Newwave PUREWATER PW 100-M5 Series User manual

Warning!

Hazardous Voltage: Can Shock, Burn or Cause Death.

6Disconnect power at main panel before connecting electrical power

supply to reclaim unit panel or working on electrical connections.

6Ground reclaim unit before connecting to the electrical power

supply. Failure to ground reclaim unit can cause severe or fatal

electrical shock hazard.

6Wire reclaim unit for correct voltage. See “Controls and Electrical”

section of this manual and “Installation & Operating Instructions”

label on the electrical panel cover.

6Meet National Electrical Code and local codes for wiring.

6Follow wiring instructions in this manual when connecting the

reclaim unit to the power supply.

Caution! This Reclaim Unit has been evaluated for use

with water only.

For Assistance, Contact PurWater 800-882-8854

Table of Contents

Reclaim Water Systems

6Reclaim General Description ...............................................................5

6PurWater Reclaim System Description ……………………………..…5-9

System Installation

6Frame ...............................................................................................10

6Reclaim Unit Piping …………………………………………………..10-14

6Reclaim Tanks ……………………………………………….………..14-17

6Electrical Safety ................................................................................18

6Controls and Electrical Wiring …………………………………….…19-21

System Start-Up, Operation and Maintenance

6Electrical Component / Control Functions …………………………22-25

6Start-Up ………………………………………………………………..26-29

6Operation ………………………………………………………………30-34

6Maintenance Schedule for Air Sparger Systems ………………….35-42

6Maintenance Schedule for Ozone Systems ……………………….43-55

Troubleshooting Guide ………………………………………….57-59

Warranty ....................................................................................... 60

Returned Goods Authorization Policy ...................................... 61

Start Up Warranty Validation ...................................................... 62

Appendix

a. Ozone Material Safety Data Sheet (MSDS)

b. Sta-Rite Self-Priming Centrifugal Pumps – “D” Series

Reclaim Water Systems

General Description:

The use of reclaim water has become an important method for the car wash

operator to reduce his / her operating expenses (water / sewer costs) and start-up

costs (impact / connection fees). Many municipalities are requiring the use of

reclaim water in car wash operations and operators are continually looking for

ways to increase profits, so reclaim systems are becoming essential in the overall

operation of the wash.

Reclaim water is the re-use of water that has already been used in the wash and

recovered by the drain system in the wash bay. Most drain systems consist of a

catch basin to settle out the large solids, followed by two or three underground

reclaim tanks to remove oil & grease, floatable materials and settleable solids.

Overflow water from the last reclaim tank is then discharged to sewer or an oil /

water separator.

Water from the reclaim tanks contains solids that have not settled within the tank.

These solids are typically small in size (less than 150 microns) and consist of sand,

clay, and silt. These solids can increase wear on pumps, piping, and nozzles, and

increase the potential of plugging nozzles. Reclaim water also is a great

environment for growing bacteria which can create plugging and odor problems.

Typically, anaerobic bacteria (bacteria that grow in the absence of oxygen) will

grow beneath the settled solids in the reclaim tank. This type of bacteria produces

hydrogen sulfide and methane that has an odor similar to rotten eggs. A properly

designed reclaim system must both remove solids and provide biological / odor

control.

A PurWater reclaim system takes water from the last compartment of the reclaim

tank and treats it further so that the quality is acceptable for re-use in the wash.

The PurWater reclaim system also returns a portion of the water back to the

reclaim tank to provide biological / odor control. Reclaim water that is treated by a

PurWater system can then be used for the undercarriage, side panel blasters,

mitters, and high pressure rinse cycles which greatly reduces the overall amount of

city water required by the wash and the amount of water discharged to sewer.

Typically, 60-85% of the water used on the car can be reclaim water.

PurWater Reclaim System:

The PurWater Reclaim System consists of cyclone separators to remove solids

down to the 5 micron range and one of three methods (air sparger, enzyme

addition or ozone addition) to control odor and biological growth. The system is

contained on a compact frame with its own pump / motor and controls. The system

will recirculate water continuously back to the second compartment of the reclaim

tank for odor and biological control. When a demand for reclaim water is received

from the wash, the system will provide treated reclaim water.

PWFS (Flood) Series Systems: The PWFS (Flood) series systems consist of a

cyclonic sand separator, pump / motor, controls, and an air sparger designed to

treat 60 or 100 gpm of reclaim water. The sand separator will remove down to 70

micron solid particles and is adequate for use in Auto Dealer or Fleet / Flooder

Arch Friction wash applications. When the wash demands water, the system

provides treated water to the wash and recirculates water through the air sparger,

located in the reclaim tank, for odor and biological control. If the wash does not

demand water for 10 minutes, the system will automatically recirculate treated

water back to the reclaim tank through the air sparger for five minutes. This

operation ensures that odor and biological control are performed periodically to

prevent the reclaim tank from going septic. Drawing #1G shows the Process &

Instrumentation Diagram (P&ID) for the PWFS (Flood) series design.

PW 100/200/300-M5 Series Systems: The PW 100/200/300-5M series systems

consist of high efficiency cyclones, pump / motor, controls and one of three odor

control systems … air sparger, enzyme addition, or ozone addition. The standard

systems are designed to treat 30, 60, and 90 gpm of reclaim water. The new

generation of high efficiency cyclones will remove down to 5 micron solids, so that

the treated water can be used by high pressure touchless or friction in-bay

automatics and tunnel wash applications. The system utilizes a Variable Frequency

Drive (VFD) on the pump motor which is controlled by the wash demand, to vary

the amount of water that is treated and delivered. Water continuously recirculates

back to the reclaim tank, both when water is demanded by the wash and when

there is no demand. Up to three different demand inputs from the wash can be

incorporated into the VFD. The PW 100/200/300-5M system piping also

incorporates a city water intake line for use as: 1) a by-pass to meet wash water

demands in case the system is not operating due to an extremely low level in the

reclaim tank or a fault; and 2) an automatic pump prime operation for system start-

up.

Air Sparger

Biological and odor control are accomplished by using one of three methods,

depending upon the model number supplied. The first method uses an air sparger

(models ending in 5MAS), which is mounted within the reclaim tank above the

water level. The air sparger will bring in air as water is passed through the sparger.

The aerated water will add oxygen to the tank water which will control the

anaerobic bacteria growth. Drawing #2G shows the Process & Instrumentation

Diagram (P&ID) for the Air Sparger Design.

Biological

A second method of control is to add periodically an enzyme that consumes the

organic material in the reclaim water that is used as a food source by the bacteria

(models ending in 5MB). With no food source, the bacteria cannot survive and

multiply. The enzyme is fed into the recirculation water using a small feed pump

that draws from a feed tank. The feed tank is periodically filled with concentrated

enzyme and city water. The recirculation water with enzyme goes through an air

sparger in the reclaim tank to provide aeration and better biological / odor control.

Drawing #3G shows the Process & Instrumentation Diagram (P&ID) for the

Biological Design.

Ozone

The third method utilizes ozone to kill the bacteria (models ending in 5M12O or

5M24O). Ozone is a contact killing agent, similar to chlorine used in city water.

Ozone (O3) is generated by concentrating the oxygen (O2) in ambient air and

passing the concentrated oxygen through a high voltage electric current to produce

ozone. The ozone laden gas is then educted into the recirculation water stream

and into the reclaim tank to kill the bacteria. Drawing #4G shows the Process &

Instrumentation Diagram (P&ID) for the Ozone Design.

Caution: Breathing concentrated ozone can create severe breathing problems.

Precautions must be made to prevent exposure to concentrated ozone.

PWFS – 5MAS (Flood Series)

Left: PW200-5MAS Center: PW300-5M240

Right: PW400-5MAS

Drawing #1G

Drawing #2G

PG

To Car

Wash

S

Recirculation

Water

Cyclone

Reclaim

Water

PurWater Reclaim Water System

Biological (Enzyme) Design

Underflow

(Solids)

Overflow

(Treated Water)

Reclaim

Water Feed

Pump / Motor S

Pump Prime

S

City Water ByPass

City

Water

In

LS

M

S

Solenoid

Valve

By Customer

Flapper

Foot

Valve

PG

Orifice

Sparger

Pressure

Gauge

Solenoid

Valve

(N.C.)

Check

Valve

Solenoid

Valve

(N.C.)

Cyclone

Motorized

Ball Valve

Pressure

Gauge

Check

Valve

Basket

Strainer

Level

Switch

Process & Instrumentation Diagram (P&ID)

Low

Low

S

Solenoid

Valve

(N.O.)

PS

Pressure

Switch

PT

Pressure

Transmitter

Catch Basin

TANK #3

From Car

Wash

Overflow

To Sewer

TANK #2 TANK #1

M

Enzyme Feed

Tank Enzyme Feed

Pump / Motor

Check

Valve

Drawing #3G

Drawing #4G

System Installation

PurWater systems are designed for easy installation. However, if you should have

any questions, please contact us at (916) 978-9990 or (800) 882-8854 in

Sacramento, CA. Office hours are 7AM to 5 PM, Pacific Standard Time, Mon-Fri.

I. PW 100/200/300-5M Series Reclaim Systems, including:

a) Model PW100-5MAS (3HP, 30 GPM, Air Sparger)

b) Model PW100-5MB (3HP, 30 GPM, Enzyme Feed System and Air

Sparger)

c) Model PW100-5M12O (3HP, 30 GPM, 12 Gram Ozone)

d) Model PW200-5MAS (5HP, 60 GPM, Air Sparger)

e) Model PW200-5MB (5HP, 60 GPM, Enzyme Feed System and Air

Sparger)

f) Model PW200-5M12O (5HP , 60 GPM, 12 Gram Ozone)

g) Model PW200-5M24O (5HP , 60 GPM, 24 Gram Ozone)

h) Model PW300-5MAS (5HP, 90 GPM, Air Sparger)

i) Model PW300-5MB (5HP, 90 GPM, Enzyme Feed System and Air

Sparger)

j) Model PW300-5M12O (5HP , 90 GPM, 12 Gram Ozone)

k) Model PW300-5M24O (5HP , 90 GPM, 24 Gram Ozone)

Frame:

The system is to be installed in a dry / clean / temperature controlled / covered

area. It is not designed to be in the wash bay or outdoors. The frame requires a

floor space of 48” wide by 16” deep, with a height of 75” (86” for ozone units). We

recommend a minimum clearance of 18” along the sides, front and top of all frames

to allow for routine maintenance and inspection. The floor frame should be placed

with its back along a wall and should be secured to the wall to prevent movement

of the frame. Some models may also have a wall mount frame for the ozone

generation system. This wall mount frame needs to set in close proximity of the

floor frame to allow both electrical and piping connections. The area should be free

of excessive moisture which can cause extreme corrosion or electrical failure.

Piping:

Fittings on these systems have some threaded connections which can come loose

during shipment. There are two unions used on the motorized ball valve on the inlet

piping, on the cyclone overflow piping, on the check valve on the recirculation line,

and on the Mazzei eductor (on ozone units only) on the recirculation line. There is

also a union on the cyclone underflow. Re-tighten these union connections and any

other threaded connections prior to introducing water into the system. We

recommend using Schedule 80 PVC for all connections to the reclaim unit. Rubber

hose is acceptable on all lines except the Suction Line (needs reinforced suction

hose) and the Recirculation Line on ozone systems (rubber is not compatible with

ozone).

1) Treated Water Line: This line has a pressure gauge (and a pressure

transducer on some units) and is to be connected to the wash. Solenoid

valves (supplied by others) need to be installed and controlled by the

wash controller when water is demanded by the wash. Do not reduce the

line size until reaching the wash equipment to prevent flow restriction

and pressure reduction. If connecting to a high pressure pump, we

recommend piping directly into the pump and not into the pump suction

tank. (See Drawing #1S.)

2) City Water Line: This line has a check valve that leads to two brass

solenoid valves on the reclaim unit. City water is to be connected, which will

then provide fresh water for a by-pass function to the wash and an

automatic pump prime operation. The city water supply line needs to be 1”

for the PW 100 series and 2” for the larger units to ensure enough pressure

and flow are available. Do not exceed a pressure of 100 psig on the city

water inlet.

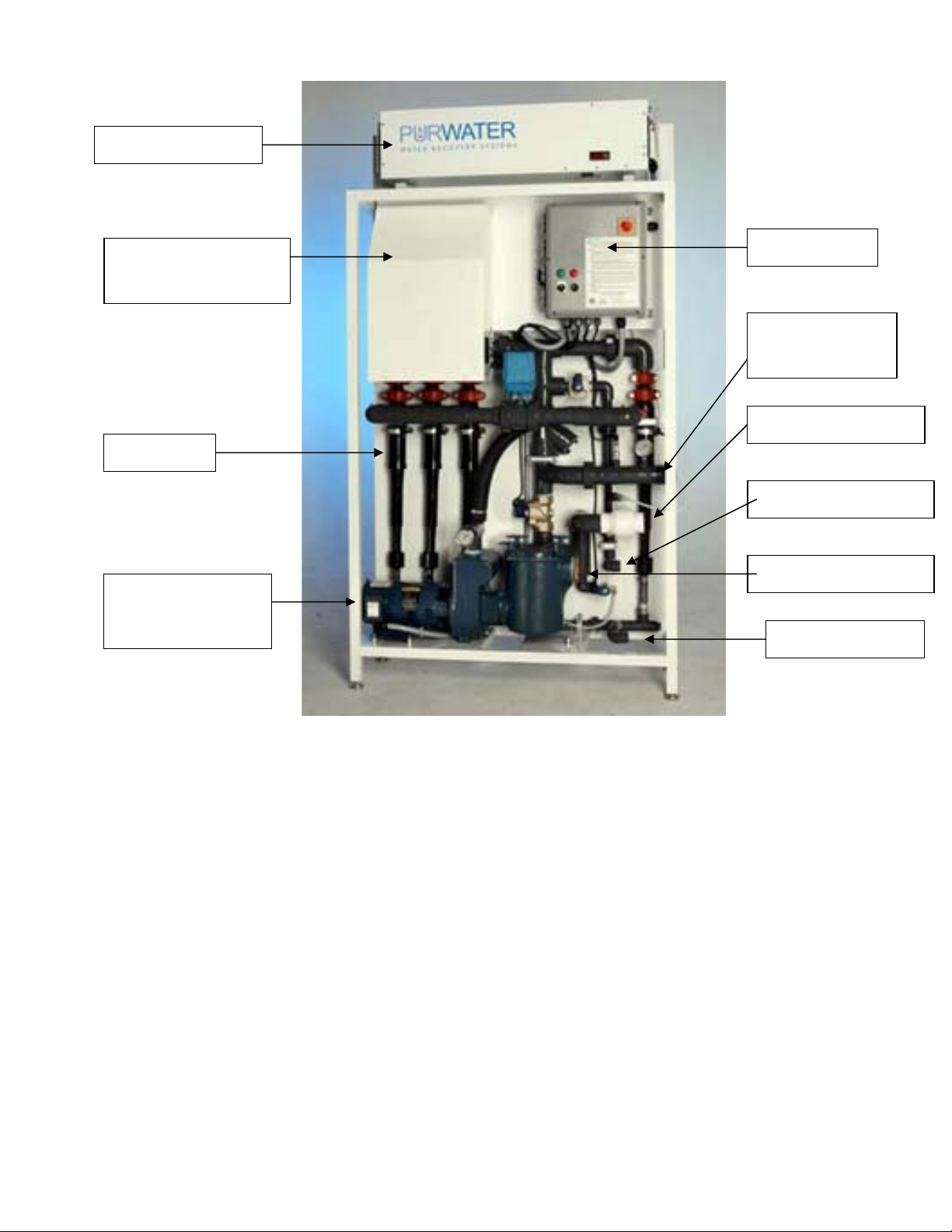

Ozone Generator

Oxygen

Concentrator

Cyclones

Pump / Motor

and Basket

Straine

r

Control Box

Treated Water

Line

City Water Line

Recirculation Line

Pump Suction Line

Underflow Line

S

M

City

Water

Inlet

Fresh Water

Storage Tank

Mechanical Float /

Valve

High Pressure

Pump

Water to

Wash

Check

Valve

Solenoid

Valve

Treated Reclaim

Water from Pur-

Water Unit

Plumbing Direct from Pur-Water

Reclaim Unit to High Pressure Pump

Notes:

1. Solenoid Valve to Open when High Pressure Pump Starts. Same Signal to be Used for Reclaim Activation.

2. Solenoid Valve Needed to Prevent Reclaim Unit from Pushing Water thru High Pressure Pump.

3. Solenoid Valve to be Mounted 4 Ft. Minimum from Pump Suction.

4. Check Valve to be Flapper Check Type. Do not Use Spring Check.

5. City Water Line and Mechanical Float / Valve Must be Sized to Ensure Enough Water Volume is Available to High Pressure Pump.

6. Suction Piping, Solenoid Valve, and Check Valve Must be Sized to Ensure Enough Water Volume is Available to High Pressure Pump.

Plumbing Reclaim Water Direct to the High Pressure Pump Prevents

Reclaim Water from Setting Stagnant in the Suction Storage Tank.

Biological Activity Will Accelerate in Stagnant Reclaim Water, Causing

Growth in the Tank and Odor in the Area.

Operation:

A) No Wash Demand / Reclaim Unit in Recirculation Mode: High Pressure

Pump is Off and Solenoid Valve is Closed. Line Pressure Keeps Check

Valve Closed.

B) Wash Demands Reclaim Water / Reclaim Unit On: High Pressure Pump

Operates and Solenoid Valve Opens. Reclaim Unit Ramps Up to Meet

Water Demand. As Long as Water Demand to High Pressure Pump is Met,

Check Valve Remains Closed.

C) Wash Demands Reclaim Water / Reclaim Unit Off: High Pressure Pump

Operates and Solenoid Valve Opens. No Reclaim Water from Reclaim

Unit, So Check Valve Opens to Feed Fresh Water from Storage Tank.

Drawing # 1S

3) Recirculation Line: This 1” line provides a return line of treated water back

into the first reclaim tank, compartment #2. A solenoid valve (normally open)

on this line closes only during the Automatic Pump Prime operation.

a. Air Sparger Units (Models ending in -5MAS): The recirculation line is

connected to the air sparger within the reclaim tank. (See below for air

sparger assembly installation.)

b. Enzyme Units (Models ending in -5MB): The recirculation line will be

supplied with an enzyme injection point on the reclaim unit and is connected

to the air sparger within the reclaim tank. (See below for air sparger

assembly installation.)

c. Ozone Units (Models ending in -5M12O or -5M24O): The recirculation line

will be supplied with a Mazzei eductor connected to an ozone generation

system. The line in the tank should extend halfway down the normal water

level and terminate in a tee to split the flow. An air sparger is not required.

(Note: Rubber hose is not compatible with ozone. All piping containing

ozone should be PVC.)

d. Air Sparger Assembly: The air sparger assembly is installed into the first

reclaim tank, compartment #2. It should be located so that it is accessible

from the manway as occasional inspection and maintenance are required.

Ensure the wall mount bracket is placed to allow the assembly to be

removed easily. The assembly consists of the air sparger, mounting

brackets, and inlet piping with a union. The bottom of the sparger nozzle

should be set 6-12” above the water level and pointed downward. If this is

not possible, mount the sparger horizontally so that it sprays against a side

wall. The top opening on the sparger body should have clearance to allow

air flow into the sparger. The union on the inlet allows the assembly to be

easily pulled out of the tank for maintenance and inspection.

Air Sparger Assembly

4) Pump Suction Line: Connect the suction line from the last compartment of the

last reclaim tank into the basket strainer inlet on the reclaim unit. Keep the size

of the line 2” for the PW 100 / 200 units and 3” for larger units. If hose is used,

ensure it is reinforced suction hose. Piping between the tank and reclaim system

should have a minimal amount of bends, threaded connections, and should

never go higher than the basket strainer inlet. The inlet pipe within the tank

should have a flapper type foot valve with a quick disconnect for maintenance,

and the bottom of the valve should be a minimum of 16 inches above the bottom

of the tank floor. We do not recommend the use of spring loaded check valves or

screens on the suction line. Pressure testing of both suction lines is

recommended before connecting to the reclaim unit.

5) Cyclone Underflow: The 1” line from the bottom of the cyclones should be

connected to the catch basin or the first reclaim tank compartment. An

underflow orifice assembly is installed on this line between two unions. Solids

captured from the cyclones are continuously removed when the system is

operating. The underflow line should be level or sloping downward to prevent

solids build-up in the piping or cyclones.

Air Sparger

Sparger Nozzle

Sparger Water Inlet

Air Intake Opening

(On Top)

Wall Mount Bracket

Underflow Orifice Assembly

Some units will have a few components that will mount off of the main reclaim unit

frame:

a) Enzyme Systems: For models ending in -5MB, the enzyme feed tank will set

on the floor close to the reclaim unit and must be connected to the enzyme feed

pump mounted on the reclaim unit frame. The feed tank is supplied with a

spigot and tubing which connects directly to the inlet of the feed pump. Tubing

and a plumbing kit with instructions is shipped with the system.

b) Wall Mount Ozone Systems: For certain models ending in -5M12O and -

5M24O, the oxygen concentrator and the ozone generator are installed on a

wall mount panel. If possible, locate the wall mount panel close to the reclaim

unit frame and on the right hand side (when facing the front). The Teflon tubing

supplied between the ozone generator and the Mazzei eductor on the

recirculation line must be connected. Ensure that the tubing has a minimal

amount of bends (not pinched) and is sealed tightly on the fittings.

II. Reclaim Tanks:

PurWater does not supply the underground reclaim tanks. These are typically pre-

cast concrete vaults that are sourced locally. However, we do recommend that the

tanks follow the following design parameters to ensure a successful operation.

Location Considerations for Reclaim Tanks:

1) Locate the Reclaim Tanks close to the Equipment Room to minimize the

length of suction pipe run to the Reclaim Unit.

2) Locate the Reclaim Tanks so that bends & elbows are minimized on the

suction piping.

3) Keep the piping below the reclaim pump inlet.

4) For ozone units, the Reclaim Tanks should be located outside the Wash Bay

and Equipment Room in an area that is well ventilated.

The following drawings show the recommended internal lay-out for the reclaim

tanks:

1) The Catch Basin is typically located in the bay and

is part of the trench used to collect water from the

wash that goes to the Reclaim Tanks.

2) The Catch Basin will collect heavy, large solids

(rocks) and floating materials (plastic bags &

bottles), keeping these items out of the Reclaim

Tanks.

3) The outlet of the Catch Basin must have an elbow

below the water level that will prevent floating

trash from entering the Reclaim Tanks. This elbow

also prevents ozone gas in the Reclaim Tanks from

moving up the inlet pipe and into the bay.

4) The separated solids (underflow) line from the

PurWater Reclaim Unit should be piped into the

Catch Basin. The drain line between the PurWater

Reclaim Unit and the Catch Basin should have a

minimal number of elbows to prevent plugging and

be large enough (2” to 3”) to allow for cleaning.

Reclaim Tank Plumbing – Suction Lines:

1) Two suction lines are recommended. One is used and one is a spare.

2) The minimum suction line size for a PW100 & 200 series is 2”. Larger units

require a 3” suction line.

3) Unions can be used above the water level to allow removal of the suction

line from the manway without draining the tank. Unions must be tight to

prevent suction leaks.

Reclaim Tank Plumbing – Foot Valves:

1) PurWater will supply two PVC Flapper Check Valves to attach to the suction

lines. We do not recommend the use of spring loaded check valves.

2) PurWater does not recommend using screens as part of or around the check

valves.

3) The bottom of the check valve should be a minimum of 16 inches above the

tank floor.

Reclaim Tank Plumbing – Low-Low Level Switch:

1) PurWater will supply one two-wire (yellow float) level switch.

2) The low-low level switch should be wired into a water-tight junction box

within the Reclaim Tank and wired through the 1” conduit to the PurWater

Reclaim Unit.

3) The switch should be installed a minimum of 9” above the bottom of the

check valve when the float is in the down position.

Reclaim Tank Plumbing – Sewer Overflow:

1) The sewer (overflow) connection is above the normal liquid level and should

only overflow when washing cars.

2) The sewer connection should slope downward to the main sewer line.

3) There must be a backflow preventer installed between the Reclaim Tanks

and the main sewer line.

Reclaim Tank Plumbing – Interconnecting Piping:

1) The piping between the tanks will set the liquid level in each tank. The

elevation and downward elbow help prevent floating material and settled

solids from moving to the next tank.

2) The piping between compartments within each tank helps prevent floating

material and settled solids from moving to the next compartment.

3) For the PW100 / 200 / 300 series, the interconnecting piping needs to be a

minimum of 4”. For larger units, the piping is a minimum of 6”.

Reclaim Tank Plumbing – Recirculation Lines:

1) The 1” Recirculation Line continuously flows from the PurWater Reclaim Unit to

provide odor control. The line should go into the second compartment of the first

tank.

2) For ozone systems, the line terminates halfway below the liquid surface in a tee.

3) For sparger systems, the line terminates above the liquid level and is connected

to the air sparger.

Reclaim Tank Plumbing – Miscellaneous Items:

1) Piping and conduit materials should be PVC. PurWater recommends using

Schedule 80 pipe as it is stronger than Schedule 40.

2) All piping to / from the PurWater Reclaim Unit should be accessible from a

manway. Occasional checks and maintenance are required.

3) All floor drains emptying into the Reclaim Tanks should be piped to go below

the water level within the tanks. This prevents any gas from backing up

through the line into the bay or equipment room. This is especially important

on ozone systems.

4) The following should not be piped into the reclaim system: a) Domestic

sewer lines (sinks / toilets); b) Backwash from carbon tanks; c) Regeneration

from softeners; d) Blowdown from compressors or boilers; e) Drains from

Service / Detail Bays; and f) Areas where tire shine is applied.

5) If Self Serve Bays are to be piped into the Reclaim Tanks, a separate

Reclaim Tank should be used. Contact PurWater for details.

Safety

Warning!

Hazardous Voltage: Can shock, burn, or cause death.

6Disconnect power at the main panel before connecting the electrical

power supply to the reclaim unit panel or working on electrical

connections.

6Ground the reclaim unit before connecting to the electrical power supply.

Failure to ground the reclaim unit can cause a severe or fatal electrical

shock hazard.

Step 1: Install, ground, wire and maintain the reclaim unit in accordance

with local electrical codes and ordinances that apply. Consult with local

building inspector for local code information.

Step 2: Ground the reclaim unit permanently using a wire of size and type

specified by local or National Electrical Code.

Do not ground to a gas supply line!

Step 3: Connect ground wire first. Connect to ground first, then to green

grounding terminal provided. Do not connect the reclaim unit power supply

until the unit is permanently grounded; otherwise serious or fatal electrical

shock hazard may be caused.

6Do not connect the 3-Phase reclaim power leads to a 1-Phase power

supply. Do not connect the 1-Phase reclaim power leads to a 3-Phase

power supply.

6The supply voltage must be within ±10% of the designated reclaim unit

voltage as shown on “Installation & Operating Instructions” label on

the electrical panel cover. Incorrect voltage can cause fire or seriously

damage reclaim unit and voids warranty. If in doubt consult a licensed

electrician.

Caution! This Reclaim Unit has been evaluated for use

with water only.

This manual suits for next models

14

Table of contents