Newport IsoStation User manual

IsoStation™Vibration

Isolated Workstation

I

NSTRUCTION

M

ANUAL

Warranty

Newport Corporation warrants the frame to be free from defects in material

and workmanship for a period of one year from the date of shipment and

isolators for a period of two years from date of shipment. In addition, the

laminated honeycomb tops have a lifetime performance and delamination

warranty under normal use and proper handling. If found to be defective

during the warranty period, the product will either be repaired or replaced

at Newport’s option.

To exercise this warranty, write or call your local Newport representative or

contact Newport headquarters in Irvine, California. You will be given

prompt assistance and return instructions.

Repaired or replaced products are warranted for the balance of the original

warranty period or 90 days, whichever is longer.

This warranty does not apply to defects resulting from modifications or

improper use of the system or its component parts.

This warranty is in lieu of all other warranties, expressed or implied,

including any implied warranty of merchantability or fitness for a particular

use. Newport Corporation shall not be liable for any indirect, special, or

consequential damages.

©1997, Newport Corporation

Irvine, California, U.S.A.

Part No. 21413-01, Rev. UA

IN-08951 (03-00)

ii

iii

Table of Contents

Warranty .................................................................................................................. ii

Table of Contents .................................................................................................. iii

List of Figures ........................................................................................................ iv

Section 1 – General Information

1.1 Introduction .............................................................................................. 1

1.2 Getting Started .......................................................................................... 1

1.3 Unpacking and Inspection ....................................................................... 1

1.4 Safety Terms ............................................................................................. 1

1.5 Workstation Placement ........................................................................... 3

1.6 Warranty Information .............................................................................. 3

Section 2 – Assembly

2.1 Loose Assembly of IsoStation Frame and Air System.......................... 4

2.1.1 Frame Assembly ............................................................................... 4

2.1.2 Air System Assembly ....................................................................... 5

2.1.3 Installing the Table Top ................................................................... 6

2.2 Squaring and Leveling the Frame ........................................................... 6

2.3 Isolating the Table Top ............................................................................ 7

2.4 Installing Accessories ............................................................................ 10

Section 3 – Operation

3.1 Principles of Operation .......................................................................... 15

3.2 Performance Adjustments ..................................................................... 15

3.3 Maintenance ............................................................................................ 16

3.3.1 Cleaning ........................................................................................... 16

Section 4 – Troubleshooting

4.1 Poor Isolation Performance .................................................................. 17

4.1.1 Table Top Does Not Lift Up (Float) .............................................. 17

4.1.2 Other Causes of Poor Isolation ..................................................... 17

4.2 Oscillations.............................................................................................. 17

4.3 Releveling the System ............................................................................ 17

4.4 Water in the Air Supply ......................................................................... 17

Section 5 – Factory Service

5.1 Obtaining Service ................................................................................... 18

5.2 Service Form ........................................................................................... 19

iv

List of Figures

Figure Title Page

1.1 Assembly Orientation....................................................................... 2

2.1 Leveling Pad Adjustment .................................................................4

2.2 Caster Installation .............................................................................5

2.3 Air Regulator/Filter (ARF) ................................................................6

2.4 Air System Diagram ..........................................................................7

2.5 Leveling Arm Orientation ................................................................ 7

2.6 Leveling Valve .................................................................................... 8

2.7 Installing Isolator Modules ..............................................................9

2.8 Workstation Diagram ......................................................................11

2.9 Ground Strap Attachment .............................................................. 14

3.1 Newport Laminar Flow Damping Isolator Design ....................... 16

1

Section 1

General Information

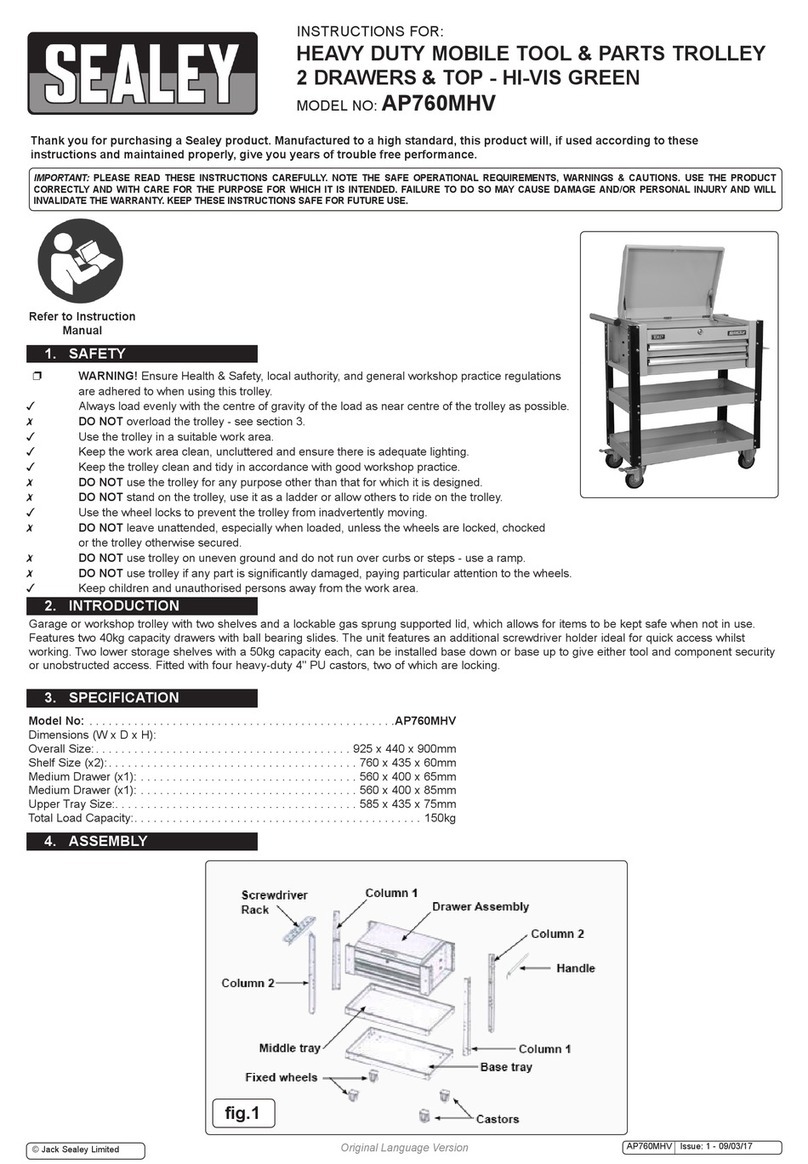

The IsoStation Vibration Isolated Workstation provides an ideal working

platform for vibration influenced devices such as interferometers, micro-

scopes, and balances. Sensitive instruments such as these will show

significant improvements in resolution and repeatability when isolated from

floor motion by the IsoStation pneumatic suspension system. This versatile

workstation is available in a broad range of sizes, working surfaces, isolator

capability, and accessory options.

Special care was taken to ensure excellent performance in the 20-50 Hz floor

vibration frequency range corresponding to dominant ambient vibration

frequencies common to multi-floor buildings. The modular pneumatic

isolators provide excellent protection against both vertical and horizontal

floor motions.

These workstations integrate Newport’s rigid, laminated honeycomb panel

technology and pneumatic isolation systems to provide a mounting plat-

form which is rigid, yet thin and lightweight. The system accommodates

high-center of-gravity loads with exceptional stability. Equipped with

optional casters, the system is easy to move without heavy equipment and

may be safely lifted by building elevators.

It is possible to tailor the system to a wide variety of applications using the

range of sizes and available working surfaces.

Please read and understand this instruction manual thoroughly before

beginning the assembly of the IsoStation workstation. The components

have been partially assembled at the factory and only require final assem-

bly and performance adjustment tasks. A bubble level is provided to aid in

leveling the system.

IsoStation components have been packed in labeled boxes. Make sure the

total number of delivered crates equals the total number listed on the

shipping documentation. Go over the assembly orientation diagram (Figure

1.1) while unpacking and verify the presence of all ordered parts. Carefully

inspect all components for any damage that may have occurred during

shipping. Report any such damage to the shipping agent at once.

The following safety terms are used in this manual:

The Warning term used in the text indicates dangers that could result in

personal injury.

The Caution term indicates situations that may result in damage to the

IsoStation components.

Getting Started

Introduction

1.1

1.2

Unpacking and

Inspection

1.3

Safety Terms

1.4

2

Figure 1.1 — Assembly Orientation

Support Ring with Armrests

The support ring encircles the top, providing

a mounting surface for shelves and support

ring mounts. Two armrests are included

with the support ring.

Sliding Shelves

Available in 6, 10, 14 and 21-inch

widths, these durable laminated

shelves rest on the optional support

ring. Be sure to order one for a handy

place to keep essential tools, samples

or documents close at hand. Or, for

maximum shelf space, order two —

one on each side of your system.

Equipment Shelves

One or two equipment shelves attach to the optional support

ring, providing extra storage space without transmitting

vibrations to the work surface.

Support Ring Mounts

Mounts may be moved any-

where around the support

frame for secure attachment

for virtually any type of spe-

cial equipment. A generous

array of tapped holes on the

top and side surfaces per-

mits secure mounting. Many

customers order an extra

mount for last-minute equip-

ment additions.

Instrument Rack

Standard 19-inch rack-mounted electron-

ics modules can be integrated into the

workstation with the instrument rack ac-

cessory. The rack is constructed of welded

heavy-gauge steel for stability and rug-

gedness. For additional isolation from

vibrations transmitted through control,

signal and power cables, the Cable Man-

ager accessory is recommended.

Casters

With these heavy-duty cast-

ers, a workstation can be

quickly and easily moved by

one person. IsoStation is also

compact enough to fit in most

elevators.

Front Support Bar

Includes two armrests for comfort-

able all-day operation of equip-

ment. Also allows attachment of

movable support ring mount.

[Note: Back support bar without

armrests also available.]

3

To ensure optimal performance carefully consider placement of your

workstation. Try to locate the unit on as level a surface as possible. Place-

ment on an uneven floor may make proper frame leveling more difficult. If

the unit will be located on floors other than the ground floor, attempt to

place it near primary vertical building structures such as exterior walls or

support columns. This will minimize the possibility of lower frequency floor

motion affecting the isolation performance. It is also advisable to avoid

locations adjacent to major sources of floor vibration such as operating

machinery.

WARNING

If installation site is susceptible to earthquakes it is recommended

that the legs be securely fastened to either the floor or an adjacent

wall. A support ring or support bars are also required to provide

earthquake table top restraint.

Warranty information may be found on page ii. Should it be necessary to

exercise the warranty, contact your Newport representative to determine

the correct course of action. Newport Corporation maintains offices in the

United States and worldwide. Check the back cover of this manual for the

addresses and phone numbers of these offices.

Workstation

Placement

1.5

1.6 Warranty

Information

4

Section 2

Assembly

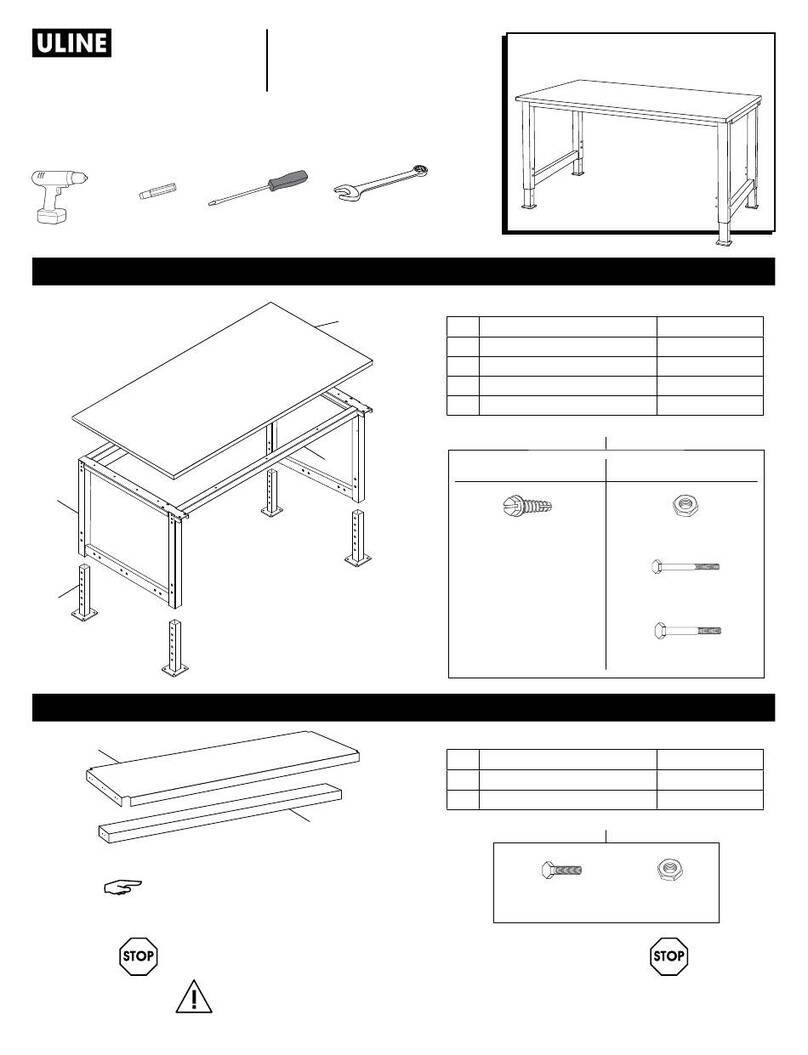

2.1.1 Frame Assembly

A. Typically, all IsoStation frames are fully assembled and tested at the

factory. If this is true in your case please disregard Sections 2.1.1 and

2.1.2. In some instances, overseas shipping will result in a partially

unassembled frame. In this case you should follow the procedures

outlined below.

B. Adjust the leveling pads on the bottoms of the legs (Figure 2.1).

Rotate the pads until the bottom of the pad extends 2 inches from the

bottom of the frame.

Jam nut

Height adjust nut

2.00"

(50mm)

Figure 2.1 — Leveling Pad Adjustment

C. If casters have been ordered, fasten them to the frame assemblies at

the pre-drilled and tapped locations on the lower cross members

(Figure 2.2), placing the 1 1/2 inch spacers between the caster and the

frame. Transferring the load to the casters is accomplished by simply

retracting the leveling pads into the legs once assembly is completed.

After the workstation has been moved to the desired location, re-

extend the leveling pads to lift the casters off the floor. Do not use the

IsoStation with the casters in contact with the floor.

Loose Assembly of

IsoStation Frame and

Air System

2.1

5

1-1/2" thick

spacer

Lower horizontal

leg brace

Caster

5/16"-18x2.0 hex bolt

5/16 lock washer

Figure 2.2 — Caster Installation

D. Layout the right and left leg assemblies along with the rear brace as

shown in Figure 1.1.

E. Assemble the leg units to the rear brace leaving the bolts slightly

loose. If armrest support bars are included, install them to the leg

assemblies. Make sure to consider the desired working height of the

armrest and/or shelf with respect to the table top surface and posi-

tion the support bars accordingly, also leaving the bolts slightly

loose.

2.1.2 Air System Assembly

The IsoStation workstation is shipped with the air regulator/filter (ARF),

Figure 2.3, and leveling valves installed on the leg assemblies.

A. Using the white tubing provided connect the inlet fitting on the right

leg assembly valve (single valve) to the “T” fitting on the left leg

assembly (see Figure 2.4). To connect the tubing to the fittings, insert

and firmly press the tubing into the fitting. ( Warning: Do not attempt

to disconnect the tubing once the system is pressurized.) Route the

tubing along the rear brace and secure it in position using the stick-on

tubing clips.

B. Turn the ARF control knob counterclockwise all the way to the “OFF”

position.

C. Use the translucent tubing provided to connect the ARF inlet to the

air supply.

6

Pressure

gauge

Filter

canister

Control

Knob

Top View Front View

Drain Valve

Figure 2.3 — ARF

2.1.3 Installing the Table Top

Lift the table top and carefully set it on the frame. Use a ruler to ensure that

the top is approximately centered on the frame.

WARNING

The table top can weigh as much as 250 lb (114 kg). It is important

to ensure that adequate personnel is available when installing the

table top or employ the use of a forklift or hoist.

For optimum performance the IsoStation frame must be assembled so that

the tops of the four legs are coplanar. If not, isolator travel may be limited.

A. Adjust the four leveling pads (Figure 2.1) until the table top contacts

evenly on all four of the legs and does not rock when pressed down

on at any of the four corners.

B. Tighten all frame and armrest support bolts.

C. Level the table top using the standard bubble level provided, or

equivalent, making any necessary further adjustments to the four

leveling pads.

D. Recheck that neither the frame nor the top can be rocked.

After the table top has been installed, but before the isolators have been

pressurized, remove the two Philips-head screws located on the sides of

each isolator.

Whenever the table top is removed, for example when the workstation is

transported to another location, reinstall the screws. Moving the workstation

with the table top installed does not require reinstallation of the screws.

2.2 Squaring and

Leveling the Frame

7

From

air

supply

Inlet

fitting

White

plastic

tubing

ARF

Left leg

“T” fitting

“T” fitting

See Figure 2.5

Figure 2.4 — Air System Diagram

A. Position the pads on each of the three leveling valve arms so that they

contact the underside surface of the table top (Figure 2.5).

Adjustment screw

Approximately

1/8" (3mm)

Isolator Pad

Table

top

Figure 2.5 — Leveling Arm Orientation

B. Fully close (turn clockwise) the needle valves located on the leveling

valves (Figure 2.6). Then open each needle valve approximately 1/8

turn for each isolator the valve supplies, i.e. the single valve at the

right side of the IsoStation controls the two right side isolators and

must be opened 1/4 turn.

Isolating the

Table Top

2.3

8

Needle valve

adjustment screw

Leveling valve body

EXH

GAUGE

IN

OUT OUT

Leveling

valve arm

Figure 2.6 — Leveling Valve

C. Turn up the air pressure with the ARF to approximately 50 psi. Adjust

the valve arm pad height until the table top is raised up (or floated)

above the flange of the isolator module by 0.175 inch (4.4 mm). Use a

No. 16 drill for a height reference.

CAUTION

Do not exceed the maximum allowable system pressure of 90 psi

(6.3 kg/cm2).

D. If the table top rocks back and forth (or hunts) on its own, reduce the

air pressure until the system is stable or close the needle valves

slightly.

E. Lift and press down each corner of the table top to ensure that the

approximate ±1/8 inch (±3 mm) of desired vertical travel exists. Push

the top horizontally in each axis to verify that there is approximately

±1/8 inch (±3 mm) of lateral travel.

F. Once the table top is loaded to the expected working load the system

air pressure should be adjusted to a level high enough so the top

floats in a stable manner, relevels quickly, and maintains the 0.175

inch (4.4 mm) clearance from the leg tops.

For assistance on any of the assembly operations please contact the

Newport applications staff or your nearest Newport representative at

the phone numbers listed on the back of this manual.

9

SHIPPING SCREWS

LOCK HORIZONTAL MOTION

TWO SCREWS SECURE ISOLATOR

MODULE TO EACH LEG

WHITE TUBE

CONNECTOR FLANGE FLUSH

WITH INSIDE OF LEG

(GREY) PIGTAIL TUBE

FACE IN TOWARD

CENTER OF FRAME

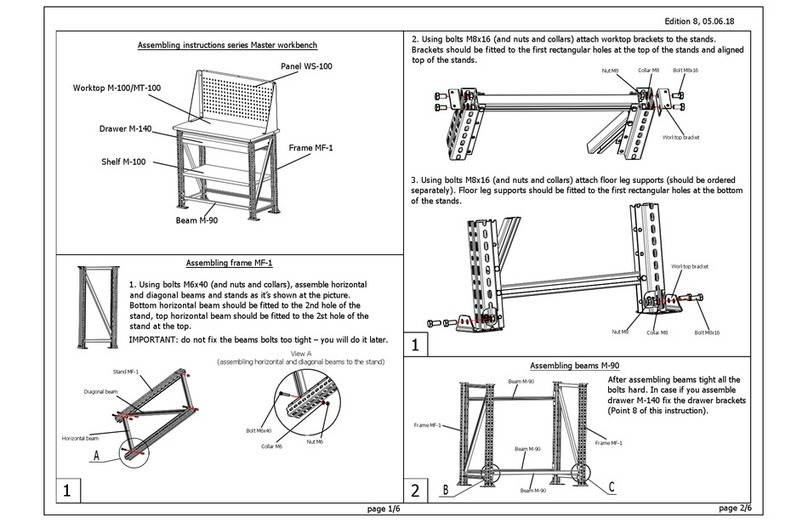

Figure 2.7 — Installing Isolator Modules

10

These additional assembly steps are necessary for optional items you may

have ordered for your workstation.

Support Ring

WARNING

Install the support ring only after installing the table top

(see Section 2.1.3).

Place the four support ring tubes (P/N 20306) in a rectangle with the holes

in the ends facing up and to the inside of the rectangle. Slide into the ends

of the support tubes the support arm corners (P/N 20305), making sure that

the three through-holes in the ends of the tubes and the threaded holes in

the corners are aligned. Install six 1/2-inch long button-head screws (P/N

3664-BA-244) in each corner.

Install the four support arm brackets (P/N 20308) , which connect the

IsoStation’s frame to the support ring assembly. Each bracket is mounted to

the frame with two 1-inch long hex-head screws (P/N 17054). A set of five

threaded holes in the frame enables the support ring to be mounted at the

level of 1", 2" or 4" thick work surfaces. Use the following list to determine

which of the five threaded holes to use:

4" thick work surface Install the bolts finger-tight in the first and

second holes, counting from the top

2" thick work surface Install the bolts finger-tight in the third and

fourth holes, counting from the top

1" thick work surface Install the bolts finger-tight in the fourth and fifth

holes, counting from the top

WARNING

Two people are required to install the support ring safely. Damage

or personal injury may result from attempting to install the support

ring alone.

Turn the support ring assembly over so that the button head screw in each

corner faces down (see Figure 2.8), position each support arm corner over

a bracket, and install a 1-inch long 5/16-18 hex bolt (P/N 3751-AF-248)

through the bracket and into the support arm corner.

Tighten the eight bolts that connect the support brackets and the

IsoStation frame. Place armrests (P/N 20012) on top of support ring.

Installing Accessories

2.4

11

P/N 20387 Front uprights

P/N 20385 Mount brackets

P/N 21252 Brace

P/N 20657 H-shaped rear frame

P/N 20380 Shelf assembly

P/N 20305 Support arm corners

P/N 20306 Support ring tubes

P/N 3847-BA-252 Cup pt. set screw

P/N 20389-01 Washer, neoprene

P/N 3664-BA-244 Screw, button HD

P/N 20308 Support arm bracket

P/N 3941-JO-0905-060 Flat washer

P/N 3751-AF-248 Hex head screw

P/N 3941-0829-048 Flat washer

P/N 17054-03 Screw, hex head (thread cutting)

15

14

13

12

11

10

9

8

7

6

5

4

1

3

1

2

2

34

5

8

9

7

10

11

12

13

15 14

6

Figure 2.8 —Workstation Diagram

12

Support Rail

WARNING

Install the support rail only after installing the table top (see

Section 2.1.3).

Place the rail (P/N 20306) with the holes in the ends facing up. Slide the

support arm endpieces (P/Ns 20948 and 20949) into ends of the support

ring tubes, making sure the three through-holes in each end of the tube and

the threaded holes on each endpiece are aligned. Install three 1/2-inch long

button-head screws (P/N 3664-BA-244) in each endpiece.

Install the two support arm brackets (P/N 20308) , which connect the

support rail and the front of the IsoStation frame. Each bracket is mounted

to the frame with two 1" hex-head screws (P/N 17054). A set of five threaded

holes enables the support rail to be mounted at the level of 1", 2" or 4" thick

work surfaces. Use the following list to determine which of the five

threaded holes to use:

4" thick work surface Install the bolts finger-tight in the first and

second holes, counting from the top

2" thick work surface Install the bolts finger-tight in the third and

fourth holes, counting from the top

1" thick work surface Install the bolts finger-tight in the fourth and fifth

holes, counting from the top

Position the rail assembly over the support arm brackets with the threaded

holes facing down, and install a 1-inch long hex bolt (P/N 3751-AF-248)

through the bracket and into each endpiece.

Tighten the four bolts that connect the bracket and the IsoStation frame.

Place armrests (P/N 20012) on top of support rail.

Casters

Casters are installed before initial frame assembly as described in 2.1.1.C. If

casters are being added to an existing assembled workstation it will have

pre-drilled and tapped holes on the lower leg assembly crossbraces.

Equipment Shelves

Attach the supplied mount brackets (P/N 20385) to the two front uprights

(P/N 20387) and the H-shaped rear frame (P/N 20657) at the desired shelf

height. Place the shelves in the uprights and attach to the mount brackets.

Attach the corner braces (P/N 21252) between the rear uprights and the top

shelf, using the Phillips-head screw already installed on the underside of the

shelf to attach the corner brace (see Figure 2.8). Install the plastic covers in

the top of each of the uprights.

WARNING

Two people are required to install equipment shelves safely.

Damage or personal injury may result from attempting to install

shelves alone.

Install the 5/16-inch threaded studs in the corners of the support ring, then

place a rubber washer over each. Place the equipment shelf so that the

uprights cover the studs and rest on the rubber washers on the tops of the

support rail corners.

13

Instrument Rack

The instrument rack installs between the front legs of the frame and is revers-

ible so that the operator can sit on the right or left side of the workstation.

Before installing the instrument rack, check the mounting holes on the inside

of the frame legs for plastic covers. Remove the covers as required.

Position the instrument rack between the front legs. Attach the instrument

rack to the frame with the provided one-inch long 1/4-20 bolts. (It may be

necessary to loosen the bolts on 2 braces at the rear of the frame).

Monitor Arm and Base Clamp

The monitor arm includes a base clamp to attach it to the workstation

support rail or ring. To install a base clamp on the support ring, loosen the

hex screw on the front face and remove the bar and knob by sliding it to the

side. To reinstall the clamp, place it over the rail, center the slide bar and

reinstall the hex screw. Position the clamp on the rail and then tighten the

knob to lock it in place.

Cable Manager

To minimize the vibrations transmitted by electrical and supply cables to

isolated equipment, mount the cable manager on the support rail or ring

using a base clamp. Place cables and supply lines between the jaws of the

cable manager, maintaining as much slack as possible on both sides of the

Cable Manager.

Retrofit Isolators To Non-Isolated Frame (see Figure 2.7)

Remove the two screws securing the molded insert on the top of each leg

and remove and discard the inserts. Save the screws to secure the isolators.

Feed the white tubing located between the control valve and the isolator

through the hole in the leg and up over the edge of the leg. Insert the fitting

on the 1/8 inch pigtail tube on the bottom of the isolator into the end of the

1/4 inch white tube. Back out the white tube until the flange on the connec-

tor fitting is flush with the inside of the leg.

Insert the isolators into the top of each leg, ensuring that the single nut on

the side of the isolator faces toward the center of the frame. Secure the

isolator using the two screws removed from the insert.

Install the leveling valves and ARF as shown in Figures 2.3, and 2.6. Plumb

the air system with the tubing provided per Figure 2.4. Secure the tubing in

place along the IsoStation frame using the stick-on tubing clips provided.

Clean the frame with alcohol before attaching clips.

Check the system for leaks by connecting the air supply to the ARF and

adjusting the pressure to 80 psi. Ensure that all leveling valve needle adjust-

ments have been set open at least 1/8 turn. Open each leveling valve in turn

by holding the leveling arms down. After 15 seconds shut off the air supply

to the ARF. If the air pressure on the ARF gauge falls steadily this indicates a

leak in the branch of the system controlled by the leveling valve held open.

Leaks may be found by applying soapy water to all connections and check-

ing for bubbles. Tubing-to-fitting leaks are generally caused by uneven or

non-square ends on the tubing. Careful cutting of the tubing ends should

remedy this problem.

Turn off the air supply at the ARF and allow the isolator pistons time to

settle. Proceed to install the table top as directed in Section 2.1.3 and

14

continue with the instructions given in Section 2.3 for isolating the table

top. For help in identifying any isolation problems see Section 4, Trouble-

shooting.

Static Dissipative Table Tops

Figure 2.9 indicates how to attach the special ground strap hardware to

your IsoStation if it has come with the static dissipative table top.

Wrist band

Connection to

ground

Table top

connection

Figure 2.9 —Ground Strap Attachment

15

Section 3

Operation

The IsoStation pneumatic isolators are one of the best methods of vibration

isolation for critical applications. They are designed and constructed to

provide very effective isolation of vibrations at frequencies above 5 Hz by

exhibiting the “fast roll-off” characteristics of the simple harmonic oscilla-

tor. In addition, they provide the low amplification at resonance (1.5 to 2

Hz) that is associated with the classic damped harmonic oscillator.

The basic design for a Newport pneumatic isolator with laminar flow

damping is depicted in Figure 3.1. The isolated mass (for example, an

optical table, or precision instrument such as a microscope) is supported

by pistons which rests on a flexible rolling diaphragm. The diaphragm

separates the piston from an air chamber called the “compliance chamber”.

Air flowing through the laminar flow restrictor dissipates energy, reducing

the amplification of the isolator at resonance.

To achieve high performance horizontal isolation the IsoStation design has

incorporated a three point support pendulum system for each of the

isolator units. This approach renders horizontal isolation performance that

is comparable to that in the vertical direction and results in a work platform

that will provide the highest level of isolation from unwanted vibrations in

any direction.

Once the system is assembled and the table top is floating it is possible to

make minor performance adjustments to the isolation system to suit the

individual users needs. This involves adjustments to the system air pres-

sure, leveling arms, and needle valves.

A. Stabilizing high center-of-mass loads: Working loads on the table

which have a relatively high center-of-mass (approximately 1/2 times

the shortest table dimension above the working surface) may make

the system more difficult to stabilize. Operating at a lower system

pressure will improve stability and tend to reduce the rocking or

hunting.

B. Improving leveling response times: If the system is stable, it is pos-

sible to improve the releveling response time by increasing the

system pressure. This is desirable if moving components are regularly

disturbing the working surface.

C. Fine tuning the leveling valves: Further performance adjustments can

be made by using the needle valve on each leveling valve (discussed

in Section 2.3.B). If faster releveling is desired open all the needle

valves in 1/8 turn increments (counter-clockwise) until the required

releveling time is achieved. All needle valves should always be

opened the same for each isolator they control. See Section 2.3.B. If

instability is more of a concern and it is desirable to reduce the

potential for the top to oscillate or hunt it is necessary to close the

needle valves as much as possible, without closing them completely.

Experimentation will help determine the best settings for the needle

valves, the optimal ARF pressure, and the correct leveling arm posi-

tion to best serve each particular application.

Principles of

Operation

3.1

Performance

Adjustments

3.2

16

3.3.1 Cleaning

To clean any of the optional work surfaces (either 400 series stainless steel

or high pressure laminate) spray household cleaner, such as “409” or

“Fantastic”, on a clean cloth and wipe down. Avoid using abrasive cleaners

since they will foul the mounting holes and also damage the laminate tops.

Isolated mass

(work surface)

Rolling

diaphragm

Piston

Laminar flow

damping

element

Figure 3.1 —Newport Laminar Flow Damping Isolator Design

Maintenance

3.3

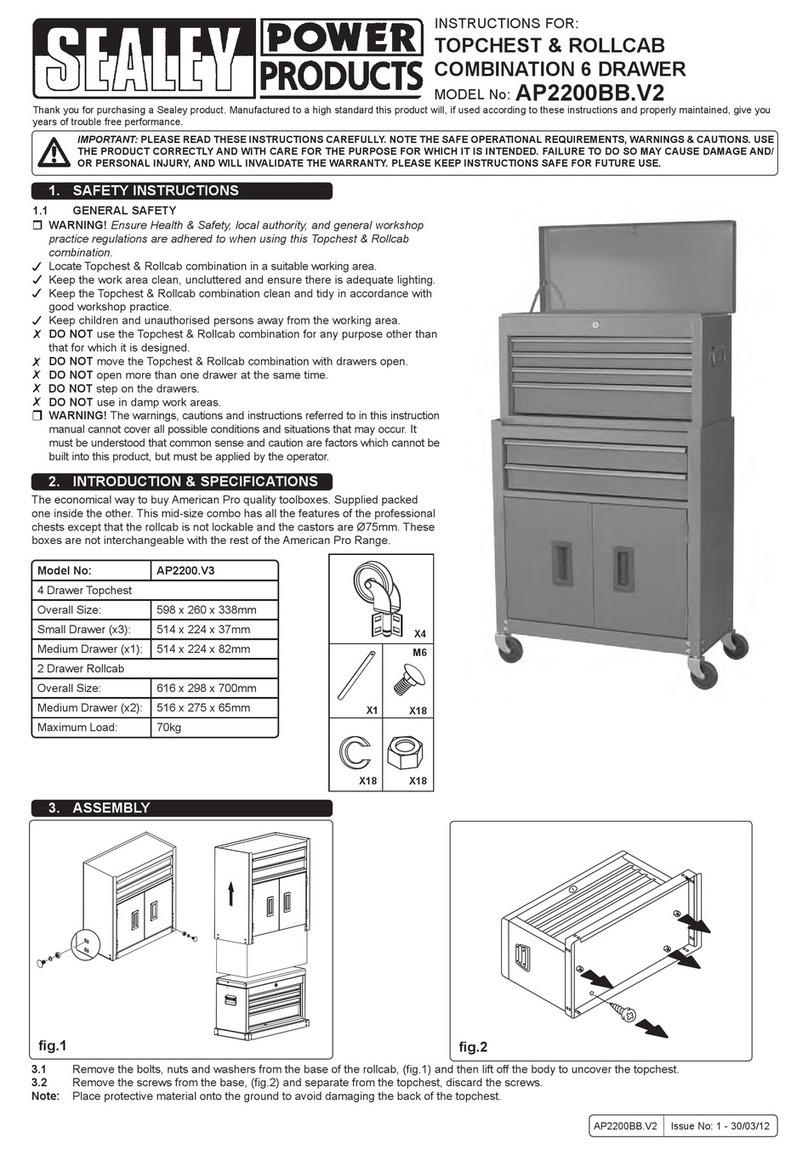

Table of contents

Popular Tools Storage manuals by other brands

RIDGID

RIDGID AC9910 owner's manual

MIRKA

MIRKA Modular Trolley operating instructions

Triton

Triton TWX7 Operating and safety instructions

Bahco

Bahco Tool Holders Collection brochure

Riverstone Networks

Riverstone Networks Monticello Work Bench System 8 x 8 installation manual

Stanley

Stanley STST83400 instruction manual