Newton Waterproofing NP400 Quick start guide

DATA SHEET |MSDS |OPERATIONAL MANUAL

NEWTON PUMPS, PUMPING SYSTEMS AND ANCILLARIES

© Newton Waterproong Systems

(a trading name of John Newton & Co. Ltd.)

Newton House, 17-20 Sovereign Way, Tonbridge, Kent, TN9 1RH

T: +44 (0)1732 360 095 W: www.newtonwaterproong.co.uk E: tech@newtonwaterproong.co.uk

Rev 2.0 - 11 October 2017 PRODUCT CODE - P2 & P3

Page 1 of 6

Pumps, Pumping Systems and Ancillaries

NEWTON NP400

Clean Water Pump

®

INTRODUCTION

Congratulations on your purchase of this pump product. All Newton pump products are developed with the help of

the latest technologies and manufactured with the most advanced electrical/motor parts.

Please check the following points upon receipt of your pump:

1. The pump is the model that you ordered.

2. Has any damage been caused during delivery?

3. Are the pipe/valve ancillary parts you asked for included as requested?

Please take the time to read these instructions carefully before using the appliance.

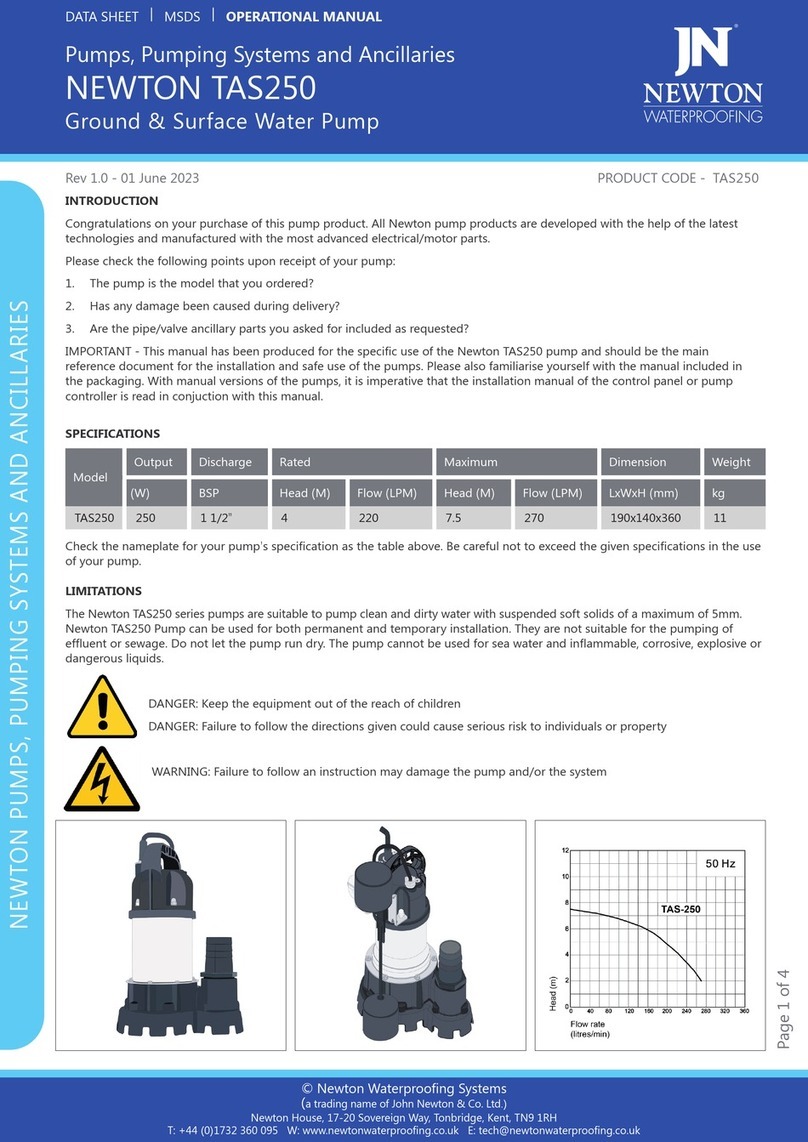

SPECIFICATIONS

Check the nameplate for your pump’s specication as the table above. Be careful not to exceed the given

specications in the use of your pump.

LIMITATIONS

The Newton NP400 is suitable to pump clean water with suspended soft

solids of up to 7 mm. The pump can be used for both permanent and

temporary installation. Do not use for the pumping of efuent or sewage.

Do not let the pump run dry. The pump cannot be used for sea water and

inammable, corrosive, explosive or dangerous liquids.

DANGER: Keep the equipment out of the reach of children

DANGER: Failure to follow the directions given could

cause serious risk to individuals or property

WARNING: Failure to follow an instruction

may damage the pump and/or the system

Output Discharge Rated Maximum Dimension Weight

(W) BSP Head (M) Flow (LPM) Head (M) Flow (LPM) LxWxH (mm) kg

400 2” 4 160 12 204 241x185x328 11.3

Flow Rate (litres/minute)

Head (m)

14

12

10

8

6

4

2

0

0 25 50 75 100 125 150 175 200 225

INSTALLATION - IMPORTANT

• Pump(s) must receive power directly from a fused

switched spur that is in line of site of the pumping

station. Do not connect the pump to extension

cables

• If possible, each pump should have its own

connection to the consumer board and be protected

by a 30 mA RCD

• Use the correct size fuse for the pump as conrmed

on page 2

NEWTON NP400

Clean Water Pump

© Newton Waterproong Systems

(a trading name of John Newton & Co. Ltd.)

Newton House, 17-20 Sovereign Way, Tonbridge, Kent, TN9 1RH

T: +44 (0)1732 360 095 W: www.newtonwaterproong.co.uk E: tech@newtonwaterproong.co.uk

Page 2 of 6

NEWTON PUMPS, PUMPING SYSTEMS AND ANCILLARIES

INSTALLATION

• Do not work on pump until power is unplugged

• Do not cut off ground pin or use an adapter tting

• Do not use an extension cord

• Before installing or servicing this pump, be certain pump power source is disconnected

• Installation and electrical wiring must be carried out by trained and qualied personnel

• Pump must be correctly earthed

• Voltage of power supply must match the voltage of the pump

• Before installing pump, clear sump basin of any water, debris or sediment

The following may cause severe damage to pump and will void warranty:

• Using extended wiring not suitable for the pump motor size and the distance of the extended cable

• Not having the pump correctly grounded to earth

• Working on the pump without it being disconnected

• Running the pump continuously

• Pumping chemicals or corrosive liquids

• Pumping gasoline or other ammable liquids

• Do not use the pump if it is damaged

Overload protection:

The Newton NP400 includes a built in thermal protection switch. The pump stops if an overload condition occurs.

The motor restarts automatically after it has cooled down.

Electric Supply:

The NP400 pump requires a single phase 230V AC power supply. It is advisable that all pumps are connected to

their own individual power supply directly from the consumer board so that each of the pumps does not share a

consumer board supply with the other pump or with any other electrical circuit or device. In reality, this is normally

only achievable with new build properties or where fundamental refurbishment of the whole property or the

electrical supply is to be undertaken. Where it is not planned or possible to have each pump connected to a separate

supply from the consumer board, it is preferable that each pump is supplied from a separate circuit. If this is not

possible, each pump should be connected to a separate fused and switched spur or socket. Each separate circuit

should have its own RCD protection as required by the 17th Edition Wiring Regulations. The RCD should be correctly

sized at 30mA so as not to trip during normal pump start or pump run parameters.

It is preferable for the pumps to be wired to the rear of a switched spur. The spur should be switched and have

a neon light conrming the ‘ON’ position. Pumps may be plugged into wall sockets and again these should be

switched and have neon light notication of the ‘ON’ position. It is recommended that the spur or socket have a label

conrming that the switch must not be switched off unless in an emergency.

The spur or socket should be tted with the correctly sized fuse appropriate to the motor size of the connected

pump: NP400 - 10 amps

The spur or socket should be located in direct eye sight line of the sump and to the wall closest to the sump so that

in an emergency it is obvious which switch will turn off the pumps.

SUPPLIED FITTINGS & PIPE INSTALLATION

The Newton NP400 is supplied with: 1 x 2” BSP threaded male to 1 1/2” BSP threaded female reducing bush; 1 x

1 1/2” BSP threaded male to 1 1/2” BSP threaded male check-valve and 1 x 1 1/2” BSP threaded female to 50 mm

female socket adapter, ready for 50 mm pressure pipe.

Fit the pump into the sump chamber with correctly sized and cut pipework and pipe ttings, ensuring that the pipe

build includes a means of removal of the pumps for servicing and repair. This leaves the pump ready to receive

50 mm uPVC pressure rated pipe. The correct pipe, shut-off valves and pipe ttings should be ordered prior to

installation.

Screw the reducing bush into the pump; the valve into the reducing bush and then the socket adapter onto the valve.

The pump is now ready to receive the 50 mm uPVC pipe.

NEWTON NP400

Clean Water Pump

© Newton Waterproong Systems

(a trading name of John Newton & Co. Ltd.)

Newton House, 17-20 Sovereign Way, Tonbridge, Kent, TN9 1RH

T: +44 (0)1732 360 095 W: www.newtonwaterproong.co.uk E: tech@newtonwaterproong.co.uk

Page 3 of 6

NEWTON PUMPS, PUMPING SYSTEMS AND ANCILLARIES

ELECTRICAL PRECAUTIONS

Before servicing a pump, always shut off the main power breaker and then unplug the pump.

Make sure you are not standing in water and are wearing insulated protective sole shoes.

Connection or disconnection of the pump from the electrical supply should be by trained &

qualied persons only.

TROUBLESHOOTING - DISCONNECT PUMP FROM MAINS & CONVERTER POWER SUPPLY

PROBLEM POSSIBLE CAUSES

Pump motor hums

but no water is being

pumped

Impeller may be clogged. Free impeller from debris.

The check valve may have been installed in the wrong direction. Ensure arrow on valve is

pointing in direction of ow.

Discharge shut-off valve (if used) may be closed.

Pump could be air-locked. Start and stop several times by raising and lowering the switch.

Check for clogged vent hole in pump case.

Float may be set too low – pump has removed as much water as it can but cannot switch

off. Raise oat so that the pump turns off before pumping out all the water it can.

NOTE: If all of the above are OK, then the motor winding could be damaged.

Pump runs and

pumps out sump but

does not stop

Switch may be caught and so unable to reach the ‘OFF’ position. Make sure switch is

unhindered in its operation.

Possible defective vertical switch. Speak with Newton Waterproong with a view to

replacing with vertical switch.

Float may be set too low – pump has removed as much water as it can but cannot switch

off. Raise oat so that the pump turns off before pumping out all the water it can.

Pumps runs but

delivers only a small

amount of water

Pump could be air-locked. Start and stop several times by raising and lowering the switch.

Float may be set with a too narrow band between ‘ON’ & ‘OFF’. Reset oat so that the

pump turns on and off to remove the optimal volume of water.

Inlet holes in pump base are clogged. Clean the inlets of debris.

Impeller or volute openings maybe fully or partially clogged. Remove pump and clean the

openings.

Pump impeller could be partially clogged with matter, causing motor to run slow and

overload. Remove pump and clean.

Fuse blows or circuit

breaker trips when

pump starts

Pump impeller or impeller housing may be partially clogged with foreign matter, causing

motor to run slow and overload. Remove pump and clean.

Motor starter may be defective.

Fuse size may be too small. Use a 10 amps fuse.

Circuit breaker could be too sensitive. Use 30mA breaker.

Motor runs for a

short time, then stops

Inlet openings in pump base may be clogged. Remove pump and clean the openings.

Pump impeller may be partially clogged with foreign matter, causing motor to run slow

and overload. Remove pump and clean.

Motor starter may be defective.

Impeller may be fully or partially clogged. Remove pump and clean.

NEWTON NP400

Clean Water Pump

© Newton Waterproong Systems

(a trading name of John Newton & Co. Ltd.)

Newton House, 17-20 Sovereign Way, Tonbridge, Kent, TN9 1RH

T: +44 (0)1732 360 095 W: www.newtonwaterproong.co.uk E: tech@newtonwaterproong.co.uk

Page 4 of 6

NEWTON PUMPS, PUMPING SYSTEMS AND ANCILLARIES

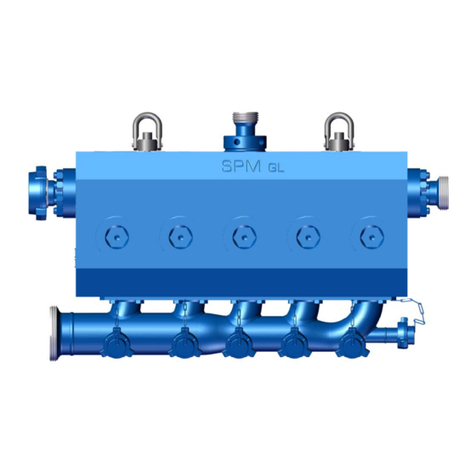

STRUCTURE & PARTS LIST

NEWTON NP400

Clean Water Pump

© Newton Waterproong Systems

(a trading name of John Newton & Co. Ltd.)

Newton House, 17-20 Sovereign Way, Tonbridge, Kent, TN9 1RH

T: +44 (0)1732 360 095 W: www.newtonwaterproong.co.uk E: tech@newtonwaterproong.co.uk

Page 5 of 6

NEWTON PUMPS, PUMPING SYSTEMS AND ANCILLARIES

GUARANTEE

The right to claim under guarantee must be proven by the purchaser by presentation of the purchase invoice.

Note:

• Should your equipment not function correctly, please rstly check whether this is due to other reasons, e.g.

interruption of the power supply or incorrect handling are the cause

• Please do not return goods to Newton Waterproong Systems unless accompanied by proof of purchase and a

Newton Returns Form. The form should be correctly and fully completed

NEWTON NP400

Clean Water Pump

© Newton Waterproong Systems

(a trading name of John Newton & Co. Ltd.)

Newton House, 17-20 Sovereign Way, Tonbridge, Kent, TN9 1RH

T: +44 (0)1732 360 095 W: www.newtonwaterproong.co.uk E: tech@newtonwaterproong.co.uk

Page 6 of 6

NEWTON PUMPS, PUMPING SYSTEMS AND ANCILLARIES

LIMITED WARRANTY

Newton Waterproong Systems will repair with new parts or replace the pump if proven to be defective due to

materials or workmanship.

Newton Waterproong Systems shall possess the sole right to determine whether to repair or replace defective

equipment, parts or components.

PUMPS: Newton NP Pumps are supplied with a 3-year manufacturers warranty from the proven date of installation

or the date of purchase if this cannot be veried. A 5-year warranty is available if the pumps are serviced at intervals

agreed by a Newton approved service engineer. In all cases, the warranty is ‘back-to-base’. Newton Waterproong

Systems have a returns policy and any issues regarding pumps under warranty should, in the rst instance, be

referred to our Head Ofce by contacting 01732 360 095. Please see our Terms & Conditions of Sale for further

information.

LABOUR & COSTS: Newton Waterproong Systems shall in no event be liable for the cost of eld labour or other

charges incurred by the customer in removing and/or re-afxing any Newton pump product, parts or components.

THE WARRANTY WILL NOT APPLY:

• to defects or malfunctions resulting from failure to correctly install, operate, or maintain the pump in accordance

with printed instructions provided

• to failures resulting from abuse, accident or negligence

• to normal maintenance services and the parts used in connection with such service

• to units which are not installed in accordance with applicable local codes, ordinances and good trade practices

• if the unit is used for purposes other than for what it was designed and manufactured for

Table of contents

Other Newton Waterproofing Water Pump manuals

Popular Water Pump manuals by other brands

Pratissoli

Pratissoli LK-LKN Use and maintenance manual

Weir

Weir SPM QWS 2500 Operation Instruction and Service Manual

Barmesa Pumps

Barmesa Pumps BCS Series Installation, operation & maintenance manual

Sam

Sam AD Series MANUAL FOR OPERATION AND MAINTANACE

GORMAN-RUPP

GORMAN-RUPP SUPER T6A65S-B Installation, operation and maintenance manual

ITT

ITT FLYGT BWS Series Installation, Care and Maintenance