TABLE OF CONTENTS

Replacing External Parts

Face cover .................................................................................................................................................................1

Belt cover ..................................................................................................................................................................1

Top cover unit ............................................................................................................................................................2

Base plate..................................................................................................................................................................3

Base cover.................................................................................................................................................................3

Bed cover ..................................................................................................................................................................3

Free arm cover ..........................................................................................................................................................4

Front cover.................................................................................................................................................................5

Rear cover .................................................................................................................................................................6

Replacing Mechanical Parts

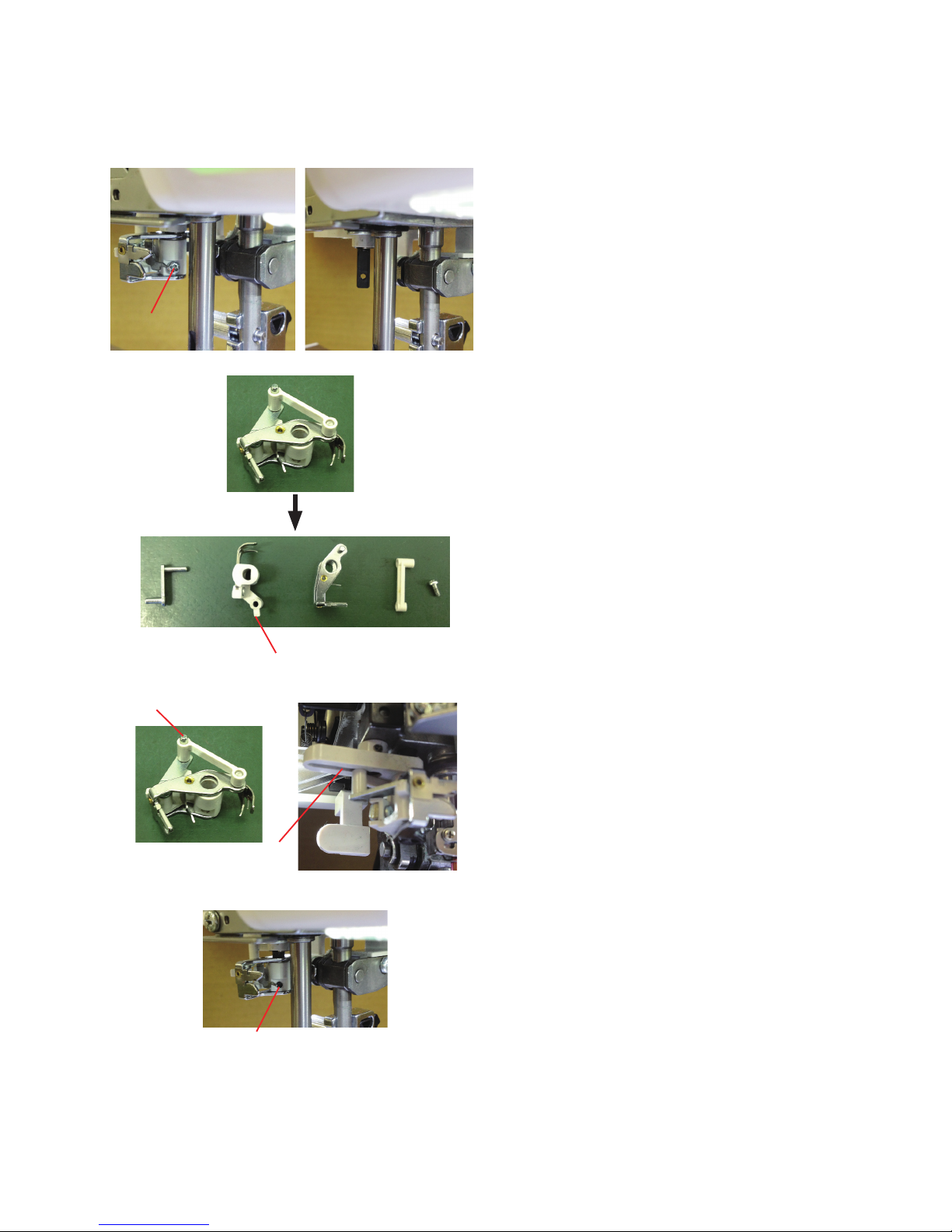

Needle threader holder (threader hook) ....................................................................................................................7

Replacing Electronic Components

Printed circuit board A ...............................................................................................................................................8

Printed circuit board U1.............................................................................................................................................9

Printed circuit board U2...........................................................................................................................................10

Printed circuit board K .............................................................................................................................................11

Printed circuit board F .............................................................................................................................................12

Auxiliary power supply unit......................................................................................................................................13

Switching power supply unit ....................................................................................................................................14

USB unit ..................................................................................................................................................................15

Driving motor ...........................................................................................................................................................16

Thread tension unit..................................................................................................................................................17

Needle threader motor.............................................................................................................................................18

Mechanical Adjustment

Feed dog height.......................................................................................................................................................19

Needle drop position................................................................................................................................................20

Hook Timing.............................................................................................................................................................21

Needle bar height ....................................................................................................................................................22

Clearance between needle and tip of rotary hook............................................................................................. 23-24

Backlash between hook drive gear and lower shaft gear ........................................................................................25

Upper shield plate position ......................................................................................................................................26

Upper thread tension...............................................................................................................................................27

Tension release mechanism ....................................................................................................................................28

Needle threader hook position.................................................................................................................................29

Thread drawing lever...............................................................................................................................................30

Upper feed dog.................................................................................................................................................. 31-33

Buttonhole lever adjustment ....................................................................................................................................34

Thread cutter ...........................................................................................................................................................35

Presser bar lifter position.........................................................................................................................................36

Presser foot lifter stopper position ..................................................................................................................... 37-39

Automatic presser foot lifter initializing sensor position ...........................................................................................40

Presser bar height ...................................................................................................................................................41

Embroidery foot height ............................................................................................................................................42

Stretch stitch balance ..............................................................................................................................................43

Knee lifter ................................................................................................................................................................44

Remaining bobbin thread sensor.............................................................................................................................45

Cloth guide start position.........................................................................................................................................46

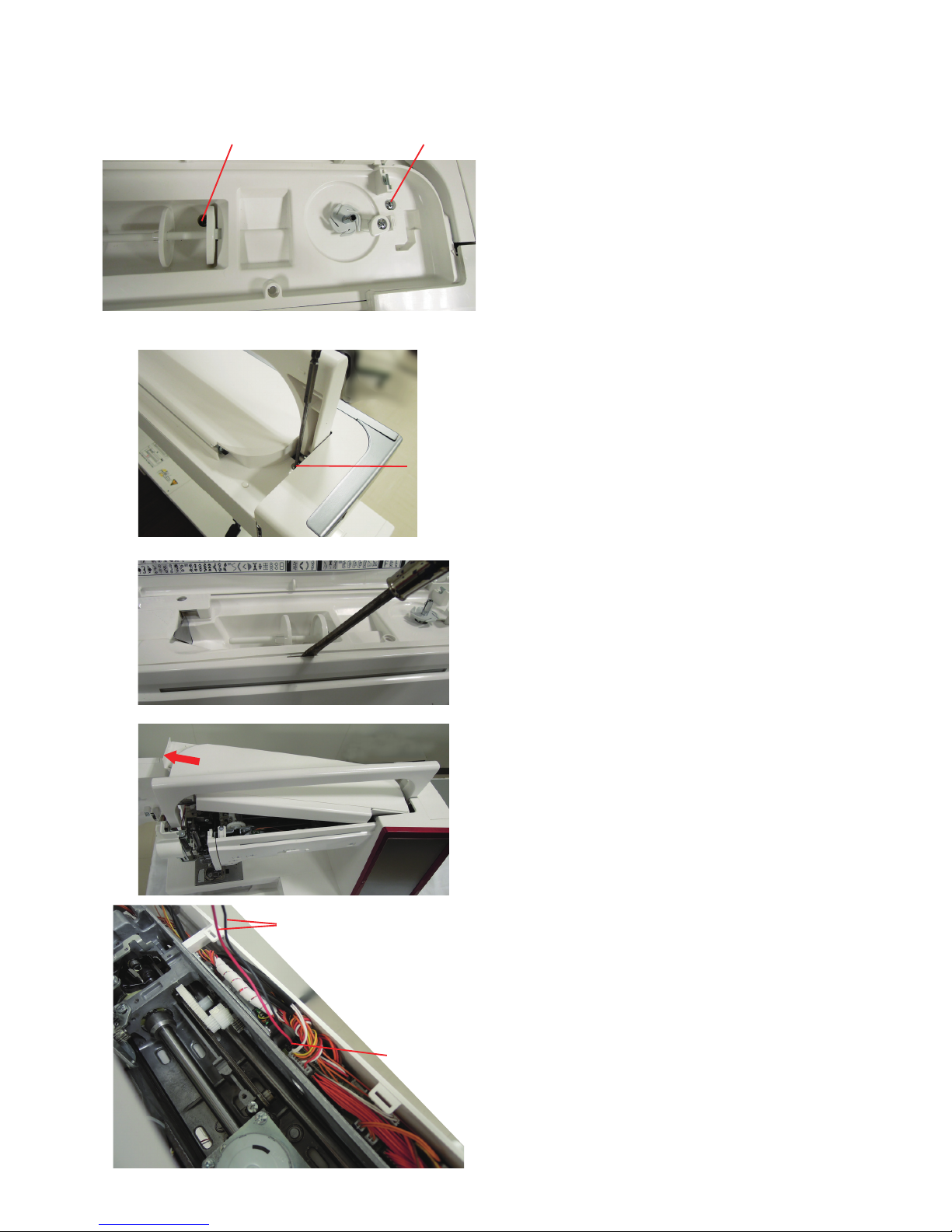

Preparation ........................................................................................................................................................ 47-50

• Removing Y-carriage cover (upper) ...................................................................................................................... 47

• Removing X-carriage cover and Embroidery unit cover.................................................................................. 48-50

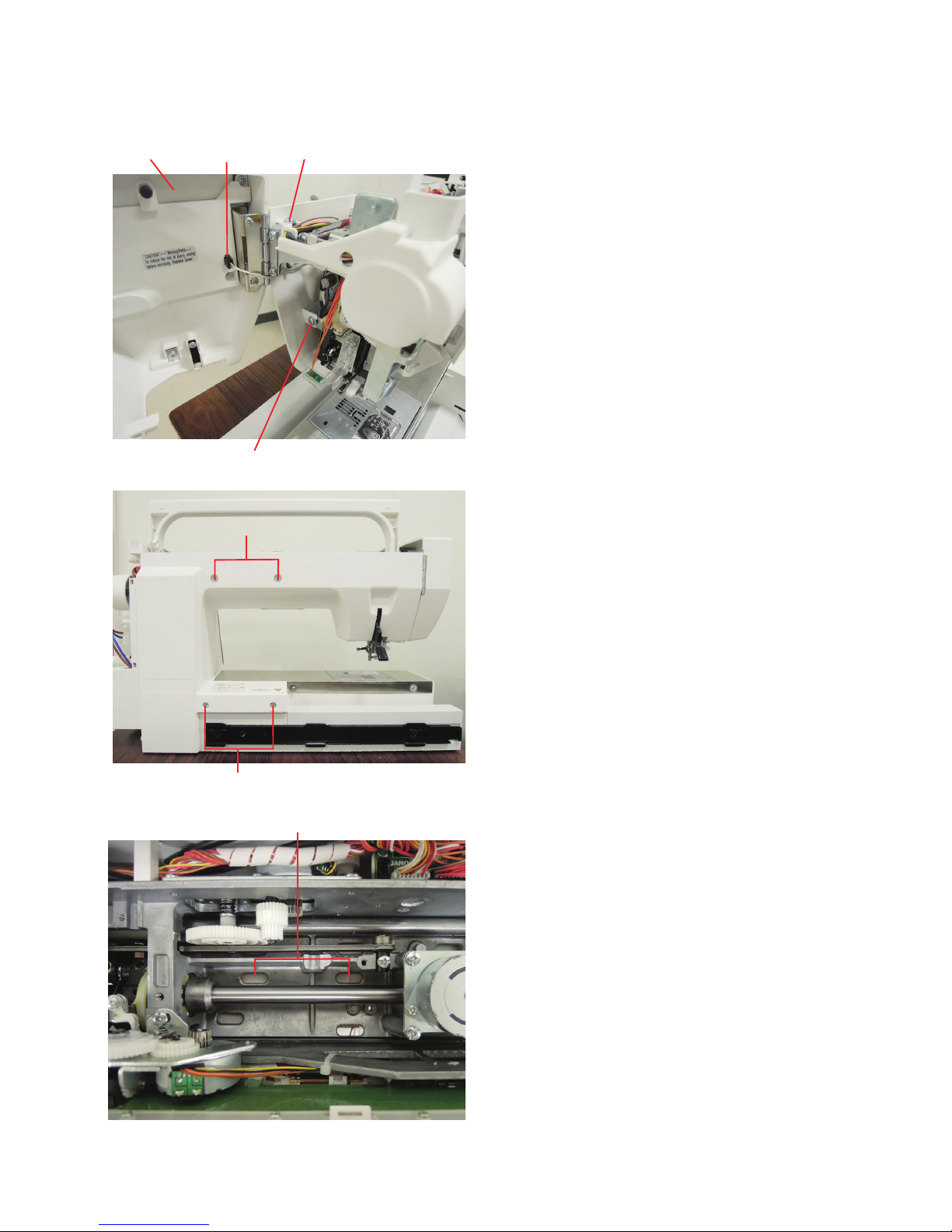

Replacing X-motor.................................................................................................................................................. 51

Replacing Y-motor............................................................................................................................................. 51-56

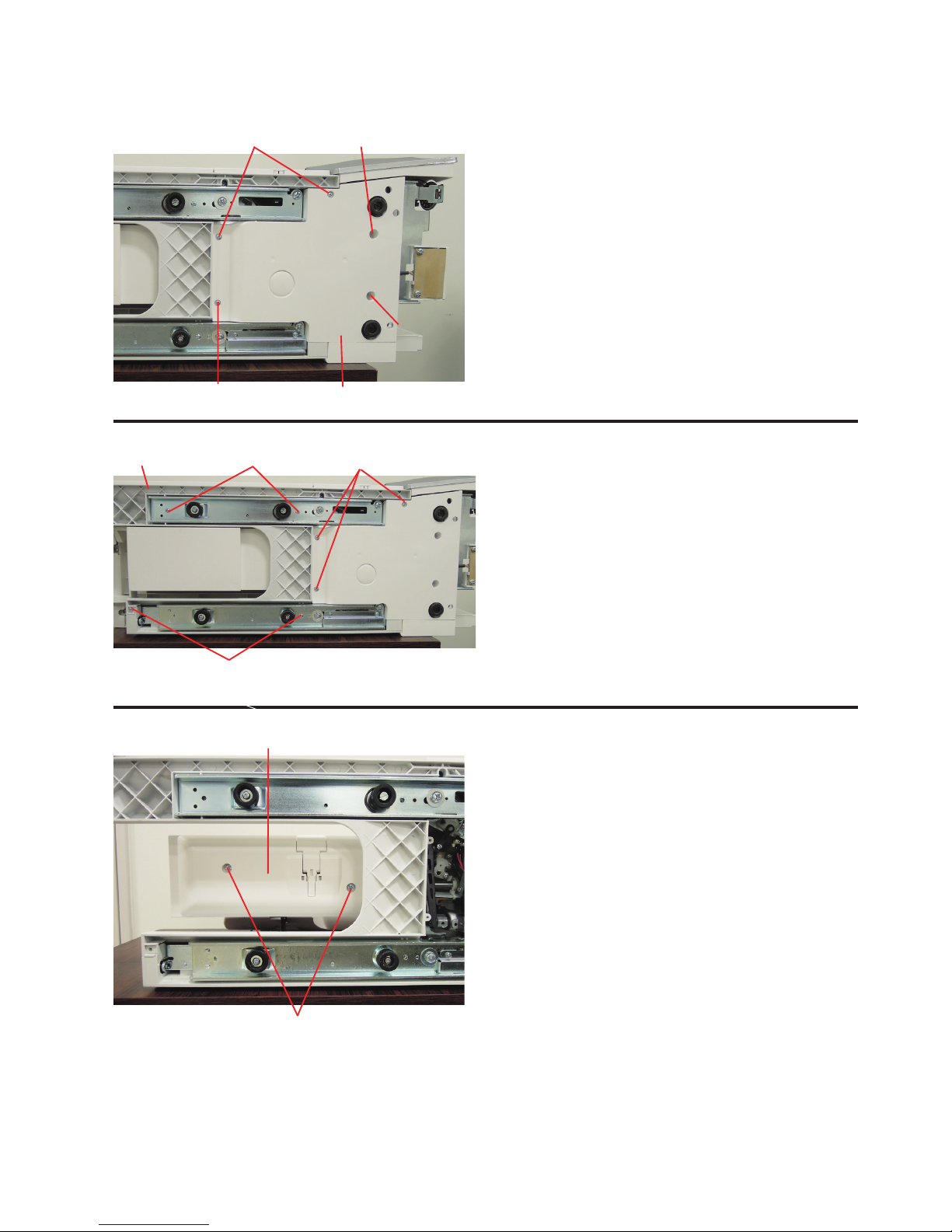

• Removing Y-carriage cover (lower)................................................................................................................. 51-52

• Removing Film ..................................................................................................................................................... 52

• Removing Film guides.......................................................................................................................................... 53

• Removing Y-carriage ...................................................................................................................................... 53-54

• Removing Y-motor .......................................................................................................................................... 55-56

Replacing Printed Circuti Board S1........................................................................................................................ 57

Replacing Embroidery Unit Detecting Switch......................................................................................................... 57

Replacing Film........................................................................................................................................................ 58

Replacing X-sensor .......................................................................................................................................... 59-60

Replacing X-belt ..................................................................................................................................................... 61

Replacing Printed Circuit Board S2........................................................................................................................ 62

Replacing Y-sensor ................................................................................................................................................. 62

Replacing Y-belt ...................................................................................................................................................... 63

Carriage Adjustment (Backlash of Y-carriage) ........................................................................................................ 64