Newport Brass 1-594 User manual

INSTALLATION INSTRUCTIONS

Tempress Pressure BalancingValve

Valve Body No. 1-594

as used with Shower Fittings

D

Description

This valve is precision engineered to provide satisfactory performance provided it is installed and operated in

accordance with our recommendations contained in these instructions. In order to fully enjoy the comfort,

safety and the reliability of this valve, be certain to familiarize yourself with these instructions.

Operation

The pressure balancing cartridge contained in this valve compensates for pressure fluctuations in the water

supply system through a diaphragm-connected pressure balancing mechanism.The outlet temperature will

change by no more than a mere ±2°F (1°C) with a 50% drop in either the hot or cold water pressure.

Even if the coldwater pressure fails completely,the anti-scald design will reduce the flow rate to a safe level

ensuring reliable protection against scalding.The built-in check valves prevent cross flow between the hot and

cold supplies.

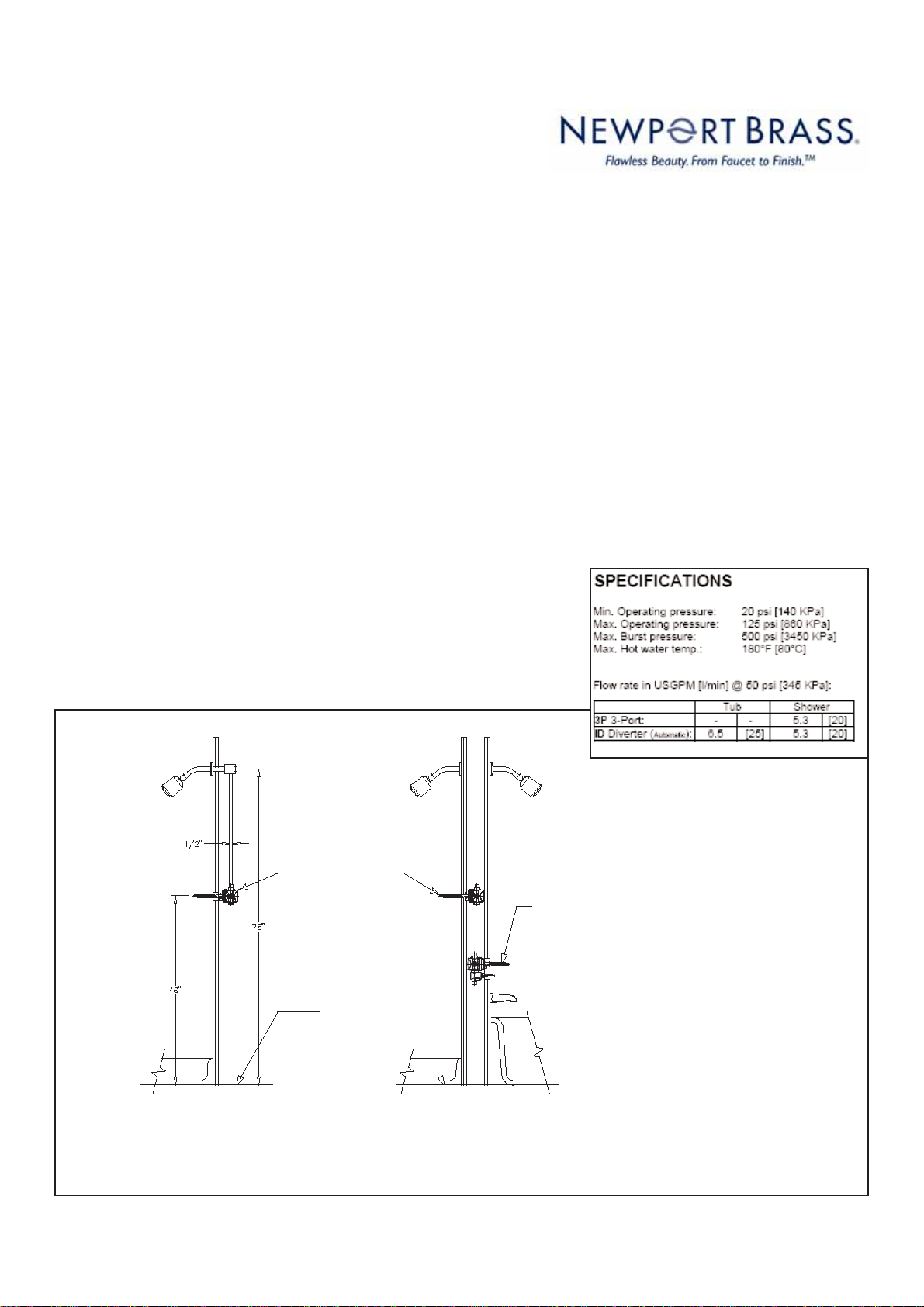

Illustration 1

Balance

Pressure Valve

w/ Diverter

Floor Line

Back-to-Back Installation

In back-to-back installations, one cartridge

must be rotated 180 degrees to ensure

proper valve operation.

Standard Installation

Balance

Pressure Valve

w/ Diverter

Floor Line

1-594 1-595 Balance

Pressure Valve

w/ Diverter

Floor Line

Back-to-Back Installation

In back-to-back installations, one cartridge

must be rotated 180 degrees to ensure

proper valve operation.

Standard Installation

Before you begin

Make sure valve is securely fastened to studs.Be sure to remove trim items,handles,escutcheons and plates before

installation.Wrap carefully and store until finished wall is completed.

Install the valve by positioning the 1/2” shower outlet in the up position.Finished wall must be within dimensions

shown on the chart below.

On tiled wall surfaces,grouting must be either flush or raised for proper sealing of the cover plate.

IMPORTANT

:It is not necessary to remove the cartridge from the valve during

NORMAL

soldering operations using

propane-butane gas.

DO NOT USE OXYGEN-ACETYLENE

. When soldering CxC connections,do not solder within

4” of valve port.Open the stop valves when soldering inlets.

To test pipe joints, pressurize both hot and cold inlets.

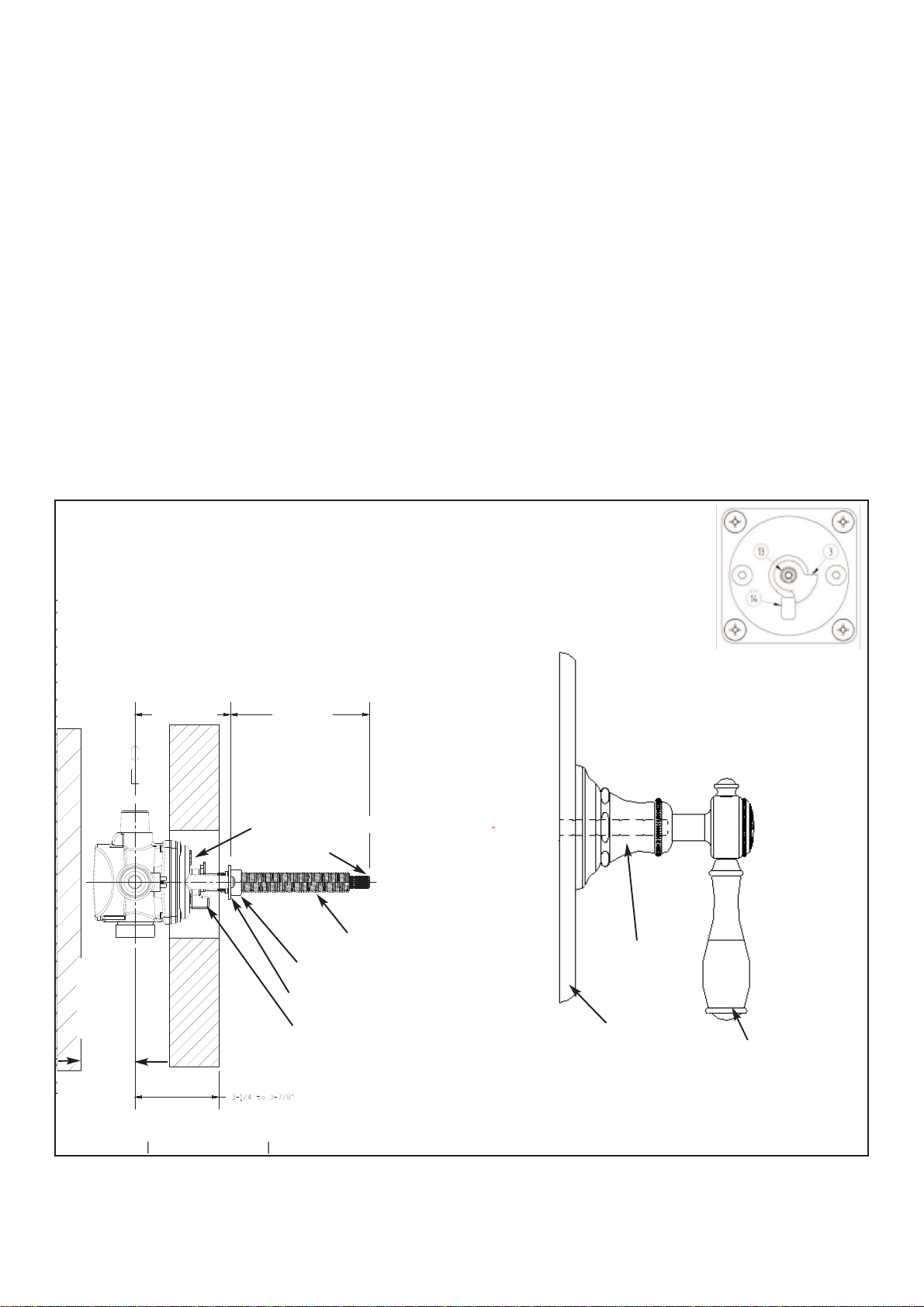

Installing Trim

Place cover plate on valve stem and slide into position.Install escutcheon/bonnet trim and mark the all-thread nipple,

(Item 1) were excess needs to be trimmed.

Remove escutcheon/bonnet trim and cut all-thread nipple 1/16” less than indicated mark to prevent exposure of nipple

threads.NOTE: Do not cut stem, (Item 6), or all-thread nipple until finished wall is complete and a dimension check of

handle and escutcheons/bonnet trim is done. (Stem is grooved at ½” intervals) Cut stem at least ½” past the end of

the cut all-thread nipple.Final stem length may vary based on individual handle base insertion.Reinstall escutcheon/bon-

net trim and handle. Secure handle into place by tightening the handle setscrew.(Ref.Illustrations 2 & 3)Turn on water

supply to check for leaks.

Illustration 2

Face of stud

Escutcheon

All thread

nipple

Broach stem

4” hole for valve

Cover plate Handle

Retaining plate

Stop block

Locking nut

Face of finished wall

NOTE:Dimensions shown are from the inlet ports to the finished wall.

NWP-1-594

Face of stud

Ensure that the stop ring (3) is

correctly installed as follows:

- Rotate the cartridge stem (13)

fully clockwise.

- Position the stop ring on the

stem such that it rests against

the stop post (14).

The stop ring must be correctly

installed prior to finish trim

installation.

3-1/8” 3-3/4”

1-3/8”Min

Setting the Temperature Limit Stop

This valve has an upper temperature limit stop ,which can allow desired and

safe hot water temperature (recommended maximum is 110°F).This stop

may be adjusted once the valve is installed.Before making this adjustment,

run the water with the valve turned to the hot setting.If the water temper-

ature is too high in this position,then perform the following adjustments:

·

Remove the trim (handle, escutcheon and cover).

·

Remove the all-thread nipple, retaining screws and retaining plate.

·

Remove the broach and the limit stop.Do not remove the mechanical

stop.

If for any reason the mechanical stop or the cartridge is removed, the follow-

ing steps must be performed:

1.Close the valve by turning the cartridge stem clockwise

until it stops,(Do not forcefully rotate).

2.Position the mechanical stop on the cartridge against

the stop block as shown in Illustration 5 and continue with the following

steps.

·

From the CLOSED position, rotate the cartridge stem counter-clockwise

until the desired temperature is achieved.

·

Place the limit stop on the cartridge stem against the stop block as shown

in Illustration 7.Rotate several times to make sure the stop is at the desired

temperature setting.

·

Replace the full extension broach, retaining plate and screws,all-thread,nip-

ple and locking nut.(NOTE:For stem to be fully seated into cartridge, all-

thread nipple and locking nut must be tightly secured against retaining

plate.)

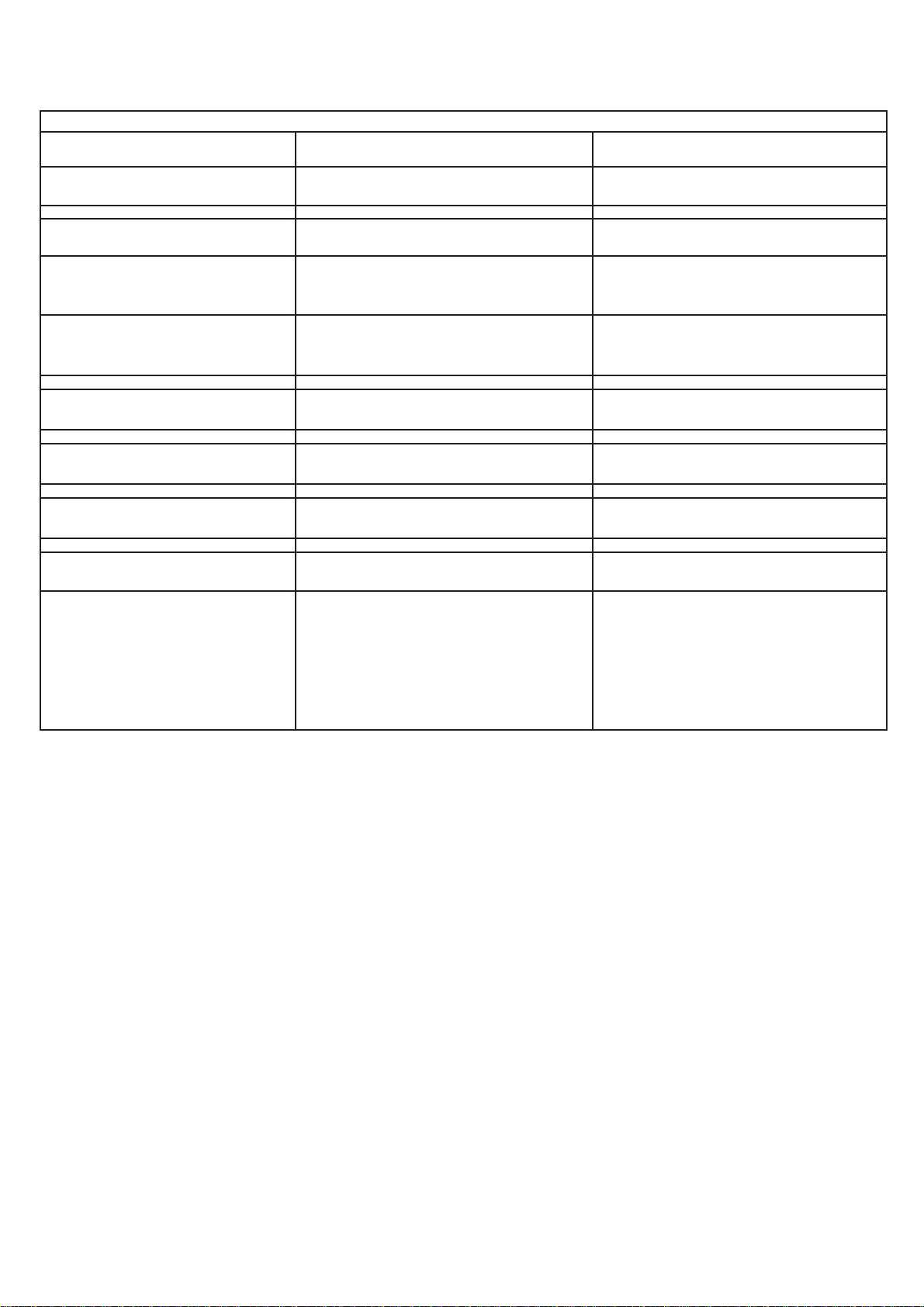

Illustration 3

Illustration 4-7

9/16/2011

1

2

6

5

43

7

8

9

10

11

12

13

14

15

Item Qty Description P.N.

1 1 All-Thread Nipple 10631

2 2 Retaining Plate Screw 92014

3 1 Retaining Plate 11459

4 1 O-ring 91099

5 1 Full Broach 10632

6 1 Limit Stop 10493

7 1 Mechanical Stop

8 1 O-ring 91049

9 4 Cover Screw 10714

10 1 Valve Body Cover -

11 1 Cover O-ring -

12 1 Cartridge 1-207

13 2 Check Vavle 11491

14 1 Valve -

15 1 Locking Nut 10259

* WARNING - Never try to stop dripping by applying extreme force or overtightening the handle.

MALFUNCTION CAUSE REMEDY

Opening immediately to hot water. Hot and cold water supplies have been

connected in reverse. Rotate cartridge. (See Page 3)

Water drips after shutting off the

valve. Residual water in valve and piping. Allow approximately 3-8 minutes to drain.*

Incorrect setting of the mechanical stop

against the stop block causing a partially

opened cartridge. Reset the mechanical stop. (See Page 3)

O-ring seal on the inlet of the cartridge is

faulty or seat assembly is damaged.

Check the O-ring & seat for cuts or over-

heating damage during installation.

Replace if necessary.

Water insufficiently hot. Adjustable handle position stop incorrectly

set. Refer to the instruction on “Setting

Temperature Limit Stop”.

Valve body too deep into wall. The measured rough in or finished wall sur-

face is incorrect. Reset the valve.

Diverter will not stay on during show-

er. Not enough backpressure between shower-

head and diverter valve. Flow restrictor @ shower head 2.5 GPM

No or low flow of hot or cold water. Either the hot or cold side is not fully pres-

surized. Verify that all service stops for both the hot

and cold are fully open and pressurized.

Debris caught inside the inlet of the car-

tridge.

Remove the cartridge (See Page 3). If

debris is lodged in the inlet of the cartridge

or check the valve located in the cast valve

body. The debris can be removed with a

straightened paper clip or fine wire. Gently

insert the wire and move it in a circular

motion to dislodge any debris.

(949)417-5207

NWP-1-594 SantaAna, CA 92704 9/16/2011

www.brasstech.com

Other Newport Brass Control Unit manuals