Techno Premium Series Manual

Techno

Inc.

HTT03170704

Premium Class Setup Instructions

Phone: 516-328-3970 · Web: www.technocnc.com

ADDITIONAL DOCUMENTATION

Can be found in the “More Manuals”

folder on your TECHNO CD-ROM.

INSTALLATION & SETUP TABLE OF CONTENTS

I. Machine Identifications

II. How To Use the Vacuum Table

III. Scale Factor Setup

APPENDICES

A. Techno Electronics

B. Colleting Guidelines

C. Machine Maintenance

CUSTOMER SUPPORT WEBSITE

http://support.technocnc.com/

Visit this site for software updates

and the Tech-Support Wizard.

This Wizard is password protected

for our customers.

Username: technocnc

Password: multiaxis

Techno

Inc.

HTT03170704

2

Premium Class Setup Instructions

Phone: 516-328-3970 · Web: www.technocnc.com

Continue to next page …

HAVE A LICENSED ELECTRICIAN PERFORM ALL ELECTRICAL

CONNECTIONS BASED ON YOUR LOCAL CODES

Leveling Bolts / Feet

Airline Connection /

Leveling Feet Thru Hole

1- The toolchanger models must be connected to

an air supply from a clean, dry, non-fluctuating

source (90-110 psi). Please set the regulator to an

appropriate psi level. Machine regulator should

be set to 90 psi.

Screw the leveling bolts in the threaded holes.

Adjust them to level the machine.

Remove the packing material from around the computer. Please keep the computer

documentation in the CNC Control Unit Computer Cabinet. The WARRANTY paperwork

is part of this package.

1

Incoming AC Power

Connect the incoming AC

power to the machine here

Note: The indicated voltage on

the box. Turn power OFF when

the machine is being serviced.

CNC Control Unit

CNC Control Unit Panel

Emergency Stop

Button (E-Stop)

Vacuum Pump

1 Switch

Vacuum Pump 2 Switch

(If Present)

Start / Stop

Switches

Brake Switch

Spindle Control

Panel / Display

(Factory Preset)

CNC Control Unit Wires

There are two wires coming

from the rear of the CNC

Control unit. These must be

plugged into an outlet with

the voltage indicated on the

label. Please note the specified

Voltage label.

I. MACHINE IDENTIFICATIONS

IMPORTANT: KEEP YOUR TECHNO CD-ROM. IT CONTAINS ADDITIONAL DOCUMENTATION.

NOTE ¹: Voltage on the main

power line must be measured

and the correct tap on the input

transformer must be selected.

NOTE ²: Clean, dry air must be

used otherwise damage to the

spindle and air solenoids will

result. THIS IS NOT COVERED

UNDER WARRANTY.

It is strongly recommended

that all 220 and 440VAC

connections be connected

through a power disconnect

switch (example seen left) for

use with either CNC Router

spindle and/or vacuum pump

setup. This switch is required

for safety and to meet National

Electrical Codes. A licensed

electrician should perform this

installation.

Power Disconnect Switch

(not included with Purchase)

Techno

Inc.

HTT03170704

3

Premium Class Setup Instructions

Phone: 516-328-3970 · Web: www.technocnc.com

Continue to next page …

Vacuum Pump Motor

Starter Box & Connector

II. HOW TO USE THE VACUUM TABLE

The motor has been wired to the Motor

Starter. The incoming voltage must be wired

to the Motor Starter Box.

NOTE: Voltage is specified on the box

Vacuum Pump w/ Motor Starter

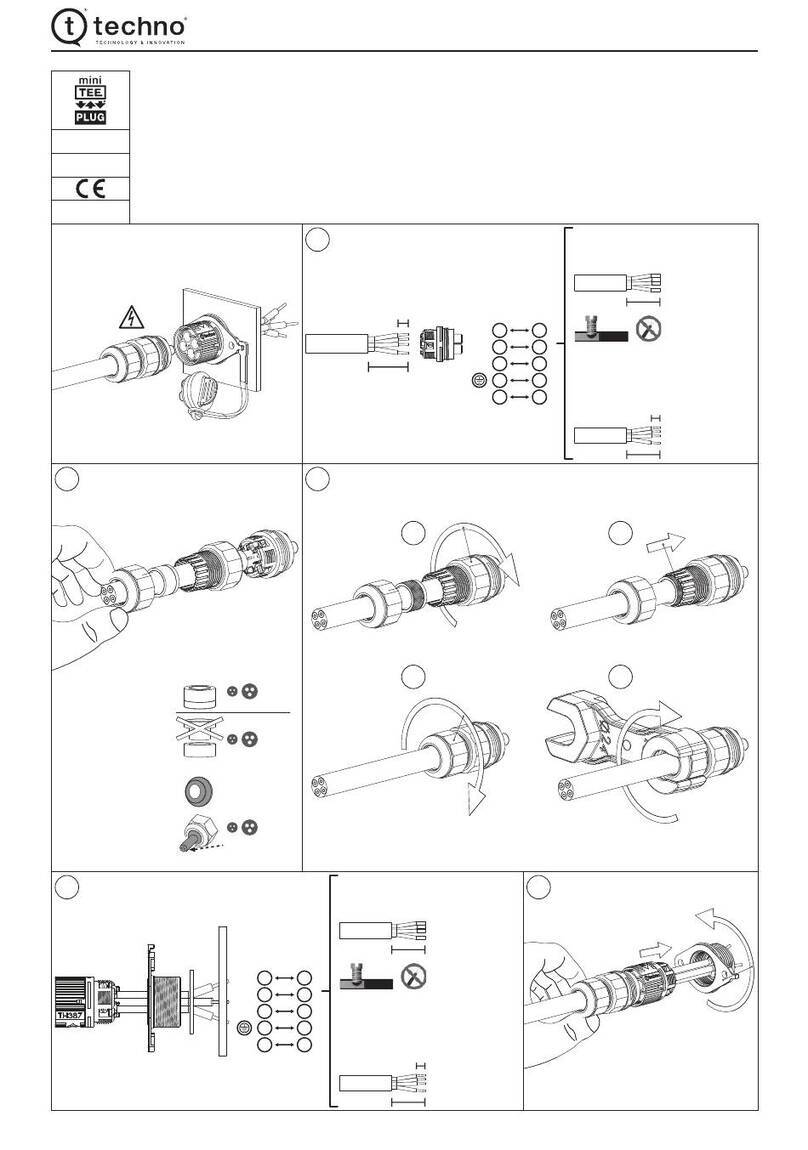

The signal connector needs

to be connected to its mating

connector (shown left).

Pump/Blower Cable

You will need to connect the

AC power (220 or 440 VAC)

as specified on the unit to

the Motor Starter.

Connect one end of the 2”

diameter vacuum hose to

the manifold fitting …

… and connect other end of the

vacuum hose to the Vacuum

Pump filter.

Vacuum Hose Fittings …

Tool Changer Rack (if applicable)

Vacuum Shroud

Place the toolholders here on the tool

holder rack. Please note the collets

and the collet wrenches are supplied

with the unit. Refer to manual on how

to teach tool locations.

Note¹: Make sure the distance

between Tool Holders is greater than

the length of the vacuum shroud/dust

collector.

WARNING: Direction of Rotation is critical. Briefly start motion and check rotation (arrow

on casing). Exchange phases if rotation is incorrect. IF YOU RUN THE PUMP/BLOWER

CONTINUOUSLY IN THE WRONG DIRECTION THE VANES WILL BE DAMAGED.

The dust collector shroud is

mounted through the block next to

the spindle and the dust collector

hose should be attached to the

fitting supplied with the shroud.

Techno

Inc.

HTT03170704

4

Premium Class Setup Instructions

Phone: 516-328-3970 · Web: www.technocnc.com

Continue to next page …

TO REORDER VACUUM SUPPLIES:

Call Techno Today at: 516-328-3970

ITEM PART NUMBER

Rubber Plugs H91X30-PL006-001

Foam Rubber Gasketing HX4892-W0002

II. HOW TO USE THE VACUUM TABLE (CONT.)

Vacuum Hold-Down - 1

The Techno Vacuum Table is very effective in

“holding down” parts to be routed. For this method

to work and work well, simple procedures need

to be followed. First, you need to define the

area where your workpiece will be positioned on

the vacuum table. Second, using the red rubber

plugs, you need to plug-up and close-off all of the

area outside your defined work area. Fill in ALL

the vacuum grid holes outside your defined work

area with the plugs and leave the holes within your

work area open. Next, use the black foam rubber

gasketing to section/wall-off your work area. The

idea is to create an area of concentrated vacuum,

which will generate the greatest amount of vacuum

“hold-down.”

Vacuum Hold-Down - 2

After you have defined your workpiece

area and closed off all the vacuum

outside of that area, there is another

option to greater your vacuum: the

vacuum control valves. Each valve

controls the flow of vacuum to two rows

of extrusions. Turn ON (valve vertical)

the valves that pertain to your work area

and turn OFF (valve horizontal) the ones

outside of that area. This will concentrate

all the vacuum “hold-down” capacity to

your defined work area.

NOTE: You do not need to plug vacuum

holes in a section that has the valve

turned OFF.

WARNING: Proper care should be taken to make sure that objects held down with the vacuum table

are secure. There is a danger that objects held down with the vacuum can become loose and could be

thrown by the action of the cutting tool. Proper safety precautions against flying debris must be taken.

Safety glasses must be worn when the vacuum table is being used.

Important Gasketing Installation Notes:

1) DO NOT STRETCH the gasket material while

inserting it into the gasket slots. This will

produce tears in the gasket material which

causes leaks leading to the loss of vacuum

and unsecure pieces flying off of the vacuum

table.

2) When joining two separate pieces of gasket

material, make sure to push them together

so the two pieces forma tight seal.

Techno

Inc.

Phone: 516-328-3970 · Web: www.technocnc.com

5

HTT02740704 Scale Factor Interface Setup

Continue to next page …

IF THE VALUES ARE NOT WRITTEN ON THE FRONT LEG OF

YOUR TECHNO CNC ROUTER THEN THE INTERFACE DEFAULT

VALUES SHOULD APPLY.

III. SCALE FACTOR SETUP:

STEP 1: Start Techno CNC Interface.

STEP 2: From the Main Menu click on

the Setup button. See SCREEN

CAPTURE 1.

STEP 3: Click on System in the Setup

screen’s menu list. See SCREEN

CAPTURE 2.

NOTE¹: The Setup/System screen will

appear.

STEP 4: Input the numbers printed

on the Scale Factor Sticker

located on the front leg of the

machine.

NOTE²: See the circled section in

SCREEN CAPTURE 2. Make sure

to type the numbers exactly

how they appear on the sticker

including any negative values

(i.e. -20320).

STEP 5: Click the OK button in the

Setup/System screen to save

the changes made.

SCREEN CAPTURE 1

SCREEN CAPTURE 2

Techno

Inc.

HTT03170704

6

Premium Class Setup Instructions

Phone: 516-328-3970 · Web: www.technocnc.com

Continue to next page …

APPENDIX A

PCI CARDS CONTROL BOXES

NOTE: THE MP ELECTRONICS MAY SHIP WITH GANTRY III SYSTEMS, CHECK ROUTER SPEC. SHEET FOR DETAILS.

PCI Interface Card The PCI Controller Card

This card works with:

· LP(LC) Electronics

· CNC Lathes

· Servo DaVinci

· Gantry III Machines

LP (or “LC) Electronics are stan-

dard on the Servo Lathes (Metal

& Wood), Servo DaVinci’s and

the standard LC Machines (NOT

THE SPEED UPGRADE LC’s!)

They can also be used on Gantry

III Tabletop Series machines and

as a stand alone product.

MP Electronics are sometimes

referred to as Servo Box 2

(H26T56-SRVBOX2).

LP (LC) ELECTRONICS MP ELECTRONICS

HP ELECTRONICS

CNC CONTROL TOWER

The HP Electronics Box com-

ponents are located within the

Techno CNC Control Tower,

which comes standard with a

Premium Class machine and as

an upgrade for the RG Series

machines.

WARNING: Make sure to match the correct PCI Card with the corresponding Techno Electronics.

Mixing the Interface Card with the MP/HP Electronics, or using the Controller Card with the LP Electronics

may cause damage to the Electronics, the PCI Card and your computer.

9.25’’

5.75’’

This card works with:

· MP Electronics

· HP Electronics:

RG+ Servo Box 3

· Premium Class

Electronics

· LC Speed Upgrades

· RG Machines

· Some Gantry III

Machines

HP Electronics are referred to as

Servo Box 3 or RG+ Servo Box

3 (H26T56-SRVBOX3HR).

Techno

Inc.

HTT03170704

7

Premium Class Setup Instructions

Phone: 516-328-3970 · Web: www.technocnc.com

Continue to next page …

APPENDIX B

Techno

Inc.

HTT03170704

8

Premium Class Setup Instructions

Phone: 516-328-3970 · Web: www.technocnc.com

Continue to next page …

Y-Axis – THK Products

Grease: Lithium-based grease (JIS NO. 2) or Urea-based Grease (JIS No.

2), such as AFB Grease (THK), Alvania Grease No. 2 (Shell), Daphne Eponex

Grease No. 2 (Idemitsu Kosan) or equivalent.

Oil: Sliding surface oil or turbine oil (ISOVG32-68), such as Super Multi 32

to 68 (Idemitsu Kosan), Vactra No. 2S (Mobile), DT Oil (Mobile), Tonner Oil

(Shell) or equivalent.

TABLE 1

THK

BALLSCREW RAIL CARRIAGE

GREASE

OIL

√

√

√

√

√

AVAILABLE ACCESSORIES

TECHNO LUBE KIT PART NO.: H90Z00-LUBEKIT3 PRICE: $75.00

THK LUBE KIT PART NO.: H90Z00-LUBEKIT4 PRICE: $105.00

LUBRICATION SPECS FOR PREMIUM CLASS MACHINES

Note: On some items you can use either the grease or oil.

APPENDIX C

Techno

Inc.

HTT03170704

9

Premium Class Setup Instructions

Phone: 516-328-3970 · Web: www.technocnc.com

Continue to next page …

PREMIUM CLASS MACHINE MAINTENANCE

For regular work loads, machine maintenance is

required at least once a month. The machine should

also be lubricated once it is received.

Warning: Before inserting any object into the

machine, press the E-stop button.

Notes: Do not use WD-40 or silicon spray on

the machine. It may damage the drive

components of the machine.

Use the Grease and Oil recommendations

listed on the previous page, paying close

attention to what grease/oil must be

used!

I. LONG AXIS (Y) BALL SCREW:

1. Clean the ball screw with a dry rag removing old

grease and debris that may have collected.

2. Apply grease on the ball screw and run the

machine back and forth several times to spread

the grease out. By applying the grease and

running the axis back and forth, small particles

that may have collected in the ball nut may be

flushed out. It is recommended to repeat steps 1

and 2 again.

II. X-AXIS, Z-AXIS

BALL SCREWS AND END BEARINGS:

Notes: To access the X-Axis you must first remove

the top panel covering it. This can be done by

unscrewing the screws on either side of the

axis and lifting the panel completely off of the

machine.

On the reverse side of the X-Axis are

the Ball Nuts, remember to apply grease to

those fittings!

1. Clean the ball screws with a dry rag, removing old

grease and debris that may have collected.

2. Apply grease to the the grease fittings on the ball

nuts and the grease fittings located on the end bear-

ings of the X-Axis and grease Z-Axis.

3. Run the machine back and forth along the axes

several times to spread the grease out and complete

the process.

LONG AXIS (Y)

X-AXIS BALL NUTS

(REAR VIEW)

END BEARINGS

(REAR VIEWS OF X-AXIS)

X-AXIS (FRONT VIEW)

Z-AXIS END BEARING

Techno

Inc.

HTT03170704

10

Premium Class Setup Instructions

Phone: 516-328-3970 · Web: www.technocnc.com

Continue to next page …

III. THK RAILS:

THK specifications indicate that a small amount of

grease needs to be applied to the rails after 4 months

of use.

The following pictures indicate the location of the

grease fittings. Be sure to grease all 4 fittings, on all

three axes!

Y-AXIS RAIL

(ONE OF FOUR GREASE FITTINGS)

X-AXIS RAILS

(SIDE VIEW, TWO OF

FOUR INCLUDING

THE Z-AXIS)

Z-AXIS

(UPPER SIDE VIEW,

ONE OF FOUR

GREASE FITTINGS)

Other Techno Control System manuals