEM

QUICK SET-UP FOR ROBO-PONG 545

The Newgy Table Tennis Robot System includes Robo-

Pong models 545, 1040+, and 2040+. Upgrade kits are

incorporated into the system to enable a customer to retain

their investment in their robot and to add features and

capabilities as needed. These upgrades consist of the Robo-

Pong 545 Upgrade Kit to convert a 545 into a 1040+ and the

Recycling Net Upgrade Kit to transform a 1040+ into a

2040+.

Robo-Pong robots require no assembly or tools. They

are pre-assembled and factory tested before being packed

and shipped. They only require a brief set-up before

they’re ready for play! The following quick set-up steps

will assist you in properly setting up your robot.

If you purchased a 2040+, a video is included that also

explains set-up and operation. Additionally, the video

includes some simple table tennis techniques for returning

the different spins your robot can deliver (also see page 8).

Please view the video first if you have a video player.

For maximum enjoyment of and benefit from your

Robo-Pong, it's best to follow the simple set-up steps as

outlined below or as shown in the video. Later chapters of

this Owner'sManual will discuss in detail robot operation,

complete disassembly, maintenance, troubleshooting,

accessories, parts replacement, service, and warranty. In

general, instructions will apply to all models except when

clearly designated by a caption, heading, or the following

footnotes: 1Robo-Pong 1040+ only, 2Robo-Pong 2040+ only,

or 5Robo-Pong 545 only.

The rObO-POng Training Manual in your robot pack-

age (for 2040+ models sold from the U.S.) explains in detail

table tennis strokes, spins, serves, footwork, and other

techniques. It also tells how to use your robot for fitness

training and as fun entertainment for kids and adults. If

you purchased a 1040+ or 545 model, you can download

the Training Manual from our website, www.newgy.com.

In addition, there is a wealth of coaching articles and other

information on our website.

Your robot comes with a supply of Newgy 40mm

Robo-Balls (for robots sold from the U.S.). Robo-Balls are

specially selected for the best robot performance possible.

To order additional balls, Training Manual, video,

upgrade kits, or any other robot accessory or part, please

contact Newgy Customer Service or visit our website.

Contact info is given on the front cover of this manual.

GENERAL INSTRUCTIONS

3

VERIFY ALL PARTS

Unpack all the parts and check that all parts

are present. If unable to identify a part, look

for a small silver label with the name of the

part. If any part is missing, please contact

Newgy immediately. You may want to keep your box and

styrofoam pieces in case you ever need to ship your robot.

WASH BALLS, THEN PLACE IN BUCKET

Open the bag(s) of balls and wash them in

lukewarm, soapy water. Then rinse in clear

water and dry. Place the washed balls in the

Ball Bucket. Other new balls you use should

be washed and dried before placing them in the bucket.

You may also include used balls with worn surfaces. All

balls must be 40mm.

CONNECT CABLE TO ROBOT

Plug one end of the

Connector Cable into the

5-Pin Connector on the

back of the robot as

shown. (Also see Figure 17, page 13.)

1

2

3

4

5

➨

➨

Warranty &

Tell-A-Friend

Flyer

Quick Start

Guide

Pong Pal

(U.S. Only)

GET READY TO PLAY!

With your paddle in your playing hand, turn

the Ball Speed knob to 2–3 and the Ball

Frequency knob to 4–5. It takes about 30 sec-

onds for the balls to load up before the first

one is delivered. To become more familiar with the controls

and adjustments for your machine, read the OPeraTiOn sec-

tion of this manual starting on page 6.

FOLLOW STEPS 2–6 OF 545 SET-UP

Follow Steps 2–6 of the set-up instructions

for Robo-Pong 545 on the opposite page and

above.

SET CONTROL LEVERS TO 3 & 4

Verify that the

Oscillator

Control Levers

are in the 3 & 4

positions. If not, pick up

slightly on the lever and

swing it or the lever guard

into the correct position.

More info on oscillator

adjustment is on page 9.

CONNECT CABLES TO CONTROL BOX

Plug the Connector

Cable into the 5-pin

socket on the rear of

the Control Box. Then

insert the Trans-

former’s pin into the adjacent

Power Jack (see Figure 2B, page 6).

Position the Control Box at the corner of the table (See

Figure 15, page 12).

8

ATTACH CABLE CLIP TO TABLE

Bring the free end

of Connector Cable

to the player’s end

of the table.

Remove the protective backing

from the bottom of the Cable Clip.

Press it onto the side of the table

about 12 inches from the end in a

horizontal position. If you’re right-handed, place it on the

left side of the table. If you’re left-handed, place it on the

right side of the table. Open the clip and place the

Connector Cable and the Transformer’s cord inside the clip

so approximately 12 inches of cable are free. Close the clip.

Plug the Transformer into a suitable electric power source

as printed on top of the Transformer.

7

6

VERIFY ALL PARTS

Unpack all the parts and check that all are

present. If unable to identify a part, look for

a small silver label with the part name. If any

part is missing, please contact Newgy imme-

diately. You may want to keep your box and styrofoam

pieces in case you ever need to ship your robot.

ATTACH BUCKET EXTENDER

Slide the Bucket

Extender onto the

top of the bucket

so that the hooks

on the bottom of the Extender

capture the top lip of the Bucket.

Stop when the hook on the front

of the Extender grabs the front

lip of the Bucket. It may be nec-

essary to lift the rear of the

Extender over the Locating Tab protruding above the rear

lip of the Bucket. Reattach the Robot Body to the Bucket by

reversing step 2.

QUICK SET-UP FOR ROBO-PONG 1040+

4

Locating

Tab

1

3

4

5

DETACH ROBOT BODY

Loosen the two Wing

Nuts holding your

robot body onto the

Ball Bucket. Rotate

the black, rectangular Clip Washers

180˚. Pull the Robot Body off the

bucket.

2

➨

➨

Cable

Clip

Warranty &

Tell-A-Friend

Flyer

Quick Start

Guide

Pong Pal

(U.S. Only)

PULL DOWN SUPPORT LEGS

Place the robot on the

table with the open

front side facing you.

Pull the curved black

metal support legs

toward you.

5

CONNECT CABLES TO CONTROL BOX

Bring the free end

of Connector

Cable to the play-

er’s end of the

table. Plug the Connector Cable

into the 5-pin socket on the bot-

tom of the Control Box. Then insert the Transformer’s pin

into the Power Jack of the Control Box (see Figure 1B, page 6).

ATTACH CONTROL BOX TO TABLE

Place the Control Box

on the side of the table

about one foot from

the end. If you're

right-handed, place it on the left side

of the table. If you're left-handed,

place it on the right side. (See Figure

15, page 12 for more detail.) Plug the Transformer into any

suitable electric power source. Transformer specifications

are printed on top of the Transformer.

7

6GET READY TO PLAY!

Turn Oscillator Speed on and when the head

aligns with the centerline of the table, turn

Oscillator Speed off. Pick up your paddle,

turn the Ball Speed knob to 2–3 and the Ball

Frequency knob to 4–5. Turn the Power

switch to “on” and get ready to return the ball. It takes

about 30 seconds for the balls to load up before the first

one is delivered. When you’re ready for random delivery,

turn the Oscillator Speed on and the balls will be randomly

delivered across the entire table. To become more familiar

with the controls and adjustments for your machine, read

the OPeraTiOn section of this manual starting on page 6.

8

QUICK SET-UP FOR ROBO-PONG 2040+

VERIFY ALL PARTS

Unpack all the parts and check that all are

present. If unable to identify a part, look for

a small silver label with the part name. If a

part is missing, please contact Newgy. You

may want to keep your box and styrofoam pieces in case

you need to ship your robot. If you purchased Pong-Master,

check the photo below to verify all of its parts. In your

Owner’s Packet is a separate

Ow n e r ’sM a n u a l for Pong-

Master. That manual will tell you

how to set up and operate Pong-

Master. To help you separate

robot parts from Pong-Master

parts, the silver labels have “RP”

before the part names for the

robot and a “PM” before the part

names for Pong-Master.

1

SPREAD SUPPORT LEGS APART

Spread out the sup-

port legs to their

fully open position.

JOIN NET SUPPORT TUBES

Turn the robot around

180° so the Net

Support Tubes are now

facing you. Grasp the

second tube from the right and pull

up, removing it from its storage hole.

Place the bottom of this tube into the

top of the first tube on the right as

shown. Repeat on the left side.

2

3

4

Support Legs

Joining Net Support Tubes

➨

➨

➨

Pong Pal

(U.S. Only)

SET CONTROL LEVERS TO 3 & 4

Walk around

to the rear of

the robot, open

the slot in the

back of the net by pulling the

velcro apart and verify that

the Oscillator Control Levers

are in the 3 & 4 positions. If

not, pick up slightly on a

lever and swing the lever or

lever guard into the correct

position. (See page 9 for more details.)

6

LOWER BALL TRAYS

Grasp one of the Ball Return Trays, lift

straight up to unlock it, grasp the adjacent

Net Support Tube, and slowly lower them

into position. Be careful not to let the tray or

support tube slam down. Repeat on the other side.

58

ATTACH ROBOT TO TABLE

Pick up the robot by the bottom of the

Center Trough and secure it to the table by

angling it downward and pushing it onto

the end of the table. The Support Legs go

underneath the table and the Front Support Plate sits on

top of the table. The center of the Front Support Plate

aligns with the centerline of the table. The robot will be

held by its own weight. (See Figure 10, page 9 for more detail.)

FOLLOW STEPS 2–5 OF 545 SET-UP

Follow steps 2–5 of the set-up instructions

for Robo-Pong 545 on, except after washing

the balls, place them in the robot’s Ball

Return Trays instead of the Ball Bucket.

7

FOLLOW STEPS 6–8 OF 1040+ SET-UP

Follow Steps 6 to 7 of the set-up instructions

for Robo-Pong 1040+ on the opposite page.

69

➨

➨

➨

ATTACH SIDE NETS

Attach a Side Net to

your table tennis net

by slipping the red

flexible band over

your table net's support base and

wrapping it around the table net's

clamp screw. (If your table net

doesn't have these parts, see Figure

18 on page 20 for alternative Side Net attachment). Be sure

Side Net follows and is directly above the sideline of the

table. Repeat on the other side (see page 20 for more details).

10

Linking Cable from Pong-Master

Scoreboard (optional) plugs in here

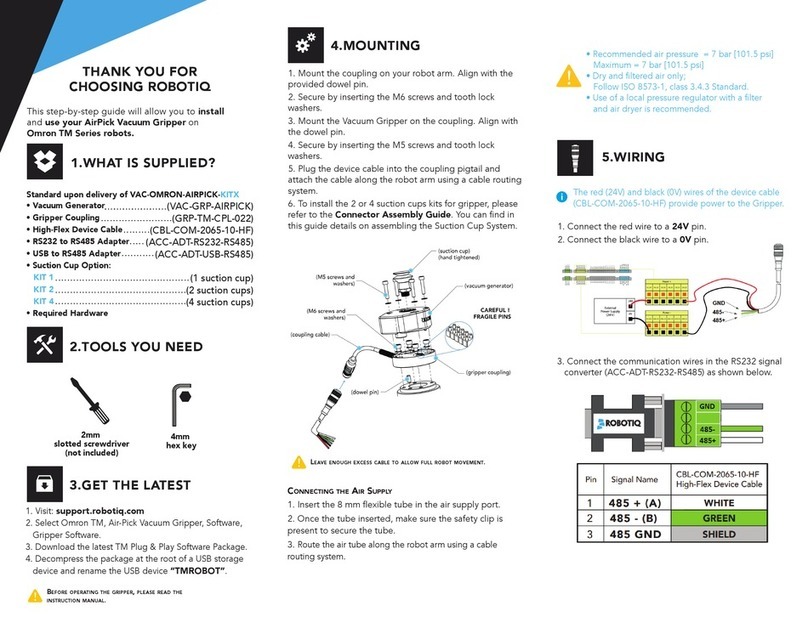

CONTROL BOX FOR 1040+/2040+

TOP VIEW

FIGURE 1A

1 3 42

If you open Control Box, remove ONLY these 4 screws

Connector Cable from

robot plugs in here

Pin of Transformer

plugs in here

CONTROL BOX FOR 545

TOP VIEW

FIGURE 2A CONTROL BOX FOR 545

REAR VIEW

13

2

Connector Cable from

robot plugs in here

Pin of Transformer

plugs in here

7

OPERATION OF YOUR ROBOT

Your robot is extremely versatile and fully adjustable to

suit a wide variety of playing abilities and styles. Ball

speed, frequency, spin, trajectory, and placement can all be

adjusted, as well as oscillator speed and range. The follow-

ing section will explain the various controls and adjust-

ments of your robot.

CONTROL BOX (ALL MODELS)

The robot’s motors are controlled electronically by the

Control Box. Figures 1A and 1B illustrate the functions and

controls for the 1040+ & 2040+ models. Figures 2A and 2B

illustrate the functions and controls for the 545.

1. POWER—Used to turn the robot “ON” or “OFF”.

2. BALL SPEED—Regulates the ball speed and spin.

Higher settings increase the amount of spin and forward

speed on the ball. On the 545, this control also functions as

the on/off switch. See also Ball Trajectory on page 7.

3. BALL FREQUENCY—Regulates the time between

shots. Lower settings increase the time between shots.

Higher settings decrease time between shots. Lowest set-

ting at which balls will come out is approximately 2 (13 to

26 balls per minute). At a setting of 10, the robot delivers

approximately 90 balls per minute for the 1040+ & 2040+

models and 60 balls per minute for the 545.

4. OSCILLATOR SPEED—Regulates the speed at

which the robot head sweeps side to side. Higher settings

make the head sweep faster. This control is also used to

position the head in the desired direction when you want

balls to be delivered to one spot. First set the control levers

on the rear of the robot to positions 3 & 4 (see page 9). Turn

Oscillator Speed on, and when the head reaches the desired

position, turn it off. See also Figures 3A & 3B below.

WARNING: Use the Oscillator Speed control to make the

robot head move sideways. DO NOT attempt to move the robot

head sideways by hand. Doing so will likely result in broken

parts and may void your warranty.

FIGURE 2B

CONTROL BOX FOR 1040+/2040+

BOTTOM VIEW

FIGURE 1B

FIGURE 3A FIGURE 3B

Because oscillator speed has not

been set correctly, the second ball is

placed too closely to the first ball.

This results in not having to move the

feet very much.

Oscillator speed has been adjusted

so the second ball lands well away

from the first ball. This makes the

player move the feet a greater

distance, resulting in better footwork

and more exercise.

1

21

2

INCORRECT OSCILLATOR SPEED

(1040+/2040+ ONLY)

CORRECT OSCILLATOR SPEED

(1040+/2040+ ONLY)

8

BALL TRAJECTORY (ALL MODELS)

The trajectory of a ball is regulated by adjusting the angle

of the robot head. The angle can be changed from low to

high. At its lowest setting, the ball will be delivered so it

first strikes the robot's side of the table, bounces over the

net, and lands on the player's side of the table (just like a

serve). At its highest setting, the ball will be delivered in a

high arc over the net (like a lob return).

The trajectory is adjusted by loosening the Brass Knob

on the right side of the robot head, tilting the head to the

desired angle and then re-tightening the Brass Knob (see

Figure 4). For reference, there are head angle indicators

next to the Brass Knob (see Figure 5).

WARNING: DO NOT adjust the head angle when the

head is moving side to side. Failure to follow these instructions

will likely result in broken parts and may void your warranty.

The ball trajectory setting is directly related to the Ball

Speed setting. When the head is set so the ball first strikes

the robot's side of the table (robot “serving”—see Figures

6C & 6D), maximum Ball Speed is 3–5. As the Ball Speed is

turned up, the head must be angled up to deliver the ball

so it first strikes the player's side of the table (robot

“returning”—see Figures 6A & 6B). As the Ball Speed is

turned up even more, adjust the head angle down to pre-

vent the ball from being thrown off the end of the table.

INCORRECT ROBOT HEAD ANGLE,

ROBOT “RETURNING”

FIGURE 6A

ADJUSTING HEAD ANGLE

FIGURE 4 HEAD ANGLE INDICATORS

FIGURE 5

CORRECT ROBOT HEAD ANGLE,

ROBOT “RETURNING”

FIGURE 6B

INCORRECT ROBOT HEAD ANGLE,

ROBOT SERVING

FIGURE 6C

CORRECT ROBOT HEAD ANGLE,

ROBOT SERVING

FIGURE 6D

Robot head is tilted too high, resulting

in ball being thrown off the end of the

table.

Same ball speed as Figure 6A, but

now robot head is tilted down so the

ball lands on the table.

When robot is set to serve onto its

side of table first, and the head angle

is too severe, the ball will rebound

abnormally high.

Same ball speed as Figure 6C, but

head angle has been raised slightly

so ball stays low to the net. With

robot serving, maximum ball speed is

limited to 3–5 before ball is thrown off

the end of table.

Robot Head

67

Brass Knob

71

Angle Pointer

Head Angle

Indicators

Robot Head

Robot Head

Robot Head

Loosen Brass Knob

(66) To Adjust Angle

Of Head Up Or

Down.

DO NOT FORCE!

BALL SPIN (ALL MODELS)

Robo-Pong robots are capable of putting any type of spin

on the ball. Topspin, backspin, sidespin, and even combina-

tion spins can easily be selected. To change the spin, simply

rotate the head of the robot until the desired spin is at the

top of the Ball Discharge Hole (see Figure 7).

For combination spins, move the head until one of the

rotational arrows is at the top of the Ball Discharge Hole.

For instance, if the arrow between Topspin and Sidespin is

selected, the robot will deliver a ball containing both top-

spin and sidespin. Likewise, if the arrow between Backspin

and Sidespin is selected, the robot will deliver a combina-

tion backspin/sidespin ball.

Before discussing how to return spins, it's important to

know that your robot simulates the play of a modern table

tennis professional using inverted sponge rubber. With

Robo-Pong robots, there is always some kind of spin on the

ball. To learn how to produce your own spin and return an

opponent’s (or the robot’s) spin, it is important to use the

correct equipment—a quality inverted or pips out sponge

rubber racket. Using old-style paddles such as hard rubber

or sandpaper will make it more difficult to control spin.

Each spin has a different effect on the ball and how the

ball reacts when you strike it with your paddle. Following

are some brief pointers to help you return the different

spins. More detail is available in Chapter 7 of the Training

Manual which is included with your Robo-Pong 2040+ if

bought in the U.S., or available separately.

The secret to returning spin is to angle your paddle

correctly when contacting the ball. Any spin can easily be

returned if you angle your paddle properly. Set your pad-

dle angle at the beginning of your stroke and maintain the

same angle until your stroke ends. Avoid changing your

paddle angle during your stroke. (See Figure 8.)

9

Rotate Head So

Desired Spin Is

Listed In Upright

Position

CAUTION:

Do Not Twist Power

Cord Around Head.

Rotate No More

Than 180° In Either

Direction From

Position Shown

SPIN SELECTION

FIGURE 7

TOPSPIN

SIDE VIEW

BACKSPIN

SIDE VIEW

PADDLE

PADDLE

LEFT SIDESPIN

TOP VIEW

RIGHT SIDESPIN

TOP VIEW

RETURN SHOT

RETURN SHOT

RETURN SHOT

PADDLE

PADDLE

RETURN SHOT

PADDLE ANGLE ADJUSTMENTS

FOR VARIOUS SPINS

FIGURE 8

Topspin causes the ball to dip downward as it travels

through the air. When you strike the ball with your paddle,

it has a tendency to pop up high in the air. To compensate

for topspin, angle your paddle face down as you stroke

through the ball in a forward and upward direction.

Contact the top surface of the ball. (See Figure 8A.)

Backspin causes the ball to rise upward and float as it

travels through the air. When you strike the ball with your

paddle, it has a tendency to go straight down into the table.

To compensate for backspin, angle your paddle face

upward as you push your paddle straight forward. Contact

the bottom surface of the ball. (See Figure 8B.)

Sidespin makes the ball curve sideways through the

air. Left sidespin makes the ball rebound off your paddle to

your right; right sidespin to the left. To compensate for left

sidespin, angle the paddle face to the left and contact the

right side of the ball. To compensate for right sidespin,

angle your paddle face to the right and contact the left sur-

face of the ball. (See Figures 8C &8D.)

Combination spins take on the characteristics of both

spins, although to a lesser degree than the pure spins. To

compensate for topspin/right sidespin, you must angle

your paddle face down and to the right and contact the top

left surface of the ball. Likewise, a backspin/left sidespin

ball is best returned by angling your paddle face up and to

the left and contacting the ball on its bottom right surface.

Spins are increased by turning up the Ball Speed knob

on the Control Box. You increase both the speed and spin

on the ball every time you turn up the Ball Speed knob. It is

not possible to adjust Robo-Pong robots to deliver a slow

ball with lots of spin, for instance. It is also impossible for

Robo-Pong robots to deliver a no-spin ball. Additionally,

since backspin causes the ball to rise, the maximum setting

for Ball Speed when the robot is set on Backspin is approxi-

mately 4–5.

AB

CD

10

OSCILLATION RANGE (1040+/2040+ ONLY)

Oscillation is the sweeping motion of the robot’s head,

enabling the robot to deliver consecutive balls to different

spots on the table. Since Robo-Pong 545 has no oscillation

controls, the information on this page does not apply to the

545. Furthermore, the oscillator ranges given on this page

will apply to the 1040+ and 2040+ only when these models

are positioned so the robot head is aligned with the center-

line of the table (Position 1 or 5, Figure 15, page 12).

Models 1040+ and 2040+ have 8 selectable ranges (or

zones) in which the robot head will sweep, delivering balls

randomly within that zone. These zones are regulated by

the Control Levers at the back of the robot (see Figure 9).

Ranges are identified on a label at the top of the robot (see

Figure 10). Figure 10A further clarifies these ranges.

Zones are selected by moving a Control Lever into the

desired position as indicated by the number that appears

through the hole in the Control Lever (see Figure 9). The

Right Control Lever is restricted to positions 1, 2, & 3; the

left to positions 4, 5, & 6. (Left and right designations for

the robot are given as if you are facing the robot.)

To move a lever, lift it up with your finger, move it to

the desired position, and then release it. If the lever will

not move easily, pick up the lever and move the Control

Lever Adapter instead. To access the Control Levers on the

2040+, open the slot in the back of the net by pulling the

velcro apart and reach with your fingers through the slot to

touch the Control Levers.

WARNING: DO NOT adjust the Control Levers while the

head is moving. Also do not move both levers at the same time.

Move one, then the other. Failure to follow these instructions will

likely result in broken parts and may void your warranty.

Following is an explanation of each zone that can be

selected as shown in Figures 10 and 10A:

3,4—Robot delivers balls across the entire table, from

corner to corner (whole table).

3,5—Robot delivers balls from player’s left corner to

middle of right court (3

/4table).

2,4—Robot delivers balls from player’s right corner to

middle of left court (3

/4table).

1,4—Robot delivers balls from player’s right corner to

centerline (1

/2table).

3,6—Robot delivers balls from player’s left corner to

centerline (1

/2table).

2,5—Robot delivers balls from middle of player’s right

court to middle of left court (1

/2table).

1,5—Robot delivers balls from middle of player’s right

court to centerline (1

/4table).

2,6—Robot delivers balls from middle of player’s left

court to centerline (1

/4table).

1,6—No oscillation. Place Control Levers in these posi-

tions whenever you transport or ship your robot, to pre-

vent damage to the oscillator mechanism.

If you want stationary delivery, adjust the Control

Levers to 3,4 and turn oscillator speed on. When the robot

head points to the desired landing spot on the table, turn

Oscillator Speed off. Failure to set the levers to 3,4 may

result in “head drift”, which causes the landing spot to

change even though the oscillator is turned off.

SWEEP CONTROL ADJUSTMENT

2-4

3-4

1-4 3-6

2-5

1-5 2-6

3-5

OSCILLATOR RANGES

OF ROBOT WITH

CONTROL LEVERS IN

VARIOUS POSITIONS

AND ROBOT ALIGNED

WITH CENTERLINE OF

TABLE

(1040+/2040+ ONLY)

FIGURE 10A

SWEEP ADJUSTMENT LABEL

(1040+/2040+ ONLY)

FIGURE 10

OSCILLATOR CONTROL LEVERS

TOP VIEW (1040+/2040+ ONLY)

FIGURE 9

CAUTION:

Do Not Move Robot

Head By Hand; Use

Oscillator Speed Knob

On Control Box

Numbered Oscillator

Positions

81

Control Lever, L

80

Control Lever

Adapter

82

Control

Lever, R

SWEEP CONTROL ADJUSTMENT

2-4

3-4

1-4 3-6

2-5

1-5 2-6

3-5

FINAL PROCEDURES

Place balls of the other size in the Ball Bucket or

Ball Trays. (Be sure to wash and dry new balls

before using them for the first time.) Reconnect

the Connector Cable (see Figure 17, page 13). Turn

power back on and you’re ready to play.

REATTACH ROBOT BODY

Reattach the Clear Front

Cover (reverse of Step 6).

Reattach the robot body, mak-

ing sure that it fits fully down

on the locating tab of the Center Trough

or Ball Bucket. (See Figure 17, page 13.)

Finally, re-tighten the Wing Nuts

(reverse of Step 4).

➦

REMOVE BALLS FROM INSIDE ROBOT

Remove all balls

from inside the

robot and place

in the box with

the other balls of the

same size. Also gather up

any balls that are on the

floor or lying around

loose in the playing area and place them inside the box too.

REMOVE CLEAR FRONT COVER

Place the robot body

on your table. Pull

the Clear Front

Cover off by squeez-

ing on the circular fingerholds

on the sides of the cover with

your thumb and forefinger,

and then pulling up while squeezing. Pull the cover loose

first at the top and then at the bottom.

➥

REMOVE BALLS FROM TRAY OR BUCKET

First, remove all balls

from the Bucket (545

or 1040+) or Trays

(2040+) and place

them in a box where they will

not get mixed in with balls of

the other size. Then disconnect

the Connector Cable from the

back of the robot.

LOOSEN WING NUTS

Loosen the two Wing

Nuts that hold your

robot body onto the

Ball Bucket or Center

Trough. Rotate the

black, rectangular Clip Washers

180˚.

REMOVE ROBOT BODY

Pull straight up on the

robot body to remove it

from the Ball Bucket or

Center Trough.

3

1

2

➥

7

5

6

4

REMOVING ALL BALLS FROM THE SYSTEM

➥

➨

➦

11

Clip Washer

BALL DAMS (2040+ ONLY)

Robo-Pong 2040+ comes with a pair of Ball Dams. They

serve three functions: (1) they keep balls inside the Center

Trough when the robot is folded up, (2) they keep balls

from entering the Center Trough when you want to remove

the robot body, and (3) they serve as a ball gauge for deter-

mining if a ball is the proper size and whether it should be

used in the robot.

The Ball Dams, when used for functions 1 or 2, fit into

two retaining slots at the top of the Center Trough. When

not in use, the Ball Dams fit into their storage slots on the

side of the Center Trough (see Figure 11).

To use the Ball Dams when preparing the robot for

storage or transport, remove the Ball Dams from their stor-

age slots by pulling slightly up on the trays to reveal the

storage slots (see Figure 13). Then push all the balls into the

Center Trough and insert the Ball Dams into their retaining

slots (see Figure 12). To use the Ball Dams for function #2,

push the balls up into one of the Ball Return Trays and

quickly insert the Ball Dam into its retaining slot before the

balls can roll down into the Center Trough. The balls will

be out of the way and you can easily loosen the two wing

nuts and two clip washers, then pull up on the robot body

to remove it (see Steps 4 & 5, opposite page).

The hole in a Ball Dam serve as a handy ball checking

feature. The hole is 40mm in diameter. This hole is used to

test the roundness and size of balls you use in the robot. If

you suspect a ball is out of round or too large, as indicated

by balls jamming within the robot, insert the suspected ball

into the ball checker hole. With your fingers, rotate it

around inside the hole to check all possible diameters of

the ball. The ball should have equal clearance through the

hole on all diameters. The ball should barely fit through the

hole without binding. It is also possible that a ball is too

small. In this case, you will notice a considerable gap

between the ball and the edge of the hole.

Ball Dam

Retainer Slot

Ball Dam

Storage Slot

Ball

Checker

Hole

15

Ball Dam

1

Center

Trough

BALL DAM & CENTER TROUGH

(2040+ ONLY)

FIGURE 11

INSERTING BALL DAM

(2040+ ONLY)

FIGURE 12

REMOVING BALL DAM

(2040+ ONLY)

FIGURE 13

CHECKING BALL WITH BALL DAM

(2040+ ONLY)

FIGURE 14

12

➥

➨

➨

Rotate Ball Inside

Hole To Check All

Diameters Of The

Ball. Ball Should

Pass Easily Through

Hole On All

Diameters.

POSITIONING YOUR ROBOT AND CONTROLS (ALL MODELS)

13

Robo-Pong robots are versatile in how they are positioned

in relation to the table. The 545 and 1040+ normally sit on

top of the table as shown in robot positions 1–4 in Figure

15. They can also be mounted in the optional Robo-Caddy

and placed behind the table like positions 5 & 6. The 2040+

is typically mounted to the end of the table at position 5,

but can alternatively be mounted in the Robo-Caddy just

like the 545 and 1040+.

Some positions offer certain advantages while other

positions compromise some of the robot’s functions. By

placing the robot in various positions you can achieve a

variety of angles and trajectories to simulate almost any

type of shot you would encounter in a regular game. The

following paragraphs explain this further.

Position 1—Robot positioned square to the table where

the centerline and endline of the table meet. This is the only

“on the table” position in which the 1040+’s oscillator rang-

es will be accurate (see OscillatiOn Range, page 9). Also this

is the desired starting position when first setting up either

the 545 or the 1040+. In this position, the 545 will shoot

straight down the centerline of the table.

Position 2—Robot positioned at the far left corner and

angled cross-court. This position will skew the 1040+’s

oscillator range toward the player’s right side of the table.

The 545 in this position would deliver the ball towards the

player’s right corner. This position would be the preferred

direction when simulating typical right-handers’ forehand

to forehand rallies.

Position 3—Robot positioned at the far right corner

and angled cross-court. Setting the robot in this position

will skew the 1040+’s oscillator range toward the player’s

left side of the table. A 545 placed in this position would

direct its shots to the player’s left corner. Typical backhand

to backhand play for right-handers would be ideally simu-

lated with the robot in this position.

Position 4—A robot placed in this position has the

advantage of offering slower and faster ball speeds because

it is closer to the landing spot of the ball. At a Ball Speed

setting of 0, the ball is very slow and with light spin, but is

delivered deep on the player’s end. At a Ball Speed setting

of 10, the ball speed is very fast and simulates the angle

from which a typical kill shot would be hit. However, the

1040+’s oscillator ranges are narrower than if the robot had

been positioned at the endline like Positions 1–3.

Position 5—This is the normal position of the 2040+

when it is attached to the end of the table, and its net sys-

tem would function normally. The 1040+ and 545 would

have to be mounted in the Robo-Caddy to be in this posi-

tion. Positioned here, the 2040+’s and 1040+’s oscillator

ranges would be accurate.

Position 6—Mounted in a Robo-Caddy, all three mod-

els can be freely moved around in back of the table. The

Robo-Caddy also permits lowering or raising the height of

the robot. This is great for simulating deep shots such as

chops, lobs and loops. However, the oscillator ranges for

the 1040+ and 2040+ are not accurate and the 2040+’s net

system is usually not effective at capturing balls when in

this position. Additionally, you need to purchase a

Connector Extension Cable (part# 2000-221) to extend the

Robot

Pos. 1

Robot

Pos. 2

Robot

Pos. 3

Robot

Pos. 4

Robot

Pos. 5

Robot

Pos. 6

Right Hand

Player Left Hand

Player

545 Control Box

1040+/2040+ Control Box

A

ABB

length of the Connector Cable from 10 to 20 feet. This per-

mits the Control Box to stay within reach of the player.

These positions are only a few of the ones possible, but

they will give you a good idea of the pluses and minuses of

placing the robot in a particular position.

IMPORTANT NOTE: Even though the oscillator ranges

may not be accurate as described on page 9 when the robot is in

certain positions, you should be able, with experimentation, to

find the correct settings for the Control Levers to permit ball

delivery over any particular part of the table.

Figure 15 also illustrates the ideal positions for the

Control Box. If you’re right-handed, Position A is the pre-

ferred location for the controls. If you’re left-handed,

Position B is preferred. Locating the controls in these sug-

gested positions permits the controls to stay within easy

reach of the player’s free hand.

Since a player has a longer reach on the forehand side,

it is suggested that you position your body as shown. The

overwhelming majority of tournament level players use

their backhand to cover about one-third of the table and

their forehand to cover the other two-thirds of the table.

ROBOT AND CONTROL BOX

POSITIONS

FIGURE 15

14

LEVELING ADJUSTMENT (2040+ ONLY)

Robo-Pong 2040+ is designed to sit level when attached to

the table. In proper position (Figure 16), the CT Support

Legs fit underneath the table and the CT Front Support

Plate sits on top of the table. If the robot does not sit level,

balls will not feed properly. If this condition occurs, it is

necessary to make some leveling adjustments. The first

adjustment is to level the table top by placing shims under

the table legs until the table top is level.

If this does not cause the robot to sit level, then it will

be necessary to make adjustments to the robot itself. The

Support Legs come with 3 sizes of Rubber Tips and 4 rub-

ber spacer-washers to accommodate different table top

thicknesses, and cause the Center Trough to sit level. The

Rubber Tips are marked on their top with the table thick-

ness they are used with. The longest is used for 1

/2″tops.

The mid-size one is used on 3

/4″tops and comes pre-

installed. The shortest tip is used for 1″tops.

In addition to these different sized tips, there are 4 rub-

ber spacer-washers which are used with the Rubber Tips

for finer adjustments. Either one or two of these spacer-

washers (depending on how much adjustment you need)

are placed inside the Rubber Tips before the tips are placed

on the end of the Support Legs.

Another reason why your robot may not sit level is that

it is not properly seated on the locating tab. When seated

correctly, the Support Flange of the Back Panel sits flush on

the Locating Tab that protrudes from the top of the Center

Trough (see Figure 17). Your robot serial number is located

on top of this Support Flange.

Tip: If it is possible to adjust the level of the robot’s half

of the table independently from the player’s half, you may

choose to purposely give a slight slope to the robot’s half so

balls that end up on the table roll into the robot’s trays. If

you make the table unlevel, make sure the robot sits level

by adjusting the Rubber Tips as described above. In this

case, it may be necessary to use the Rubber Tip one size

larger than normal to level the robot.

ADJUSTING NET TENSION (2040+ ONLY)

The Ball Return Trays should sit level with or just below the level of

your table top. If the tension of the Main Net is too tight, the trays

will be pulled up into a slight “V” shape with the top edge of the

trays above the level of the table top. To correct this situation, you

can loosen the adjustment straps shown in Figure 18 until the trays

sit level. If this adjustment is insufficient, stretch the net by grab-

bing it with two hands and pulling gently apart.

The Trap Net (the black net with large holes) slows down your

returns so more of them are captured. The size of the holes is slight-

ly smaller than the diameter of a ball. Hard hit shots force the ball

through the net and the ball becomes trapped between the Trap Net

and the Main Net. When slowly hit balls contact the Trap Net, they

do not have enough force to go through the net, so they immediate-

ly drop down into the trays.

The Trap Net is normally hung loosely so as to increase its

energy-absorbing capability. If you are practicing hard hit shots like

smashes or fast loops, you may find that a tighter Trap Net cap-

tures more of your shots. The tension of the Trap Net is adjusted by

tightening or loosening the velcro straps at the sides of the Trap Net

(see Figure 19).

MISCELLANEOUS ADJUSTMENTS (2040+ ONLY)

CENTER TROUGH ATTACHMENT

(2040+ ONLY)

FIGURE 16

ADJUSTING MAIN NET TENSION

(2040+ ONLY)

FIGURE 18

ADJUSTING TRAP NET TENSION

(2040+ ONLY)

FIGURE 19

Table Tennis

Table

Back Of Robot

To Control

Box

Velcro

Straps

Robot

8,9

CT Support

Legs

95

Connector

Cable

Serial #

Located

Here

10,11,12

CT Support

Leg Rubber

Tip—Come

In 3 Sizes

So Center

Trough Will

Sit Level.

Support Flange Of Robot Sits

Fully Down On Locating Tab Of

Center Trough or Ball Bucket

15

Ball Dam

In Storage

Position

5

CT Front

Support Plate

32

Wing

Nut

1

Center Trough

(Should Be Level)

SUPPORT FLANGE ALIGNMENT

& SERIAL # (2040+ ONLY)

FIGURE 17

Velcro

Straps

The Trap Net is normally hung loosely to increase its

energy-absorbing capability. If you are practicing hard hit

shots like smashes or fast loops, you may find that a tighter

Trap Net captures more of your shots. The tension of the

Trap Net is adjusted by tightening or loosening the velcro

straps at the sides of the Trap Net (see Figure 19).

Side Nets block off the sides of the table and direct

wide angled shots into the main net. The Side Nets have a

red flexible band sewn at the narrow end of the net. This

flexible band is used to attach the Side Net to either the

clamp assembly for the table’s net (the net that separates

the two halves of the table—see Figure 20) or to a clip that

is attached to the table surface (see Figure 21C). Further-

more, you can adjust the tension of the Side Nets by modi-

fying the flexible bands (see Figures 21B and 21E).

If the table net has a clamp screw, pass the flexible band

of the Side Net over the top of the net support and wrap it

around the clamp screw as shown in Figure 20.

If your table net does not have a clamp screw, use the

Plastic Clips included with your robot. Clean the table sur-

face with isopropyl alcohol along the sideline about 1–3

inches before the table net. After the alcohol dries, remove

the backing on the bottom of a clip and press it onto the

table top along the sideline about an inch from the net. The

open end of the clip should face away from the robot (21A).

Create a knot close to the centerpoint of the flexible band

(21B). Insert the band into the clip where the knot is located

(21C). Side Net should look like 21D.

The flexible bands were designed to provide the proper

tension for the side nets in most installations. If you require

more tension to hold the side nets in place, then simply

knot the band as shown in 21B to shorten the band length

and then reattach. Be careful to never use so much tension

that you pull the main net with sufficient force that the Ball

Return Trays are lifted up. If you need less tension, then

you can lengthen the band by tying a hair band of the

required size (available at many stores) to the side net’s

flexible band (see Figure 21E).

When first used, the netting material is taut. The materi-

al will relax over time by itself. If there is sufficient gap

between the bottom of the side net and the table surface

that a ball can roll through that gap, then you should manu-

ally relax the net.

Figure 21A illustrates this problem. Even though the

Side Net has been installed correctly, the bottom of the Side

Net is too high, allowing a ball to roll underneath it. To cor-

rect, gently stretch the netting material directly above the

problem area until it relaxes enough to where the bottom

edge of the net is just above the table surface (see Figure 22B).

IMPROPER/PROPER GAP FOR

SIDE NET (2040+ ONLY)

FIGURE 22

AB

ATTACHING SIDE NET TO CLAMP FOR

TABLE NET (2040+ ONLY)

FIGURE 20

ATTACHING SIDE NET WITH PLASTIC

CLIPS (2040+ ONLY)

FIGURE 21

A

B

C

D

Plastic

Clip

Plastic

Clip

Knot

Knot

LENGTHENING SIDE NET TO REDUCE

TENSION (2040+ ONLY)

FIGURE 18E

Hair

Band

Flexible

Band

Knot

1. Pass Flexible

Band Over Top

Of Net Support

2. Wrap Band

Around Clamp

Screw

15

16

1. Before connecting your robot to power, be sure the

transformer matches the power source in your area.

Transformer specifications are printed on top of the

transformer.

2. Do not use petroleum based lubricants or solvents on

the plastic parts of this product. These chemicals are

corrosive to the plastic and will result in structural

failure of the plastic parts. Use of these chemicals will

void your Warranty and/or Service Policy.

3. 2040+ and 1040+ robots are equipped with a special

safety feature to warn you when ball jams occur. Your

Control Box emits a high-pitched squealing noise

and shuts off the ball feed when it detects a ball jam!

Don’t worry—your machine is operating the way it

was designed to. This shut-off feature prevents

damage to the ball feed gears and motor.

Normally the solution is very simple. Turn off your

Control Box, then agitate the balls where they feed into

the machine. In particular, look for balls that have

become stuck around the Ball Feed pickup mechanism.

If agitating the balls doesn’t fix the problem, then the

problem is inside the robot.

To inspect inside the robot, remove the balls from the

Bucket or the Trays and then remove the robot body.

After removing the Clear Front Cover, look for balls

that are cracked, dented, too large, or out-of-round. To

test for ball roundness and correct size, read the last

paragraph on page 11 that explains the use of Ball

Dams and refer to Figure 14. Discard any bad balls.

4. New balls cause many ball jams. Before using new

balls, including those that came with your robot (if

applicable), be sure to wash them in lukewarm, soapy

water. After washing, dry all balls with a clean, dry

cloth before putting them in the Ball Bucket1,5 or Ball

Trays2. This removes the powder that is on the surface

of the balls. This powder causes excess friction,

making the robot run erratically until the powder is

removed.

After putting them in the Ball Bucket or Ball Trays,

run the balls through the machine at high frequency

by setting the Ball Frequency to 10, the Ball Speed to 3,

the spin to “backspin”, and aim the head at the middle

of the table net. The balls will hit the table net,

rebound, and automatically return into the net system

(for robots with net systems).

For robots mounted in Ball Buckets, catch these balls

by hand or in a tray or box, and return them to the Ball

Bucket. This procedure will further “rub the balls

down”. Continue this rub down procedure for about

15 minutes, then return to normal operation.

5. Use 3-Star balls or Newgy Robo-Balls for best perfor-

mance. Most other brands of approved 1-Star, 2-Star, or

3-Star balls will also work. Avoid inexpensive non-

graded and unapproved balls, especially those with

rough seams. Well-worn balls work best.

6. When moving the 2040+, always support it under the

Center Trough. Do not carry it by the rubber Tray

Strap. The strap may loosen, causing you to drop your

robot. If you want to carry it by the strap, replace the

rubber Tray Strap with our optional Carrying Strap.

After 2006, all 2040+ robots come with the Carrying

Strap included.

7. Store unit indoors only. Do not leave the robot or

Control Box outdoors. Avoid leaving unit in a hot car

or trunk. Plastic parts can warp, crack, or melt if

exposed to extreme temperatures. Do not use robot

around sand. Sand will abrade plastic surfaces.

8. When lowering the Ball Return Trays on the 2040+,

don’t let the trays fall down into place. Lower them

gently.

9. Do not use sandpaper paddles with your robot. Sand

can loosen from the paddle and end up inside the

robot where it can abrade plastic surfaces and cause

ball jams and other problems.

IMPORTANT NOTICES (ALL MODELS)

WARNING: These points are vital for proper use and care. Failure to heed these points may cause damage to the robot.

REMOVING CLEAR FRONT COVER

FIGURE 23

40

Collector Plate

(2040+ Only)

Remove Clear

Front Cover

By Squeezing

Fingerholds

Next To The

Locking Tabs.

Loosen Top

First, Then

Bottom.

Locking Tabs

On Front Cover

Snap Into Slots

On Back Panel

17

PLACE CORDS IN CENTER TROUGH

Unplug the Trans-

former and Con-

nector Cable from

the Control Box

and unplug the

Transformer from the wall

outlet. Coil both cords and

place on top of the balls in

the Center Trough. Place the

Side Net Extenders on top

of the balls. If you have

Pong-Master, you may place

its scoreboard and all of its

cords on top of the balls as

well.

PLACE SIDE NETS IN TRAYS

First, unplug

the Connector

Cable from

the back of the

robot. Then

detach the Side Nets

and place them in the

trays.

INSERT BALL DAMS

Push the balls

into the Center

Trough and place

the Ball Dams in

their retaining

slots. (See Figures 11 & 12 on

page 11 for more detail.)

ADJUST HEAD ANGLE

Loosen the Brass

Knob on the right

side of the robot head

and adjust the head

angle to its highest

position. Retighten the Brass

Knob. (See Figure 4, page 7 for

more details.)

PLACE ROBOT ON CORNER OF TABLE

Remove

the robot

from the

table and

set it down

on the cor-

ner of the table so

you can easily access

both the front and

back of the robot.

REMOVE BALL DAMS

From the

front of the

robot, raise

each tray

slightly and

remove the Ball Dams

from their storage

positions. Don’t raise

too much or the balls

will fall out! (See

Figures 11 & 13 on page

11 for more detail.)

TAKE DOWN, STORAGE, & TRANSPORT (2040+ ONLY)

1

2

3

4

5

6

Robo-Pong 2040+ can be easily taken down in less than 5

minutes. Your robot folds very compactly with all parts

inside the robot. This model is also lightweight and very

portable. Follow these steps to be sure all parts fold up cor-

rectly.

Inserting Ball

Dam Into

Retainer Slot

Brass Knob

Removing

Ball Dam

From

Storage

Slot

PUT CONTROL BOX ON STORAGE POST

Hold the Control

Box by its metal

support bracket

with knobs up.

Raise the sup-

port leg assembly half-

way and slide the

Control Box onto its stor-

age post between the

Support Legs. Keep

assembly raised to pre-

vent Control Box from

falling off the post.

FOLD BACK SUPPORT ASSEMBLY

Swing the Support Legs

inward and fold the

whole support leg

assembly, with the

Control Box attached,

into the robot as shown. You may

need to hold up the Trap Net

while folding the assembly so it

does not interfere with the folding

process.

7

8

Storage

Post For

Attaching

Control

Box

Control Box In

Storage Position

➨

➨

➨

➨

➨

FOLD TRAYS UP

Fold the Ball Return

Trays closed by lift-

ing carefully until

they lock into their

vertical position.

PLACE NET TUBES IN STORAGE HOLES

From the back

of the robot,

detach the left

and right

Curved Net

Support Tubes from their

associated Straight Net Sup-

port Tubes. Place the curved

tubes into their storage holes

(2nd & 4th holes) on top of

the Net Support Plate.

ROBOT PROPERLY FOLDED

When the robot is fully folded and with its

components in their proper storage posi-

tions, all parts fit within the confines of the

Center Trough and the Ball Return Trays.

18

9

10

11

Separating The

Upper And Lower

Net Support

Tubes

Net Support

Plate

PLACE ROBOT IN ROBO-TOTE

If you purchased

the optional

Robo-Tote car-

rying case, your

Robo-Pong

2040+ will now fit inside the

case. The carrying case pro-

tects the exterior of the robot

during movement or storage

and it comes with a backstrap

for easy transport. The exteri-

or pocket is used to store the

Pong-Master targets (if you

purchased that accessory).

When inserting the targets

into the pocket, target wires

should be furthest down in the

pocket to prevent the weight

of the wires from bending the

edges of the targets.

READY FOR STORAGE OR TRANSPORT

With your Robo-Pong

2040+ inside its carry-

ing case, it’s ready to go

anywhere you go. Carry

it on your back, store it

in a closet, or take it in your car to

your friend’s house! Your robot will be

shielded from dust, dirt, and conden-

sation and all parts will be in one

place when you’re ready to set it up

again.

13

14

SECURE TRAY STRAP

Pull the tops

of the Ball

Return Trays

together by

attaching the

free end of the Tray Strap

to the top hole of the

opposite tray. Should the

anchored end of the Tray

Strap ever come loose, it

should be reattached to the

bottom hole. It may be necessary to wet it before it will fit

back in the hole.

WARNING: Do not carry the robot by its rubber Tray Strap.

This strap is not designed to support the weight of the robot.

Replace the Tray Strap with the optional Carrying Strap (see pg.

19) if you intend to carry your robot by the strap. After 2006, all

2040+ robots come with the Carrying Strap pre-installed.

12

➨

Pong-Master

Targets

Countries/Areas Part # Pins

N. & S. America, Japan,

Taiwan, China, India, Iran

2050-223B-

US

Europe, Africa, Korea, Russia,

Middle East, S. America

2050-223B-

EU

British Isles, Hong Kong,

India, Nigeria, Middle East

2050-223B-

UK

Australia, South Pacific, New

Zealand, Argentina

2050-223B-

AUS

TRANSFORMER SOCKET ADAPTERS

CHART B

19

MAINTENANCE STEPS & TRANSFORMER SPECS (ALL MODELS)

Robo-Pong robots are easy to maintain. The only maintenance that

our robots require is an occasional cleaning. The Ball Discharge

Wheel and Friction Block are especially prone to dirt build-up.

Periodically inspect these parts and clean with Rubber Drive

Cleaner and a cloth. One indicator that these parts are dirty is errat-

ic delivery—balls are occasionally ejected sideways, down into the

net, or popped up.

It’s possible to clean these parts without disassembling the

robot head. The following steps show how it is done using the

Rubber Drive Cleaner and a cloth. This cleaner is terrific for remov-

ing dirt from rubber surfaces and restores the natural grip to these

parts. If your fingers are too large to clean these parts through the

discharge hole, you will need to disassemble the robot head.

To reduce the amount of dirt that enters your machine, keep

the table, balls, and playing area clean. Dust, pet hairs, carpet fibers,

and other fibrous material can wrap around the drive pin and liter-

ally “strangle” the Ball Speed Motor to stop it from functioning.

When wiping off the outside of your robot, use a damp cloth. Do

not use any petroleum based solvent, cleaner, or lubricant as

these chemicals are corrosive to the plastic. Be careful not to get

water on the motors, Control Box, or the 5 Pin Connector.

REMOVE ROBOT BODY

First, remove the robot

body from the Center

Trough (2040+) or Ball

Bucket (545/1040+). Then

lay it on a flat work surface.

1

CLEAN DISCHARGE WHEEL

Rotate the head so the

word “Backspin” is at

the top of the discharge

hole. To clean the

Discharge Wheel, you

must insert two fingers into the

discharge hole. Wet a clean sec-

tion of the cloth with the cleaner.

Insert one finger into the hole to

hold the side of the wheel and keep it from turning. Now,

insert the wet cloth with your other finger and forcefully rub

the rubber surface of the wheel. After you clean the initial

exposed section of the wheel, rotate the wheel a little with

your first finger to expose the next section of wheel for clean-

ing. Keep cleaning a small section of wheel at a time until

you’ve cleaned the entire wheel. Then use a dry section of

cloth to lightly dry off the wheel. Lastly reattach the robot

body by reversing Step 1.

3

CLEAN FRICTION BLOCK

Make sure the word

“Topspin” is at the top

of the discharge hole.

Wet your cloth with a

small amount of Rubber

Drive Cleaner. Insert the wet cloth

into the discharge hole with your

index finger and rub it forcefully over the curved rubber sur-

face of the Friction Block. Using a dry section of the cloth,

wipe the Friction Block lightly to remove any remaining dirt

and dry it off.

2

Country Input Output Pin

& Part # Specs Specs Shape

USA 120VAC, 12VDC

545-222 60Hz 600mA

Europe 230VAC 12VDC

545-232 50Hz 600mA *

Australia 230VAC 12VDC

545-238 50Hz 600mA

Japan 100VAC 12VDC

545-234 50Hz 600mA

China 220VAC 12VDC

545-235 50Hz 600mA

545 TRANSFORMER

SPECIFICATIONS

CHART A

*Additional adapter (2000-233) required for UK and other British

Commonwealth countries.

➨

➨

➨

➨

➨

TROUBLESHOOTING GUIDE

NOTES: 1. There are no adjustments to any part, so if a faulty or worn part causes the robot to malfunction, replace that part.

2. If you are not well-skilled at soldering, please send in your Control Box for service when soldering is indicated.

Control Box parts are small and easily damaged. Improper soldering may void your warranty and service policy.

3. If you open the 1040+/2040+ Control Box, unscrew ONLY the 4 corner screws. DO NOT remove the 4 screws in

the middle. (See Figure 1B, page 6 for more details.)

4. If the suggestions below do not help, please consult the troubleshooting section of our website at

www.newgy.com. It is updated periodically and will be more current than the information given below.

5. The following solutions will apply to all models of Newgy Robots, except if marked with the following footnotes:

1Robo-Pong 1040+ only, 2Robo-Pong 2040+ only, 5Robo-Pong 545 only.

NO POWER PROBLEMS

1. PROBLEM

No robot functions work and Power Switch on Control Box

does not light up when turned on.

SOLUTIONS

A. Make sure transformer is plugged securely into a

power outlet. Verify there is power in the outlet. Check

that transformer input (on top of transformer) matches

local electrical specifications. See Chart on pg. 17.

B. Check that the pin of the transformer cord is plugged

securely into the Power Jack of the Control Box.

C. Transformer is defective. Test for proper output with a

voltmeter. If defective, replace.

D. If Control Box has been knocked off the table, a break

may have been created on the circuit board. Inspect

and resolder any broken connections. Break is usually

where the Power Jack is soldered to the circuit board.

E. Verify that wires are properly attached to the Power

Switch. Red wire should be closest to “off”. Brown or

white wire should be attached to the middle terminal.

Black wire should be closest to “on”.1,2

F. Power Switch is bad. Replace.

2. PROBLEM

No robot functions work or only work intermittently, and

the Power Switch1,2 lights up when turned on.

SOLUTIONS

A. Make sure Connector Cable is securely plugged in at

both ends.

B. Check fuse in Control Box. If blown, replace.1,2

C. Fuse holder is not making good contact with the fuse.

If loose, tighten; if defective, replace.1,2

D. Bridge Rectifier is bad. Especially indicated if fuse

keeps blowing after power is turned on. Replace.1,2

E. Defective Connector Cable. See Solution 14A.

BALL FEED/FREQUENCY PROBLEMS

3. PROBLEM

Robot will not pick up balls.

SOLUTIONS

A. Pong-Master Scoreboard (an optional accessory) is

controlling Ball Feed. Turn Scoreboard off.1,2

B. Ball jam. See Problem 18.

C. Ball Feed Motor is not running. See Problem 14.

D. Ball Feed Motor runs backward. See Problem 13.

E. Ball Feed transfer gears and/or Main Gear are

damaged or assembled incorrectly. Replace gears with

stripped teeth or other damage.

F. Pickup fingers are broken or loose. If loose, tighten; if

broken, replace.

G. If Control Box emits a high-pitched squeal when

power is turned on, even if Connector Cable (and

Linking Cable from Pong-Master Scoreboard, if

applicable) is unplugged from the box, the U4 chip or

12V Relay on the circuit board is defective. Replace.1,2

H. If problem occurs only at low ball frequency, spray

inside Ball Feed Motor with tuner lubricant/cleaner.

I. Ball Feed Main Gear is frozen to shaft of BF Mounting

Plate. Replace gear and plate.

BALL SPEED/DISCHARGE PROBLEMS

4. PROBLEM

Ball speed seems to be slower than when new.

SOLUTIONS

A. Incorrect Transformer.

B. Hair or fibers are entwined around drive pin of Ball

Speed Motor. Remove Ball Discharge Wheel and

inspect at base of brass shaft on the motor. Clean, if

necessary.

C. The brass shaft on the Ball Speed Motor is loose. The

Ball Discharge Wheel is screwed onto this shaft and

then the shaft is permanently pressed onto the motor's

drive pin. It cannot be reattached. Replace the motor.

Test by holding the rubber wheel with a finger and

then turn power on and adjust Ball Speed to 10. If you

hear the motor spinning while you are holding the

wheel stationary, then the brass shaft is loose. If the

motor does not spin, then shaft is securely fastened.

D. Ball Discharge Wheel and/or Friction Block are worn.

Replace both parts.

E. Ball Speed Motor needs lubricating. Spray inside

motor with an electrical contact cleaner/lubricant.

F. Friction Block (FB) is not moving freely. Test by

pressing FB down with your thumb and visually check

to see if FB tabs are returning to the top of their slots.

If FB is hanging up in its travel, remove FB and smooth

its tabs and/or sides by filing. Also, clean out FB tab

slots in the head housings. Replace FB if necessary.

May also be caused by overtorquing of robot head

screws. If loosening these screws frees up FB travel,

replace left head housing.

G. Potentiometer, Voltage Regulator, and/or Bridge

Rectifier inside the Control Box are bad. Replace.1,2

H. Balls are too small. Check with Ball Dam. See page 11.

5. PROBLEM

Robot picks up balls, but balls just fall out of discharge

opening instead of shooting out.

SOLUTIONS

A. Check balls to be sure a 38mm ball is not mixed in with

20

This manual suits for next models

2

Table of contents