1. Safety Precautions

1.1 Ensure the product is used within the specification (Max. 10A).

1.2 Induction loads such as compressors, refrigerators, space

heaters, pumps may have a start-up amp of 2 to 7 times the

continuous rating. Overload start-up amp may cause damage or

shorten device’s lifespan.

1.3 Do not operate the controller near any high temperature, high

humidity, explosive or inflammable field.

1.4 Children are not allowed to operate the device. Keep children

away from the controller.

1.5 Do not use in salt water or corrosive water, the metal NTC probe

will be slowly damaged by salt water or acid-alkali water.

2. Overview

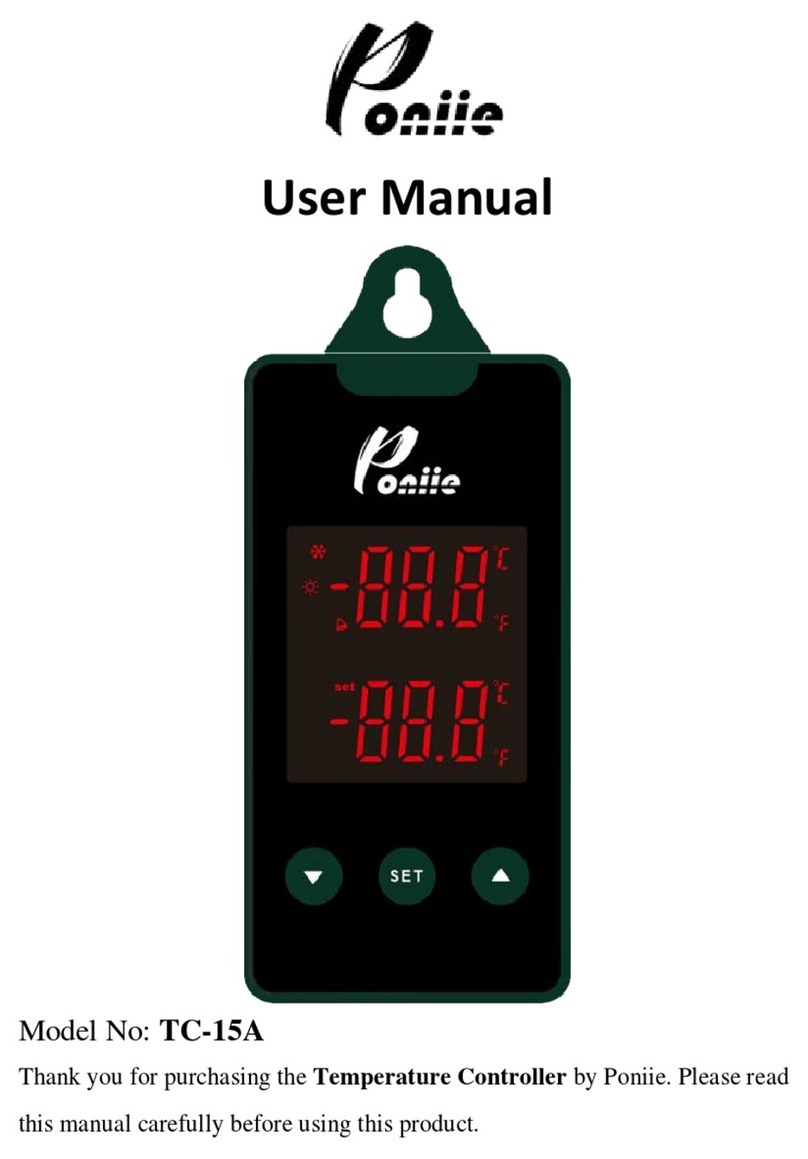

What is TC-10A?

TC-10A is an easy-to-use, safe and reliable dual relay output

temperature controller. It can be connected to both heating and cooling

loads at the same time to control temperature.

This unit can be used as over temperature protection or automatic

temperature control system for various tasks. Such as Sous-vide,

Terrarium Heat Control, Heat Mats, Germination, Fermentation and

Brewing.