Newport PM 500 User manual

PM 500 Stage Tuning Manual

1 Setup

1.1 Materials Required

1. Small standard head adjustment screwdriver

2. PC interface through which to communicate with PM500, i.e. PCS

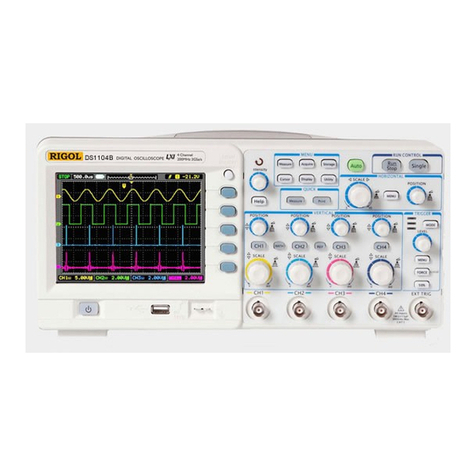

3. 10Mhz (minimum) oscilloscope with X-Y sweep mode

4. DMM (Digital Multi-Meter) with Voltmeter capability

1.2 Warm-up Controller

It is important to let the motion controller cards warm up for 15-30 minutes.

This will ensure that thermal fluctuations do not alter stage performance.

1.3 Oscilloscope Setup

1.3.1 Oscilloscope Calibration

Oscilloscopes from different manufacturers vary concerning labeling and

adjustments. The nomenclature used in this manual is applicable to all

oscilloscopes that are 30 MHz or higher, with X-Y sweep capability, and that

it can accommodate the procedures listed below.

—Note—

When performing the procedures discussed on the

following pages, power your oscilloscope from the

same outlet that powers the controllers. Take care that

the oscilloscope probe ground clips do not short any of

the components in the controller.

1. Plug into a stable, grounded (3-prong) 110 V power source, preferably

from the same source and ground that supplies the controller, such as the

power strip inside the tool.

2. Remove the ground clips from the oscilloscope probes. The ground clips

may be used if the oscilloscope has interference on the signal due to poor

grounding. The grounding clips must be used with caution to prevent them

from falling into the controller and damaging the system or shorting test

points to ground.

3. Allow a warm up period for the oscilloscope to stabilize (refer to your

oscilloscope manual).

4. Determine the probe gain (1X, 10X, etc.). Always verify that the probe

gain is taken into account when setting the oscilloscope (refer to your

oscilloscope manual).

Figure 1 Oscilloscope Calibration

5. Ensure that the probes are properly compensated by using the calibration

signal provided by the oscilloscope. This step should be accomplished

before beginning the tool calibration procedure. Adjust the probes for

sharp corners on the square wave. Verify that the calibration voltage is

displayed correctly when the variable amplitude adjustment is set in the

CAL position. Refer to your oscilloscope manual if you are not familiar

with this process.

6. Verify that the variable amplitude and frequency adjustments are set in the

CAL position.

Figure 2 Centered dot on screen

7. To setup the scope to be used in X-Y mode, set the mode to X-Y, coupling

to GND, and V/div to 1.0V/div (or .1V/div for 10X probe). Use the

horizontal and vertical position controls to center the spot on the center of

the screen. Re-verify, before adjusting each encoder, that the X-Y mode

ground reference position is at the center of the screen (some oscilloscopes

drift during warm-up and the centering may have been lost when other

scope settings were used). Failure to center the spot will cause errors in

the adjustment of the encoders.

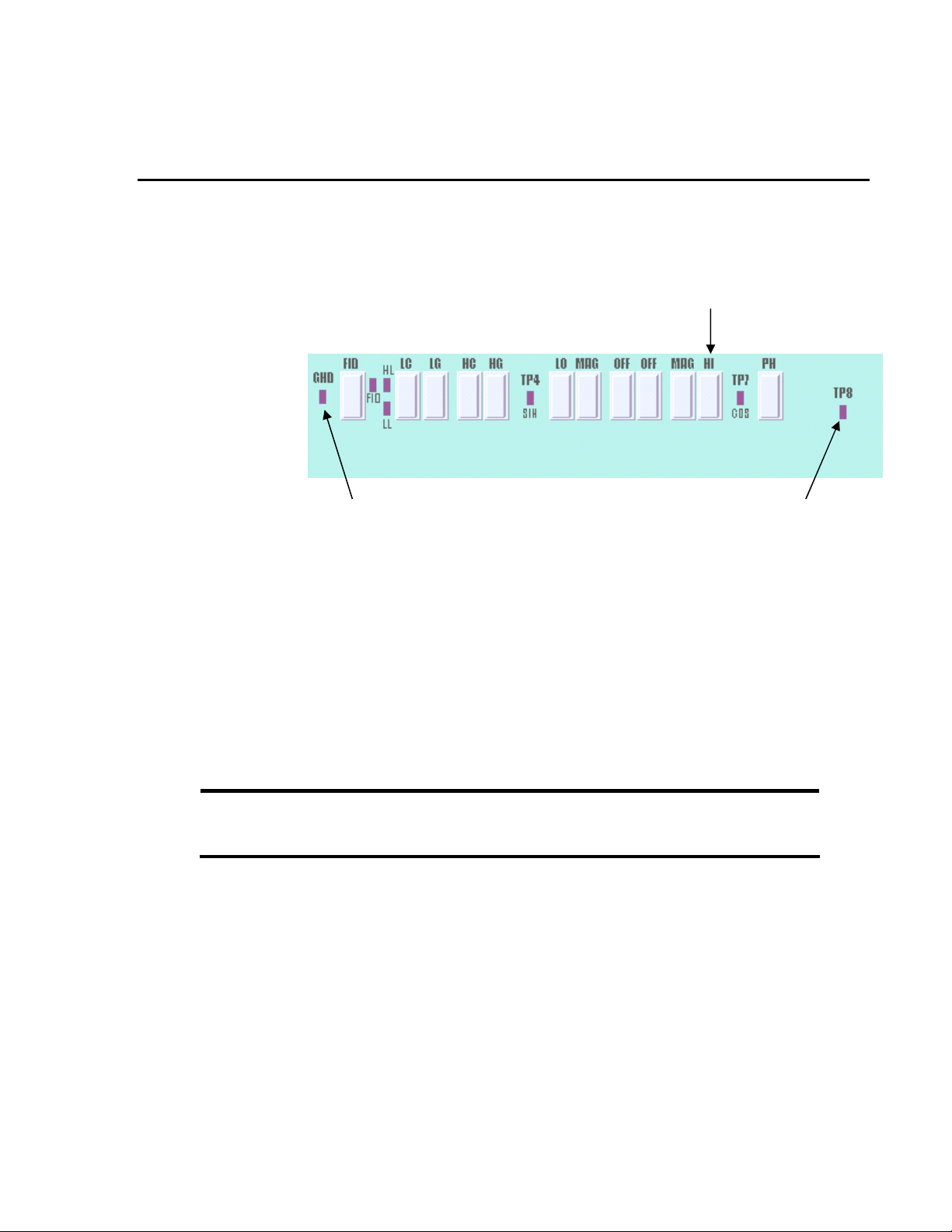

Refer to the figures on the following pages for the location of the test points

and potentiometers The following procedures are to be used with Rev R and

later axis boards.

CAUTION

Only qualified personal should attempt to perform

stage tuning.

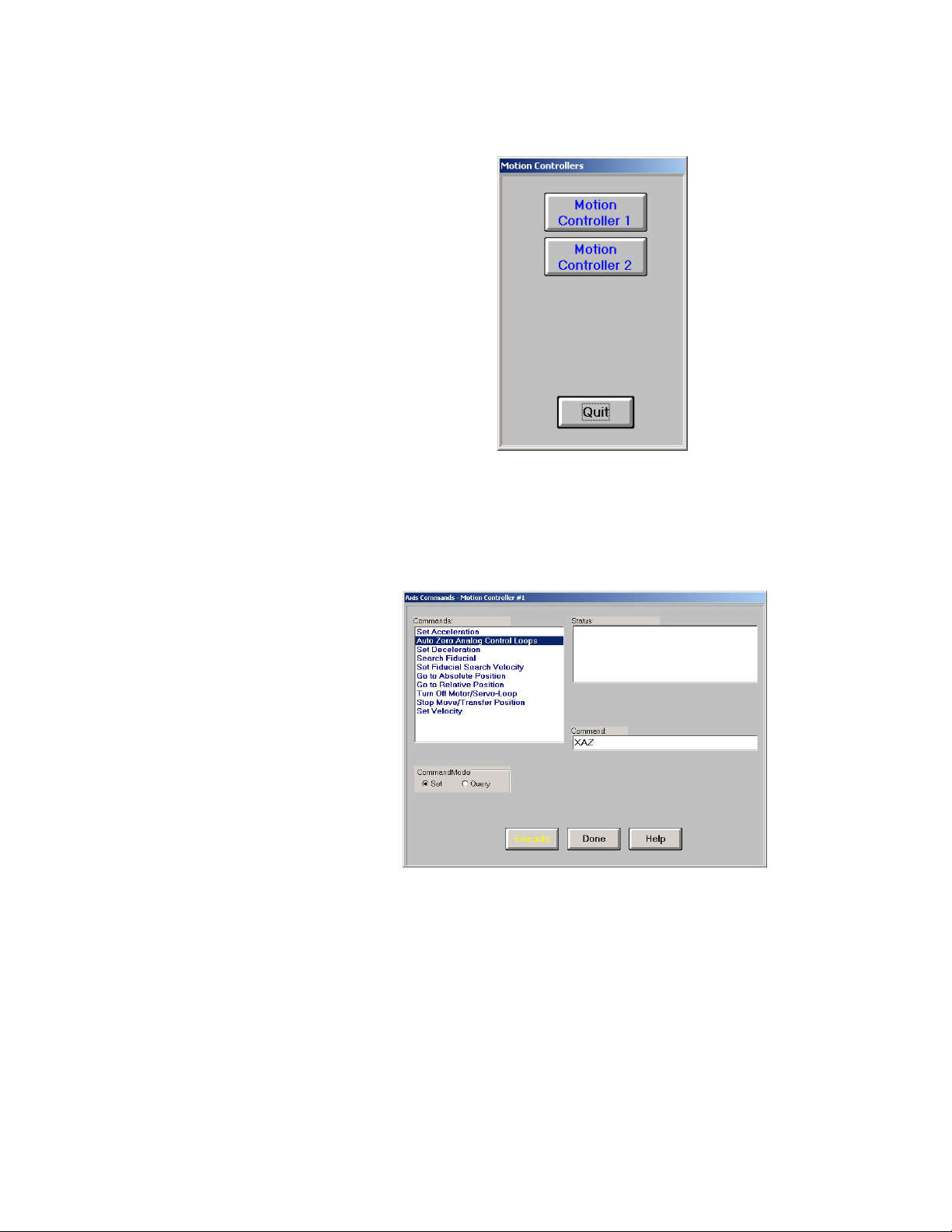

1.4 PCS Interface

During the tuning procedures it will be necessary to send commands to the

stages through PCS. The following are instructions on how to access the

interface through which commands are input and executed.

1. First, while in PCS, click on the Service tab at the bottom of the

screen to open the PCS Service window.

Figure 3 Service Tab Used to Open the Service Window

2. Once in the service window is open, click the button labeled

Motion Controllers.

Figure 4 Motion Controller Button in Service Window

3. Clicking the Motion Controllers button will open a new window

giving the user a choice of which motion controller he would like

access.

Figure 5 Motion Controller Selection Window

4. Clicking on one of these buttons will open up the interface window

of the selected stage.

Figure 6 Motion Controller Interface Window

5. From this window, commands can be entered in the field labeled

Command. Once a command is typed in, the yellow execute

button must be clicked to send the command to the stages. See

page back page for a list of commonly used commands.

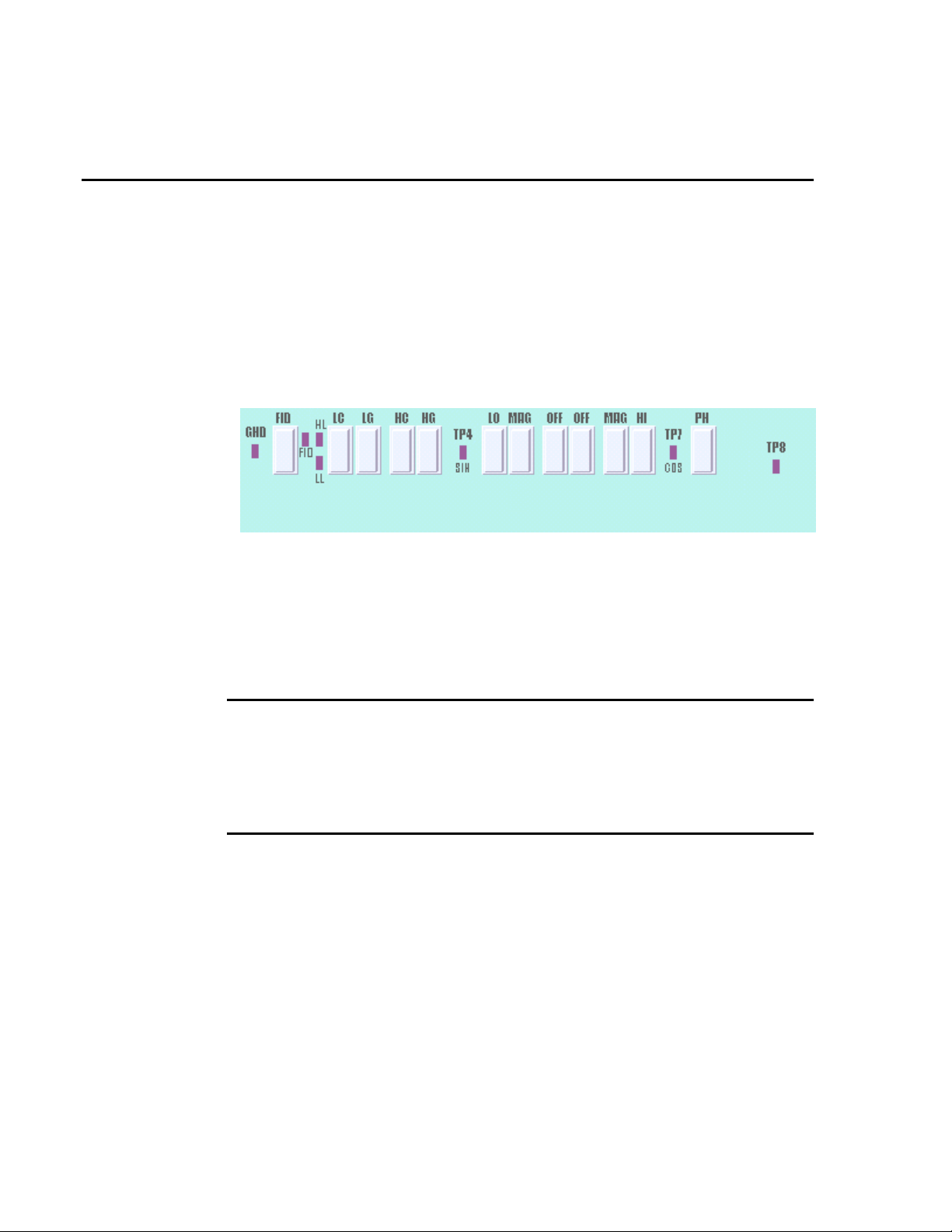

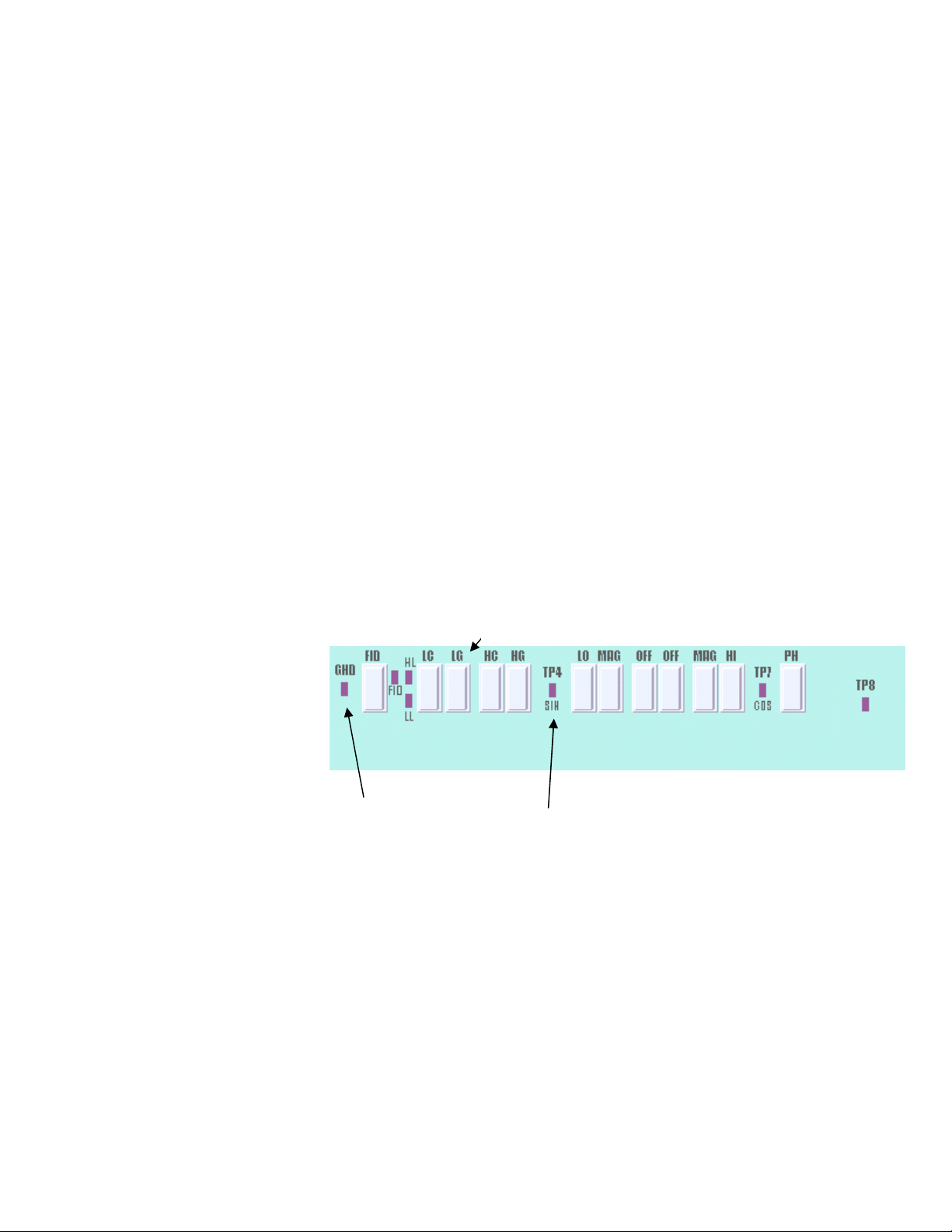

1.5 Tuning Procedure Preliminaries

The following are procedures that should be reviewed before any tuning is

done. In some cases these preliminary procedures may eliminate any small

problems. During the tuning procedure the user will be asked to take

measurements using probes and make adjustments to trim potentiometers.

The test points and trim potentiometers lie on the individual axis boards

inside the motion controller. Throughout this document a picture of the top

part of the axis board looking from the component side where the trim

potentiometers are located will be referenced to show the user which test

point and trim potentiometer to use.

Figure 7 Top of Axis Board

The left side of the picture is the section of the axis board near the back of the

motion controller case. The right side is closer to the front of the motion

controller case.

NOTE

PM500 communication level “SCUM 1” is assumed throughout

this procedure. Input the commands indicated in this procedure

from the “Motion Controllers” button of the PCS “Service”

screen.

1. First issue a SCUM? query to the controller to ensure that correct

communications mode (SCUM1) has been setup. If the response is

“1” then SCUM1 is being used, if the response is “0” then issue a

SCUM1 command to setup the SCUM1 communications mode.

2. The next step before attempting to tune is to reset the PM 500

analog electronics to their original factory settings.

3. Input command SDEFEE and wait several seconds. The status box

should return with an “Operation Successful” response. This

command resets the PM500 analog servo electronic and motion

parameters to their default factory settings.

5. Input command SRSTART and wait several seconds. This command

resets the PM500 as would a hard reset. If this command is issued

through PCS the response through PCS will be that the “Operation

Failed”. This is normal and correct since the command reboots the

controller thus making it momentarily unavailable to GPIB queries.

NOTE

The SDEFEE and SRSTART commands should only be issued

once per controller at the beginning of the tuning processing and

not between tuning each axis board.

6. Auto-Zero the stage: Issue command <axis>AZ. Do not touch or

disturb the stage or tables during the Auto-Zero.

NOTE

Replace <axis> with the letter that corresponds to the axis

controller being tuned. For example: if tuning a 4L stage in the

Y-slot, enter YAZ as the command. The controller slots are

assigned as X Y Z A B C from left to right looking from the front

of the controller. Be sure to use the correct assigned alphabet to

avoid moving and damaging the wrong stage.

7. Wait 45 seconds until the Auto-Zero routine is complete. Then

confirm it is complete by entering the command: <axis>STAT?

and observe that the commands returns the <axis>D response. If

the stage is still busy <axis>B will be the response.

8. Once the Auto-Zero is complete, use the <axis>AZVAL?

Command to query how well the stage is finding its position.

9. Once the <axis>AZVAL? Command has been issued, PCS will

response with a number for each axis. The number will be in the form:

<axis>D$000004FF. The D signifies the Auto Zero was done, if the

Auto Zero is not finished there will be a B instead. In the number that

follows we are only interested in the last two pairs of numbers (or

letters). In this example 04 and FF are the pair in which we are

interested. These two pairs of digits tell us whether the stage is

performing properly. Another possible value would be D$0000FC03.

Below is a list of allowed values for the <axis>AZVAL? response, if

either of the last two pair of digits do not match the ones listed below,

tuning is necessary.

NOTE

Some axis cards do not have the HC and LC potentiometers. For

these stages there is no specification for the AZVAL?, other then

to get it as close to all zeros as possible. All other cards should

be within the specification listed below.

Figure 8 List of allowed values for <axis>AZVAL?

7. To save the new axis parameters to non-volatile memory: Issue the

command <axis>SAVEAX.

CAUTION

BEFORE ISSUEING ANY MOTION COMMANDS SUCH

AS SETUP0, SETUP10, ETC. ENSURE THAT THERE IS

NO TOOLING OR OBSTRUCTIONS THAT MAY CAUSE

A COLLISION WITH THE STAGE. Many of these motion

commands will cause the stage to travel its full length from

limit to limit. Actuators used with goniometers must be

tuned separate from the goniometer since the goniometer

as has a shorter travel length than the actuator. A

collision of the stage with any obstruction can cause

severe damage to the stage and/or tooling. Make sure

that traveling to the limits will not cause the stages crash

into any other stage or tooling. Also have your hand on

the E-stop when initially issuing the SETUP commands.

05

04

03

02

01

FD

FE

FF

00

FB

FC

NOTE

Most potentiometers are locked with lock-tight. It is necessary to

gently chip this off in order to make adjustments. Be sure to

relock the potentiometers when finished making adjustments.

Try not to apply lock-tight directly on top of the potentiometers.

A small amount on one side of the potentiometer should prevent

movement.

2 Stage Tuning

NOTE

To stop a stage after issuing a <axis>setup# command, execute

an <axis>M command. M stands for Motor Off.

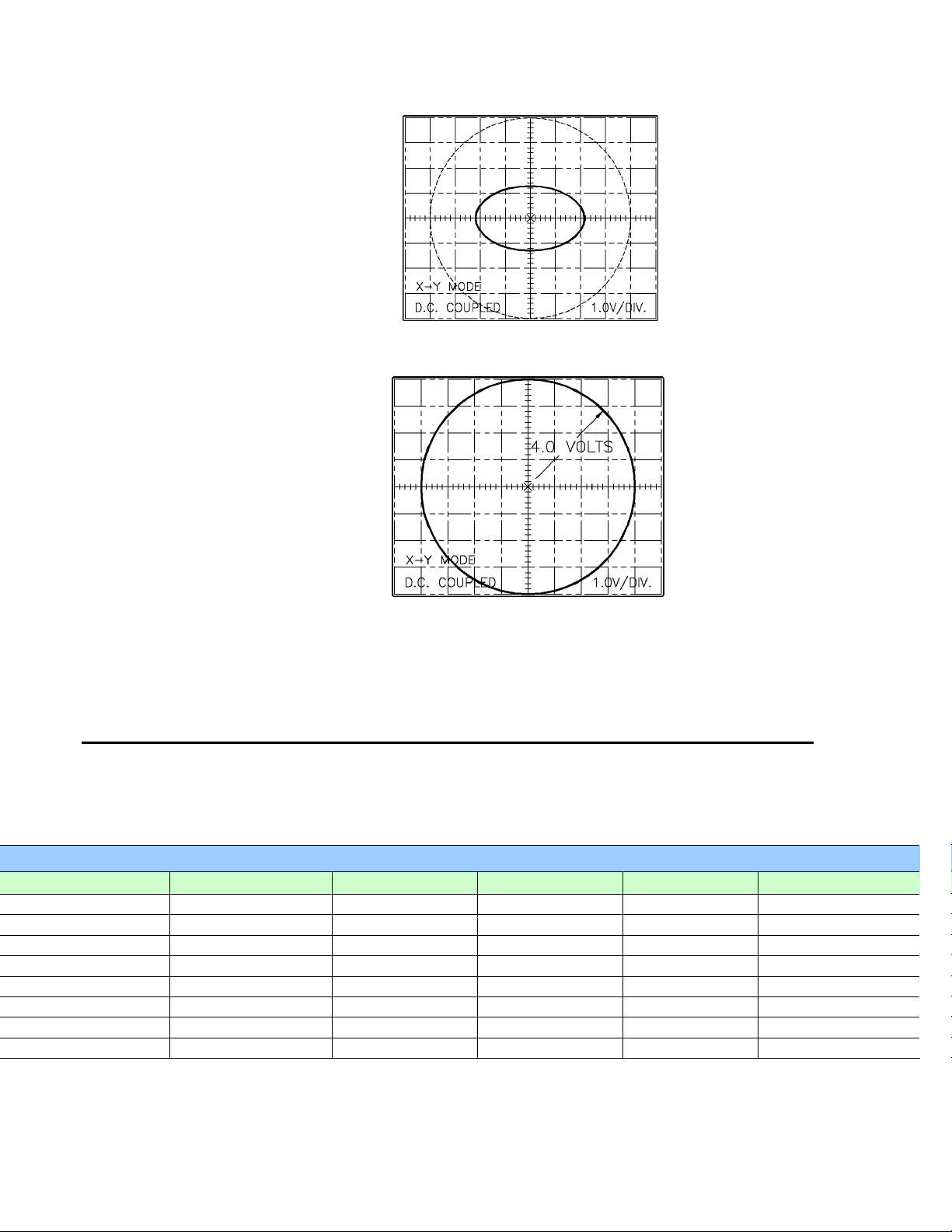

2.1 Axis Encoder Adjustment

Oscilloscope Settings:

Sweep: X-Y mode (make sure to zero scope)

DC Coupling with 1V/Div

Test Points: TP4 (SIN), TP7 (COS) GND

Potentiometers Used: MAG, OFF, PH

Criteria: 4V +/- .5V

1Attach the Channel X probe to the TP4 (SIN) test terminal and the

Channel Y probe to TP7 (COS) test terminal. Make sure both

probes are grounded.

Sin Amplitude Sin Offset Cos Offset

Cos Amplitude

Ground Test Point

Sin Test Point Cos Test Point

2. Input <axis>setup0 command (remember this will move the stage

between physical limits of travel). If one cannot use <axis>setup0

then the stage can be moved by hand (using the hand actuator).

3. A Lissajous pattern should appear on the scope screen. If one does

not, it may be because the pattern is off the scale, in this case

adjust the scale until the pattern is visible.

4. Adjust the Lissajous pattern using the MAG (Magnitude), OFF

(Offset) and PH (Phase) potentiometers until the pattern has a

radius of 4 volts +/- .5V on both axes. Below are some example

Lissajous patterns.

1. Lissajous That Needs Phase Adjustment

2. Lissajous That Needs Offset Adjustment

3. Lissajous That Needs Amplitude (MAG) Adjustment

4. Correct Lissajous Pattern

5. Once the Lissajous is correctly adjusted, issue the <axis>M command

to stop the stage motion.

2.2 Low Speed Loop Period

To perform the Low Speed Period Loop correctly, the user will need to

determine what kind of stage is being tuned as well as the ROM code of the

stage as this will determine the tuning parameters. The table below explains

list the possible stage types and their tuning parameters.

CHART

STAGE TYPE

SCALE

ROM CODE

RESOLUTION LO SPD HIGH SPEED

1V Mini Vertical

50 LPMM NMZD 0.1 40ms 800us

1V Mini Vertical

50 LPMM NMZC 0.05 40ms 800us

1A Actuator

50 LPMM NA 0.1 40ms 800us

1A Actuator

50 LPMM NAC 0.05 40ms 800us

2L - 8L 62.5 LPMM BMD 0.025 4ms 160us

2L - 8L 62.5 LPMM CMD 0.05 4ms 160us

33LR 62.5 LPMM CMI 0.05 4ms 160us

33LR 62.5 LPMM BMI 0.025 4ms 160us

1V Mini Vertical (AutoAlign): Y Axis stage

1A Actuator (AutoAlign): Actuator that moves Roll Axis (θZ)

1A Actuator (LaserWeld): Actuator that moves beam output housing

2L – 8L (AutoAlign): Stages that move X and Z Axes (generally 4L)

2L – 8L (LaserWeld): Stage that moves Upper Tooling (generally 4L)

33LR (LaserWeld): Stage that moves Lower Tooling (2 linear directions

and one rotational).

Once one has determined the type of card is being used follow the procedure

below to tune the Low Speed Loop Period.

Oscilloscope Settings:

Sweep: XT (time) mode 5 ms/Div

Vertical: DC Coupling with 1V/Div

Test Points: SIN (TP4), GND

Potentiometers Used: LG

Criteria: See Chart

1. Attach the Channel X probe to the TP4 (SIN) test terminal. Make

sure the probe is grounded.

2. Input <axis>Setup0 command

3. Adjust the LG potentiometer until the period of the sin wave on the

oscilloscope matches the criteria specified on the “LO SPD”

column of the chart.

4. Issue <axis>M command to stop stage.

LG Pot

Sin Test Point

Ground Test Point

2.3 Low Speed Loop Compensation Adjustment

Oscilloscope Settings:

Sweep: XT (time) mode 5 ms/Div

Vertical: AC Coupling with 1V/Div

Test Points:TP8, GND

Potentiometers Used: LC

Criteria: 2 Counter Clockwise turns past where

scope signal is flat

NOTE

Some newer cards do not have the LC and HC potentiometers

Adjustment of the Low and Hi Speed Loop is not necessary on

these cards.

1. Attach the Channel X probe to TP8. Make sure the probe is grounded.

2. Input the <axis>setup0 command

3. Turn the LC potentiometer clockwise until the stage begins to oscillate

and squeal. The oscillation will first be visible on the scope and the

squealing will become audible if one continues to turn the

potentiometer clockwise.

LC Pot

Ground Test Point TP8 Test Point

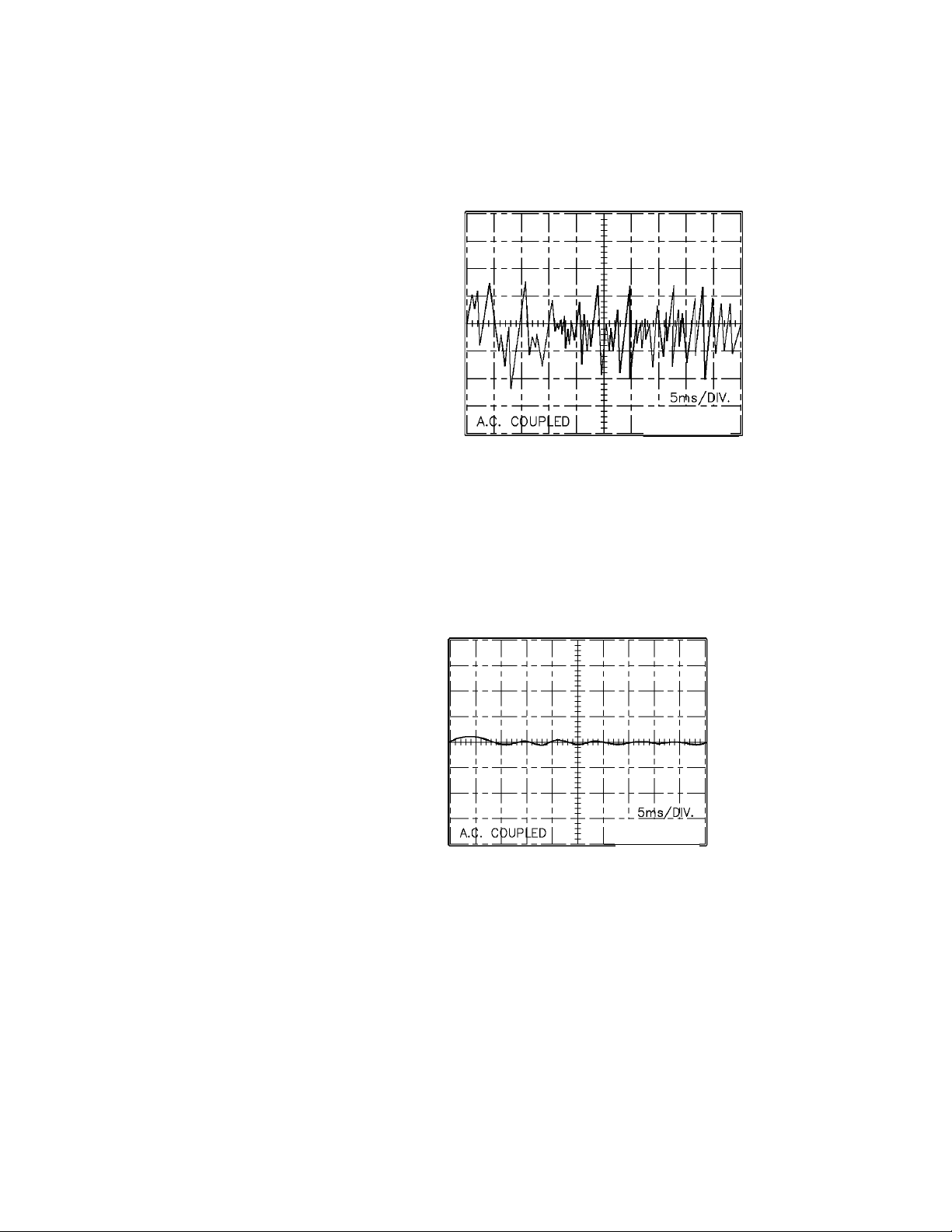

Figure 9 Scope Signal From Squealing Stage

4. Once the squealing has been observed and the oscillation has been

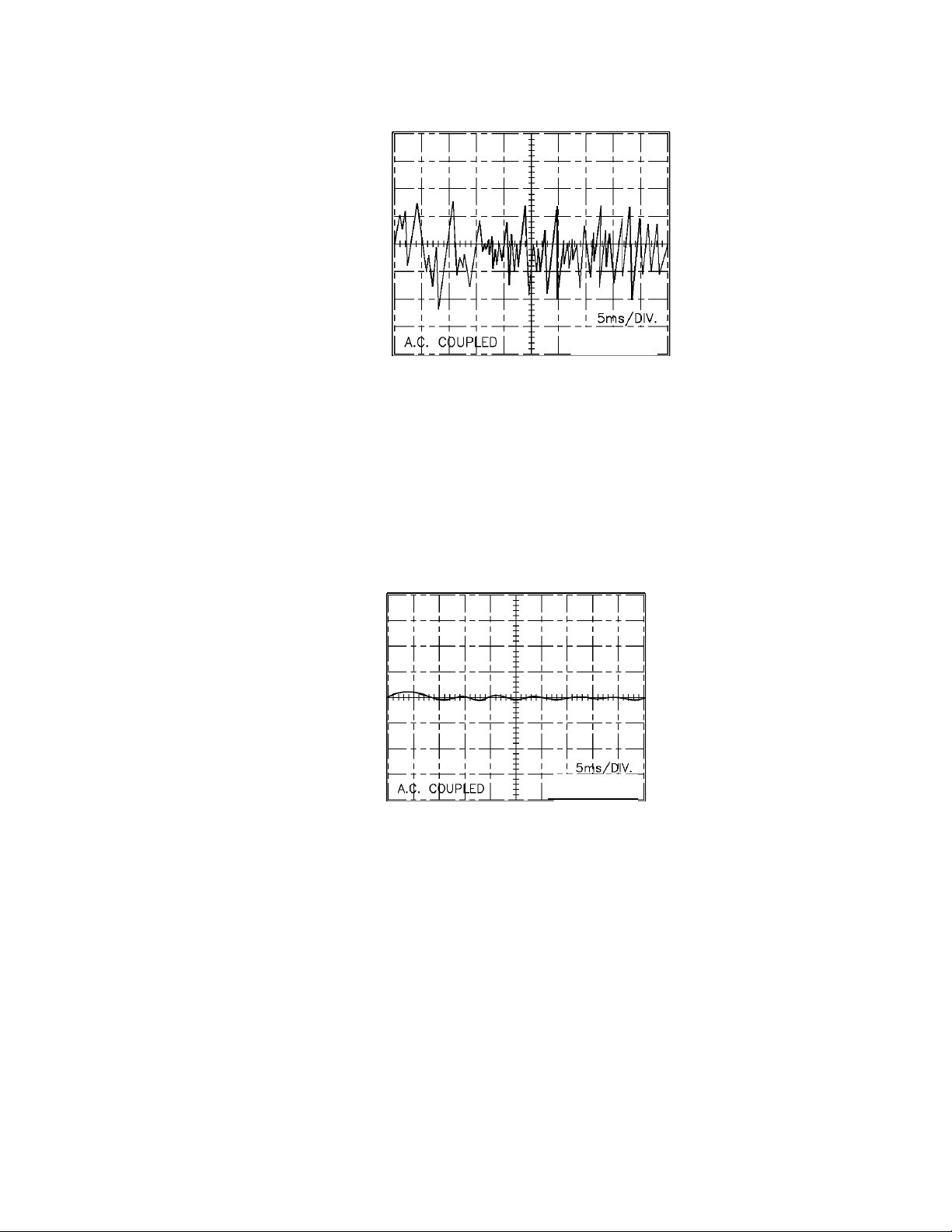

seen on the scope, turn the potentiometer counterclockwise just until

the signal on the oscilloscope becomes flat and steady and the

squealing stops. Then turn the potentiometer a 2 turns CCW past this

point.

Figure 10 Stage With No Squealing

5. Terminate stage movement with <axis>M command.

2.4 High Speed Loop Period Adjustment

Oscilloscope Settings:

Sweep: XT (time) mode 200 µ

µµ

µs/Div

Vertical: DC Coupling with 1V/Div

Test Points SIN (TP4), GND

Potentiometers Used: HG

Criteria: See Chart in section 2.2.

1. Attach channel X probe to Test Point 4 (SIN). Attach ground probe to

GND Test Point.

2. Input command <axis>SETUP1

—Note—

This command will put the stage in motion at a high

speed, try to make the adjustment as quick as possible

especially when tuning the bottom stages with heavy

load.

3. Adjust the HG trim potentiometer to achieve a sine wave with the correct

period according to the chart and the firmware code.

4. Terminate test by typing <axis>M.

HG POT

Test Point 4 (SIN)

Ground Test Point

2.5 High Speed Loop Compensation Adjustment

Oscilloscope Settings:

Sweep: XT (time) mode 5 ms/Div

Vertical: AC Coupling with 1V/Div

Test Points TP8, GND

Potentiometers Used: HC

Criteria: 2 Counter Clockwise turns past where

scope signal is flat

NOTE

Some newer cards do not have the LC and HC potentiometers.

Adjustment of the Low and Hi Speed Loop is not necessary on

these cards.

1. Attach channel X probe to Test Point 8 (TP8). Attach ground probe to

GND Test Point.

2. Input command <axis>SETUP2

3. Turn the HC potentiometer clockwise until the stage begins to oscillate

and squeal. Tuning the potentiometer further in the clockwise direction

will increase the amplitude of the scope signal and cause the squealing

to become louder.

HC POT

Ground Test Point Test Point 8

Figure 11 Stage Squealing on the Oscilloscope

4. Once the stage squealing as been observed turn the potentiometer counter

clockwise until there is no squealing and the signal looks flat on the scope.

Figure 12 Oscilloscope Signal with no Squealing

5. Once the squealing is gone and the signal looks flat, turn the potentiometer

a 2 turns in the counter clockwise direction.

6. Terminate the test with the <axis>M command.

2.6 DAC (HI) Offset Adjustment

Digital Multimeter Settings (DMM): DC Voltage

Starting measurement are typically below 5V

Test Points: TP8 and GND

Potentiometers Used: DAC (HI)

1. Disconnect oscilloscope probes from the axis card.

2. Attach DMM probes to Test Point 8 and Ground Test Point. Keep the

DMM probes away from the power supply.

3. Make sure the controller has been on for at least 20 minutes before

performing this test to ensure thermal stability during the test.

4. Input command <axis>SETUP3

—Note—

SETUP3 command does not move stages.

5. Adjust DAC (HI) potentiometer until a value of 0 +/- 20mV is achieved

on the DMM. The DAC (HI) potentiometer is very sensitive and there

may be some lag time between the turning of the potentiometer and

reading on the DMM so make adjustments slowly.

6. Terminate the test with <axis>M command.

DAC (HI) POT

Ground Test Point Test Point 8

2.7 Low Speed Offset Adjustment

Digital Multimeter Settings (DMM): DC Voltage

Starting measurement are typically below 5V

Test Points: TP8 and GND

Potentiometers Used: LO

1. To adjust the Low Speed Offset, connect DMM probes to the TP8 and

Ground Test Points.

2. Issue the <axis>SETUP4 command.

—Note—

SETUP4 command does not move stages.

3. Adjust the LO Potentiometer until the DMM reads 00.0 +/- 50mV.

4. Terminate test with <axis>M command.

5. Now go back up to section 2.6 and check to see if any further adjustment

is needed on the DAC(HI) Potentiometer. Adjust as needed until both

parameters are in spec.

LO POT

Ground Test Point Test Point 8

Other manuals for PM 500

1

Table of contents

Other Newport Test Equipment manuals