2FORM NO. L-20113-E-0501

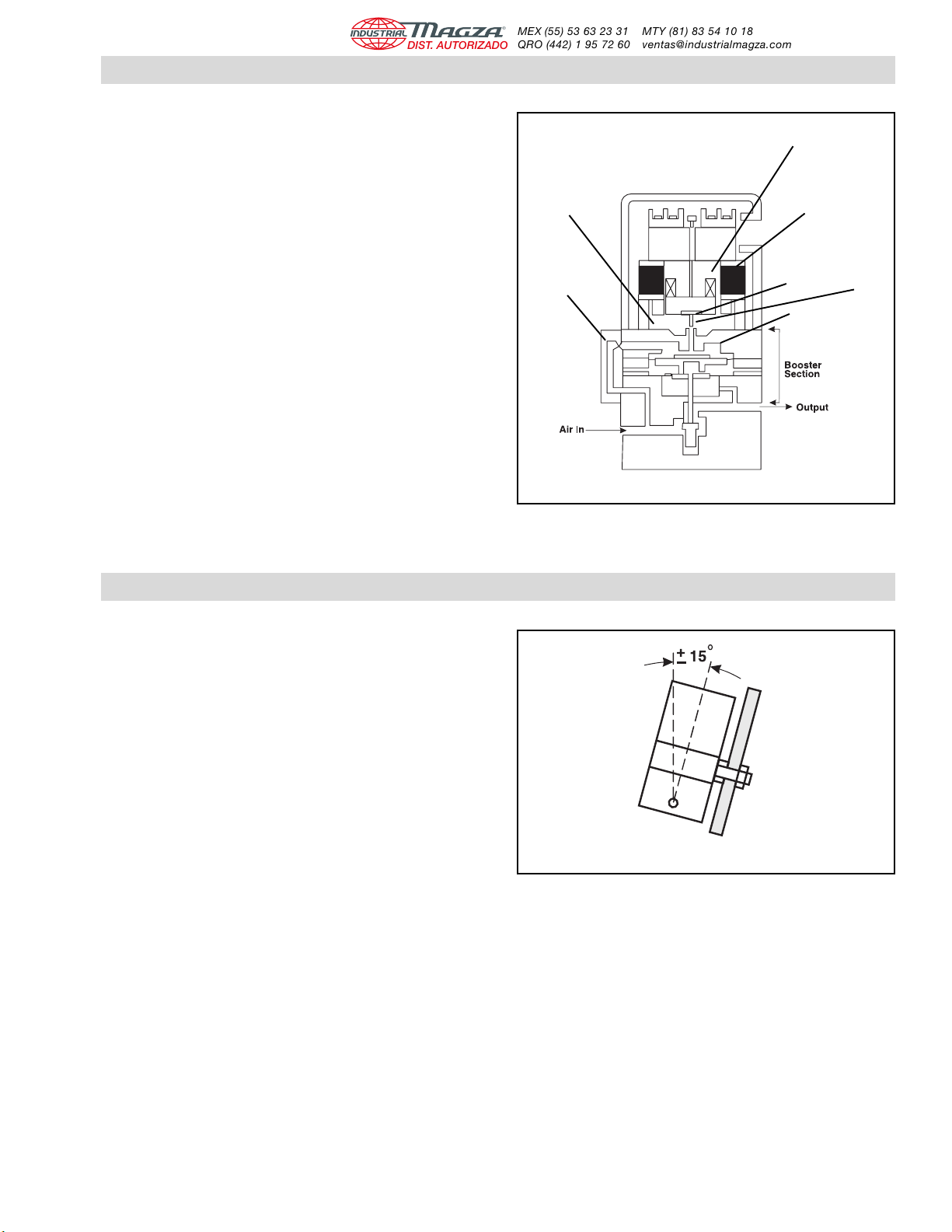

THEORY OF OPERATION

Nexen’s EN40-IS Electro-Pneumatic Converter converts

current input signals into corresponding pneumatic

signals. Normally the EN40-IS is used as part of a

Nexen-Nireco Intrinsically Safe Tension Control System,

or as an independent Electo-Pneumatic Converter,

controlled by an external signal from a Process Controller,

using an appropriate Zenier Barrier.

EN40-IS balances the force of a moving coil with the

force of a poppet valve, and amplifies the air flow and

pneumatic pressure passing through a fixed orifice by

means of the booster relay, resulting in a pneumatic

pressure proportional to the electric signal.

When current flows through the moving coil, a downward

force is induced proportionally to the current value. This

reduces the clearance between the poppet and seat,

causing back pressure to rise (See Figure 1).

Back pressure is too low to use as an output, but is used

as the pilot pressure for the Booster Section, increasing

both pressure and volume to provide a usable output. FIGURE 1

Spring

Plate

Fixed

Orifice

Moving

Coil

Permanent

Magnet

Poppet Seat

Pilot Pressure

Chamber

INSTALLATION

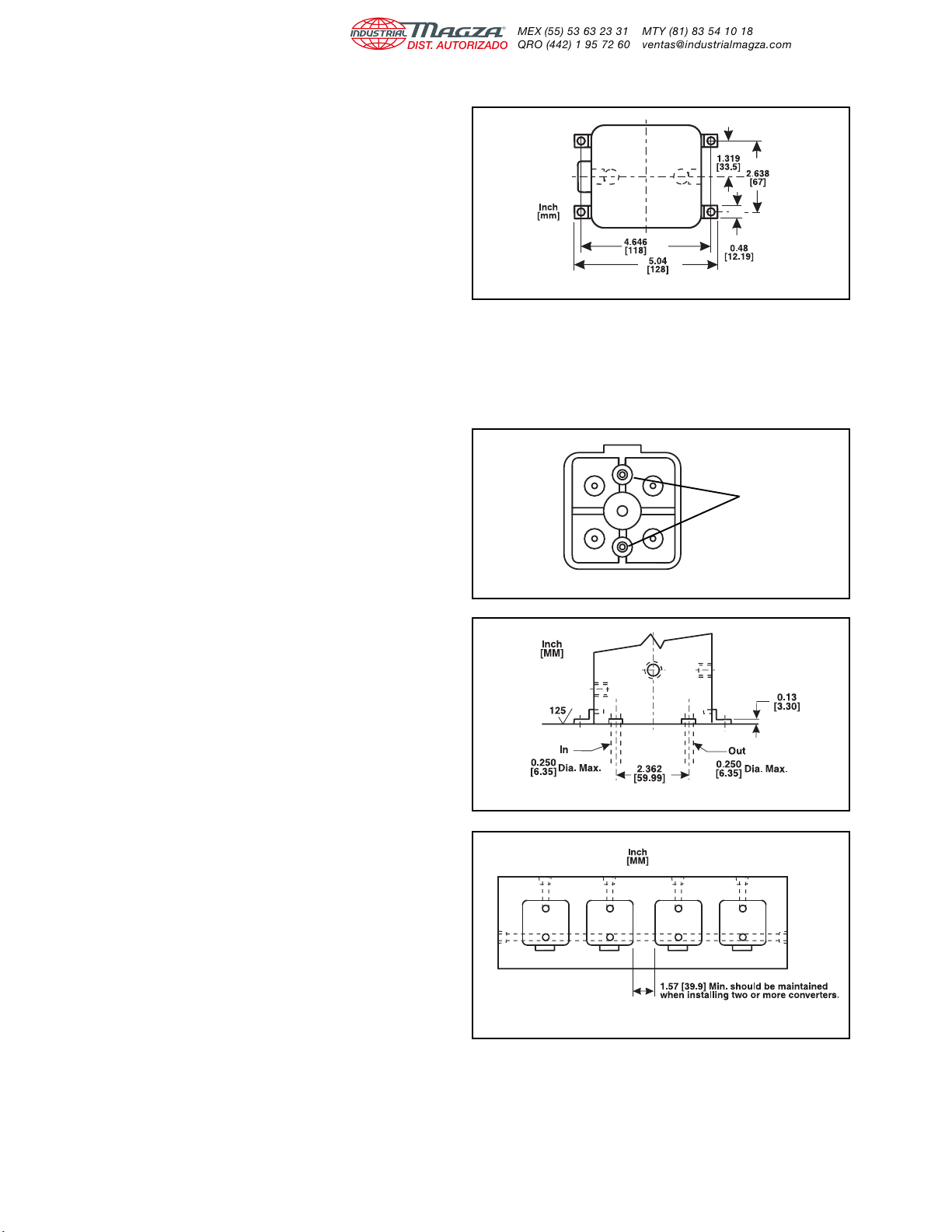

NOTE The EN40-IS must be mounted vertically within ±

15 degrees in a shock and vibration free area.

Locate the EN40-IS as close as possible to the

controlled element to guarantee quick precise

control (See Figure 2).

FIGURE 2

WALL MOUNTING

1. Drill two 0.28 In. [10 mm] diameter holes 4.57 In.

[166 mm] apart in the Mounting Panel. 2. Secure the EN40-IS to the Mounting Panel using the

cap screws provided in parts bag.

®

DIST. AUTORIZADO

MEX (55) 53 63 23 31

QRO (442) 1 95 72 60

MTY (81) 83 54 10 18