NewLine Anita User manual

Anita 2 Sided and 3 Sided Alcove

1. When you receive your Anita shower check contents for any freight damage of defect.

2. Advise Newline on 0508 639 5463 if any damage has occurred within 8 hours of receiving

the goods so this is can rectied.

3. Do not proceed with installation until resolved as there cannot be a valid claim later.

Important!

INSTRUCTION MANUAL

JULY 2018 V2

2 SIDED & 3 SIDED ALCOVE

1

WARRANTY

• Faultygoodsarecoveredunderwarrantyfor5years.Visitwww.newline.nzforwarrantyinformation.

• Breakagesincurredduringinstallationarenotcoveredunderwarranty.

• Installationsmustconformtotheinstructionstobecoveredbythewarranty

HEALTH AND SAFETY

Toughened Glass:

• Donotreworkpre-cutglasspanels.Cuttingoralteringaglasspanelwillcauseittoexplodewithoutwarning.

• Unpackallglassassemblies.Standglassonsoftpackagingwhenitisontheoorandagainstawall.Caremust

betakennottostrikeanyedgeorcorneragainstahardsurfaceasthiswillchipanddestroytheglasspanel.

Installation:

• Glasspanelsandassembliesareheavy.Twomanliftingisrecommendedforhandlingandinstallation.

• Determinepositioningofwiringandpipingwithinwallcavitiesbeforeshowerinstallation.Marktheirpositionsto

ensureelectricalandpipingareasareavoided.

• Wearappropriateprotectiveclothingandeyeprotectionduringinstallation.

TOOLS REQUIRED

NEWLINE RECOMMENDS A SKILLED TRADESMAN ACQUAINTED WITH

SHOWER INSTALLATIONS IS USED TO ENSURE THE VERY BEST OUTCOME.

IMPORTANT INFORMATION

AFTERCARE

• Theshowermustbesqueegeeddownaftereachshower.Thoroughlycleanweeklywithamicrobercloth,

milddetergentandwater.Rinsewithcleanwaterandsqueegeeandwipeddry.

2

ENSURE YOU TICK THE SPECIFIC BOXES THAT APPLY AS YOU PROGRESS

Floor & Walls:Floormustlevelwithnodeectionandwallsplumbandat.Thisisofallimportancefora

successfulinstallation.

Tray and Liner:InstallationforTiletraysorAcrylicTrays&LineraresuppliedwiththespecicTrayordered

Frame:

1. Wall Prole options

Acrylic Tray:Centred20mmooutsideoftrayedge

Hob Tile Tray:Centred45mmonishedtileedge.(Thiswillallow32mmotraybeforetiling)

Level Entry:Centredatthetransitionline(whereslopebegins)

2. Solid xing for Wall Rail Bracket

A3sidedonlyonthedoorsideadjacentwall.

Attacha300mmverticallengthofframingontheinsideofthewallprolestudstartingatthelowest

pointof1780mmotheoorto2080mmatthetop.

3. Solid xings for wall mounted plumbing ttings

Consultwiththeplumber.

Wet Grade lining: AqualineGib.orequivalent“mustbeusedbehindallshowerinstallationsforcompliance”

Plumbing:UsearegisteredplumberforinstallationallsupplyandwasteitemspriortoTrayandWalllinings

Waterproong “Pronsh Tile Trays”:ThismustcomplywithAS/NZS4858:2004andbeundertakenby

certiedapplicatorandaProducerStatementprovided.Thereisalistofprovensystemsonourwebsite

www.newline.co.nz

Tiling:

1. Newlinerequirestheuseofcompletesystemsbylicenced/trainedapplicators.Waterproong,Tile

Adhesive,GroutingandSiliconedetailingforfullaccountabilityandperformancerequirements.

2. Thetilesmustconformtogradientsprovidewiththe“ProFinishTileTray”tocomplytoNZBuilding

Code.

3. Thelinewhereshowerframesitsmustbelevelforanacceptableinstalloftheshower.

PREPARATION CHECKLIST

ANITA SHOWER - SELECTING THE CORRECT LAYOUT PLAN

There are four layout pages provided. Please ensure you select the correct layout page and combine

this with the installation details.

2ExplodedViewAssemblyDiagram Page 3

2SidedAcrylicLayoutPlanA Page 4

2SidedTilewithProFinishTileTrayLayoutPlanB Page 5

Alcove(DoorOnly)LayoutPlanC Page 6

InstallationSteps Page 7

3

ANITA SHOWER - ASSEMBLY DIAGRAM

REF. DESCRIPTION PART NO. QTY REF. DESCRIPTION PART NO. QTY

1 WallProle K8618 2 13 Rail H8601 1

2 Returnpanel 1 14 Railjoinerassembly K0970 2

3 Doorpanel 1 15 Wallgaskets K1342 2

4 Buerstrip I6105 1 16 Wallcap K1359 1

5 Buer/sealstrip I8526 1 17 Frontxedpanel 1

6 Handleset H8533 1 18 Waterdeector I8595 2

7 Lockinknobsets(door) K1519 2Screw Pack K0895 1

8 Frontglasstorailxing K1526 219 ThreadedScrewsM5x10 2

9 Endblock H8540 220 ScrewsM4x35 8

10 Slidingblocks(L/R) LH:H8557

RH:H8564 221 ScrewsM4x8 8

11 Waterbar H8571 124 Screwcovercaps 8

12 Rollersets(door) K8588 225 C/SScrewsM4x35 2

112

8

8

5

4

1

3

12

13

24

20

17

18

9

11

10

7

7

21

2

6

16

15

14

19

A

A

B

B

Screw Pack

4

ANITA SHOWER: ACRYLIC 2 SIDED - LAYOUT PLAN A

DOTTED LINE:

OUTERCHANNELBOUNDARYLINE

RETURN GLASS EDGE:

5MMBACKFROMDOTTEDLINE

IMPORTANT DETAIL

A

A

MINIMUM / MAXIMUM TABLE

SHOWER TYPE FRONT DOOR PANEL (A) MIN/MAX RETURN PANEL (B) MIN/MAX

1200x900 1165-1180mm 868-880mm

OPTION A: ANITA ACRYLIC SHOWER (APPLIES TO 1200 X 900)

Anita Acrylic Shower with Newline Acrylic Tray and ABS/Acrylic Liner:

SetouttheAnitaShowerbymarkingouttheoutsidelineofthewallchannels(A)12mminfromtheoutsideedge

ofthetray.Thiswillallowforsuitableplacementoftheshowerplussomevariancesfromplumbonthewalls.

Greatervarianceswillneedtobecalculatedinthelayout.

NOTE: Allmeasurements

assumetheoorislevel,

thewallsareplumbandall

surfacesareat.Anyvariation

mustbeadjustedforinthe

measurementsprovided.

5

ANITA SHOWER: TILE WITH PROFINISH TILE TRAY - LAYOUT PLAN B

A

A

DOTTED LINE:

OUTERCHANNELBOUNDARYLINE

RETURN GLASS EDGE:

5MMBACKFROMDOTTEDLINE

IMPORTANT DETAIL

MINIMUM / MAXIMUM TABLE

SHOWER TYPE

FRONT DOOR PANEL (A) MIN/MAX RETURN PANEL (B) MIN/MAX ProFinish Tile Tray

1200x900

1165-1180mm 868-880mm 1200X900

NOTE: Allmeasurements

assumetheoorislevel,

thewallsareplumbandall

surfacesareat.Anyvariation

mustbeadjustedforinthe

measurementsprovided.

OPTION B: ANITA TILE SHOWER WITH PROFINISH TILE TRAY

Anita Tile Shower with ProFinish Tile Tray with Hobs Application:

SetouttheAnitaShowerplacebymarkingouttheoutsidelineoftheWallchannels(A)30mminfromtheoutside

edgeofthetiledhob.Thiswillallowforsuitableplacementoftheshowerplussomevariancesfromplumbonthe

walls.Greatervarianceswillneedtobecalculatedfromtheminimum-maximumtablebelow.

PENETRATION OF WATERPROOFING

Waterproongwarrantieswillpotentiallybevoidiftherearepenetrationsthroughthemembrane.UseBostikV60to

bondwallchannelstothetiles.Allowtocureascartridgeinformation.

Ifpenetrations’throughthewaterproongareundertakenyoumustensureyouhaveanacceptablesolution

andifusinganchors’thesemustbebelowthewallcladdingsurface.Recordthedetailsastheinstalleriswholly

responsibleforfailures.

MINIMUM / MAXIMUM TABLE

Shower Type Front Door Panel (A) Min/Max Return Panel (B) Min/Max Pronish Tile Tray

1200x900 1165-1180mm 868-880mm 1200X900

6

ANITA ALCOVE (DOOR ONLY) - LAYOUT PLAN C

NOTE: All measurements assume the oor is level, the walls are plumb

and all surfaces are at. Any variation must be adjusted for in the

measurements provided.

This is a brief overview of how to set up a door assembly only. This runs in conjunction with the general

instruction sheet.

Step 1Establishanouterboundarylineacrossthebaseandupeachwall(usethe‘ShowerLineto

TrayEdge’Tableabove).

Step 2Onthesideofthexedglassfastenthewallchannel(1)(ReferItems1.1and1.2,Page9)

Step 3Placefrontxedglasspanelinposition (21) (Referitem2,Page9).

STEP 4FixtheRail(13)tothefrontglass (21)withRailxings (8)(Referitem3.2only,Page10)

Next StepToreplicatethemountingpointontheoppositesidefortheRail.

A:Measuretherailpositionbackfromtheouterboundarylineatthexedglasswallend.

B:Measuretheheightfromthebasetotherailalsoonthexedglasswallend.

C: MarkAandBonoppositeside.Holdthelevelontherailanddoublecheckthe

markedheight.

E:UsetherailJoinerassembly (15)tomarkthetwoholesonthewall.

F:PredrillthewallandfastenupJoinerassemblytoboththeWallandtotheRail.

All other installation steps can be now followed in the general instructions eliminating the return panel details

that do not apply.

OPTION C: ANITA ALCOVE (1200 DOOR SET) WITHTILE

BASEANDACRYLICBASEAPPLICATIONS

ThefollowingtablecoverstheDoorSizewiththeMinimum

andMaximumRange.Caremustbetakenifusingthe

minimumormaximummeasurementsasdiscrepanciesin

thewallsorbasemaynotallowforthis.

SHOWER DOOR TYPE FRONT DOOR PANEL MIN/MAX

1200 Door 1166 - 1180mm

SHOWER LINE TO TRAY EDGE

AcrylicTray 12mm

ProFinishTileTray(Hob) 30mm

ProFinishlevelentrytrayattransitionline(Slopestarts)

Height

Depth

Dotted Line:

Outer boundary

Shower Line to Tray Edge

(See Table)

Rail Joiner:

Mounted L/H or

R/H only

14

PENETRATION OF WATERPROOFING

Waterproongwarrantieswillpotentiallybevoidiftherearepenetrationsthroughthemembrane.UseBostikV60to

bondwallchannelstothetiles.Allowtocureascartridgeinformation.

Ifpenetrations’throughthewaterproongareundertakenyoumustensureyouhaveanacceptablesolution

andifusinganchors’thesemustbebelowthewallcladdingsurface.Recordthedetailsastheinstalleriswholly

responsibleforfailures.

25

7

1.1 1.2

ANITA SHOWER - INSTALLATION INSTRUCTIONS

IdentifythespecicLayoutPlanapplicabletoyourspecicshower.UsethecorrectLayout

Planinconjunctionwiththeinstallationinstructions.Markoutthewallchannelstakinginto

accounttheguidancenotes.

1.1

1.2

2

Acrlyic:

Pre-drill lead holes in the wall lining matching up to the Channel holes.

Apply silicone to the back of the channel and x in place with the M4 x 35 screws ensuring that the

channel remains plumb.

Insert the return panel (2) and xed front panel (22) into the wall channels (1).

TILING NOTE: Place 10mm wide thin clear plastic strips as isolation packers at 90 degrees under

the xed glass. Finally before nishing with silicone, trim the excess with a knife.

TILE: BondthewallchannelstothetileswithBostikV60.

(Referbacktotilelayoutpagere-penetrationofwaterproong)

8

Install rail bracket components (14, 15, 17 & 18) to return panel.

Insert the rail (13) into return glass bracket and attached to the front panel with the two glass xing

pieces (8) and tighten these. Tighten the allen keys on the joiner (15) to the rail (13) when the return

glass is at 90 degrees off wall. If more adjustment is required move the glass front panel within the

wall channel.

The return panel leading edge is positioned 5mm back from the outer channel line as in the Layout

plan. Plumb the glass edge and the assess if the adjustment in our out of the return panel is needed.

As this effects the door running parallel at the bottom.

ENSURE A PLASTIC GLASS PROTECTOR IS USED BETWEEN ALL METAL PARTS AND THE GLASS

3.1

3.2

3.3

3.1 3.2

3.3

B1

C1

RETURN

PANEL

ENSURE PANELS

REMAIN LEVEL

FIXED GLASS

FRONT PANEL

C1:

DOTTED LINE:

OUTER CHANNEL BOUNDARY LINE

GLASS LINE:

5MM BACK FROM DOTTED LINE

18

17

15

14

A1

GLASS

RAIL

IMPORTANT DETAIL

9

4.1

4.2

4.3

4.4

4.5

Install the roller sets (12) to door panel (3). Rollers should be on the outside of the door. Fit water

deector on bottom edge of door.

Hang the door on the rail from inside of the shower.

Carefully slide the door toward the return panel and check the gap between door and return panel

is even. Adjust if necessary using offset in rollers or adjustment from the rail support. At this point

assess if the return panel needs to go in or out slightly to align the door parallel to the tray.

Bond with Silicone the following parts to the tray. Sliding block (10) slotted into the glass front panel

edge and the waterbar (11) positioned parallel to the outside edge of the tray going across to the

end block (9) against the return panel. Tape in position and allow a minimum of 24 hours for this to

cure.

Install lock in knobs on the door & tighten rail xings.

4.5

4.1

4.2

4.3

4.4

WATER DEFLECTOR (24)

10

5.1

5.2

Plumb the ends of the glass. On the inside of shower drill 3.2mm holes through both the xed panel

proles and into the wall channels (NOTE: Ensure that the chosen position avoids drilling through

the glass - see Diagram 5.1). Screw together using M4 Screws (21). Cover the screws with screw

cover caps (22).

Install leading edge buffer strip (4), buffer/seal (5)

Install the handle set (6) with the locking screws on the inside of the shower.

5.3

FIXED GLASS PANEL

FIXED PANEL

PROFILE

BUFFER STRIP (4)

BUFFER / SEAL STRIPS (5)

ENSURE GLASS PANELS

REMAIN LEVEL DURING

INSTALLATION PROCESS

CHANNEL WALL

5.1

5.2

5.3

10

Apply high quality neutral cure silicone to the outside.

DO NOT USE SHOWER FOR 24 HOURS

Siliconeisnotusedontheinsideoftheshowerscreenbecausewatercanbuildupovertime

withinthewallchannelandleakoutoftheshowerarea.Thescreenisdesignedtoallowthe

watertoreturnintotheshowerarea,ifanyispresent.SCREENS THAT ARE SEALED ON THE

INSIDE WILL VOID WARRANTY.

24 HOURS

6

Freephone: 0508 639 5463 Phone: 09 444 2053 Fax: 09 443 0044

Table of contents

Other NewLine Other manuals

Popular Other manuals by other brands

FabiaTech

FabiaTech FD7851 Series user manual

Aquadistri

Aquadistri Superfish JellyFish quick start guide

CPR

CPR Callblocker CS600 user guide

Aquagarden

Aquagarden Marlin 300 instruction manual

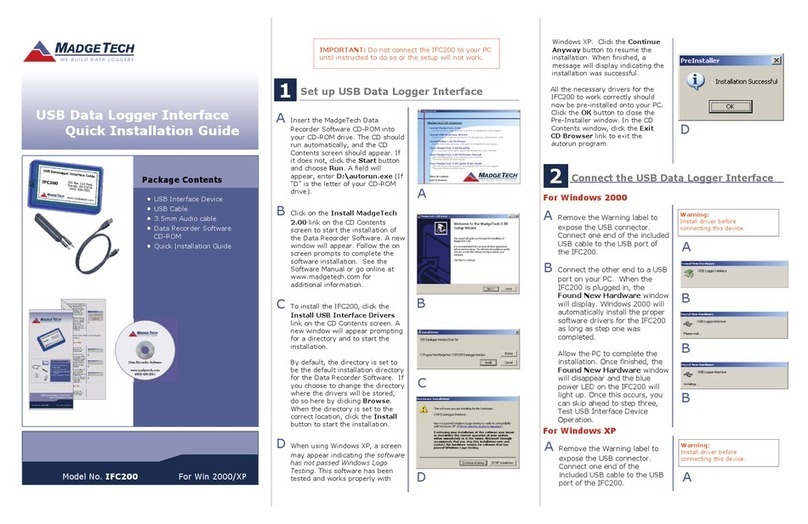

MadgeTech

MadgeTech IFC200 Quick installation guide

Whelen Engineering Company

Whelen Engineering Company PAR-32 LINZ6 installation guide