Installation Instructions

In-wall Lavatory Valve

Model: 1-532 and 1-532T

We Recommend Installation by a Professional Plumbing Contractor.

Note: Use plumbers tape or equivalent to seal all threaded port joints. This valve is designed to fit in a 2" X 4" stud

wall (or thicker) installation. Use stem extension kit #1-384 (sold seperately) if valve installed is too far away from

finished wall.

Warning:

To prevent severe damage to the valve, any solder/braze process must be performed a minimum of 4"

from ports, otherwise cartridge must be removed from the valve body.

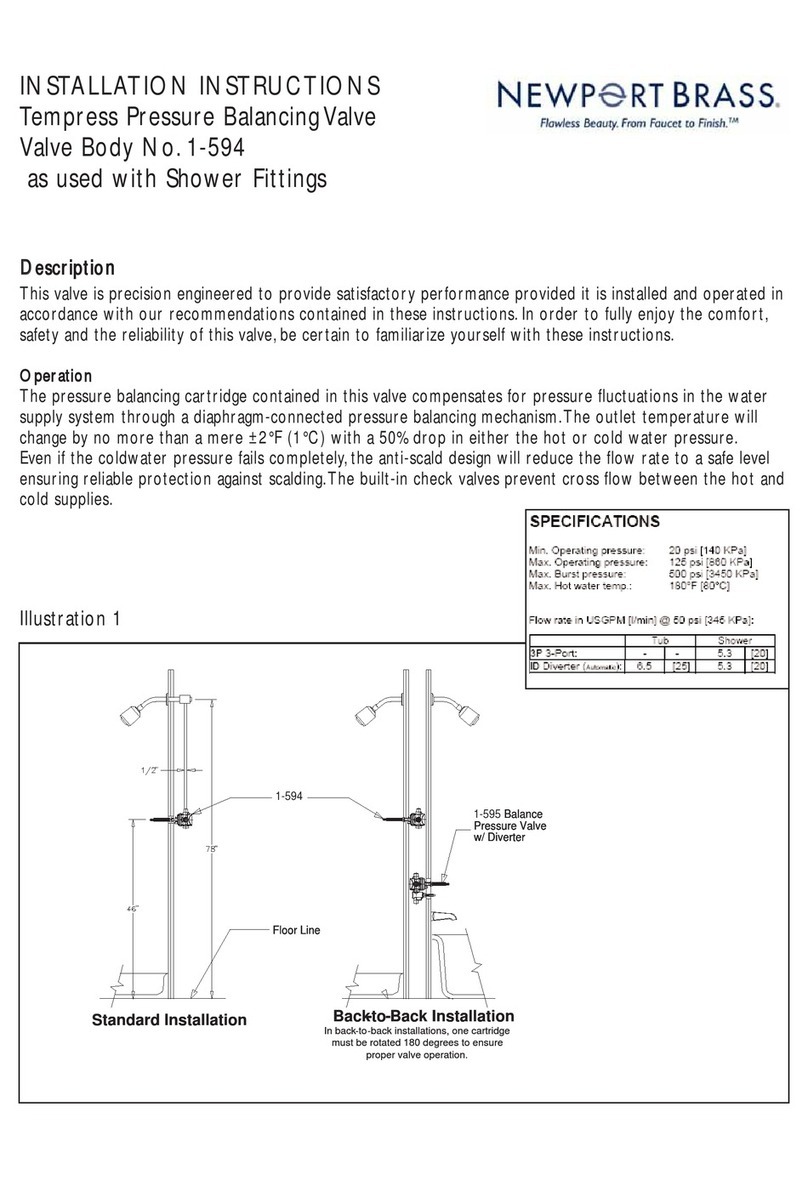

1. Use a metal strap or screw (not included) to position BODY to be 4” – 4 1/2", asmeasured from the

back side of the valve BODYto the Finished Wall surface as shown in Fig. 1 and Fig. 2 below.

2. Check the horizontal and vertical level of the valve BODY by placing a bubble across each STEM.

Also, ensure each STEM is perpendicular to the Finished Wall. Make any necessary adjustments.

3. Utilize 1/2"copper supply pipe and 1/2" Socket End x 1/2"NPT Male Pipe Adapters to sweat water supply line

to the inlets of the valve BODY (blue STEM is cold, red STEM is hot). If sweating within 4” from valve inlets,

remove cartridges during this process.

Note : If cartridges are removed during installation

,

re-torque to factory specification of 14-16 ft-lbs.

4.

FOR VALVE MODEL 1-532T ONLY.

Use lever handle from Wall Mount Lavatory Trim to adjust

stiffness of stem rotation by tightening or

loosening

TORQUE NUT (shown in Fig. 2). Check stiffness by placing

lever handle in horizontal position onto cartridge STEM. Handle should not rotate under its own weight.

(Note:

Water supply to valve should still be off; water pressure may affect the stiffness of stem.)

5.

With each STEM in closed position, turn on water supply, pressurize system and check for leaks. Next,

position a bucket in front of valve outlet, use pliers to slowly open the hot first and then cold valve. This is to

flush out any debris and check for any blockage within the valve. Allow the water to flow for at least one

minute. With the water pressure on, close the valves and carefully inspect for leaks. Repair or adjust as

needed.

6.

Installation for In-wall Lavatory Valve is now completed. Proceed to complete Finished Wall surface

(Important:to ensure enough clearance to remove the cartridge for future service, openings of the Finished

Wall around the cartridges are to be round, with a diameter between 1 1⁄8– 1 1⁄4" and concentric with the

cartridge STEM). To install Wall Mount Lavatory Trim, follow installation instruction provided with the trim

product.

NWP-1-532

2001 CARNEGIEAVE,

SANTA

ANA CA

92705

(949)

417-5207

WWW.NEWPORTBRASS.COM

06/13/2018