6

For more information, visit us online www.newtonwaterproong.co.uk

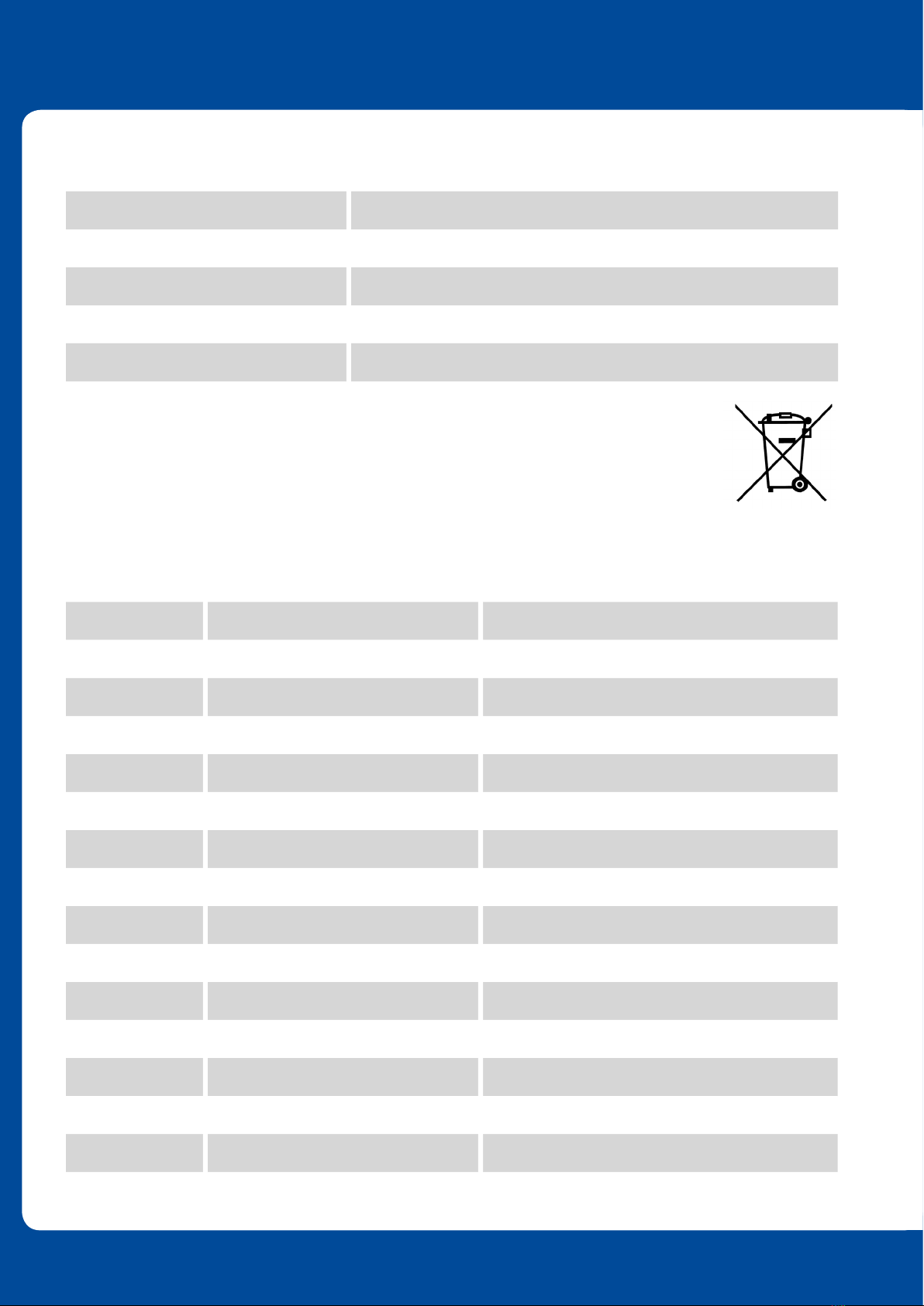

CONNECTION TO GRID MAINS

ELECTRICAL CONNECTION OF CONTROL PANEL

INSTALLATION WARNINGS:

THIS CONTROL PANEL MUST ONLY BE INSTALLED BY TRAINED ENGINEERS.

BEFORE COMMENCING INSTALLATION, ISOLATE YOUR MAINS ELECTRIC SUPPLY.

This product should be installed in accordance with the relevant sections of the building regulations code and the

current edition of the IEE Wiring Regulations (BS 7671: Requirements for electrical installations) and appropriate

statutory regulations.

As of April 2004, new installations in the UK should be wired using the EU harmonised colours for the supply

conductors. NEW COLOURS: BROWN = Live, BLUE = Neutral, YELLOW / GREEN = Earth. This installation MUST be

earthed.

This control panel is IP55 rated.

Warning: it is important to read and understand the Control Panel instructions

The panel has been designed to be wall mounted. When the unit is recessed into the wall, the routing of all

cables is also within the wall, making a neater installation than if the unit is wall mounted. Cable entry is via the

knock-outs to the bottom and side of the panel, and glands are supplied for recessed mounting.

For ease of maintenance in changing pumps, it is recommended to always use 50 mm conduit for the high-

voltage pump cable, and a separate 50 mm conduit for the low-voltage Probe Set cable.

NOTES:

Please note that low-voltage rated cables cannot be run in the same conduit as high-voltage (230V AC) cables.

The Panel must be earthed.

If the water level is above the alarm probe on rst powering up the panel, the alarm may sound.

CONNECTIONS

Power supply – 230V AC suitably rated to operate the pump from a locally fused spur, preferably from its own

feed off the consumer board.

• Probe Set Brown Wire (Common) - Terminal COM (7)

• Probe Set Green Wire (Min) - Terminal MIN (8)

• Probe Set White Wire (Max) - Terminal Max (9)

• Pump Brown Wire (Live) – Terminal U1 (14)

• Pump Blue Wire (Neutral) – Terminal N (15)

• Pump Green & Yellow Wire (Earth) – Terminal PE (17)

• Alarm oat (Option) – Terminal 1 & 2 (No polarity)

• Dialer (Option) – Terminal USCITA ALLARME 11 & 12 (No polarity)

CONNECTION TO NEWTON DIALER – PA5

The Newton Dialer - PA5 can receive a signal from the panel allowing notice of the alarm condition to be

received as a voice message or text message to mobile phones. Up to 8 separate numbers can receive the voice

or text message.

The terminals for the connection to the Dialer are at the bottom of the inside circuit board of the panel and are

marked USCITA ALLARME with normally closed – common – normally open terminals (NC – C – NA).

Use normal two core bell wire and make a connection with one of the two coloured wires between the NO

(Normally Open) terminal of the Alarm and Trigger Input 1 of the Dialer, with the other wire connecting the

C (Common) terminal of the Alarm, with the OV Trigger Input of the Dialer. The Dialer needs a separate power

supply (12V power pack PA7 or battery connection kit - PA6 if the battery backup system is used within the

pumping system).

CONNECTION DIAGRAM