6

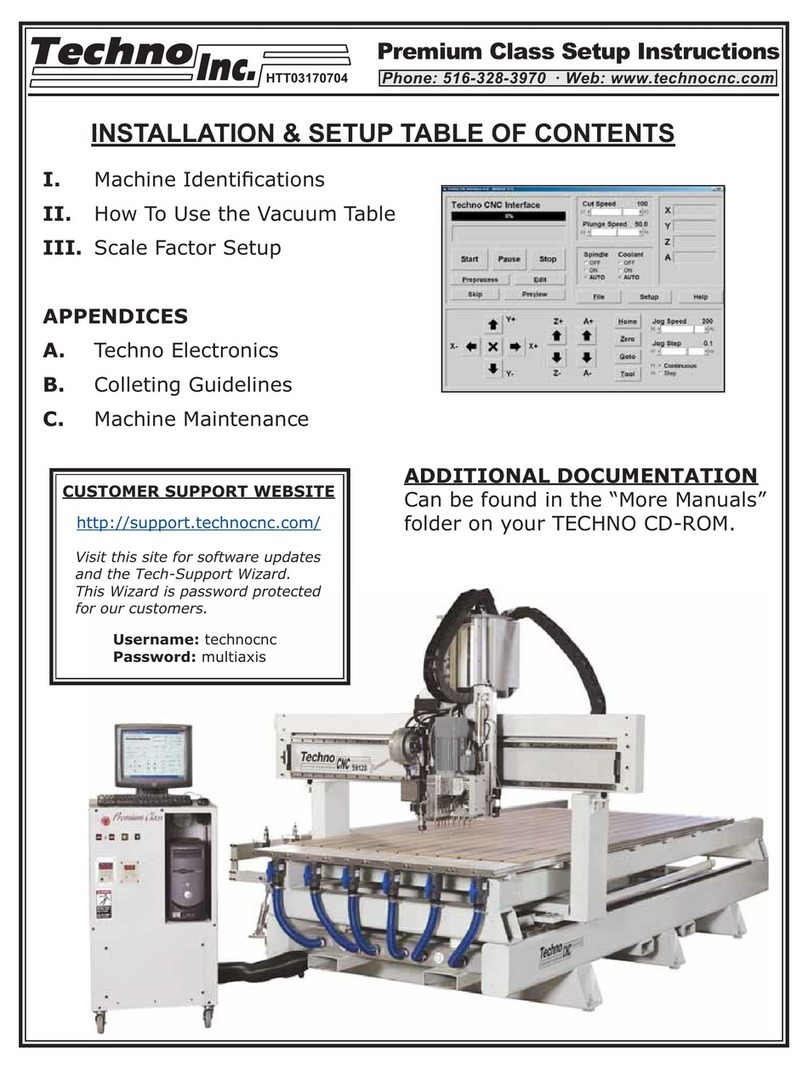

REVERSE RUN STATE - If an axis is moving in the reverse direction,

pressing this switch will stop the motion. If the axis is

moving forward, pressing this switch will cause it to

reverse direction. When moving, the velocity of the axis

is controlled by the VELOCITY STEP SIZE potentiometer.

When an overload occurs or an end of travel limit is

encountered, the REVERSE LIMIT LED lights up and the

axis will stop, but the position servo will remain active.

JOG STATE - If the axis is not moving, pressing this switch

will initiate a step movement in the reverse direction. The

size of the step is determined by the VELOCITY-STEP SIZE

potentiometer. If an axis is in the act of jogging forward,

the switch will have no effect. When an overload occurs

or an end of travel limit is encountered, the REVERSE

LIMIT LED lights up and the axis will stop, but the posi-

tion servo will remain active. Note that the maximum

velocity will be the same value that was set during RUN

State.

FORWARD RUN STATE - If the axis is moving forward, pressing this

switch stops the motion. If the axis is moving reverse,

pressing this switch will cause it to move forward. When

moving, the velocity of the axis is controlled by the

VELOCITY-STEP SIZE potentiometer. When an overload

occurs or an end of travel limit is encountered, the

FORWARD LIMIT LED lights up and the axis will stop.

JOG STATE - If the axis is not moving, pressing this switch

will initiate a step movement in the forward direction.

The size of the step is determined by the VELOCITY-STEP

SIZE potentiometer. If an axis is in the act of jogging

reverse, the switch will have no effect. When an overload

occurs or an end of travel limit is encountered, the

FORWARD LIMIT LED lights up and the axis will stop, but

the position servo will remain active. Note that the

velocity will be the same value that was set during RUN

State.

RUN STATE - When the actuator is moving, the potenti-

ometer sets the real-time velocity of the actuator. The

setting of the potentiometer determines the maximum

velocity at which the actuator will move.

JOG STATE - The potentiometer varies the jog step size.

Note that the maximum velocity will be the same value

that was set during RUN State.

VELOCITY–

STEP SIZE

CONTROL