NEWTON TAS250

Ground & Surface Water Pump

© Newton Waterproofing Systems

(a trading name of John Newton & Co. Ltd.)

Newton House, 17-20 Sovereign Way, Tonbridge, Kent, TN9 1RH

T: +44 (0)1732 360 095 W: www.newtonwaterproofing.co.uk E: tech@newtonwaterproofing.co.uk

Page 2 of 4

NEWTON PUMPS, PUMPING SYSTEMS AND ANCILLARIES

INSTALLATION

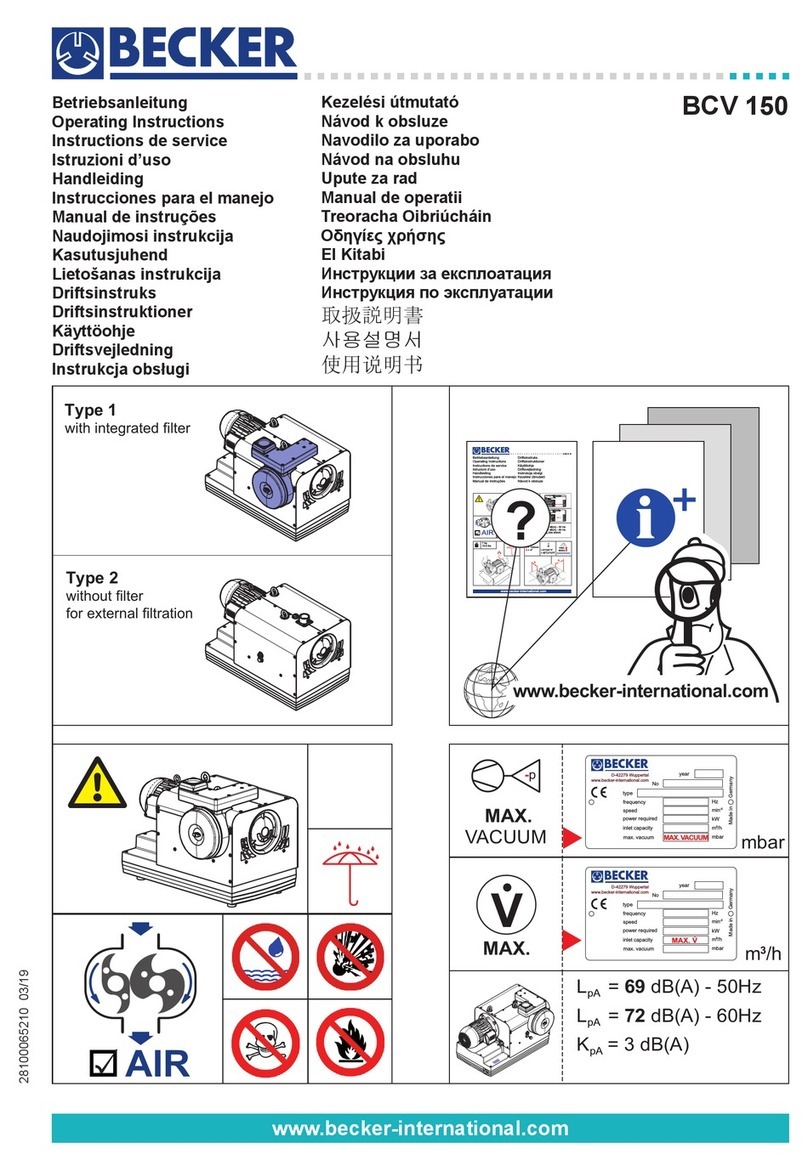

• Do not work on pump until power is unplugged

• Do not cut off ground pin or use an adapter tting

• Do not use an extension cord

• Before installing or servicing this pump, be certain pump power source is disconnected

• Installation and electrical wiring must be carried out by trained and qualied personnel

• Pump must be correctly earthed

• Voltage of power supply must match the voltage of the pump

• Before installing pump, clear sump basin of any water, debris or sediment

The following may cause severe damage to pump and will void warranty:

• Using extended wiring not suitable for the pump motor size and the distance of the extended cable

• Not having the pump correctly grounded to earth

• Working on the pump without it being disconnected

• Running the pump continuously

• Pumping chemicals or corrosive liquids

• Pumping gasoline or other ammable liquids

• Do not use the pump if it is damaged

Overload protection:

Newton TAS250 includes built in thermal protection switch. The pump stops if an overload condition occurs. The motor restarts automatically after

it has cooled down.

Electric Supply:

The Newton TAS250 requires a single phase 230V AC power supply. It is advisable that all pumps are connected to their own individual power

supply directly from the consumer board so that each of the pumps does not share a consumer board supply with the other pump or with any

other electrical circuit or device. In reality, this is normally only achievable with new build properties or where fundamental refurbishment of the

whole property or the electrical supply is to be undertaken. Where it is not planned or possible to have each pump connected to a separate

supply from the consumer board, it is preferable that each pump is supplied from a separate circuit. If this is not possible, each pump should be

connected to a separate fused and switched spur or socket. Each separate circuit should have its own RCD protection as required by the 17th

Edition Wiring Regulations. The RCD should be correctly sized at 30mA so as not to trip during normal pump start or pump run parameters.

It is preferable for the pumps to be wired to the rear of a switched spur. The spur should be switched and have a neon light confirming the ‘ON’

position. Pumps may be plugged into wall sockets and again these should be switched and have neon light notification of the ‘ON’position. It is

recommended that the spur or socket have a label confirming that the switch must not be switched off unless in an emergency.

The spur or socket should be located in direct eye sight line of the sump and to the wall closest to the sump so that in an emergency it is obvious

which switch(es)will turn off the pumps.

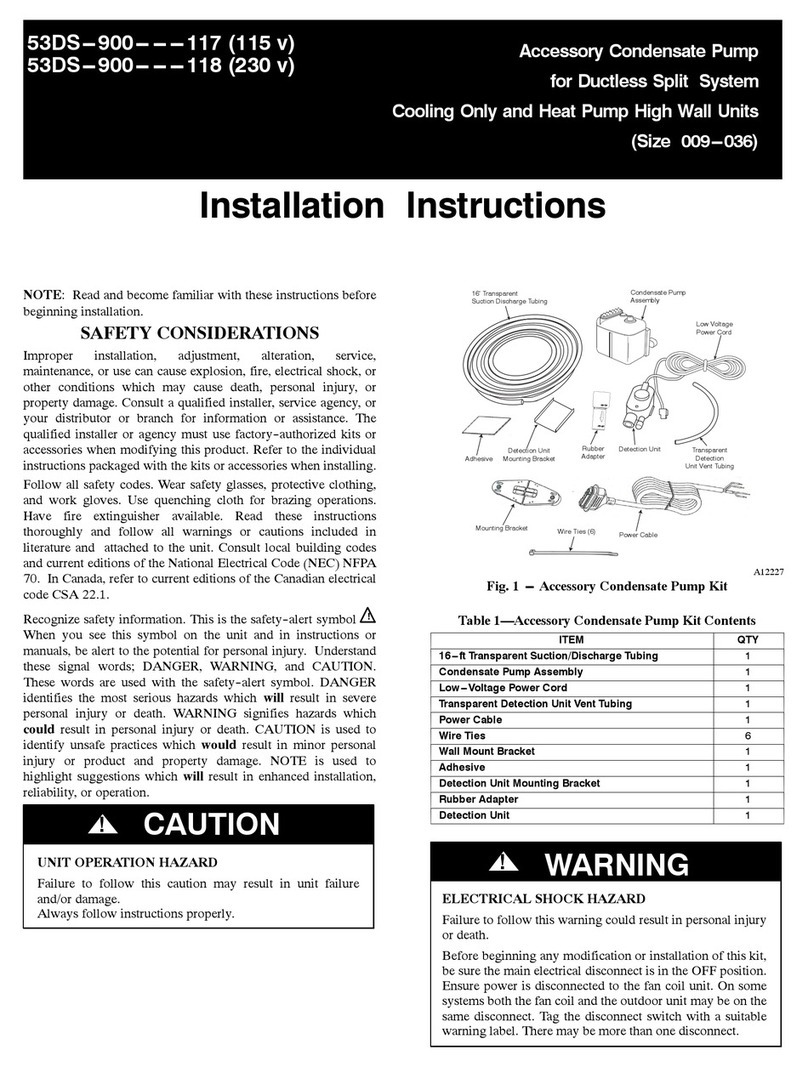

SUPPLIED FITTINGS

Newton TAS250 is supplied ready to receive pressure rated pipe, the recommended pipe for pumps. The data sheet confirms the supplied pipe

and valve options. The correct pipe, valves and pipe fittings should be ordered prior to installation.

Fit the pump into the sump chamber with correctly sized and cut pipework and pipe fittings, ensuring that the pipe build includes a means of

removal of the pumps for servicing and repair.

ELECTRICAL PRECAUTIONS

Before servicing a pump, always shut off the main power breaker and then unplug the pump.

Make sure you are not standing in water and are wearing insulated protective sole shoes.

Connection or disconnection of the pump from the electrical supply should be by trained & qualified persons only.

TROUBLESHOOTING - DISCONNECT PUMP FROM MAINS & CONVERTER POWER SUPPLY

• Pump(s) must receive power directly from a fused switched spur that is in line of sight of the

pumping station. Do not connect the pump to extension cables

•

• If possible, each pump should have its own connection to the consumer board and be protected

by a 30 mA RCD

•

• Use the correct size fuse for the pump as conrmed on page 3

INSTALLATION - IMPORTANT

INSTALLATION

• Do not work on pump until power is unplugged

• Do not cut off ground pin or use an adapter tting

• Do not use an extension cord

• Before installing or servicing this pump, be certain pump power source is disconnected

• Installation and electrical wiring must be carried out by trained and qualied personnel

• Pump must be correctly earthed